Equipment used by stamping mould

A stamping die and equipment technology, which is applied in the field of equipment used in stamping dies, can solve problems such as the unfavorable stamping of the strip material, the impact of the strip material on the feeding, and the impact on the feeding process, so as to achieve simple structure, avoid locking phenomenon, and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

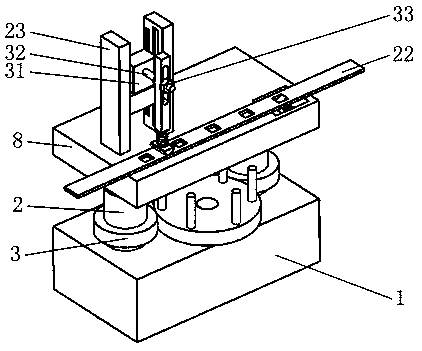

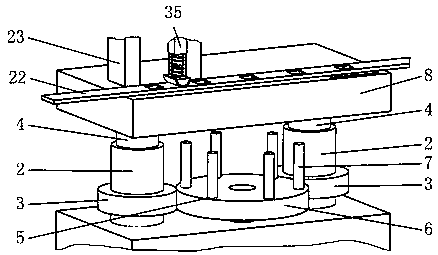

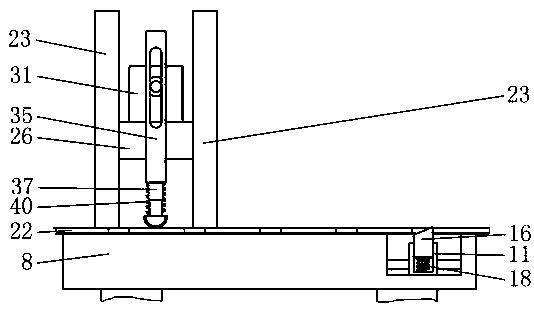

[0037] Such as figure 1 As shown, it includes base 1, screw sleeve 2, gear A3, screw rod 4, adjustment mechanism 5, lifting plate 8, slider A11, limit block 16, spring A18, guide rail 23, slider B26, L-shaped plate B29, Electric drive module 31, transmission shaft 32, nut 33, positioning ring 34, pendulum plate 35, telescoping rod 37, semicircle block 38, arc-shaped friction pad 39, spring D40, wherein as figure 2 As shown, the two screw sleeves 2 that cooperate with the upper end bearing of the base 1 are respectively connected with the lifting plate 8 through the screw rods 4 screwed together with them; The two gears A3 on the outer cylindrical surface of the sleeve 2 coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com