Patents

Literature

43results about How to "Dimensionally stable and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for cuprous oxide micron/nano crystal with controllable morphology

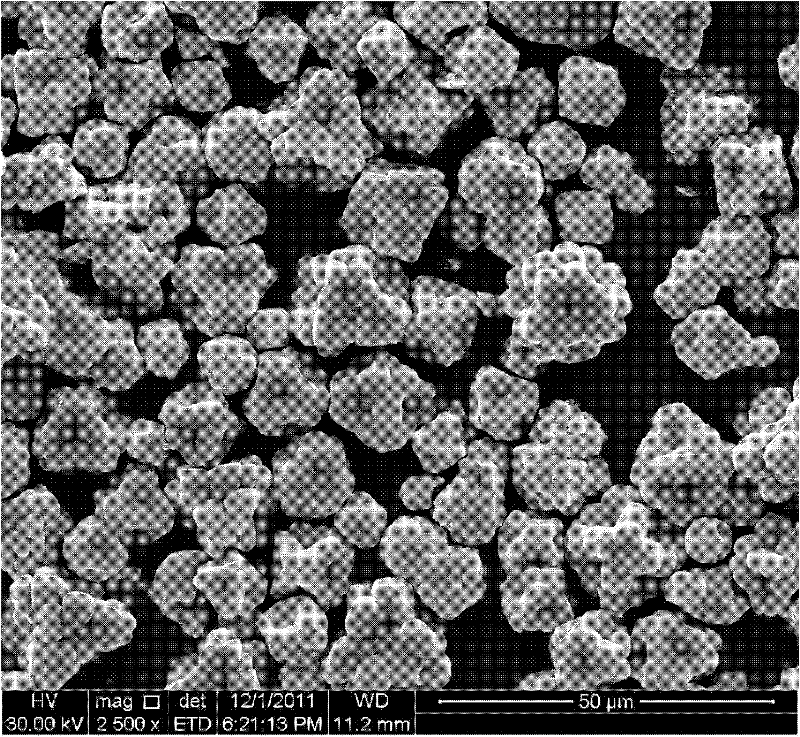

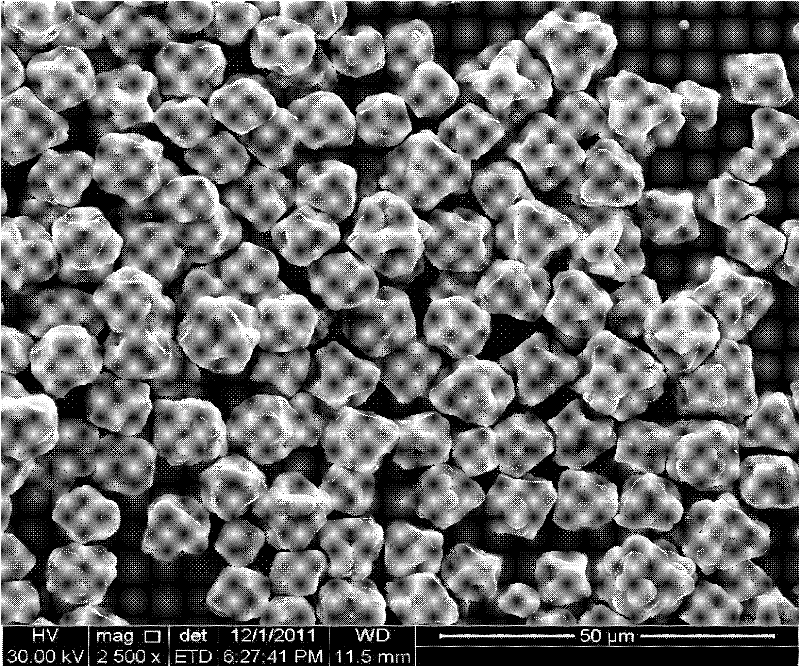

InactiveCN102583499AGood dispersionControl growth characteristicsNanotechnologyCopper oxides/halidesMicro nanoWatch glass

The invention relates to a preparation method for cuprous oxide micron / nano crystal with controllable morphology, relating to the preparation method for the cuprous oxide micron / nano crystal. The invention mainly solves the technical problems of high cost and environmental pollution in the preparation process of the micron / nano cuprous oxide. The method comprises the following steps of: 1, dissolving copper salt into ultrapure water, pouring lactic acid, continuously stirring, regulating a pH value, cooling to the temperature of 25 DEG C, keeping constant volume, measuring the pH value, and obtaining solution A; 2, moving the solution A to a hydrothermal reaction kettle, sealing the reaction kettle, putting the hydrothermal reaction kettle into a drying oven, keeping the temperature, naturally cooling to a room temperature, centrifugally washing by using the ultrapure water, centrifugally washing by using anhydrous ethanol, transferring the reaction kettle onto watch glass, and drying the reaction kettle in the drying oven; and thus obtaining the cuprous oxide micron / nano crystal. The preparation method for the cuprous oxide micron / nano crystal with the controllable morphology has the advantage of simpleness and practicability, simple equipment operation, low raw material price, easy synthesis, less pollution to environment and high synthetic concentration, the problem of the cost of the morphology control and industrialized large-scale synthesis in the prior art is solved, and the industrial production is facilitated.

Owner:HARBIN INST OF TECH

Machining process of propeller shell

The invention discloses a machining process of a propeller shell, comprising the following steps of: A, taking a steel plate and cutting the steel plate by a straight-line cutter or a cutting machine, so as to guarantee that the error degree of the cut steel plate is less than 2 mm; B, rolling the cut steel plate by using a rolling machine; C, butting and welding two ends of the rolled steel plate to form a cylinder, and carrying out nondestructive testing on a welding part; D, grinding a welding seam by using a grinding machine; and E, pressing and molding the grinded cylinder by using a mould to prepare the propeller shell. The machining process of the propeller shell has the advantages of improving the working efficiency and further improving the quality of products.

