Tensioning steel wire seal and processing method thereof

A processing method and a tensioning technology, applied in the field of one-time locking devices, can solve the problems of difficult to grasp the fixed angle, affect the use performance, and the steel wire is easy to get stuck, so as to avoid the secondary drilling operation, and simplify the processing and assembly. , The effect of accurate structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

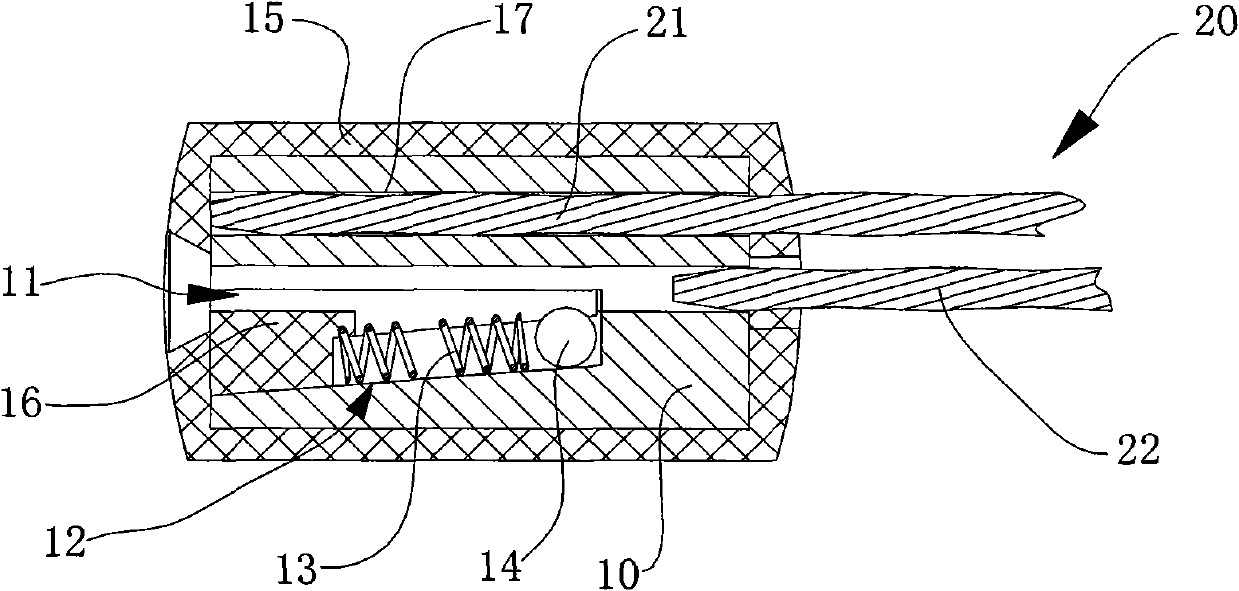

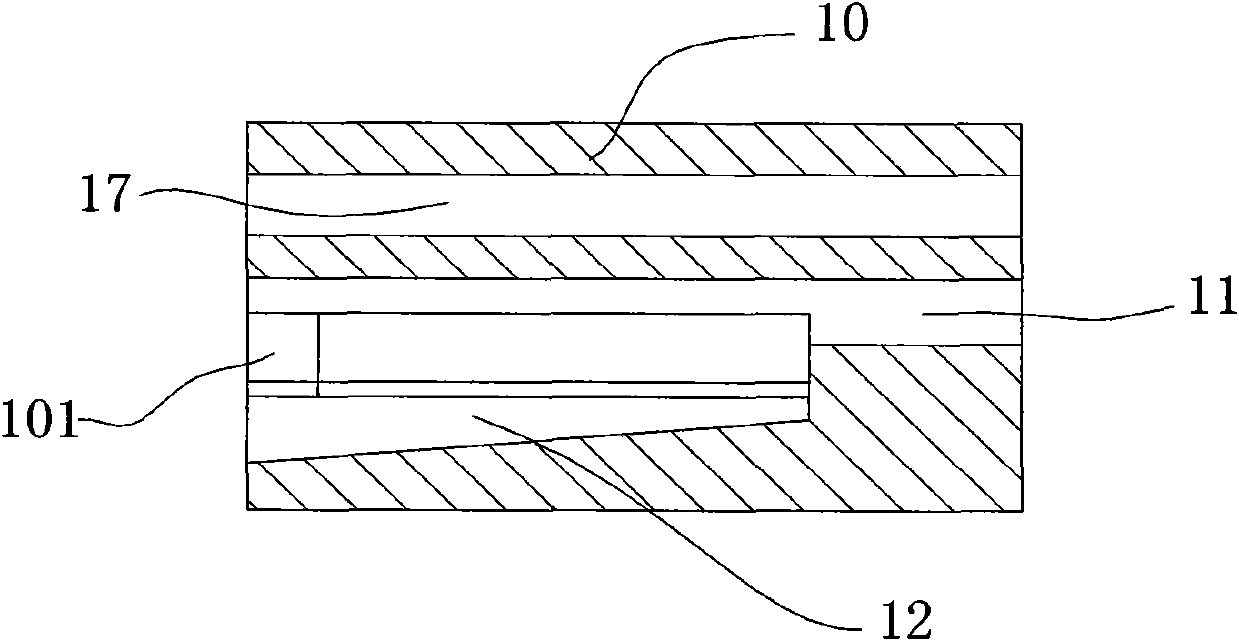

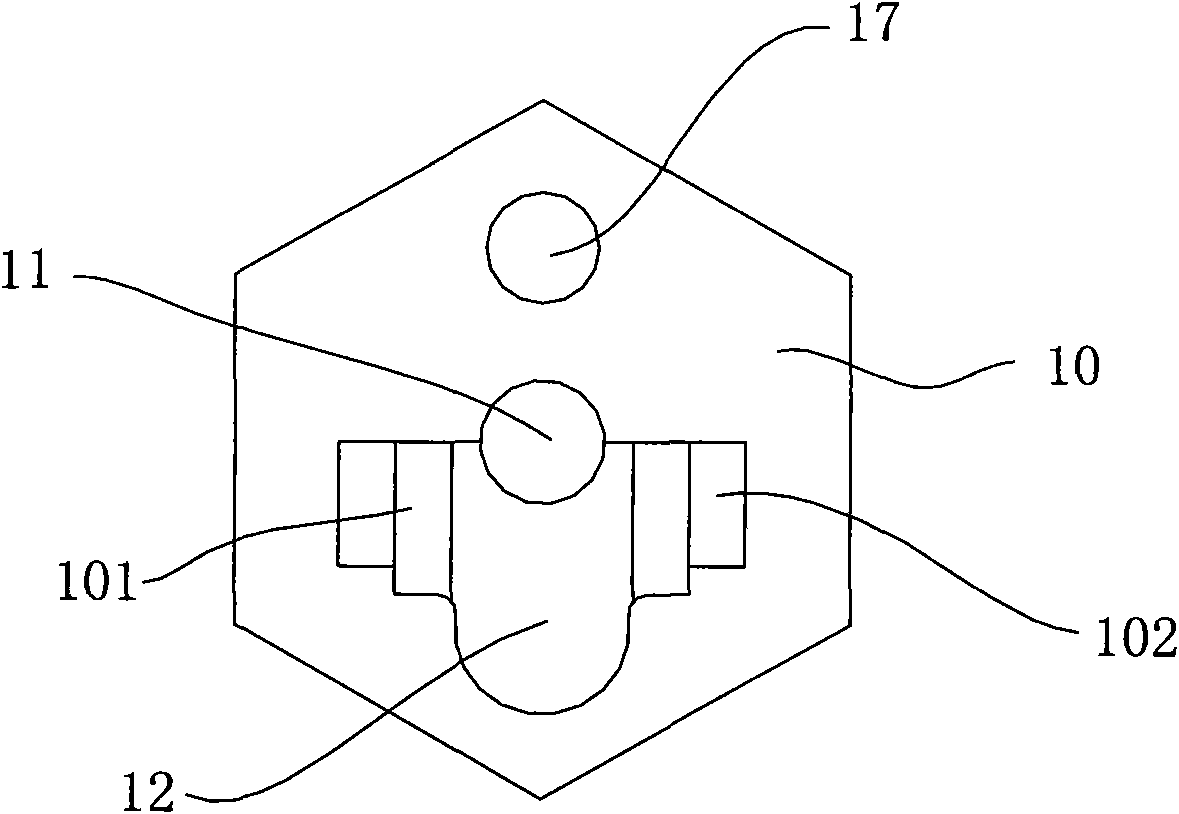

[0020] Such as Figures 1 to 6 As shown, a tensioned steel wire seal includes a lock head 10 made of zinc alloy or other anti-rust alloy material, the lock head 10 is fixedly connected with one end 21 of the steel wire 20, and the lock head 10 is also provided with a free end for the steel wire 20 22 inserted into the lock cylinder hole 11 and the pinhole 12 for accommodating the pinball 14 and the spring 13, the diameter of the pinhole 12 is equal to or slightly larger than the diameter of the pinball 14, the front part of the pinhole 12 and the middle part of the lock core hole 11 Obliquely intersecting, the size of the connected area after the intersecting is mainly smaller than the diameter of the marble 14 in the direction perpendicular to the length of the hole. Obviously, the marble 14 will partially protrude into the lock cylinder hole 11 under the support of the spring 13 , but the part protruding into the lock cylinder hole 11 is smaller than the half sphere of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com