Owner:NANTONG HONGBO MACHINERY

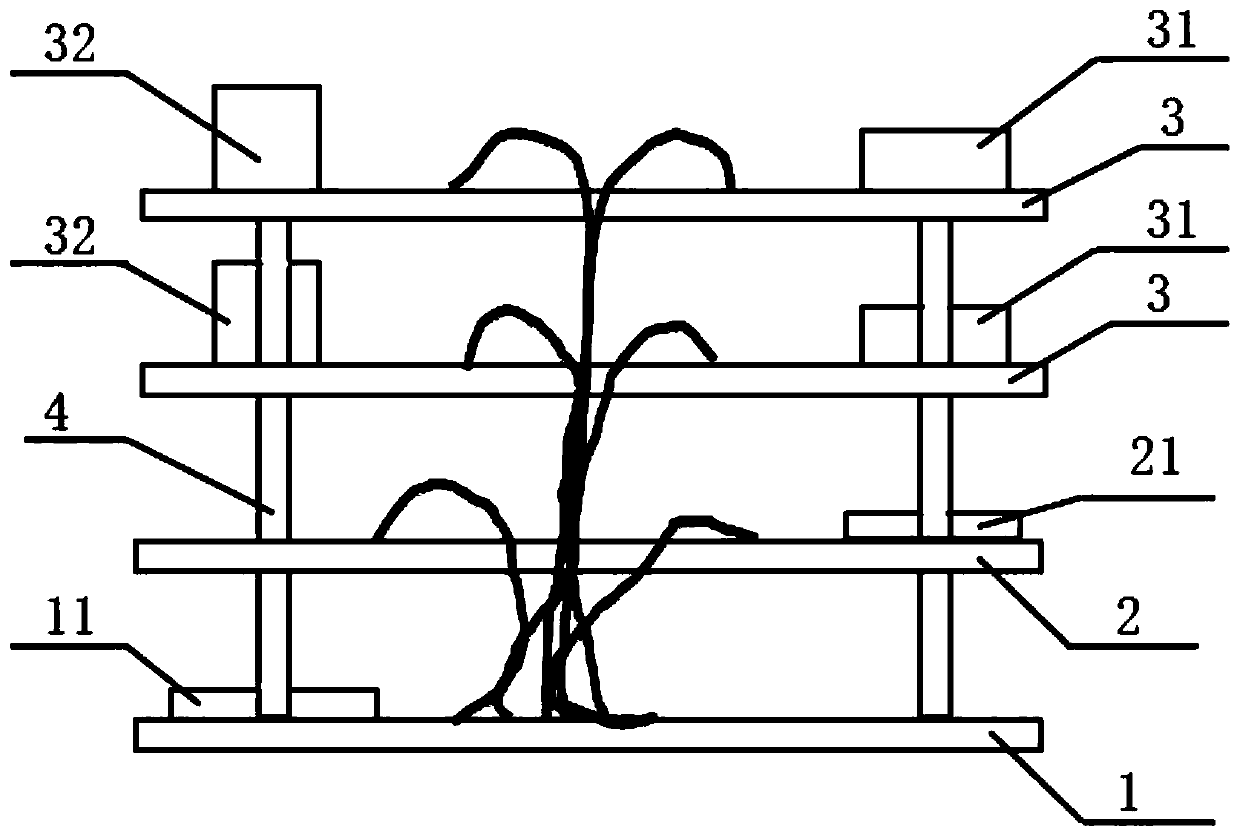

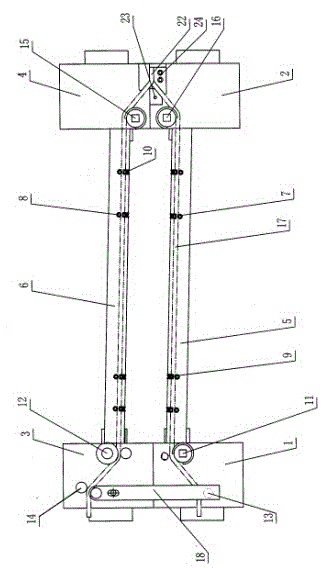

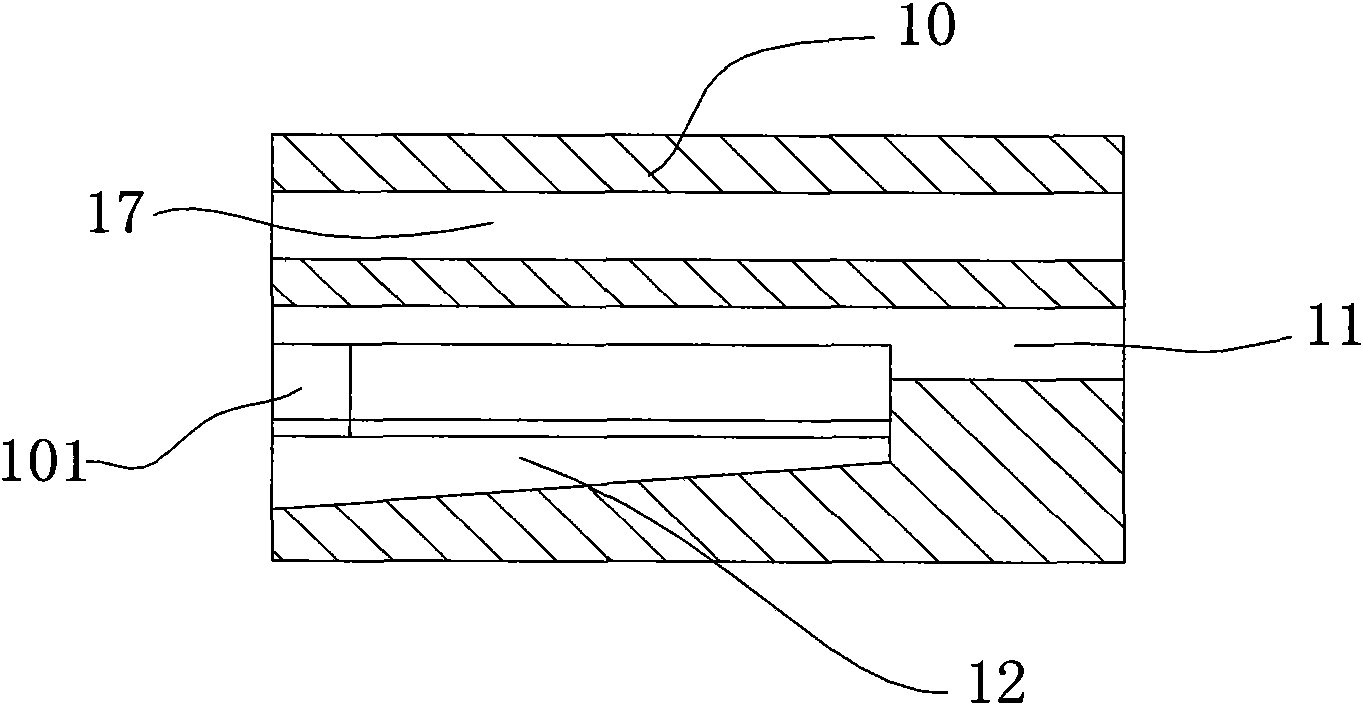

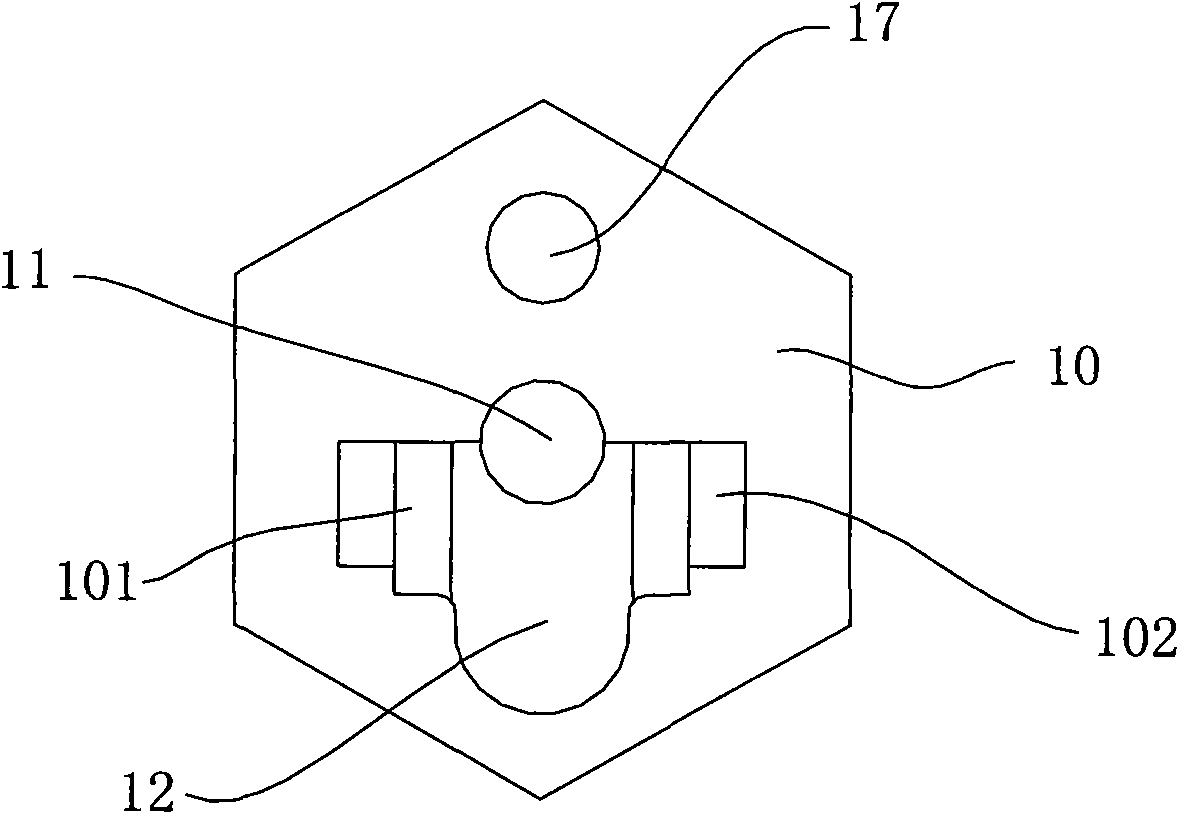

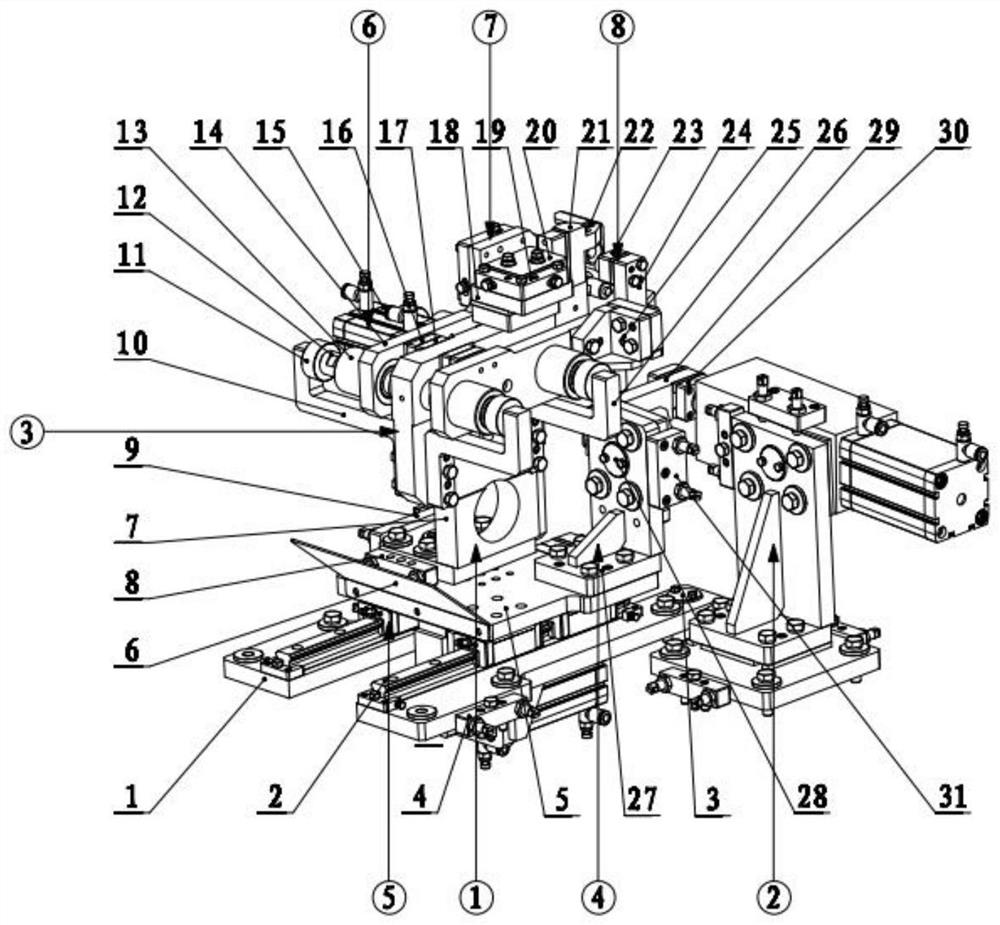

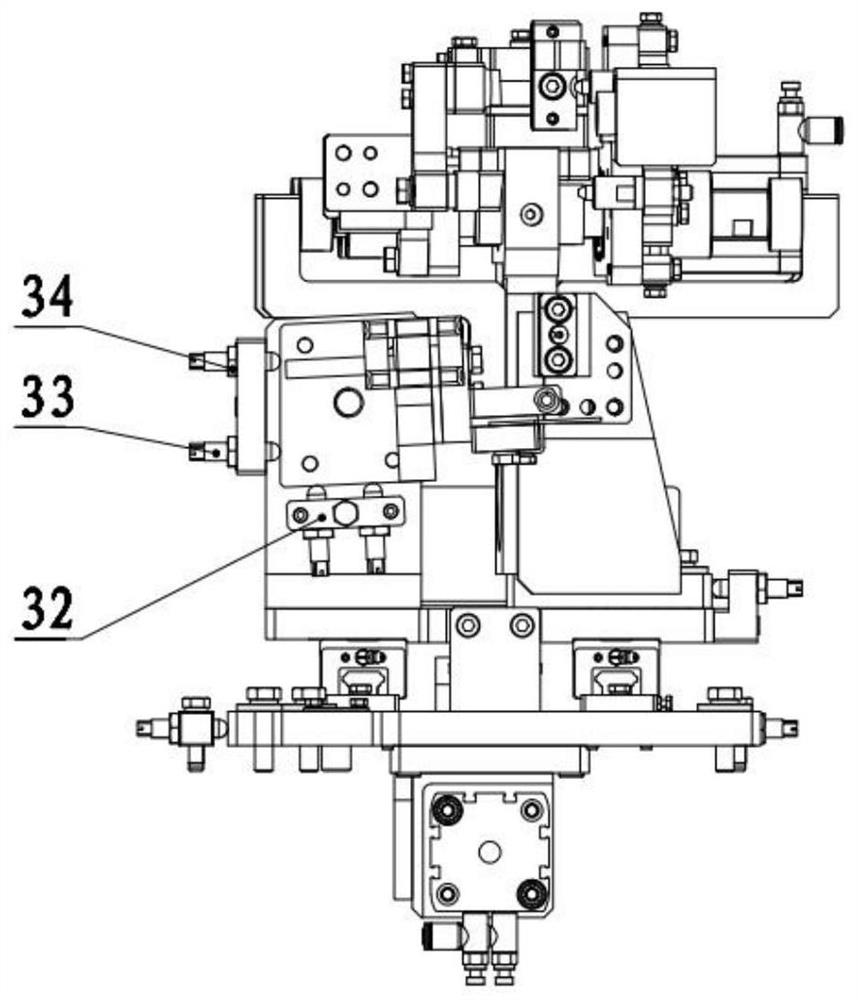

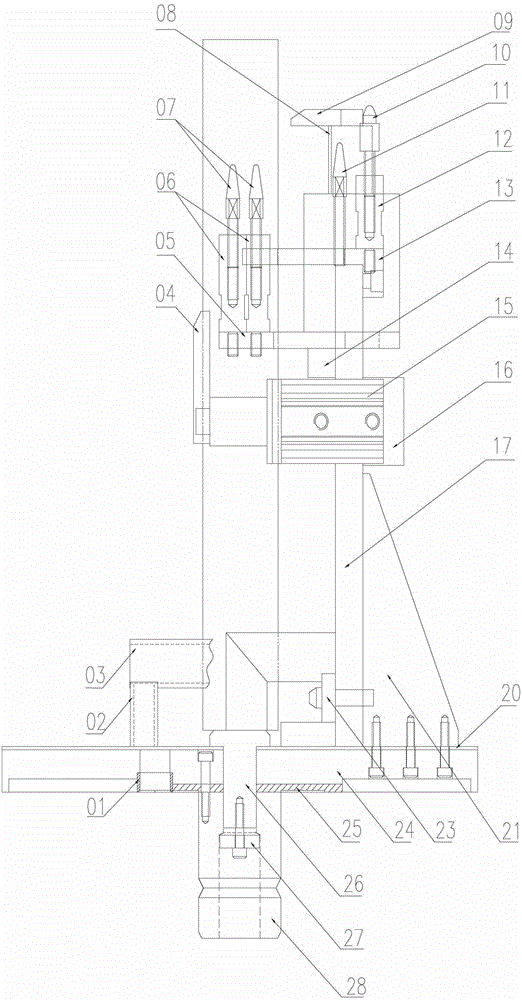

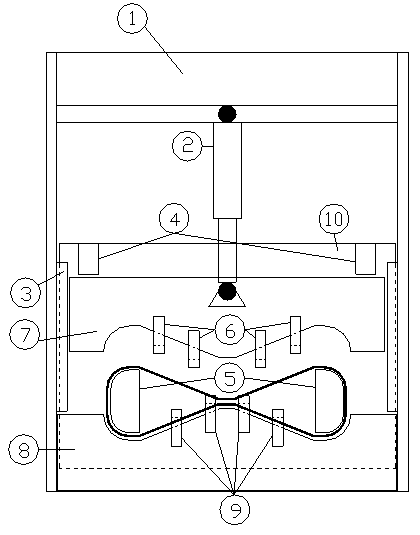

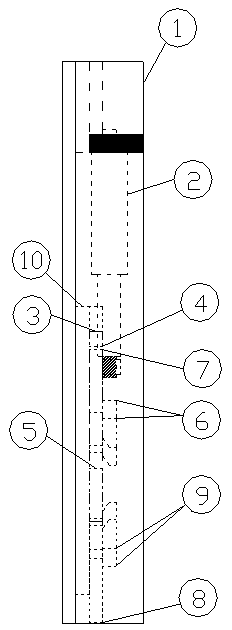

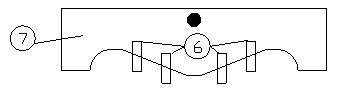

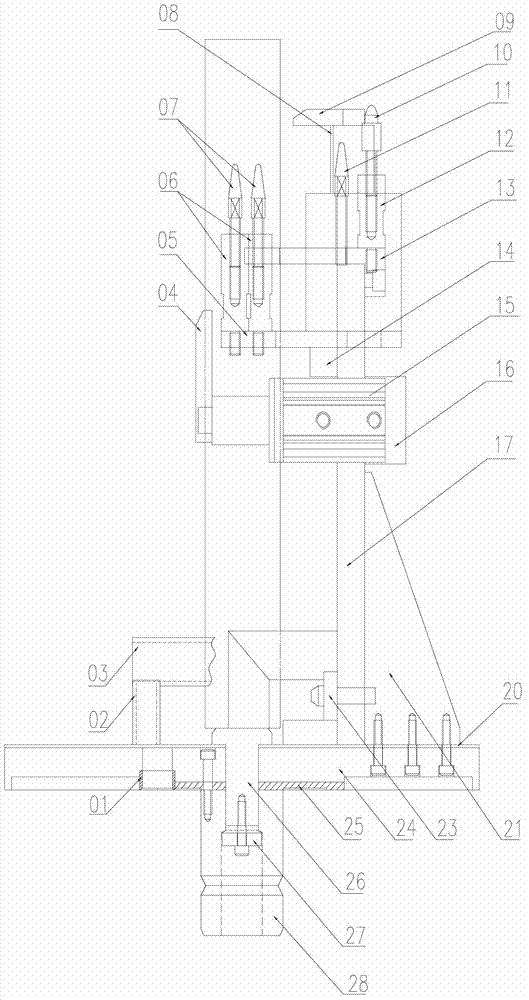

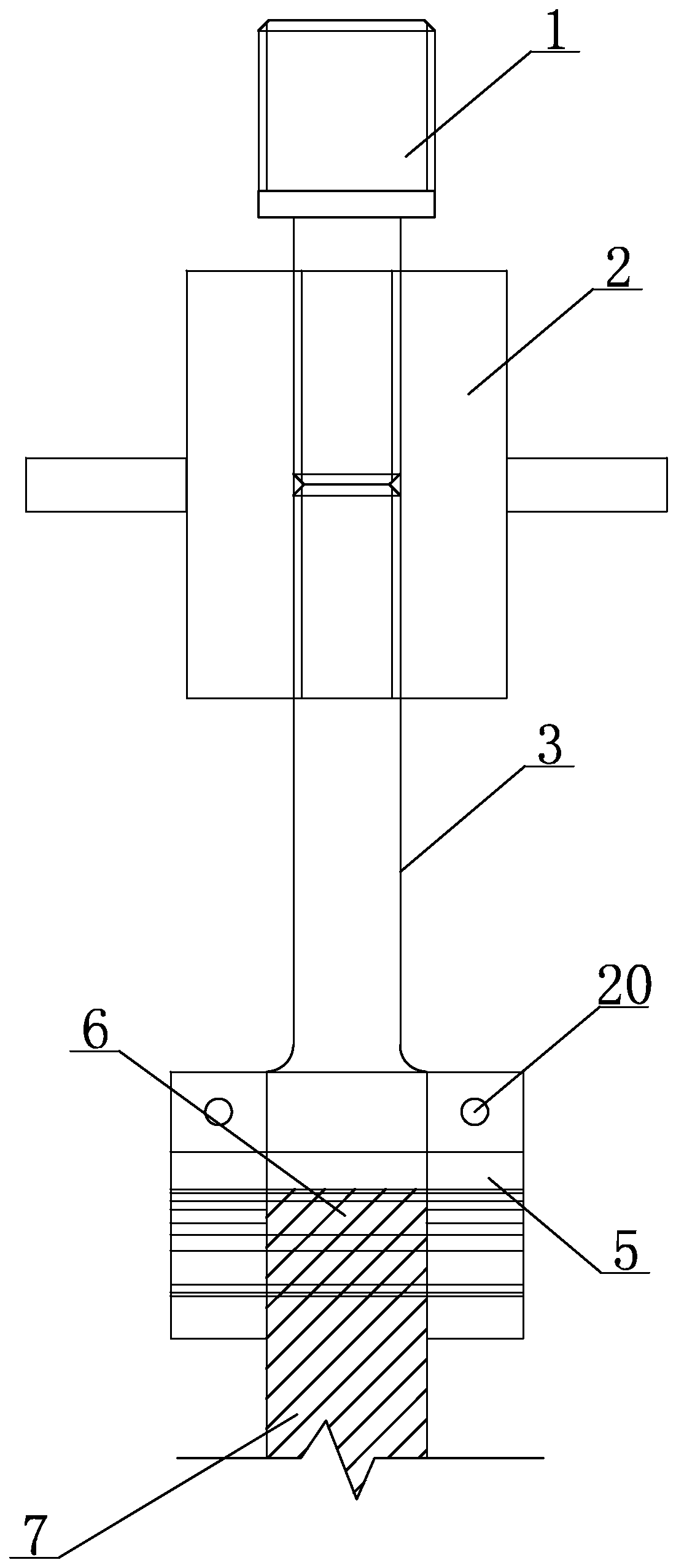

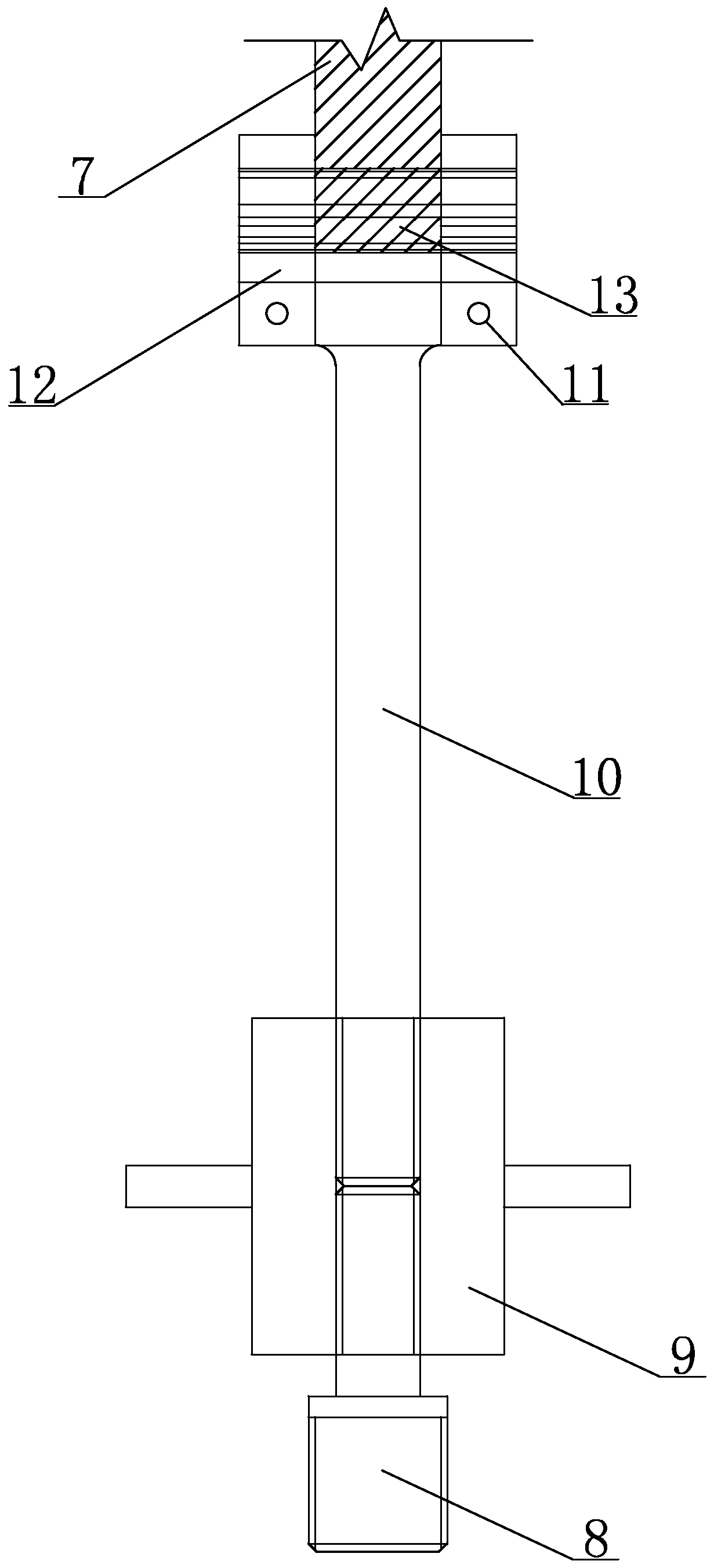

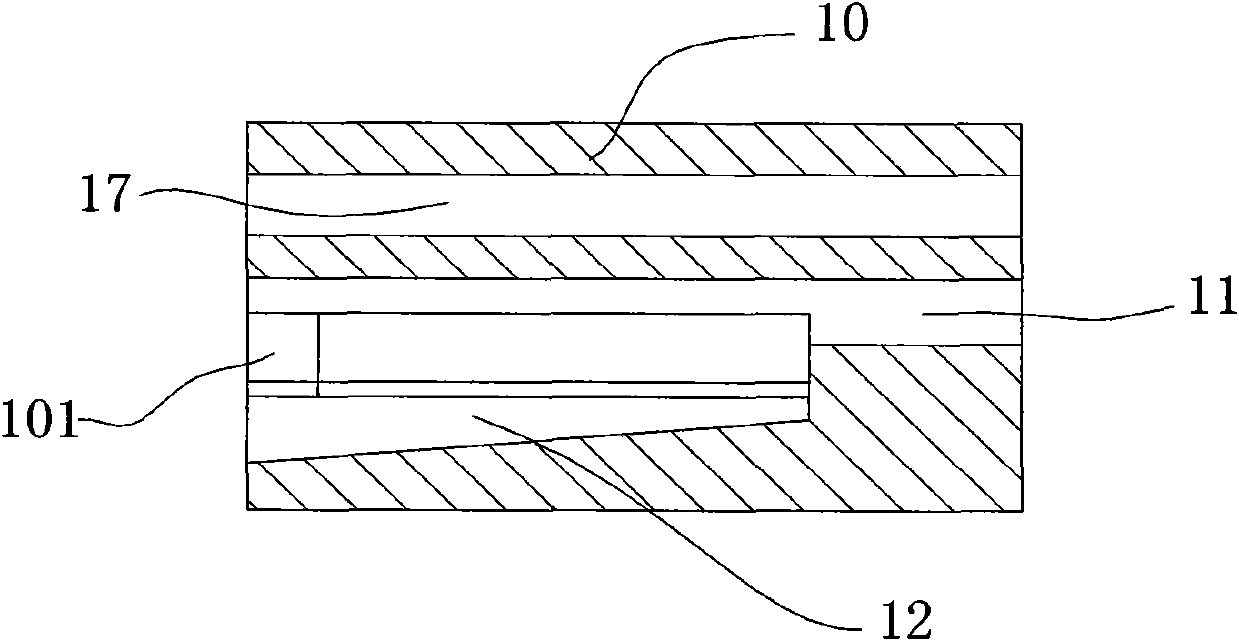

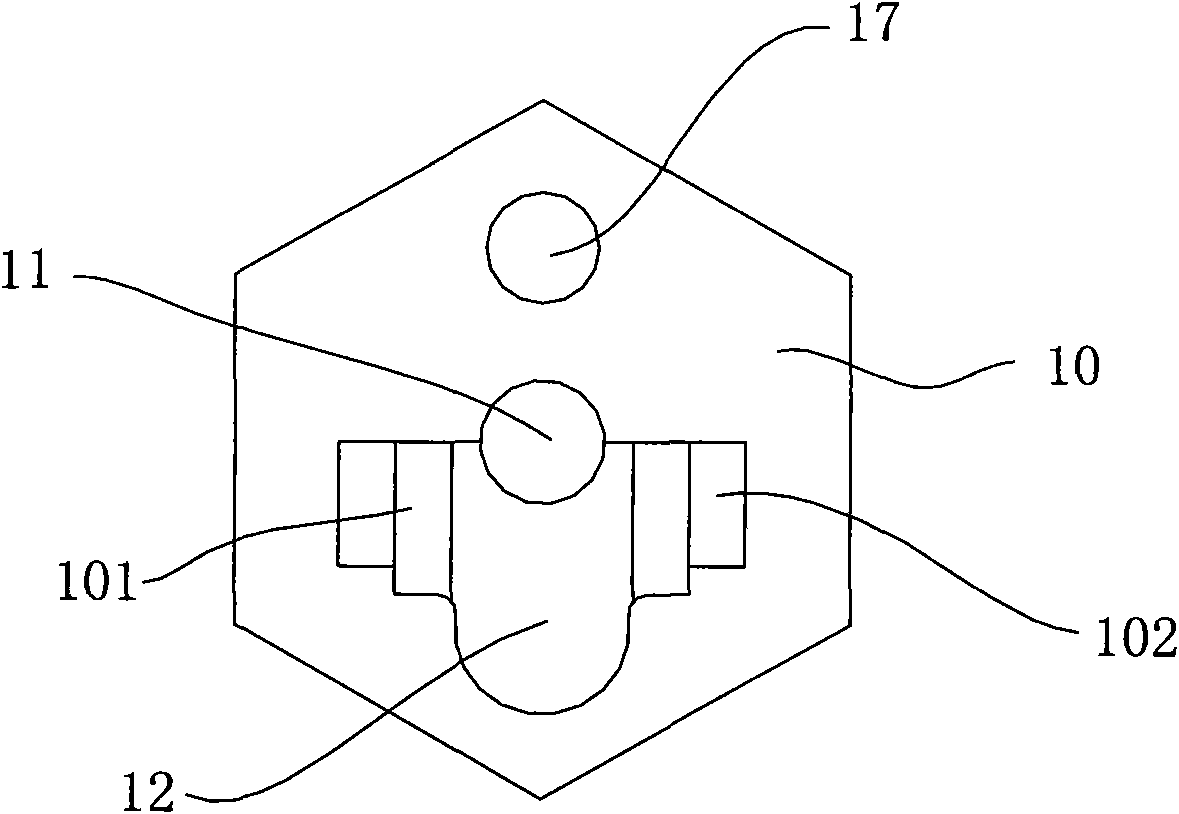

Device for forming multiple strands of double-turn stator coils

ActiveCN104518623AAvoid local deformationEnsure consistencyManufacturing dynamo-electric machinesFixed frameStator coil

The invention discloses a device for forming multiple strands of double-turn stator coils, and solves the problems that an existing fixture for multiple strands of double-turn stator coils is high in discreteness and the quality of wound coils is unlikely to control. The device mainly comprises a forming device fixing frame body and a movable bent handle (18), wherein winding wires of the multiple strands of double-turn stator coils to be wound (17) are wound along a coil winding rail on the forming device fixing frame body; a sleeve (20) on the bent handle (18) movably sleeves a corresponding vertical column at positions to be bent and cranked of the coils, and the pre-bent winding wires are clamped between a bending vertical column (21) on the bent handle (18) and the corresponding vertical column; the bent handle (18) is rotated in the pre-bending direction; the bending vertical column (21) bends the winding wires by taking the corresponding vertical column as a supporting point. The whole forming device fixing frame body is fixed on a base beam (19). The device disclosed by the invention guarantees the consistency of the size, the angle and the radian of the coil.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

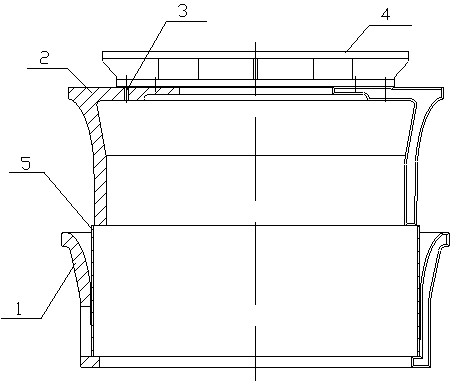

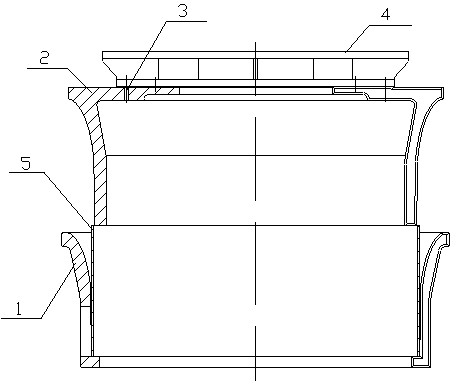

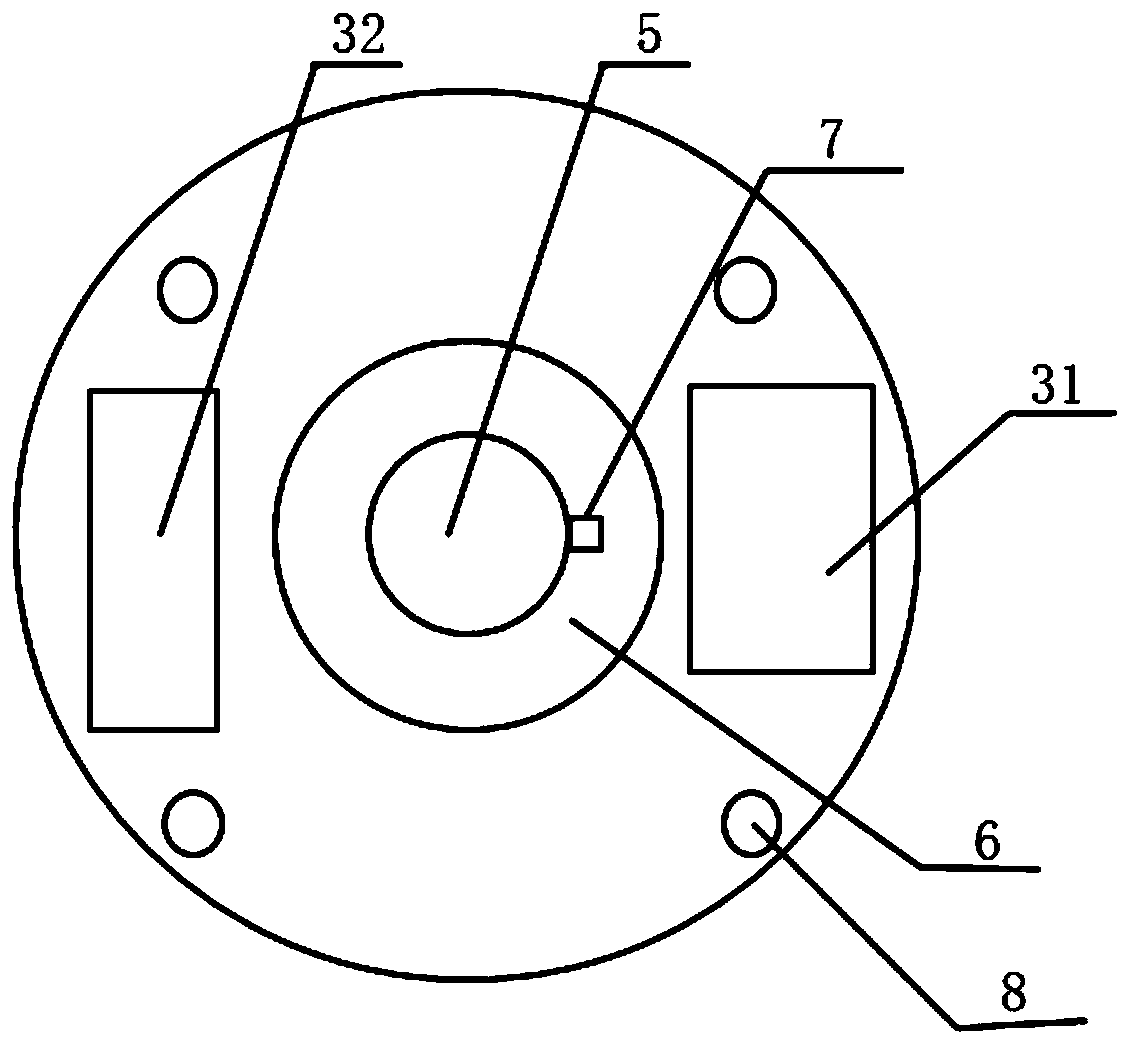

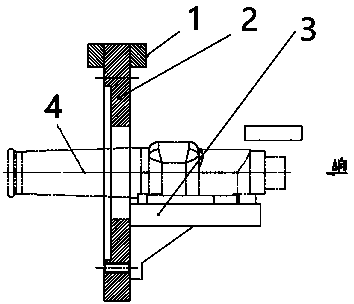

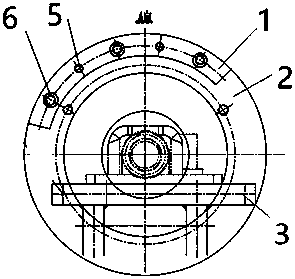

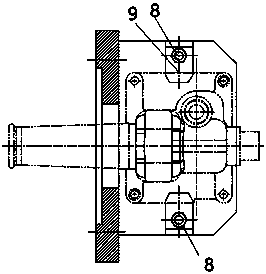

Steering engine controller structure

PendingCN110850793ADimensionally stable and reliableSmall sizeProgramme controlComputer controlMiniaturizationEngineering

The invention relates to a controller structure, in particular to a steering engine controller structure which solves the problems that an existing steering engine controller is large in boundary dimension and cannot meet the miniaturization design requirement, and even if the dimension of the existing steering engine controller is reduced to be within the design requirement range according to theexisting structure, the existing steering engine controller cannot work reliably. The controller structure comprises a control circuit board, two driving circuit boards, a controller shell, a first connector, four second connectors and an internal wire harness; the controller structure is characterized by further comprising a connecting circuit board; the control circuit board, the connecting circuit board and the two driving circuit boards are sequentially and coaxially arranged, and every two adjacent boards are connected through an installation column. Wiring holes are formed in the centers of the surfaces of the control circuit board, the connecting circuit board and the two driving circuit boards, and annular bonding pad areas coaxial with the wiring holes are arranged on the outer sides of the wiring holes; the control circuit board, the connecting circuit board, the two driving circuit boards and the internal wiring harness are positioned in the controller shell; the first connector and the four second connectors are installed on the controller shell.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Machining technology of FT1030 rear reducer shell

InactiveCN109396752ADimensionally stable and reliableGood consistencyGearboxesControl devicesEngineeringReduction drive

The invention provides a machining technology of an FT1030 rear reducer shell. The technology is characterized by comprising the steps of positioning and clamping, turning of a large outer circle andan end face, drilling and spot facing, rough and fine boring of main tooth front and rear bearing holes, mounting of a bearing cover, rough and fine boring of a differential bearing hole, milling of athreaded hole, testing of leakage and cleaning. The product meets the design requirements, the size is stable and reliable, the consistency is good, the operation is simple and convenient, the production efficiency is high, the cost is low, and the popularization and reference values are achieved.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Multi-strand double-turn stator coil forming device

ActiveCN104518623BAvoid local deformationEnsure consistencyManufacturing dynamo-electric machinesFixed frameStator coil

The invention discloses a multi-strand double-turn stator coil forming device, which solves the problems of large discreteness and difficult control of the quality of the wound coil existing in the existing multi-strand double-turn stator coil tooling. It is mainly composed of the fixing frame body of the forming device and the movable bending handle (18), and the winding wire of the multi-strand double-turn stator coil (17) to be wound is wound and arranged along the coil winding track on the fixing frame body of the forming device , when the coil needs to be bent and corners, the sleeve (20) on the bending handle (18) is movably socketed on the corresponding column, and the pre-bent winding wire is clipped to the bending handle (18) Between the upper bending column (21) and the corresponding column, rotate the bending handle (18) in the pre-bending direction, and the bending column (21) will bend the winding line with the corresponding column as the supporting point . Whole molding device fixing frame body is to be fixed on the base beam (19). The invention ensures the consistency of coil size, angle and radian.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

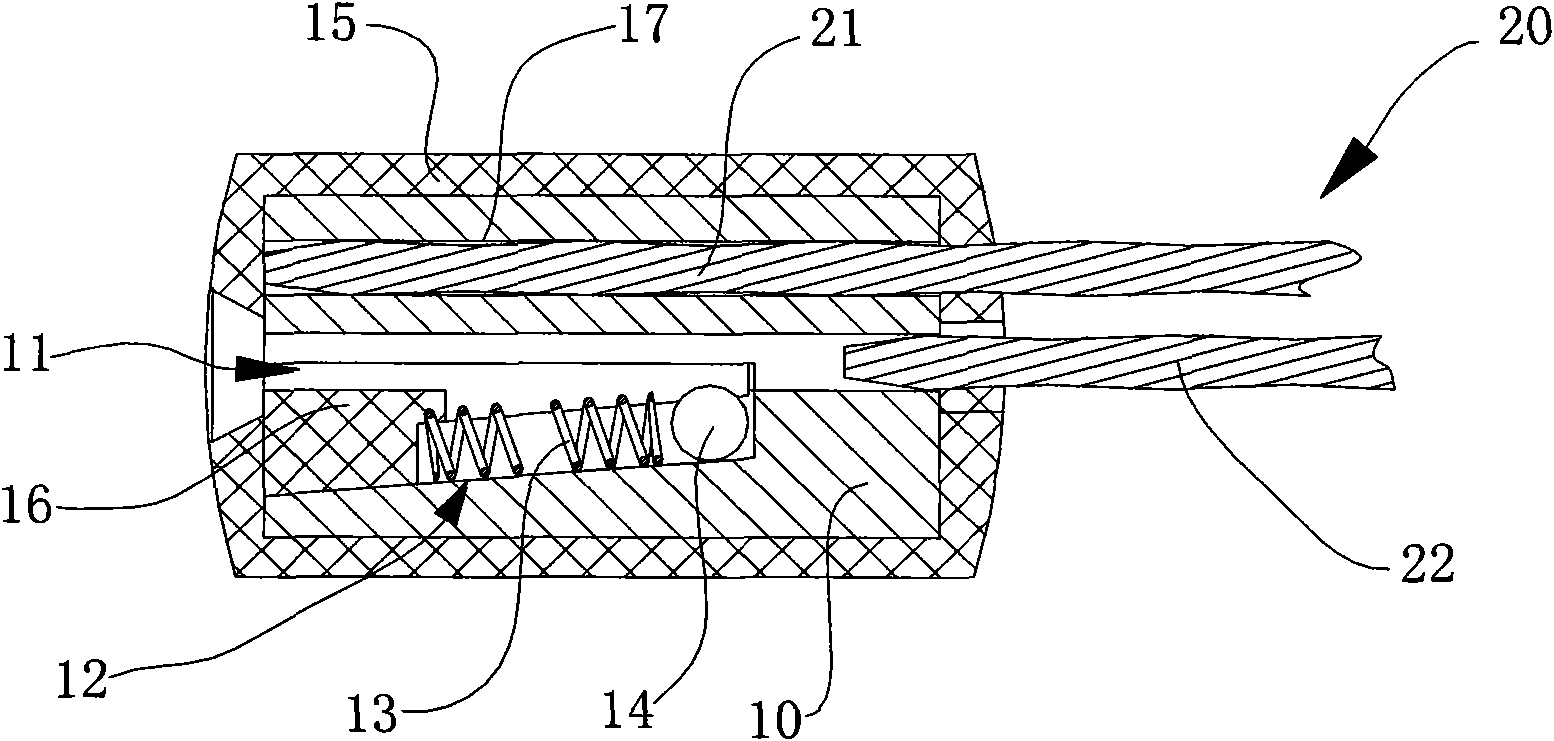

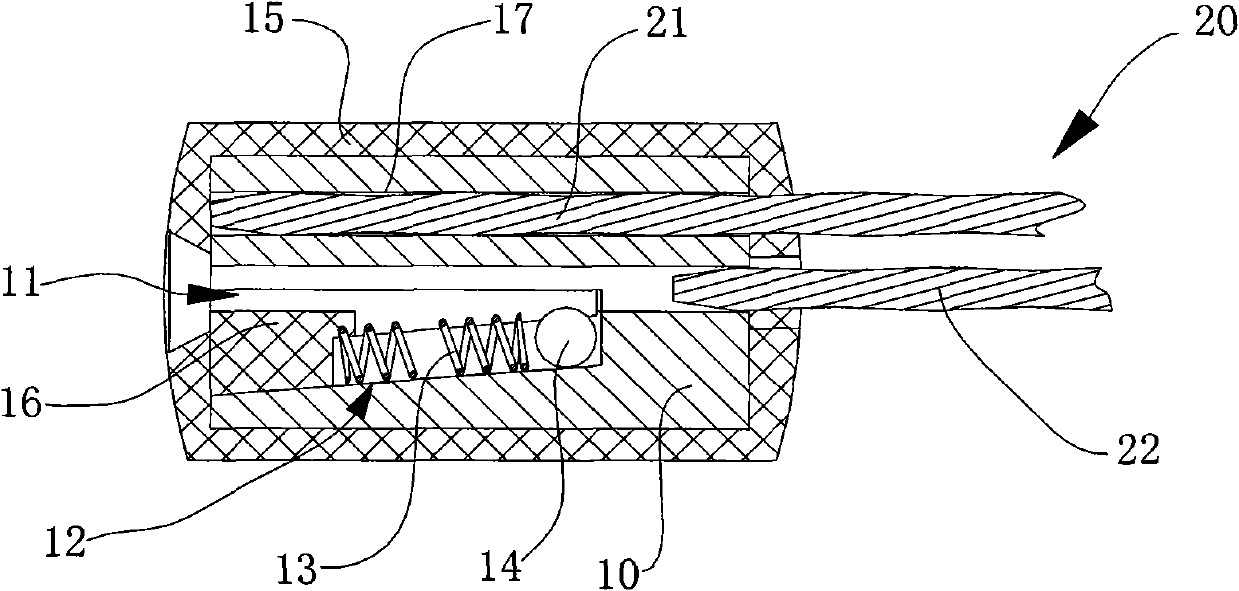

Tensioning steel wire seal and processing method thereof

The present invention provides a steel wire seal, comprising a lock head and a steel wire with one end connected on the lock head. The lock head is provided with a lock cylinder hole for inserting the steel wire and a marble hole for containing the marble and a spring; the hole diameter of the marble hole is matched with the diameter of the marble; the front part of the marble hole is obliquely penetrated through the middle part of the lock cylinder hole; the size of an area of which the marble hole and the lock cylinder hole penetrate is less than the diameter of the marble. The seal is characterized in that the lock cylinder hole and the marble hole are composed by enclosing a hole wall on the lock head and the surface of an internal core; the internal core is located at the tail end between two holes and is fixedly connected with the lock head; the part where the internal core located at the tail end of the marble hole and the spring form a stop structure; the processing method comprises the steps as follows: compression molding the lock head, the parison comprising a big hole cavity, then filling with the marble and the spring and inserting in the big hole cavity by the specific internal core, and then fixedly connecting the lock head and the steel wire, thereby avoiding the secondary drilling process of the marble hole; the seal has the advantages of accurate size of eachhole, good performance and convenient process.

Owner:黄山亿利工贸集团有限公司

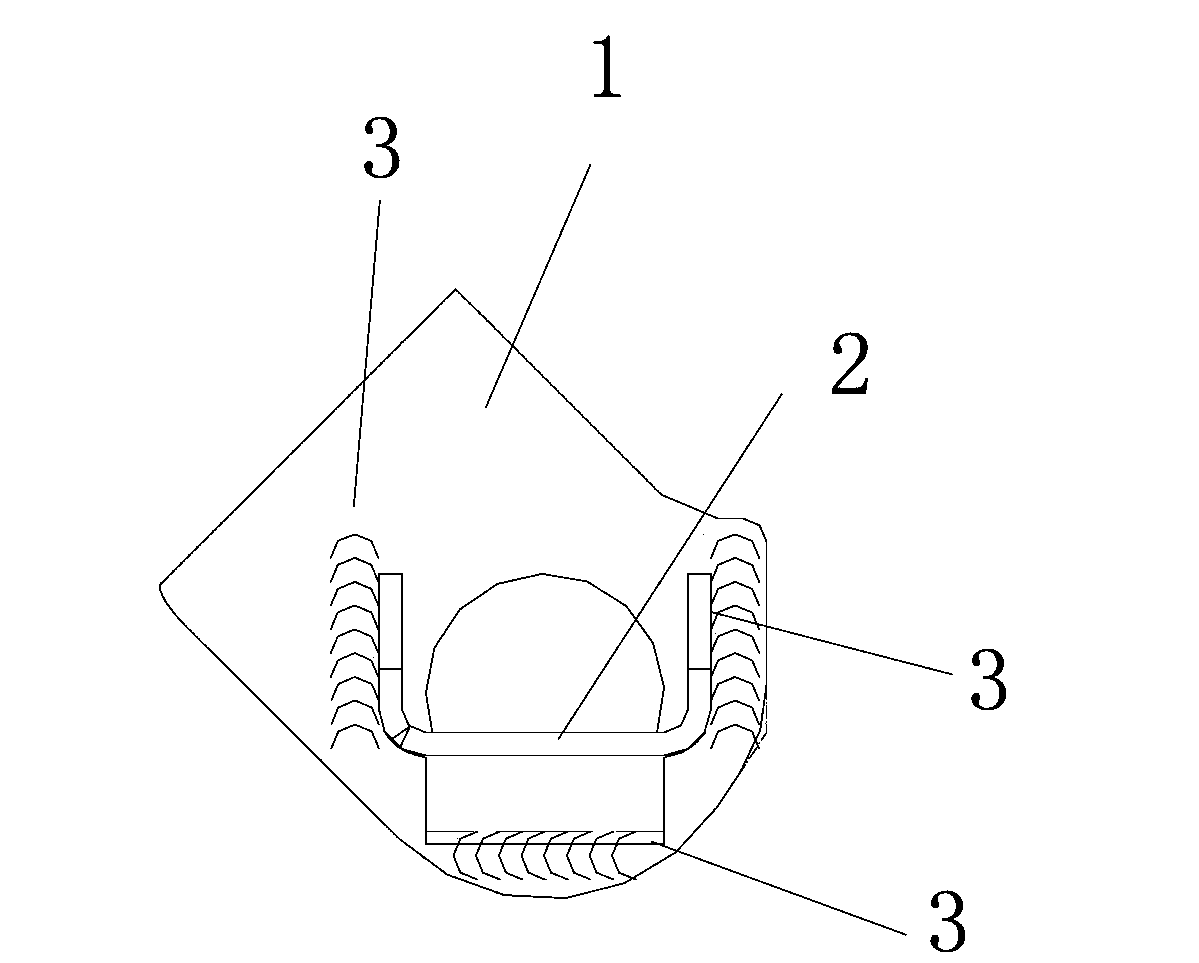

Supporting limiting structure for use in production of automobile dashboard beams

InactiveCN104722988ASafe and reliable performanceEasy to pick upWelding/cutting auxillary devicesAuxillary welding devicesDashboardEngineering

The invention discloses a supporting limiting structure for use in production of automobile dashboard beams. The supporting limiting structure is disposed on a vertical plate; the supporting limiting structure comprises a supporter and limiters; the supporter in an L shape comprises a transverse part and a vertical part integrally formed and perpendicularly connected to the same; the transverse part is fixed to the top of the vertical plate; the limiters are bilaterally symmetrically disposed on two sides of the vertical part of the supporter; multiple pads are disposed between the limiter and the vertical part, and other multiple pads are disposed between the vertical plate and the transverse part. The problem that during batch production and the manufacturing precision of the automobile dashboard beams not meeting the requirement, picking is difficult and the size of the support part is difficult to adjust is solved; the automobile dashboard beams are easy to pick during production, production efficiency is improved, and size is more stable and reliable; sizes of various mounting holes are all within an allowable dimensional tolerance range; automobiles are safer and more reliable.

Owner:SHANGHAI HEDA AUTOMOBILE FITTINGS

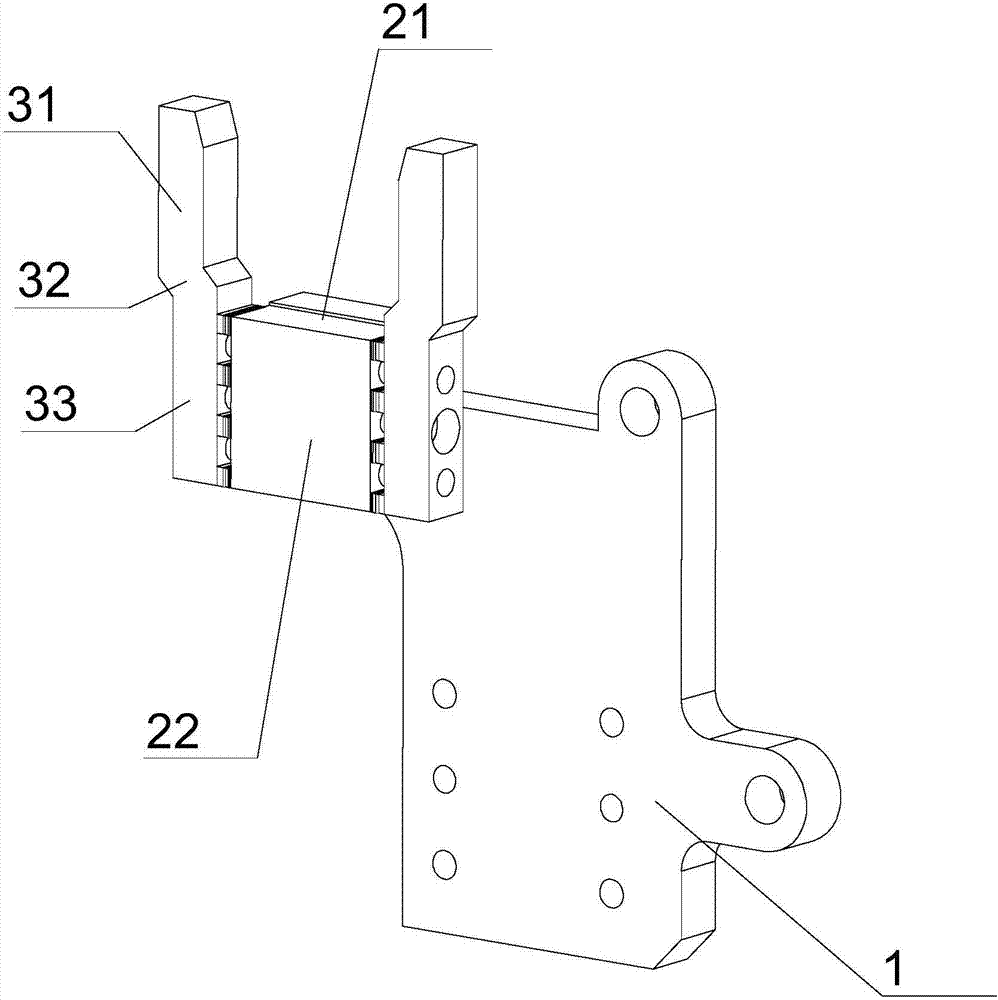

Positioning clamp for Macpherson suspension body and tower body welding

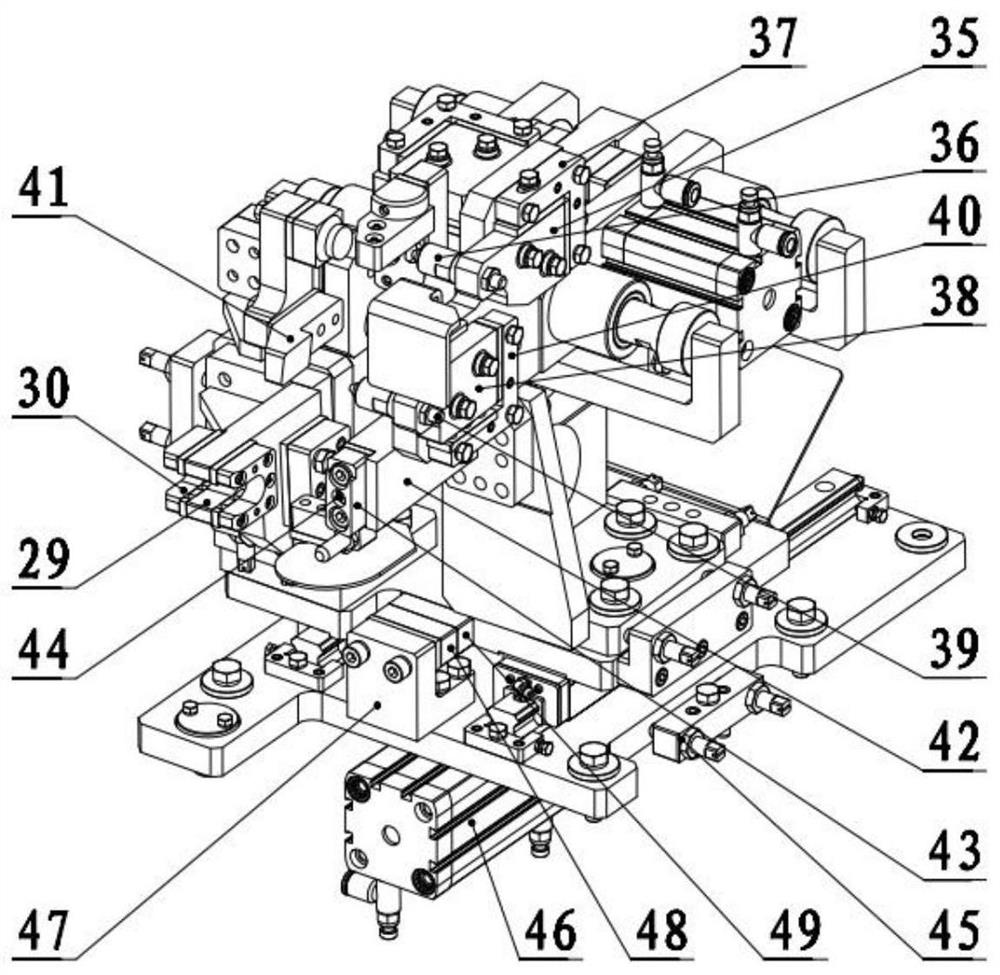

ActiveCN112872686AAchieve precisionAchieving shape and position accuracyWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsControl arm

The invention discloses a positioning clamp for Macpherson suspension body and tower body welding. The clamp comprises a tower body positioning mechanism and a suspension body positioning mechanism which are fixed on a clamp table top. The tower body positioning mechanism is provided with a positioning and clamping unit, an auxiliary supporting unit and a horizontal sliding unit, the positioning and clamping unit and the auxiliary supporting unit are installed on the horizontal sliding unit, and the positioning and clamping unit is provided with a power source, a positioning and clamping module and a supporting and clamping module. After the power source is fixedly connected with the positioning and clamping module, the power source is connected with the supporting and clamping module through a connecting base and a guiding shaft, so that clamping and positioning of a tower body are achieved. The tower body positioning mechanism and the suspension body positioning mechanism are each provided with an angle adjusting structure, so that the angles of all the mechanisms on the X-Y plane and the X-Z plane are adjustable, accurate positioning after the tower body and a suspension body are assembled is controlled, and the opening size and the shape and position precision of a control arm mounting position after welding are achieved. By means of the positioning clamp, the first time quality of products is improved, and quality is stable and reliable.

Owner:郭兵

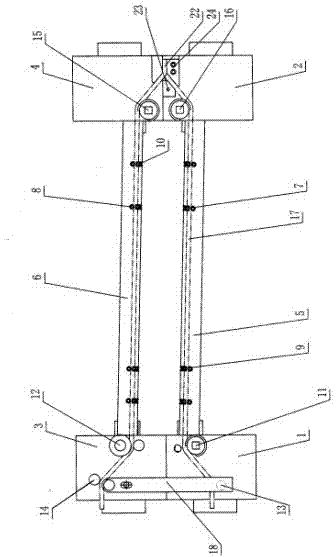

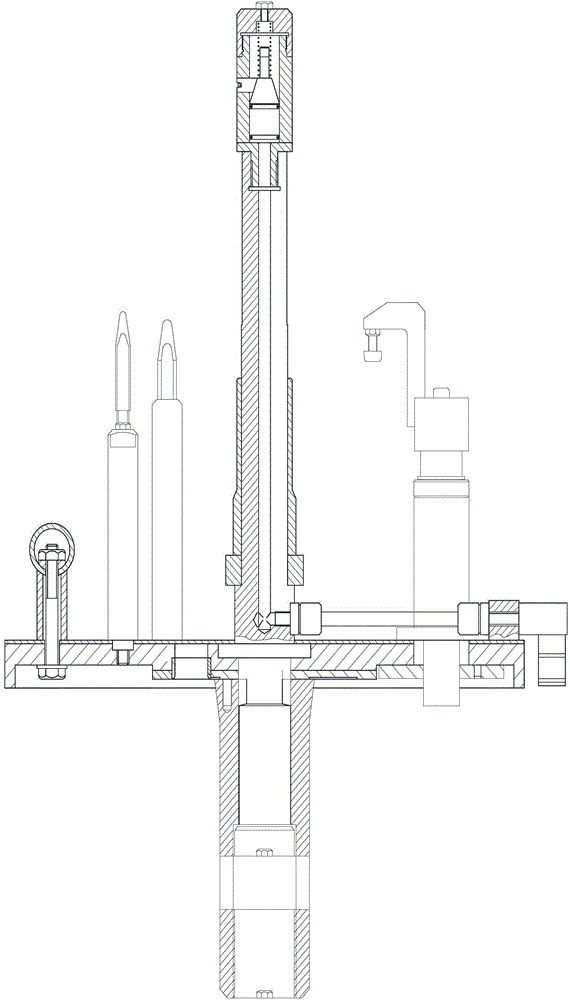

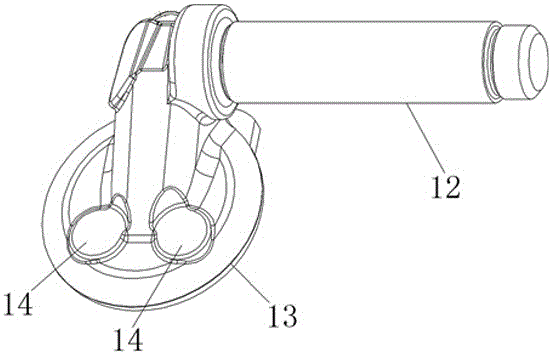

Device and process for backstep welding of damping spring disk

ActiveCN102785052BEasy maintenanceMechanical stabilityWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationComputer engineering

The invention relates to the technical field of welding, particularly to a device and a process for backstep welding of a damping spring disk. The device comprises a rotary table, a locating plate, a vertical plate, a rotating cylinder, a liquid storage cylinder pressing plate, a spring disk locating pin long seat locating plate, a spring disk locating pin long seat, a spring disk locating pin, a spring disk pressing plate, a spring disk locating round pin, a spring disk locating long pin, a spring disk locating pin seat, a liquid storage cylinder locating plate, and a reinforcement plate. Compared with the prior art, the disk is three-point located by the aid of a tooling and fixedly clamped through the rotating cylinder, welding thermal deformation after welding is reduced, dimensions after the welding are stable and reliable, and adjustment is convenient. The structure of the device for the backstep welding of the spring disk is simple and stable, the maintenance cost is low, and the device is convenient to maintain.

Owner:上海汇众萨克斯减振器有限公司

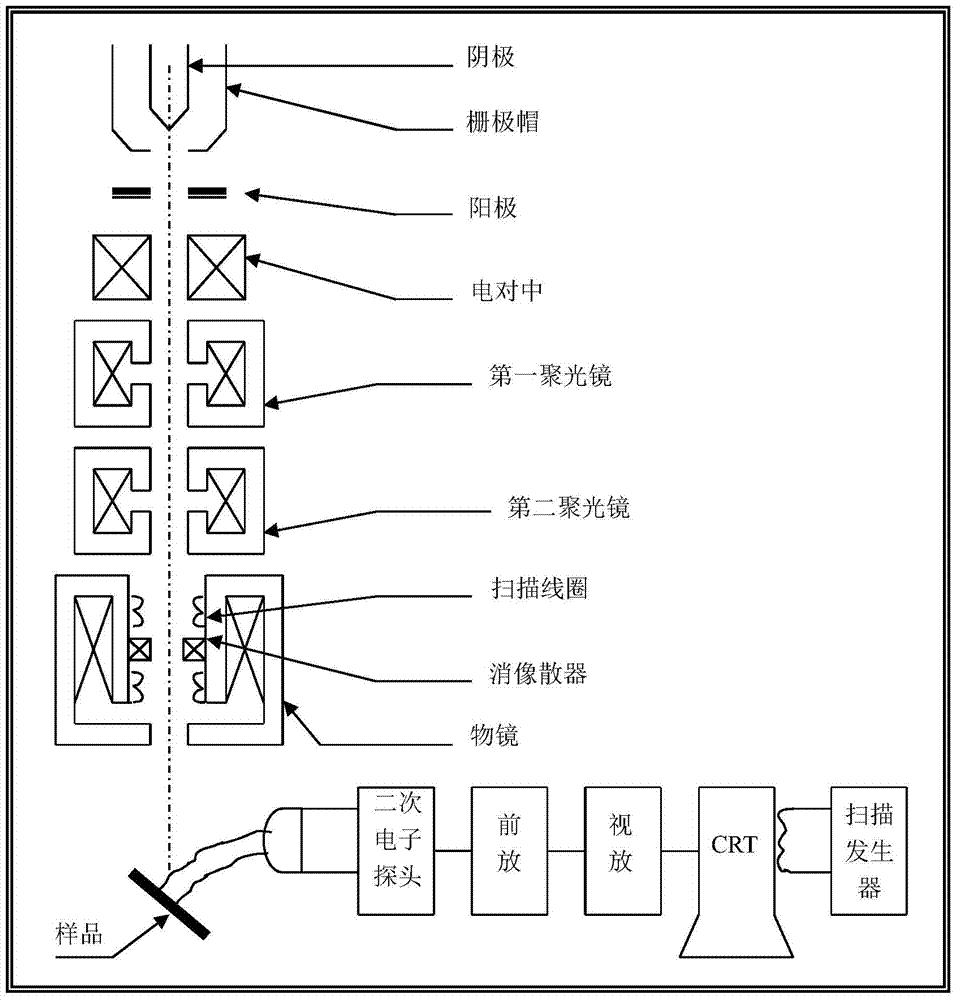

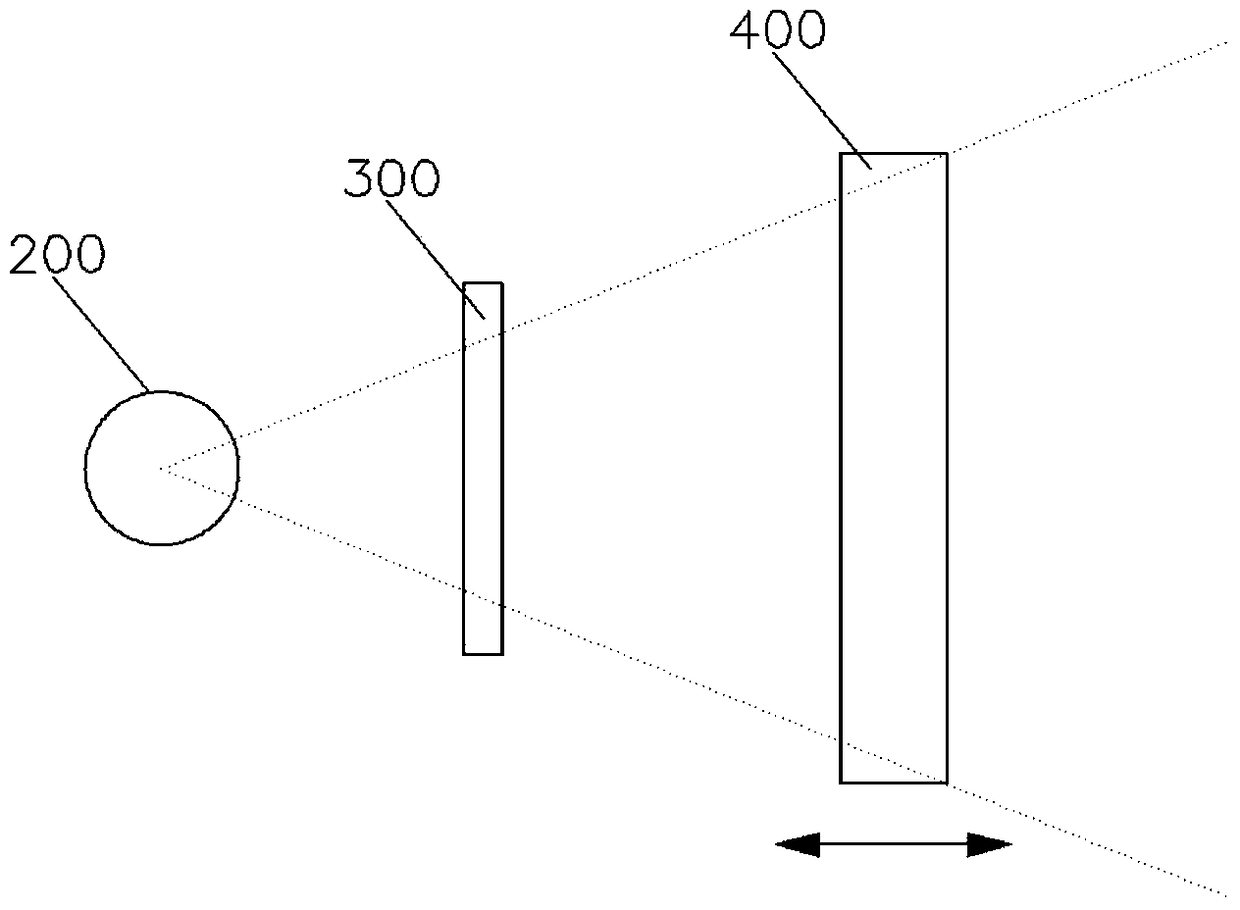

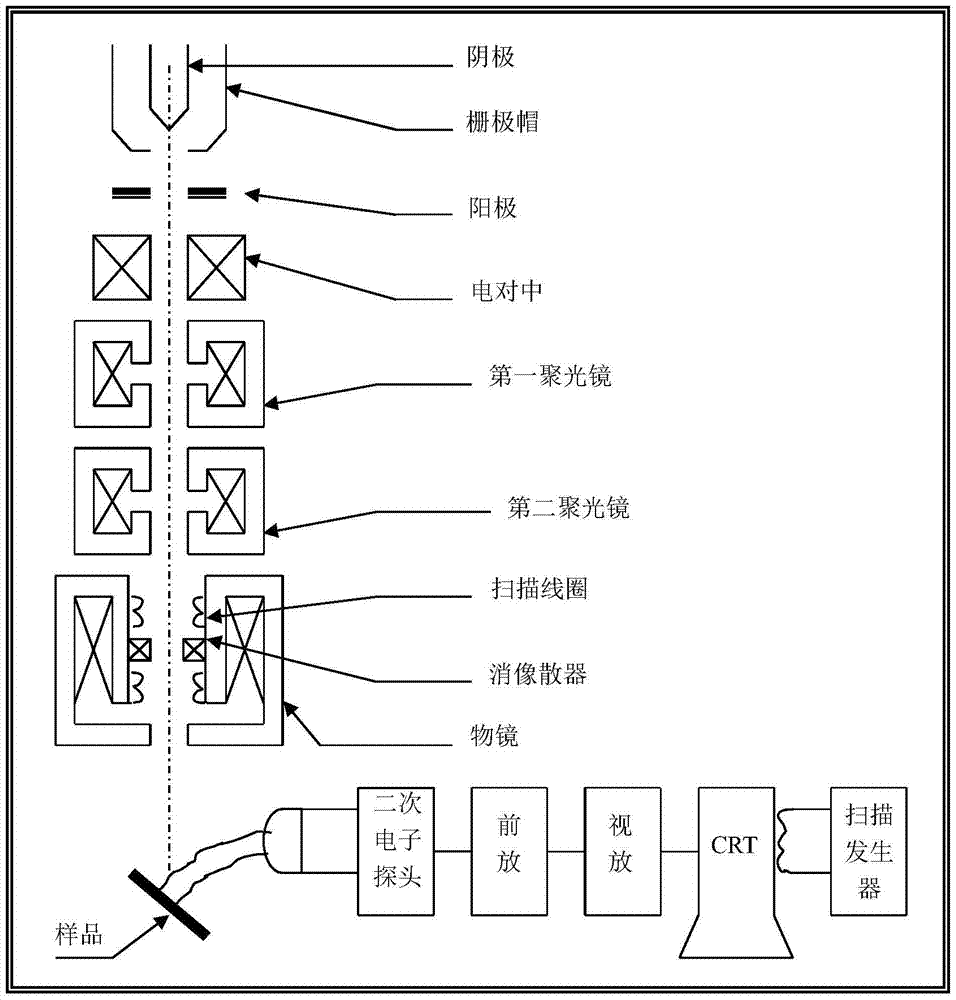

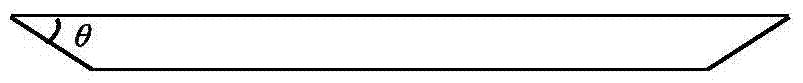

Method for measuring size of electron beam spot of scanning electron microscope

InactiveCN104266572AIncrease contrastHigh precisionUsing electrical meansScanning tunneling microscopeGray level

The invention relates to the technical field of electrons, in particular to a method for measuring the size of the electron beam spot of a scanning electron microscope. The method comprises the steps that first a metal blade placed on a cup opening of a Faraday cup is irradiated through the scanning electron microscope, and a clear metal blade image is obtained; then the image of the edge of a part of a knife edge is cut out, image data processing software is used for acquiring the RGB value of the image, and a R gray level matrix, a G gray level matrix and a B gray level matrix are obtained; the average value of the three matrixes is obtained, and an average matrix is obtained; all the columns of the average matrix are summed, a one-dimensional matrix is obtained, a two-dimensional curve is drawn according to the values of all units of the one-dimensional matrix, the width of the rising edge of the curve is the beam spot diameter of an electron beam, and the purpose of the method is achieved. Accordingly, the method for measuring the size of the electron beam spot of the scanning electron microscope has the advantages of being easy to operate, high in precision, and high in practicability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

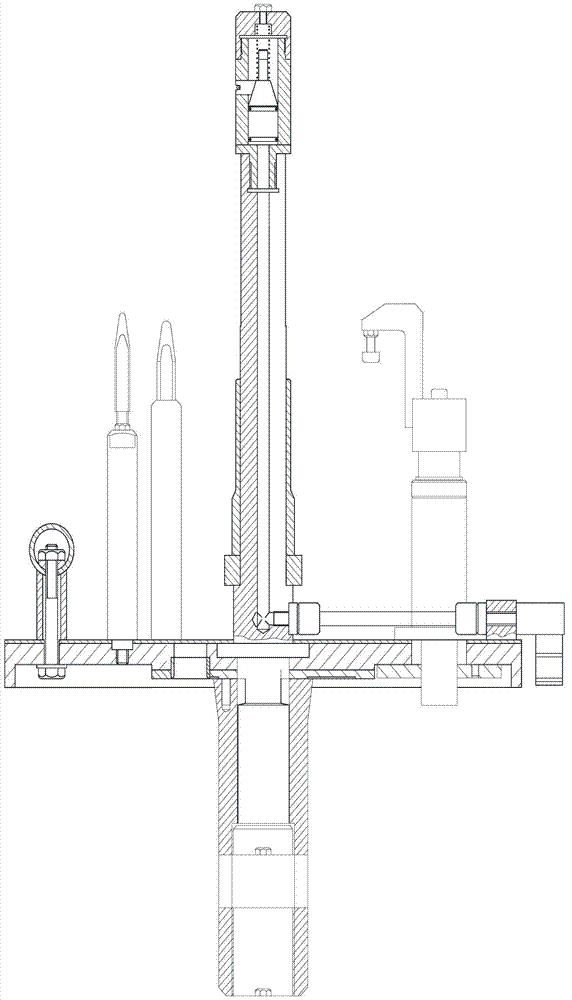

Device and method for machining reinforcing steel bar shaped like the Arabic number 8

ActiveCN103521662AImprove finished product qualityImprove processing efficiencyWire articlesArabic numeralsEngineering

The invention discloses a device and method for machining a reinforcing steel bar shaped like the Arabic number 8 and belongs to the technical field of tunnels. The device is composed of an 8 shape forming device and an arch back forming device. The 8 shape forming device is composed of a work platen, a hydraulic arm, a limiting board, a telescopic clamping board, an inner sliding 8 shape shaping die, a limiting suspension resistant clamping board, an outer sliding forming template A, an outer sliding forming template B and an 8 shape forming inner sliding die base board. The arch back forming device is mainly composed of a door frame, a hydraulic arm, a movable downward-pressing beam, an ejection head and a stamping table. The method comprises the steps that the inner sliding 8 shape shaping die is sleeved with a machined rectangular reinforcing steel bar and an 8 shape is formed through the outer sliding forming template A and the outer sliding forming template B. The machined reinforcing steel bar shaped like the Arabic number 8 is horizontally placed on the stamping table of the arch back forming device and stamped through the movable downward-pressing beam and the ejection head so that an arch back can be formed. The device for machining the reinforcing steel bar shaped like the Arabic number 8 has the advantages of being high in pass percent, high in production efficiency, good in machining quality and good in safety and reliability.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

Double box opening model of auxiliary valve body of ball valve and casting process

ActiveCN106216602ADimensionally stable and reliableIncrease productivityFoundry mouldsFoundry coresMold fillingEngineering

The invention provides a double box opening model of an auxiliary valve body of a ball valve. The double box opening model comprises an upper box, a lower box and a top core, the upper box and the lower box are divided from the inner side of a side flange of the auxiliary valve body, the upper box is subject to mold splitting from the inner side of an end flange, a top riser is arranged on the upper end face of the end flange, a chiller is allocated, and a side riser is arranged on the outer side of the side flange; a bottom mold filling pouring scheme is adopted; the top riser of the end flange and a solidification temperature field of the chiller are designed to be in axial symmetry, the top riser, the chiller and the upper end face of the end flange are jointly formed through the top core on the model, and the top core can move in a 360-degree manner in the axial direction; the side riser of the side flange is designed to be in a sinking and thermal center connection manner, and a bright casting and riser boundary is formed; and meanwhile, the uniform and in-order solidification temperature field is formed, coarse grain and solidification front secondary oxidation caused by local overheating of castings are avoided, and the reliability of the internal quality of the castings is guaranteed.

Owner:NINGXIA LANGSHENG PRECISION MFG TECH CO LTD

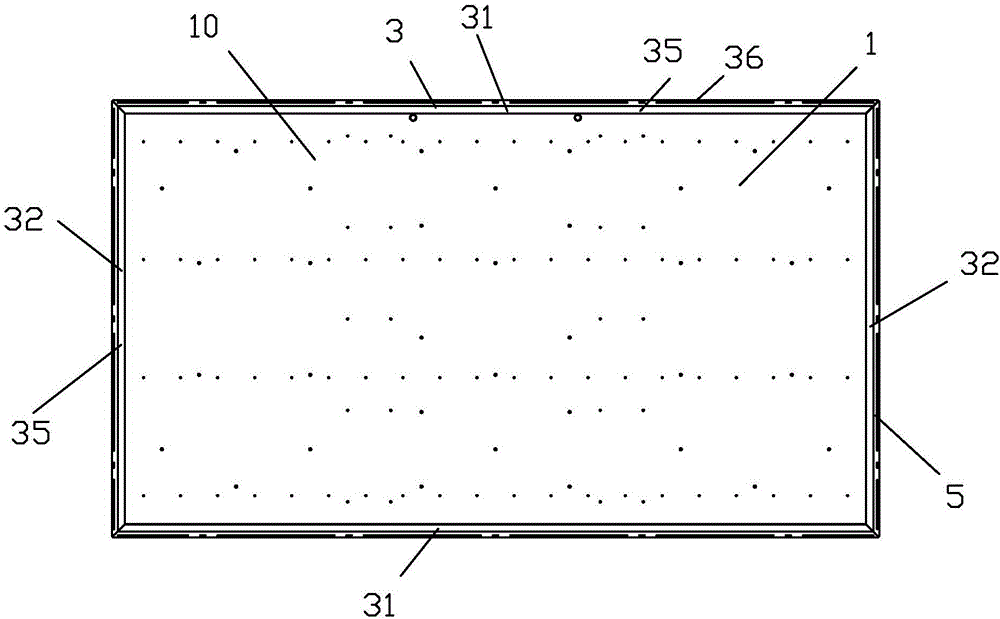

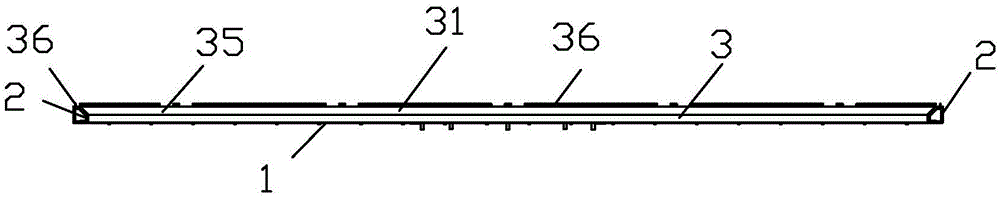

DLED liquid crystal display television backplane without hardware forming mould and preparation method thereof

ActiveCN106686331ALow costHigh strengthTelevision system detailsColor television detailsLiquid-crystal displayDie casting

The invention discloses a liquid crystal display television backplane without hardware forming mould and preparation method thereof. The backplane comprises four aluminum profiles, four die-casting angle aluminum profiles and a piece of plane steel plate. The four aluminum profiles orderly head-to-tail form a rectangle shape in the vertical; The four die-casting angle aluminum profiles are shaped L, which each inserts in die cavities of the two adjacent aluminum profiles and locks by a screw between the die-casting angle aluminum profile and the corresponding aluminum profile, and then the two adjacent aluminum profiles are fixed, so as to form a rectangular aluminum frame; The plane steel plate covers the four aluminum profiles which form the rectangular aluminum frame, and are fixed by screw locking, a cavity is enclosed by the four aluminum profiles and the plane steel plate to contain the electronic device corresponding to the DLED liquid crystal display television. There is no need to use hardware forming moulds to make the backplane. The technology is characterized by low in mould costs, simple to process, stable in processed product size, controllable in distortion and stable and reliable in quality.

Owner:XIAMEN PRIMA TECH

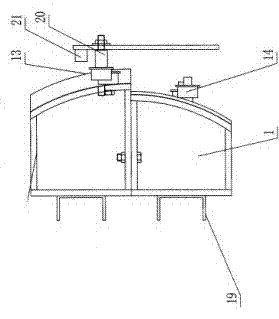

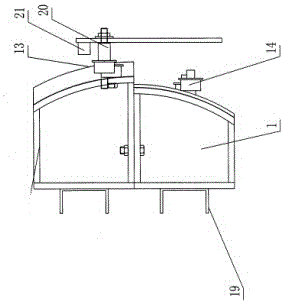

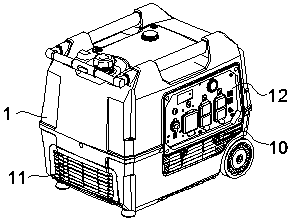

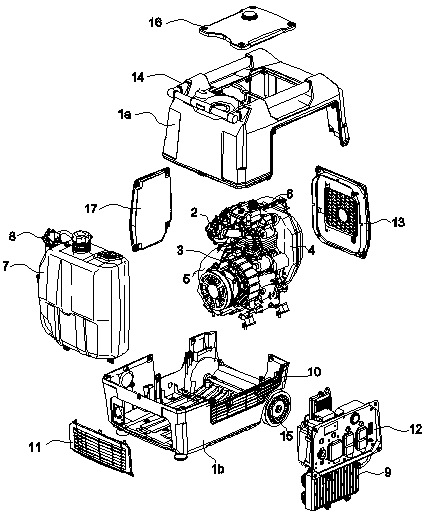

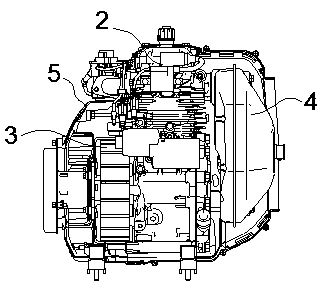

Silent variable frequency generator

PendingCN111140347AIngenious structural designReliable useAir coolingMachines/enginesFuel lineElectric generator

The invention discloses a silent variable frequency generator. The generator comprises a shell assembly composed of an upper shell and a lower shell, an engine is arranged in the lower shell, and a silencer and a stator and rotor component with a cooling fan are arranged on the two sides of the engine. A wind scooper and an air guide hood are arranged in the shell assembly, the wind scooper surrounds the stator and rotor component, and the air guide hood surrounds the engine and the silencer. A fuel tank, a fuel transfer unit and an inverter unit are arranged in the shell assembly, and the fuel tank and the fuel transfer unit are arranged on one side of the engine and are far away from the inverter unit. The silent variable frequency generator has the advantages of ingenious structure design and reliable use. The volume of the fuel tank can be increased without increasing the size of the whole machine, and the heat dissipation performance of the generator is ensured. In addition, the fire risk caused by fuel leakage due to a fuel pipeline being broken is effectively reduced. Moreover, due to the unique design mode of the upper shell and the lower shell being formed in one body, themanufacturing and assembly costs are reduced.

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

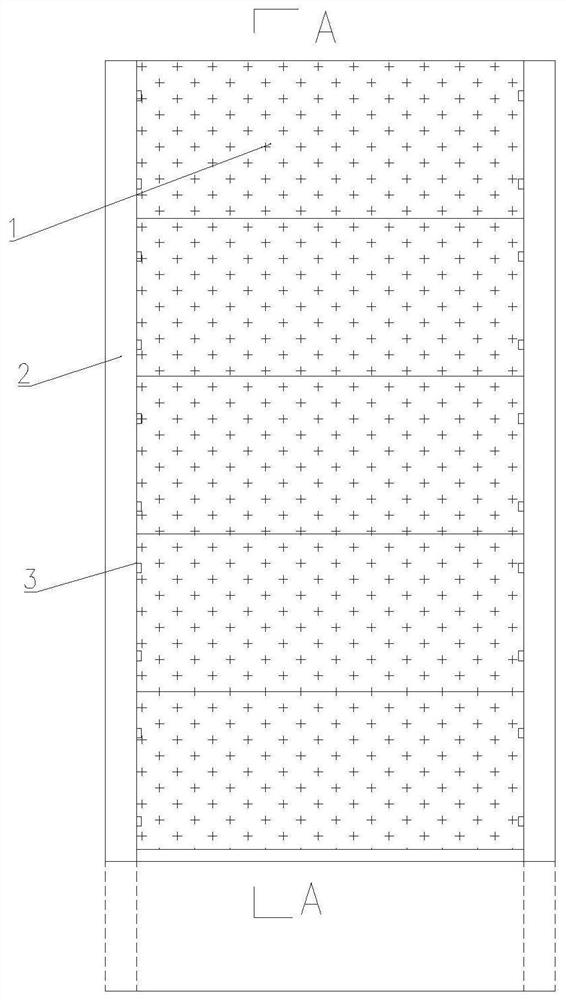

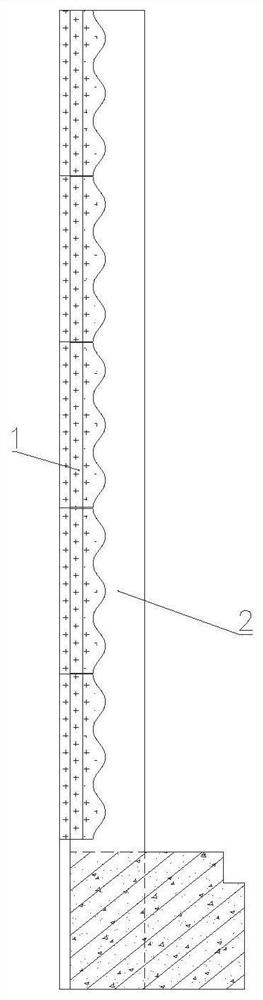

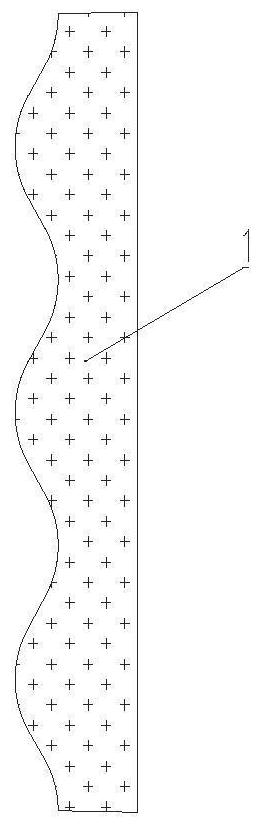

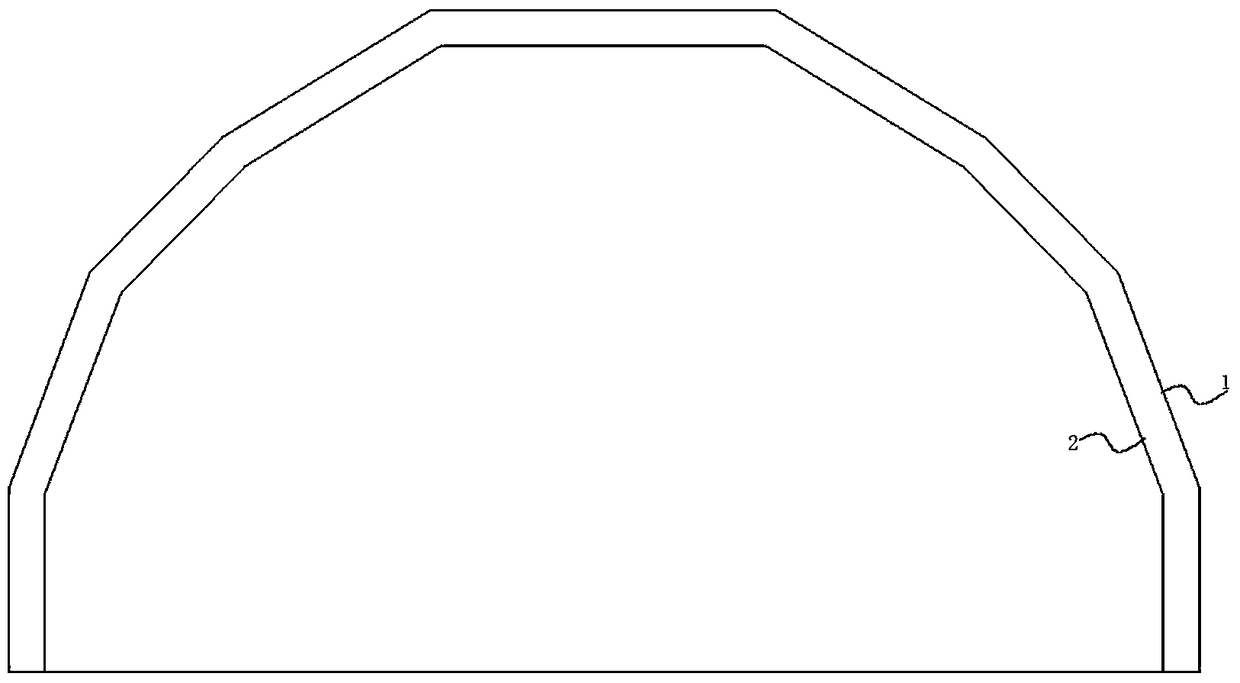

Sound barrier acoustic board installing structure

PendingCN112127291AGood adaptive stabilityThe installation structure is stableNoise reduction constructionSound barrierEngineering

The invention discloses an acoustic board installing structure. The sound-facing surface of each acoustic board consists of a plurality of concave-convex arc-shaped structures or concave-convex trapezoidal structures which are transversely arranged at equal intervals, and two sides of the sound-facing surface of each acoustic board are fixed to supporting rib columns through expansion screws boltsby two installing blocks; each installing block is an eccentric block of a cylinder structure; an eccentric hole of a through hole structure is formed in the circle center side of the cylinder; the two installing blocks at the same side are tightly matched with and fixed to the rib columns through arc-shaped or trapezoidal vertically symmetrical inclined planes of the acoustic board; and each installing block is of a cylinder structure made of elastic materials. According to the acoustic board installing structure, the eccentric blocks made of the elastic materials are used for fixing the acoustic boards with symmetrical slope structures; the back side bonding mode is assisted; the acoustic boards can be stably and firmly fixed to the supporting rib columns; and due to the characteristicsof the eccentric blocks, the acoustic boards can be balanced and stable, so that a sound barrier can realize good self-adaptive stability in a complicated environment.

Owner:CHENGDU ZHONGHONG RAIL TRANSIT ENVIRONMENTAL PROTECTION IND

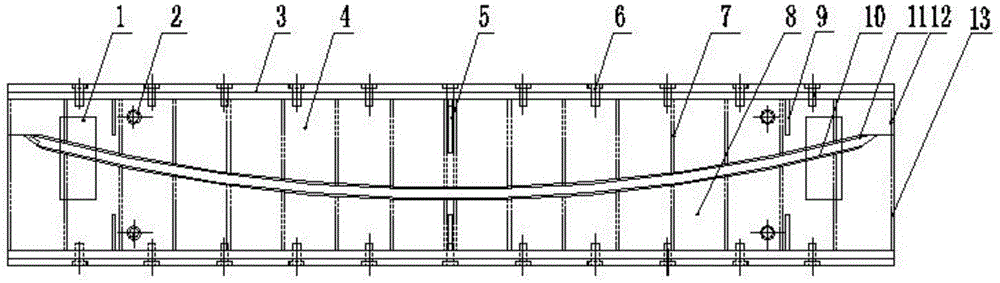

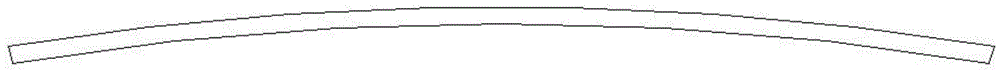

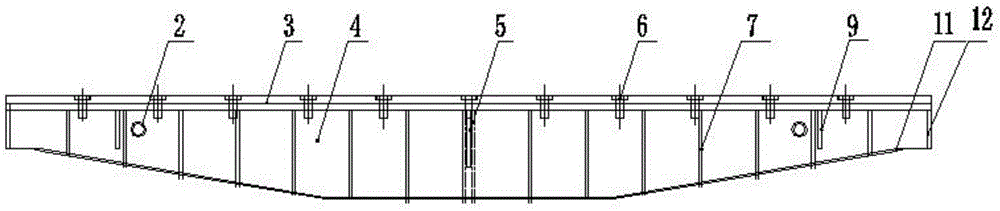

Bending forming die tool for bus roof through beam

InactiveCN105642717AStrong enoughRigid enoughLoad-supporting pillarsUltimate tensile strengthMechanical engineering

The invention discloses a bending forming die tool for a bus roof through beam. The tool comprises an upper die and a lower die which are mutually matched for work, wherein each of the upper die and the lower die comprises a bottom plate, and two rows of opposite bolts are arranged on the bottom plate; a row of upper reinforcing plates and a row of lower reinforcing plates are welded on the bottom plates of the upper die and the lower die respectively; an upper die arc plate is welded on each of two sides of the upper reinforcing plates, each of two ends of one upper die arc plate is connected with the corresponding end of the other upper die arc plate through an upper baffle plate, and the upper die arc plates and the upper ends of the upper reinforcing plates are spliced through an upper arc plate; a lower die arc plate is welded on each of two sides of the lower reinforcing plates, each of two ends of the one lower die arc plate is connected with the corresponding end of the other lower die arc plate through a lower baffle plate, and the lower baffle plates and the upper baffle plates are oppositely arranged; the lower die arc plates and the upper ends of the lower reinforcing plates are spliced through a lower arc plate. The die tool has sufficient strength and rigidity, is simple in structure and is light; under the premise that the strength and the rigidity are guaranteed, the structure is simple and compact as far as possible, the size is small, the mass is light, and workpiece loading and unloading are facilitated.

Owner:ANHUI ANKAI AUTOMOBILE

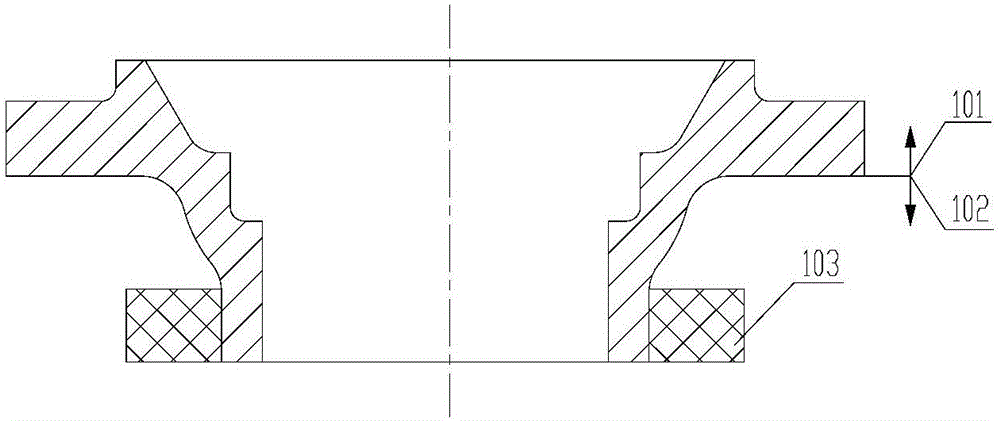

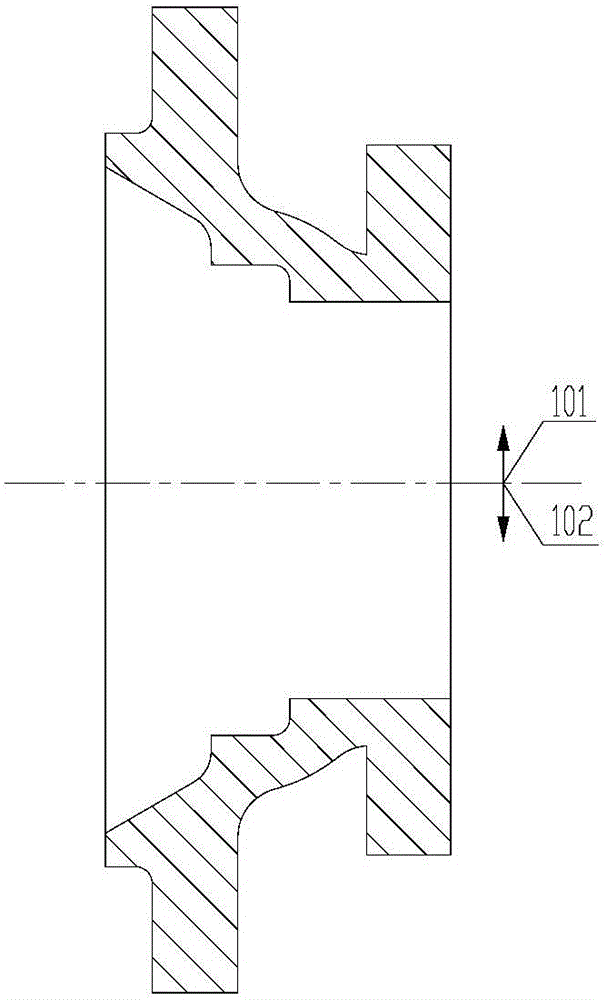

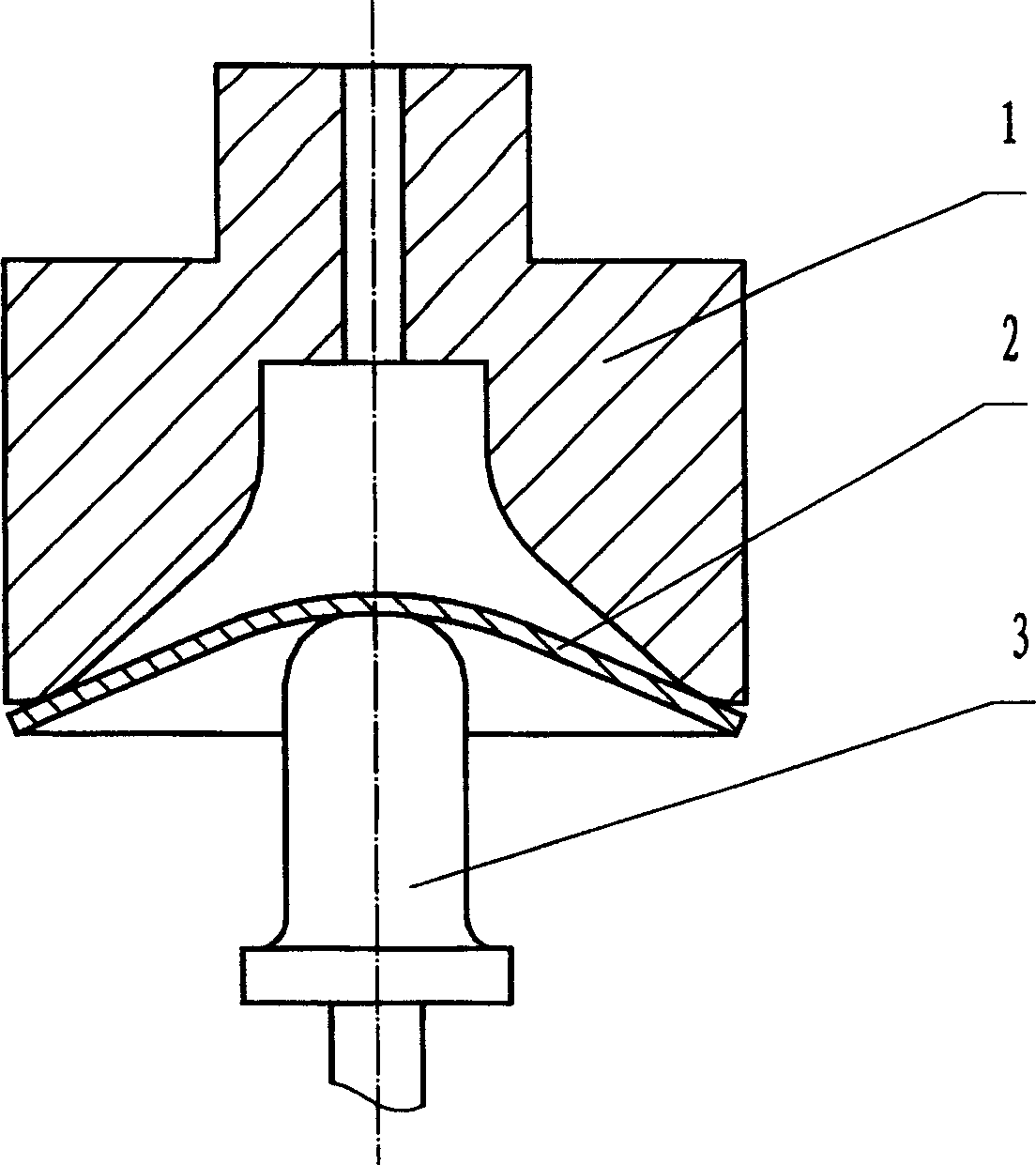

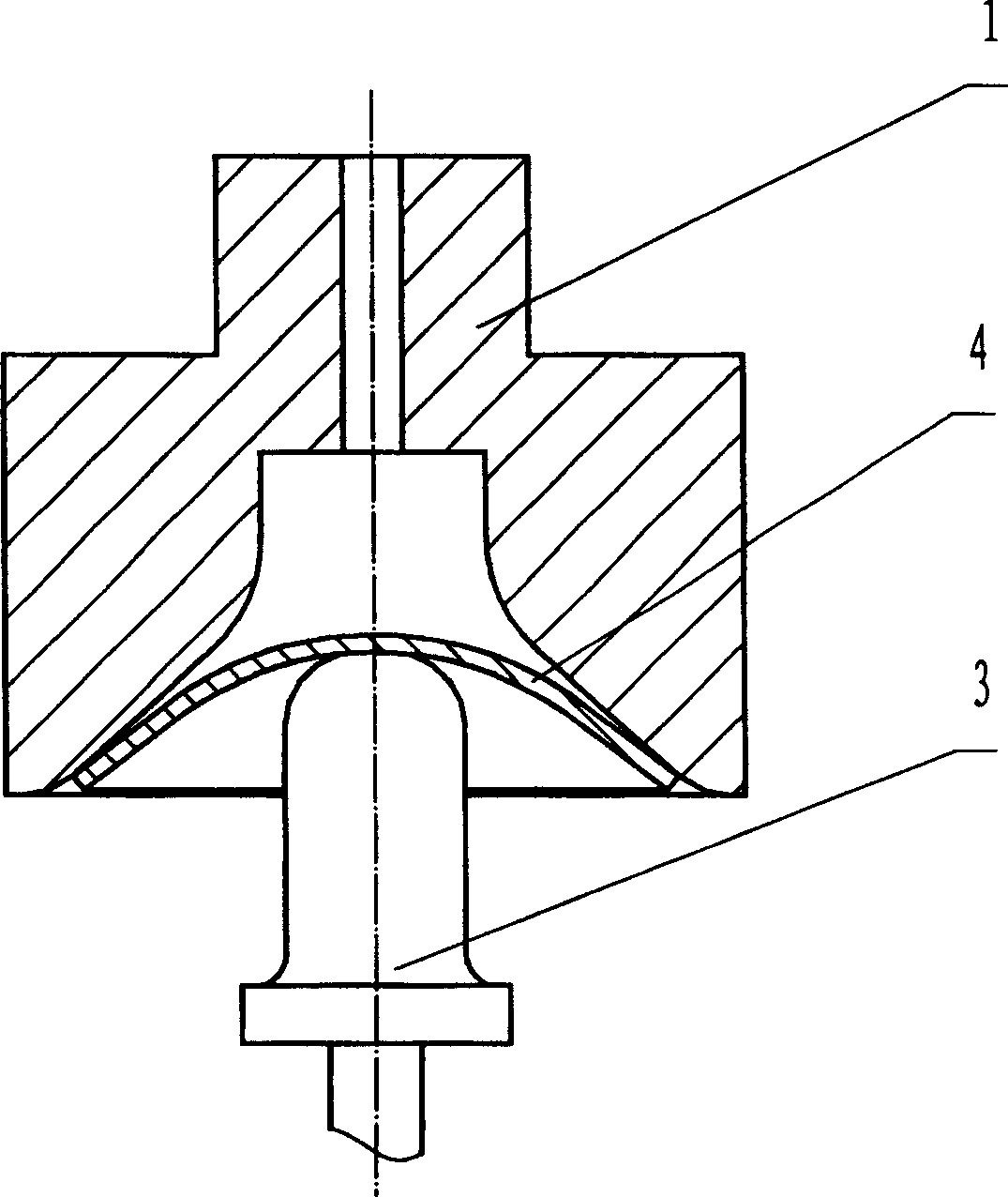

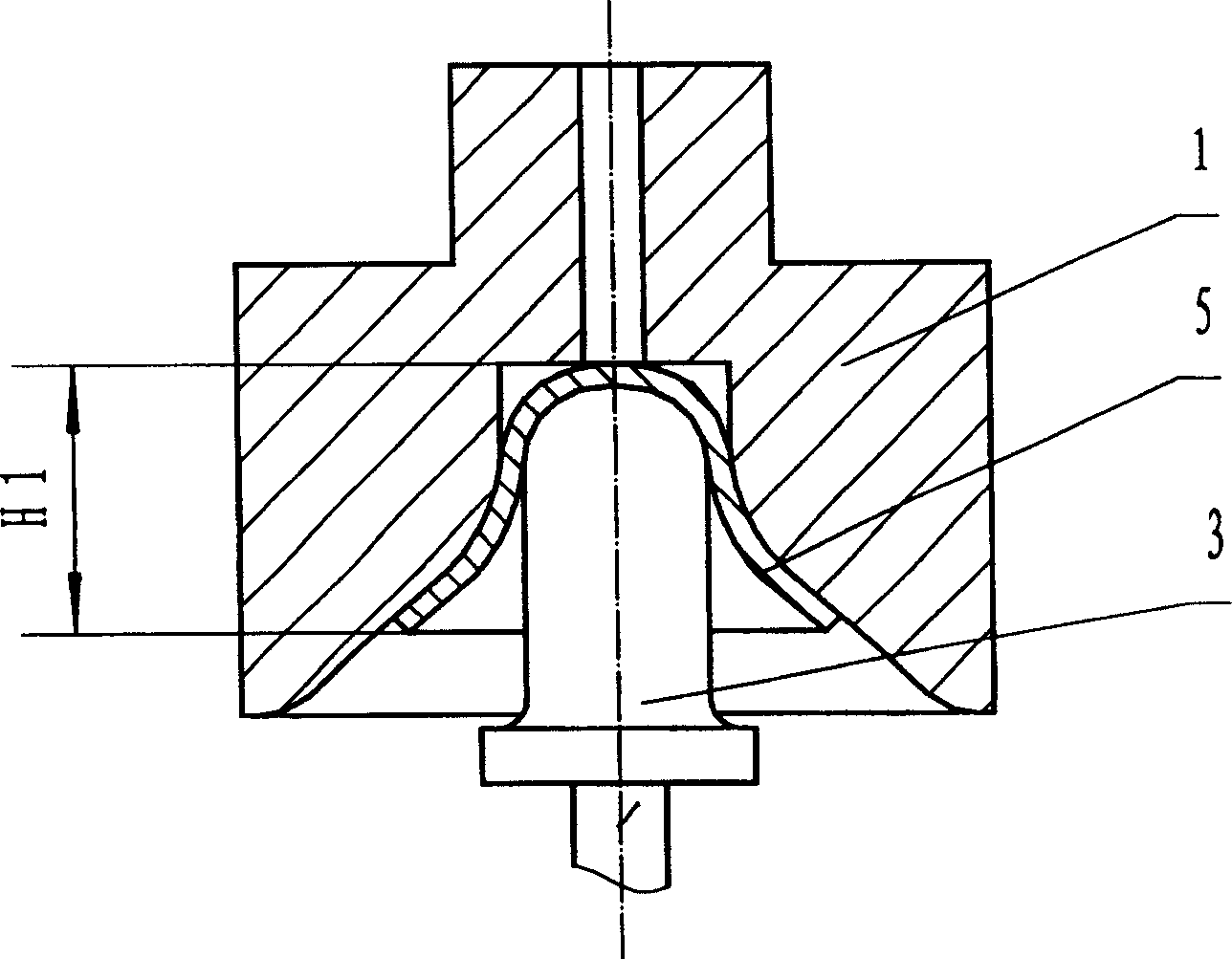

Impact forming method for hydraulic valve end shield

One kind of hydraulic pressure valve end shielding ramming take shape method, is realized according to the following steps,the initially take shape; Separately install the raised membrane and the concave membrane on the punch press work table and on the drift, starts the punch press, ram the sheet to become the sphere semifinished material; Reduces takes shape;installs the spread membrane which is the size shape with inner hole of the work, separately in the punch press work table and the drift, starts the punch press, presses evenly sphere crown of the sphere round hat semifinished materials, and reduces the lower part of the sphere, ramming full circle tubular, also hat brim presses evenly the sphere round hat semifinished materials circular, forms outside the belt along circle tubular semifinished materials; Stereotypia;install the work piece the hole size, the shape same raised membrane and with the work piece outer diameter size, the shape same concave membrane separately in the punch press work table and the drift, will start the punch press side,ramming the circle tubular semifinished material to the shape, the size tallies the request work piece semifinished materials, cutsthe work piece semifinished materials, namely will get the work piece which is conformed to the request.

Owner:李会银

Device and process for backstep welding of damping spring disk

ActiveCN102785052AEasy maintenanceMechanical stabilityWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationComputer engineering

The invention relates to the technical field of welding, particularly to a device and a process for backstep welding of a damping spring disk. The device comprises a rotary table, a locating plate, a vertical plate, a rotating cylinder, a liquid storage cylinder pressing plate, a spring disk locating pin long seat locating plate, a spring disk locating pin long seat, a spring disk locating pin, a spring disk pressing plate, a spring disk locating round pin, a spring disk locating long pin, a spring disk locating pin seat, a liquid storage cylinder locating plate, and a reinforcement plate. Compared with the prior art, the disk is three-point located by the aid of a tooling and fixedly clamped through the rotating cylinder, welding thermal deformation after welding is reduced, dimensions after the welding are stable and reliable, and adjustment is convenient. The structure of the device for the backstep welding of the spring disk is simple and stable, the maintenance cost is low, and the device is convenient to maintain.

Owner:上海汇众萨克斯减振器有限公司

Personalized Clothing Method Based on 3D Body Scanner

ActiveCN106235486BHigh degree of reductionAided designSpecial data processing applicationsClothes making applicancesEngineeringManufacturing data

The invention discloses a personalized garment manufacturing method based on a three-dimensional human body scanner. The personalized clothing manufacturing method comprises the following steps that S1, an electronic human body model is generated, the three-dimensional human body scanner is adopted to acquire user body data, and a complete electronic human body model consistent with a customer in figure characteristic is generated; S2, a garment type is determined; S3, garment manufacturing data is generated, the electronic human body model is measured through an electronic measurement system, and the garment manufacturing data is generated according to the garment type; S4, a two-dimensional garment manufacturing drawing is generated; S5, a three-dimensional effect drawing is generated; S6, a customization effect is showed, namely an electronic garment wearing effect drawing of a garment worn on the electronic human body model is generated according to the three-dimensional garment manufacturing effect drawing, and after the user selects the electronic garment wearing effect drawing, the two-dimensional garment manufacturing drawing corresponding to the electronic garment wearing effect drawing is determined; S7, garment manufacturing is performed, namely the garment manufacturing is performed according to the two-dimensional garment manufacturing drawing determined in the step S6.

Owner:XIAN SUANIER ELECTRONICS TECH

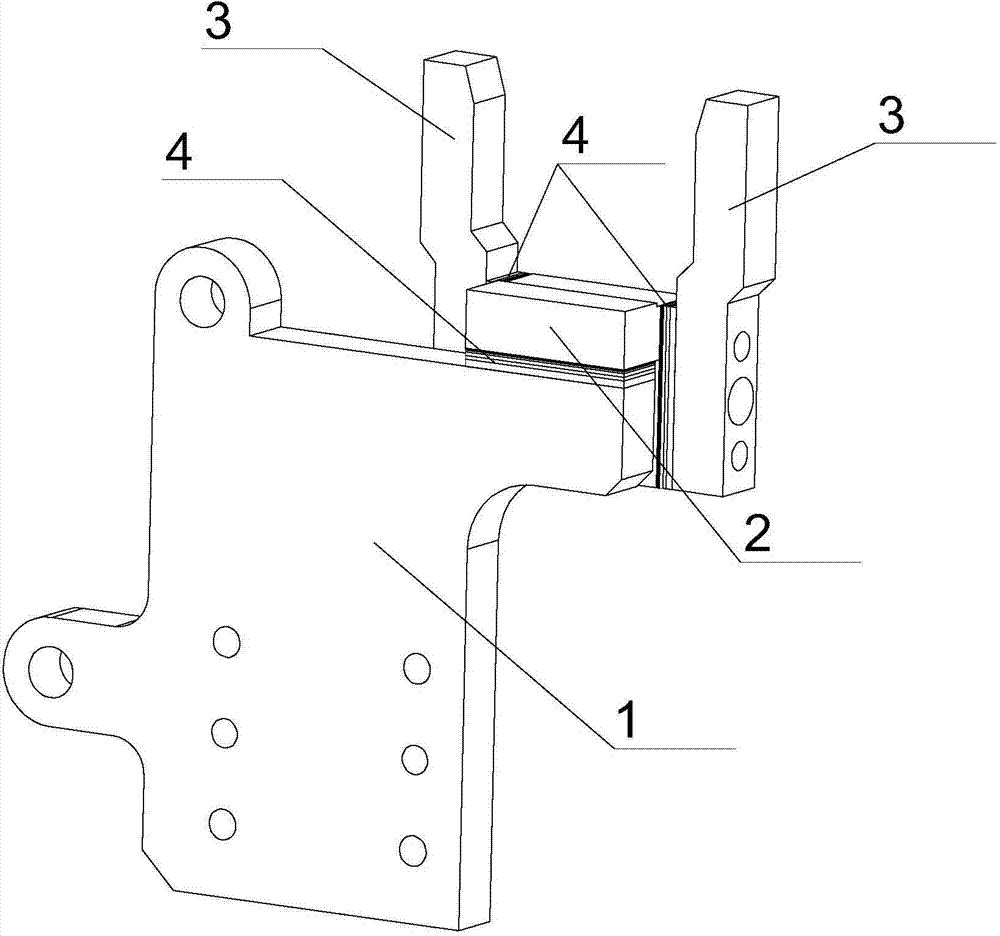

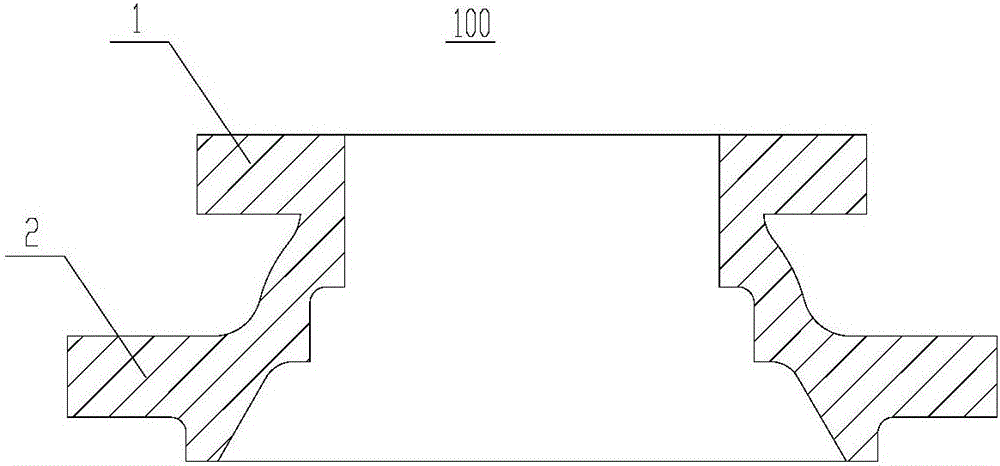

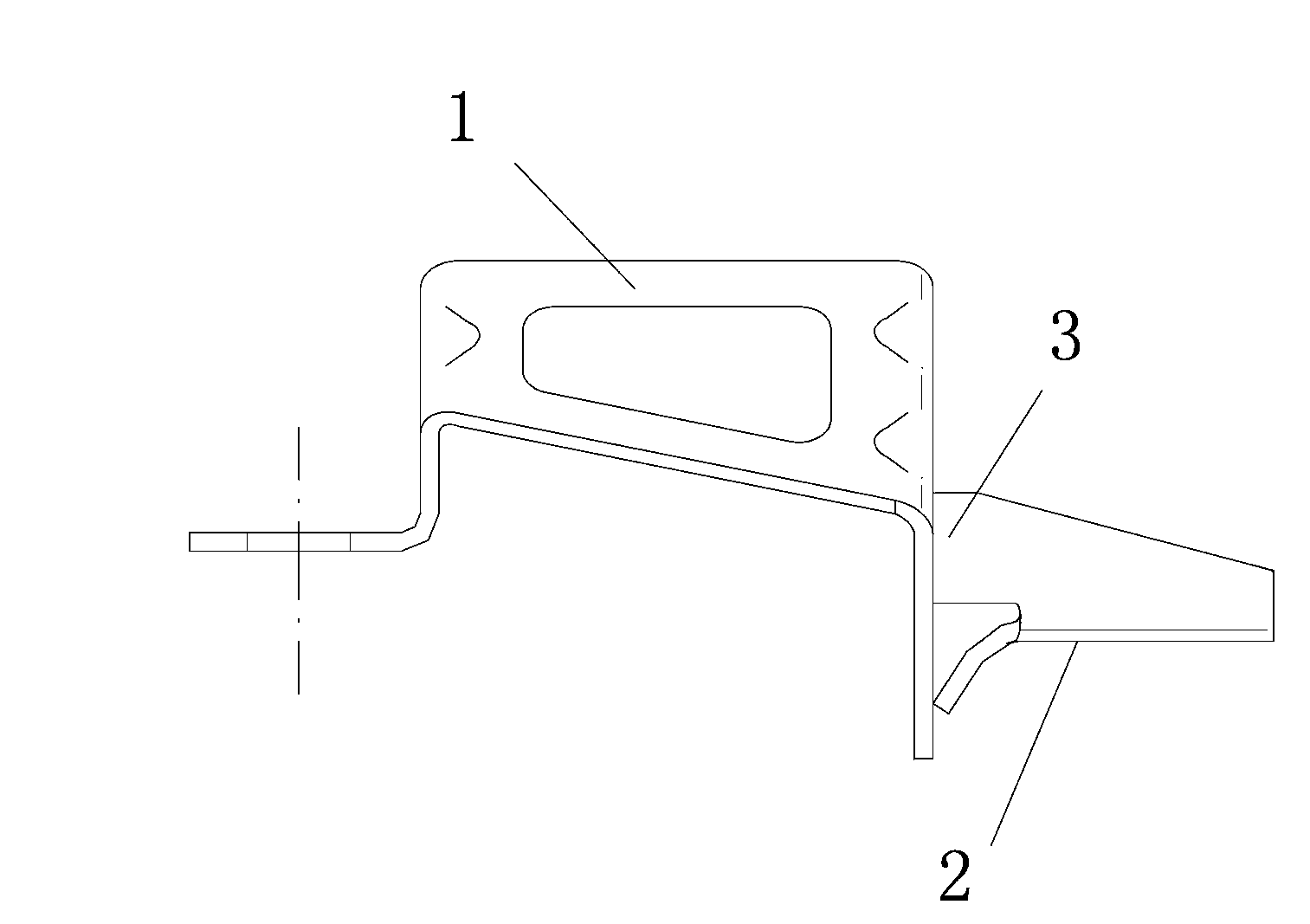

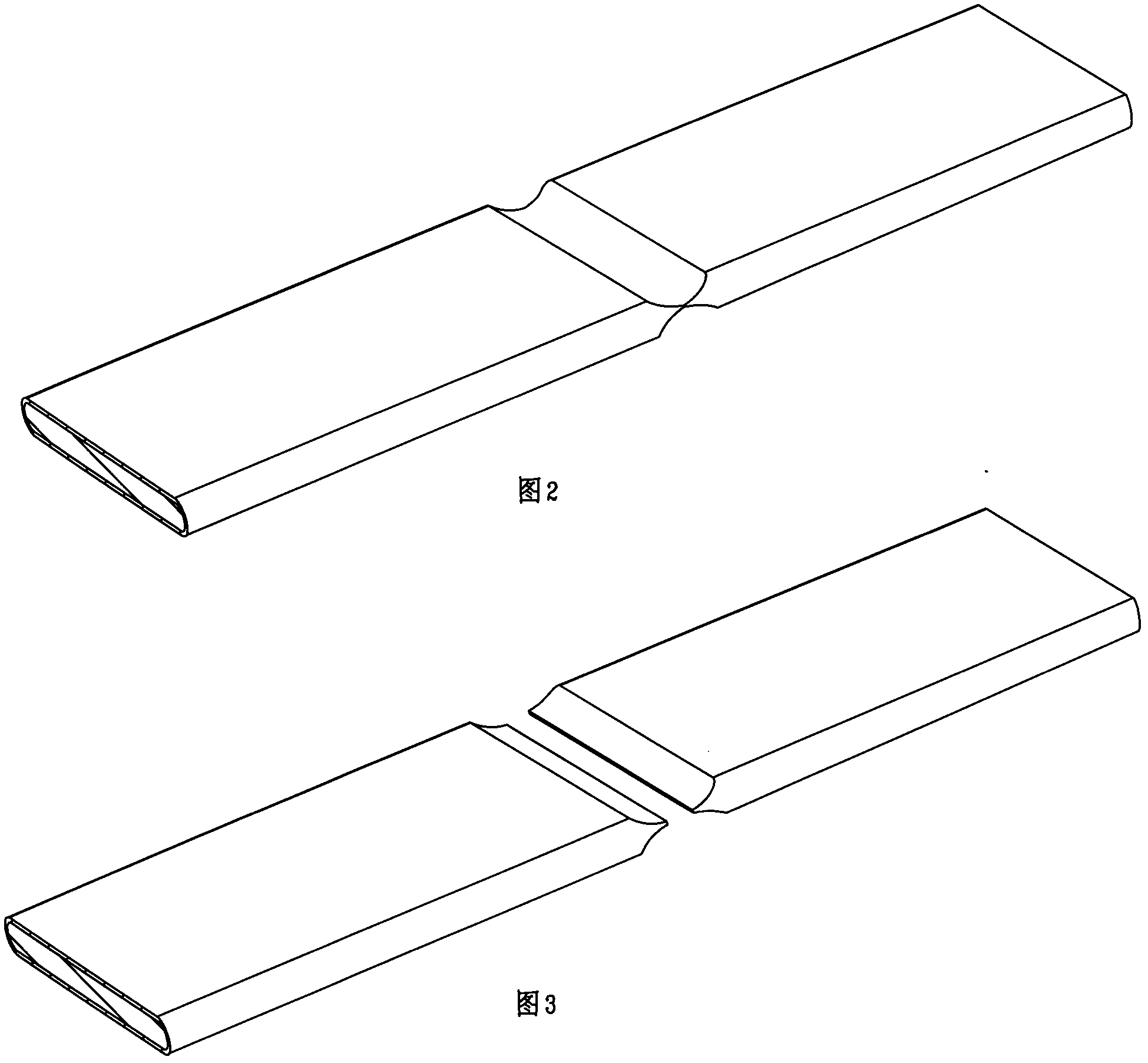

Automobile lower lining limiting support

InactiveCN103832235AIncrease weld lengthWelding heat spreads evenlyResilient suspensionsEngineeringWelding deformation

Disclosed is an automobile lower lining limiting support. The automobile lower lining limiting support is characterized by comprising a lower lining limiting support body (1) and a lower lining limiting support division part (2), the lower lining limiting support division part (2) is located at the right end of the lower lining limiting support body (1) and welded with the lower lining limiting support body (1), three welding flanges (3) are arranged on the lower lining limiting support division part (2), two welding flanges are arranged at the upper end of the lower lining limiting support division part (2) side by side, the other one welding flange is arranged at the lower end of the lower lining limiting support division part (2), and the length of the two welding flanges (3) arranged at the upper end of the lower lining limiting support division part (2) side by side is 27 mm. According to the automobile lower lining limiting support, due to the fact that the flanges on the two sides of the automobile lower lining limiting support division part (2) are lengthened by 10 mm, the welding length of a welding robot is increased, welding heat can be effectively diffused evenly, the welded deformation quantity is greatly reduced, the size is more easily ensured, and working efficiency is improved.

Owner:WUHAN HUIHENG IND

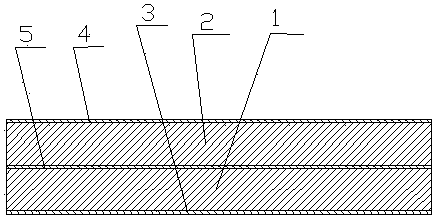

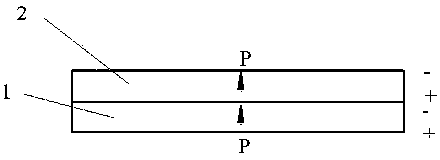

Piezoelectric bimorph and preparation method thereof

ActiveCN103647020ASolve insulation problemsReduced Diffusion DepthPiezoelectric/electrostrictive/magnetostrictive devicesWaferingPiezoelectric bimorph

The invention relates to a piezoelectric bimorph and a preparation method thereof. The piezoelectric bimorph comprises a lower piezoelectric body, an upper piezoelectric body, a lower conductive electrode layer, an upper conductor electrode layer and a common electrode layer, wherein the lower piezoelectric body and the upper piezoelectric body are made by a PZT piezoelectric material. The piezoelectric bimorph is characterized in that the lower piezoelectric body and the upper piezoelectric body are connected through the high-temperature pressure sintered common electrode layer. The related preparation method of the piezoelectric bimorph comprises the steps of printing electrodes at the surfaces of the upper piezoelectric body and the lower piezoelectric body, drying, and realizing the high-temperature pressure sintered common electrode layer under a certain pressure. The common electrode layer has bonding and conducting functions, and can also be processed into a bimorph with a special structure subsequently. The piezoelectric bimorph solves a bonding layer insulation problem of the piezoelectric bimorph, and has the characteristics of stable and reliable working process and long service life.

Owner:CHONGQING ZHONGLEI SCI & TECH

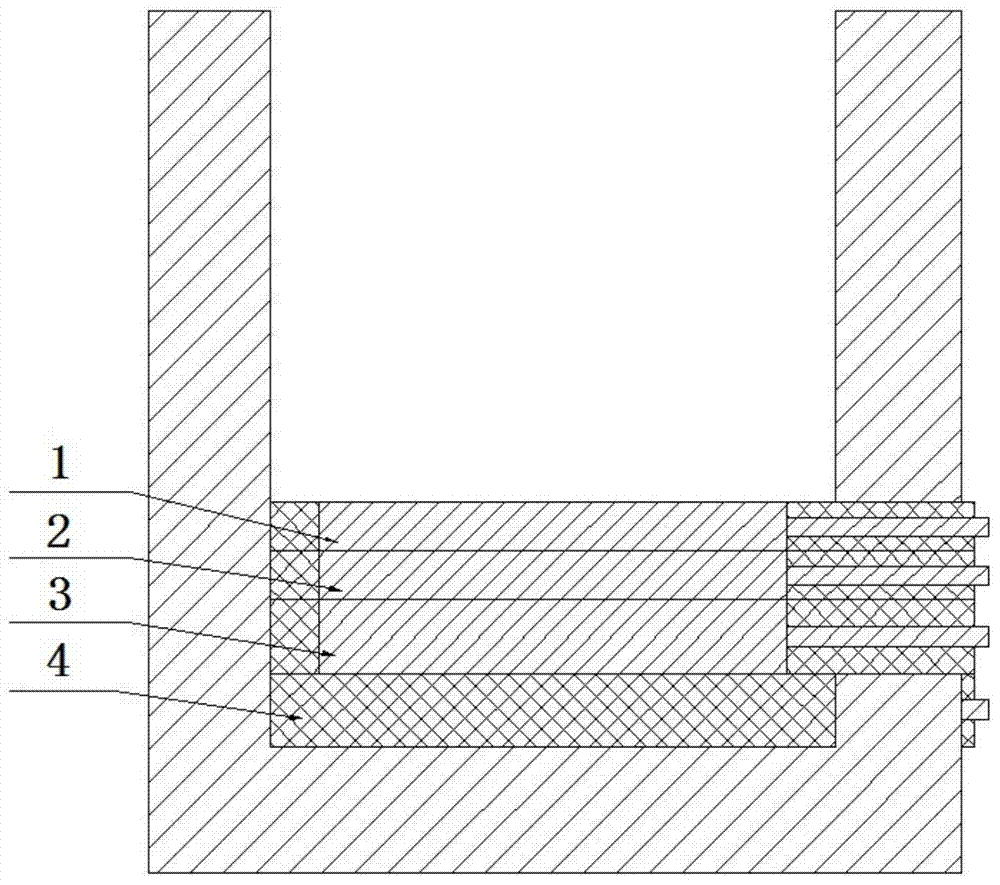

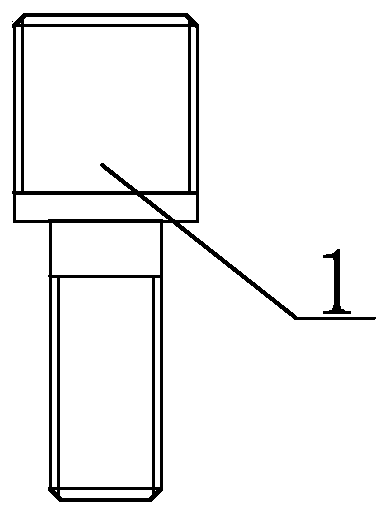

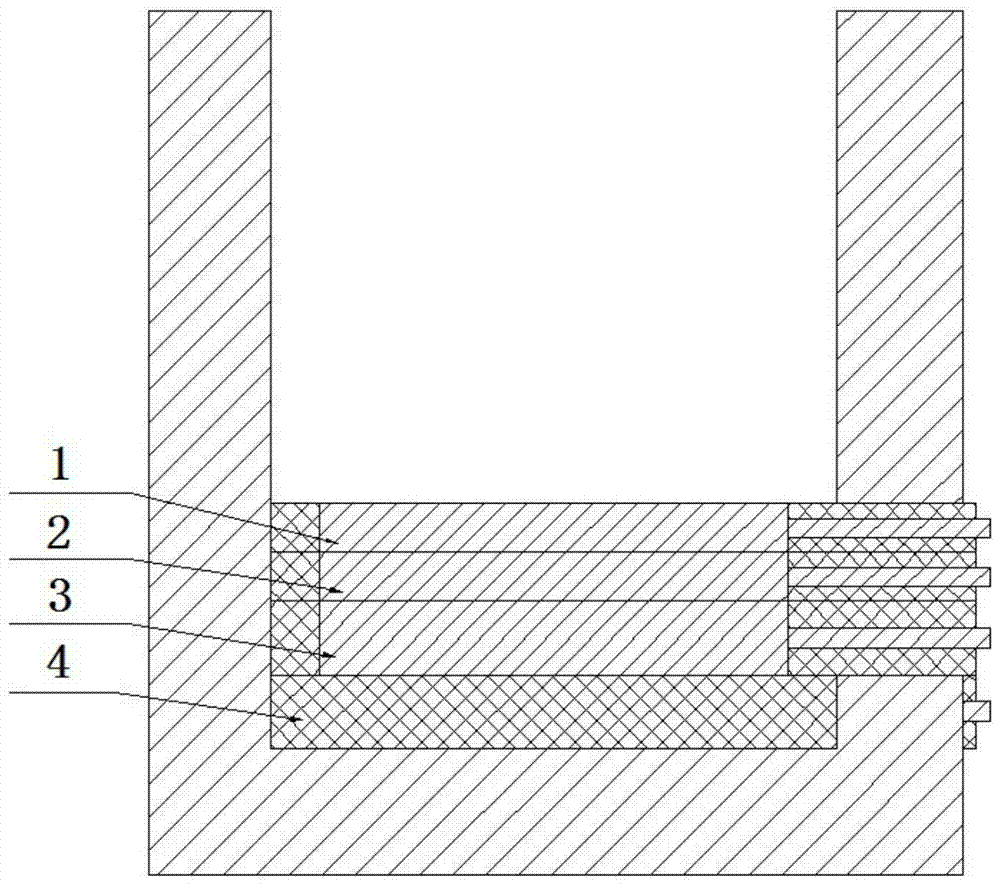

A sheet material winding high temperature tensile test fixture for architectural membrane materials

InactiveCN107860650BPrevent influence of tensile test resultsStretch continuous smoothMaterial strength using tensile/compressive forcesEngineeringStructural material

The invention provides a coiling type high-temperature stretching test clamp for a sheet-shaped material, relates to a stretching test clamp, and aims at solving the problem of the conventional building structure material high-temperature mechanical performance test that the true length variation in the stretching process cannot be detected and a normal-temperature stretching test clamp cannot beused normally. The coiling type high-temperature stretching test clamp for the sheet-shaped material comprises an upper clamp body, a lower clamp body and a test part, wherein the upper end of the upper clamp body and the lower end of the lower clamp body are connected to a stretching tester; the lower end of the upper clamp body is connected to the upper end of the lower clamp body through the test part. The coiling type high-temperature stretching test clamp for the sheet-shaped material is reasonable in size, simple, easy, reliable for high-temperature stretching test of the sheet-shaped material such as a building film, and capable of effectively performing high-temperature stretching test; the problem of effective clamping of the sheet-shaped material at the clamping end and the clampsize fitting can be solved; the clamp is applicable to the sheet-shaped material stretching test.

Owner:HARBIN INST OF TECH

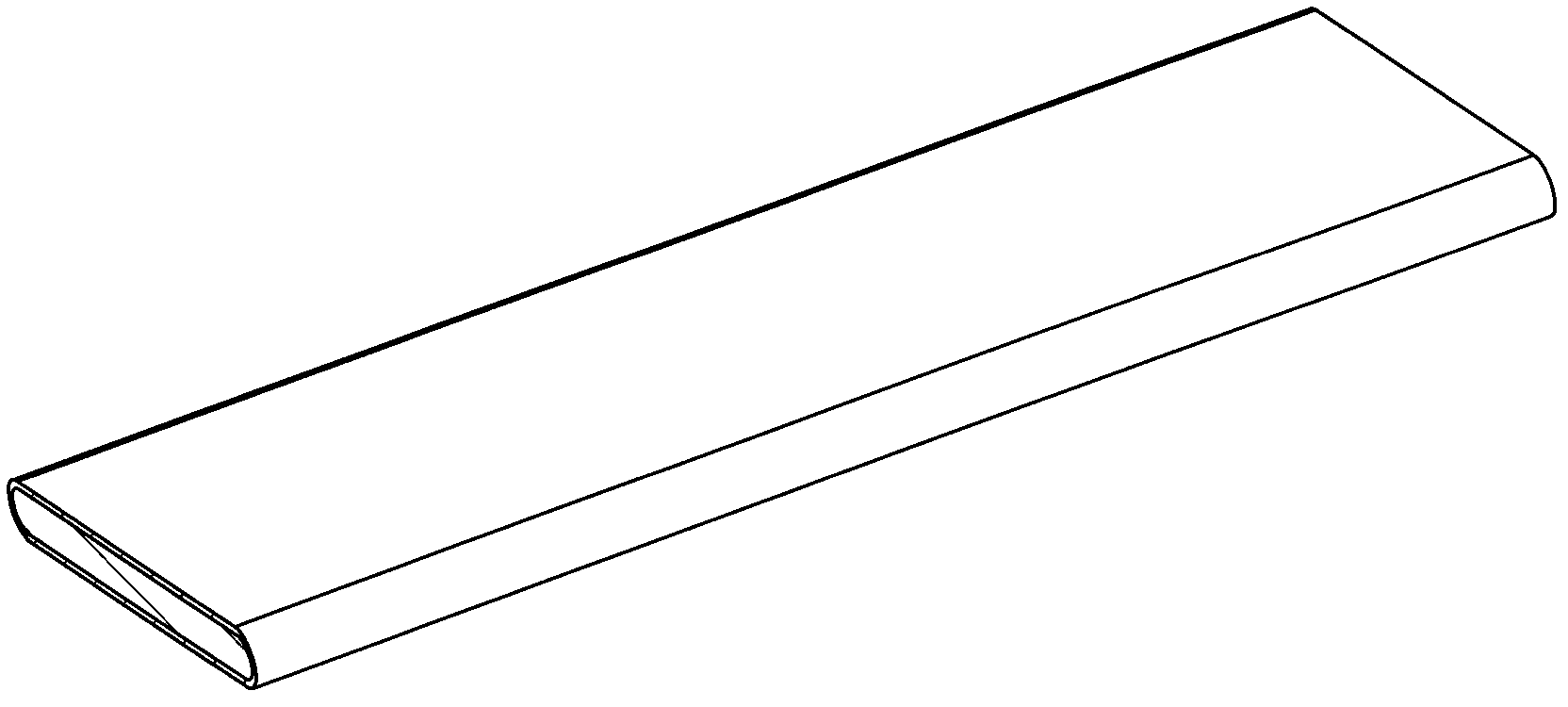

Cutting method for copper clad aluminum busbar

The invention relates to a cutting method for a copper clad aluminum busbar, which gives comprehensive consideration to different strength characteristics of the two metals of copper and aluminum, a press-type angle of an aluminum clad aluminum busbar, press-type pressure, press-type speed, the thickness of copper outer cladding layer, the thickness of inner aluminum core and the like, achieves the fact that the copper outer cladding layer wraps the inner aluminum core full and tight at the end face press-type cutting position through a special copper clad aluminum busbar cutting device after the copper clad aluminum busbar is cut off, and meets the requirements that the copper outer cladding layer has no breakage, the end face has no exposed aluminum core and the like. Therefore, the cutting method for the copper clad aluminum busbar ensures that when surface treatment of the copper clad aluminum busbar is conducted, the problems that an aluminum layer cannot be treated with a tinning process and the aluminum layer is prone to corrosion are resolved, corrosion resistance of the copper clad aluminum busbar is improved, and electric conduction of the electric conduction is ensured to be safe and reliable. In addition, by means of the special copper clad aluminum busbar cutting device, the copper clad aluminum busbar end face is led to form a press-type sharp angle and have guiding performance so that butt-joint installation of busbar products is facilitated.

Owner:江苏睿正华鹏成套电气股份有限公司

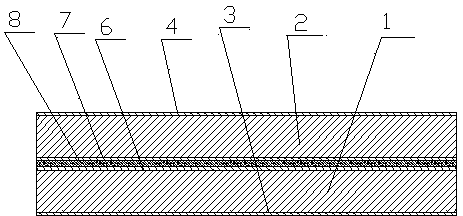

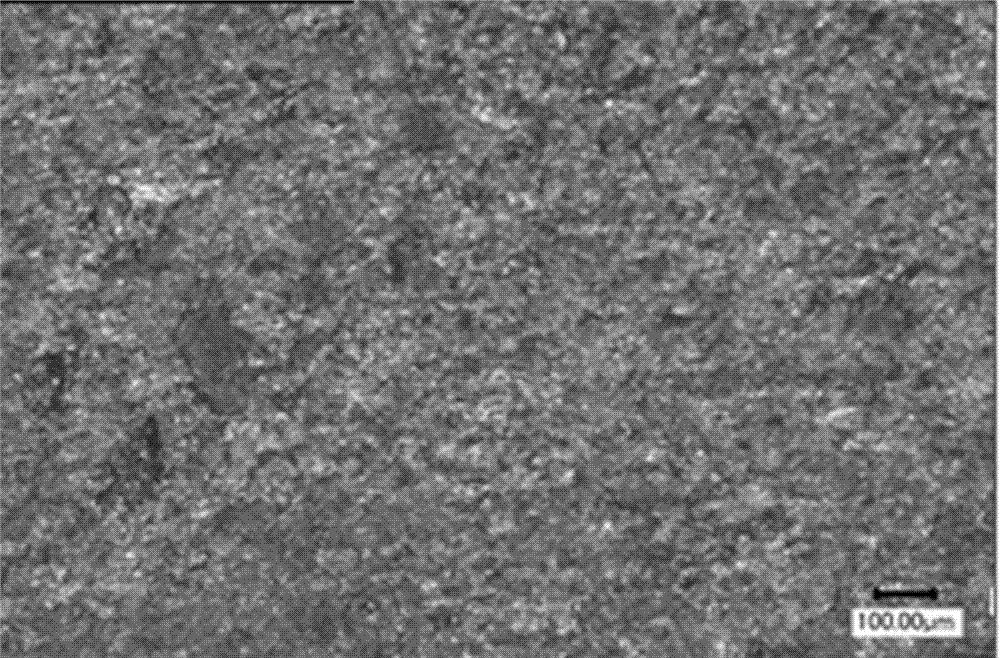

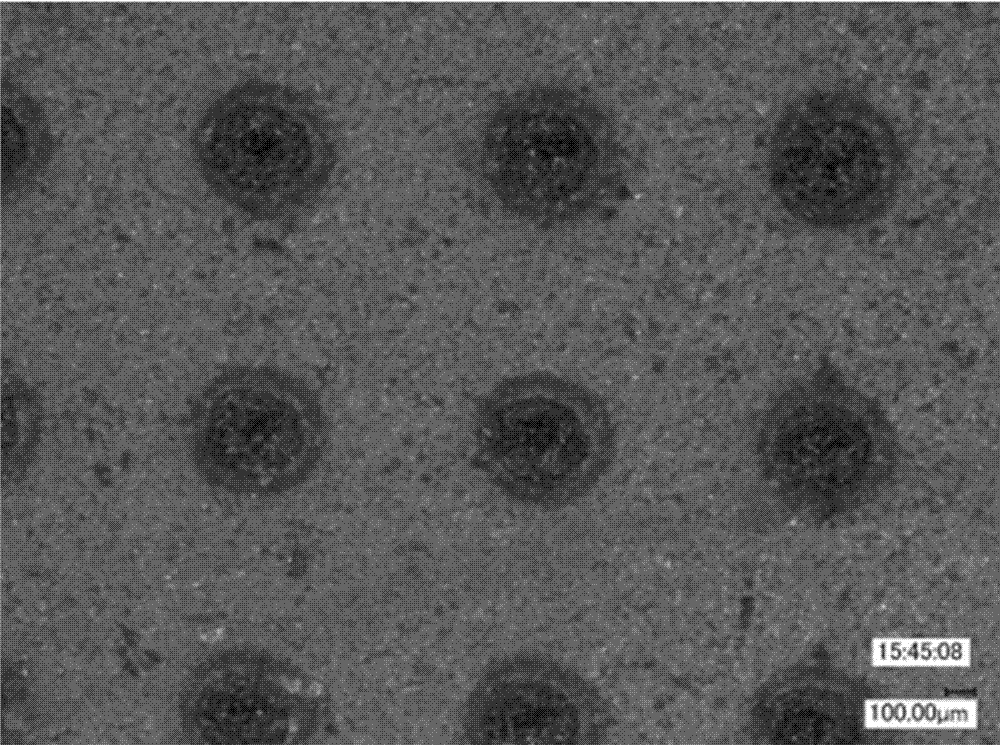

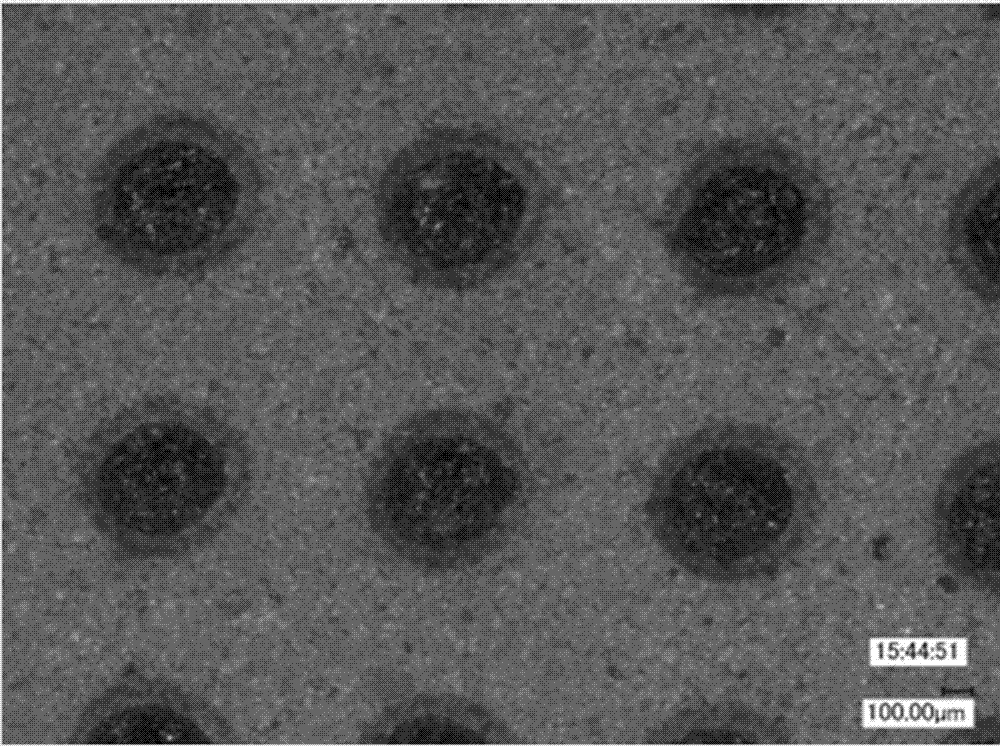

Surface texture of an ultrasonic motor rotor and its preparation method

ActiveCN105897046BEvenly distributedDimensionally stable and reliablePiezoelectric/electrostriction/magnetostriction machinesLaser etchingMicro structure

The invention provides an ultrasonic wave motor rotor surface texture and a production method thereof. The surface texture is provided with recesses, and the diameter of each recess is in a range from 200 (mu)m to 400 (mu)m, the depth of each recess is in a range from 89.77 (mu)m to 108.5 (mu)m, and the area density of each recess is in a range from 3.14% to 12.55%. The production method is characterized in that a polyimide composite material is cut into slices and polished to be a material having the roughness less than 0.1(mu)m; the forming of the surface recesses of the polished surface of the material produced by the step A is carried out by adopting a laser etching technology, and at last, the back surface of the polyimide composite material is attached to the ultrasonic motor aluminum alloy rotor surface in an adhesive manner. The surface micro-structure produced by adopting the above mentioned technical scheme is advantageous in that the production is simple and effective, the cost is low, the size is reliable, the distribution is uniform, and operation stability of an ultrasonic motor contact interface is effectively improved, and service lifetime of a rotor friction material is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

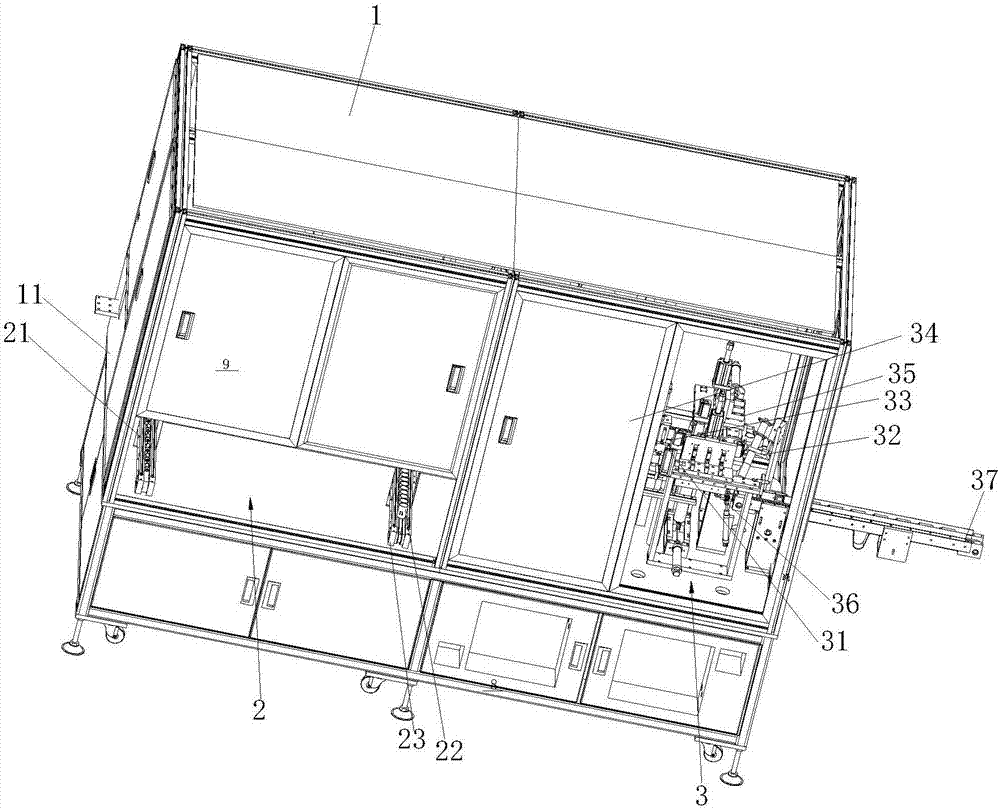

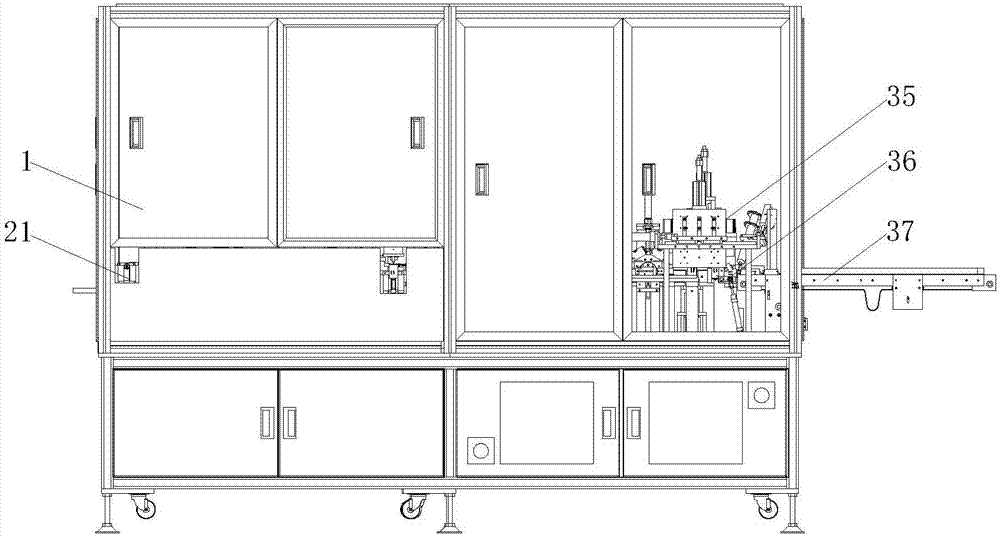

Motor assembly machine for printer

ActiveCN107134897AReduce labor intensityDimensionally stable and reliableManufacturing dynamo-electric machinesGeneral assemblyEngineering

The invention discloses assembly machine equipment for a printer motor, and the equipment comprises an assembly rack general assembly. An aluminium section conveying rotor assembly and an aluminium section conveying housing assembly pass through a rotor to enter a housing positioning assembly and extend to the interior of the assembly rack general assembly. An aluminium section conveying motor assembly passes through the assembly rack general assembly to be connected to a rotor rotating assembly. The other end of a housing rotating mechanical arm is connected with a motor conveying assembly, and the motor conveying assembly is connected with a motor rear electric oil assembly. According to the invention, the assembly rack general assembly employs an aluminium section protection cover, and the whole unit is safe, practical and beautiful. In use, all the manual placing operation of the aluminium section conveying rotor assembly and the aluminium section conveying housing assembly are automatically achieved through a conveying belt, thereby saving the manpower, reducing the labor intensity of a worker, and improving the production efficiency.

Owner:东莞市途乐电机科技有限公司

Tensioning steel wire seal and processing method thereof

The present invention provides a steel wire seal, comprising a lock head and a steel wire with one end connected on the lock head. The lock head is provided with a lock cylinder hole for inserting the steel wire and a marble hole for containing the marble and a spring; the hole diameter of the marble hole is matched with the diameter of the marble; the front part of the marble hole is obliquely penetrated through the middle part of the lock cylinder hole; the size of an area of which the marble hole and the lock cylinder hole penetrate is less than the diameter of the marble. The seal is characterized in that the lock cylinder hole and the marble hole are composed by enclosing a hole wall on the lock head and the surface of an internal core; the internal core is located at the tail end between two holes and is fixedly connected with the lock head; the part where the internal core located at the tail end of the marble hole and the spring form a stop structure; the processing method comprises the steps as follows: compression molding the lock head, the parison comprising a big hole cavity, then filling with the marble and the spring and inserting in the big hole cavity by the specific internal core, and then fixedly connecting the lock head and the steel wire, thereby avoiding the secondary drilling process of the marble hole; the seal has the advantages of accurate size of each hole, good performance and convenient process.

Owner:黄山亿利工贸集团有限公司

A method for measuring electron beam spot size of scanning electron microscope

InactiveCN104266572BIncrease contrastHigh precisionUsing electrical meansScanning tunneling microscopeScanning electron microscope

The invention relates to a method for measuring the size of an electron beam spot of a scanning electron microscope, which relates to the field of electronic technology, and in particular to a measuring method for measuring the size of an electron beam spot of a scanning electron microscope. First, the metal blade placed on the mouth of the Faraday cup is irradiated by a scanning electron microscope to obtain a clear image of the metal blade; then part of the image of the edge of the knife is intercepted, and the RGB value of the intercepted image is obtained by image data processing software to obtain R, G, B three Then calculate the average value of these three matrices to obtain an average matrix; sum each column of the average matrix to obtain a one-dimensional matrix, and draw a two-dimensional curve according to the values of each unit of the one-dimensional matrix , the width of the rising edge of the curve is the beam spot diameter of the electron beam, so as to achieve the purpose of the invention. Therefore, it has the effects of simple operation, high precision and strong practicability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Special fixtures for transmission control device shell lathe and machining method

InactiveCN109623457AReduce manufacturing costReduce manufacturing difficultyPositioning apparatusMetal-working holdersEngineeringDigital control

The invention relates to the field of machining, in particular to special fixtures for a transmission control device shell lathe and a machining method. The two fixtures, namely a clamping structure Aand a clamping structure B, are installed on spindles of two SK50P digital controlled lathes separately, both ends of a part are machined separately through two-times clamping, and the requirements of the size of both ends of the part and the coaxiality being 0.05 of both ends are ensured. A flange plate is fixedly connected with machining equipment through fastening screws, so that the part is located at a correct and efficient position, after the part of a control device shell is positioned, a fast clamping mechanism is used for fast clamping of the part; the part is fixed efficiently; after machining is finished, a pressing plate clamping state is opened, and the part of the control device shell can be taken down; and then machining of the other end is completed on another equipment following the same steps.

Owner:XIANYANG SHENGYA ELECTROMECHANICAL EQUIP CO LTD

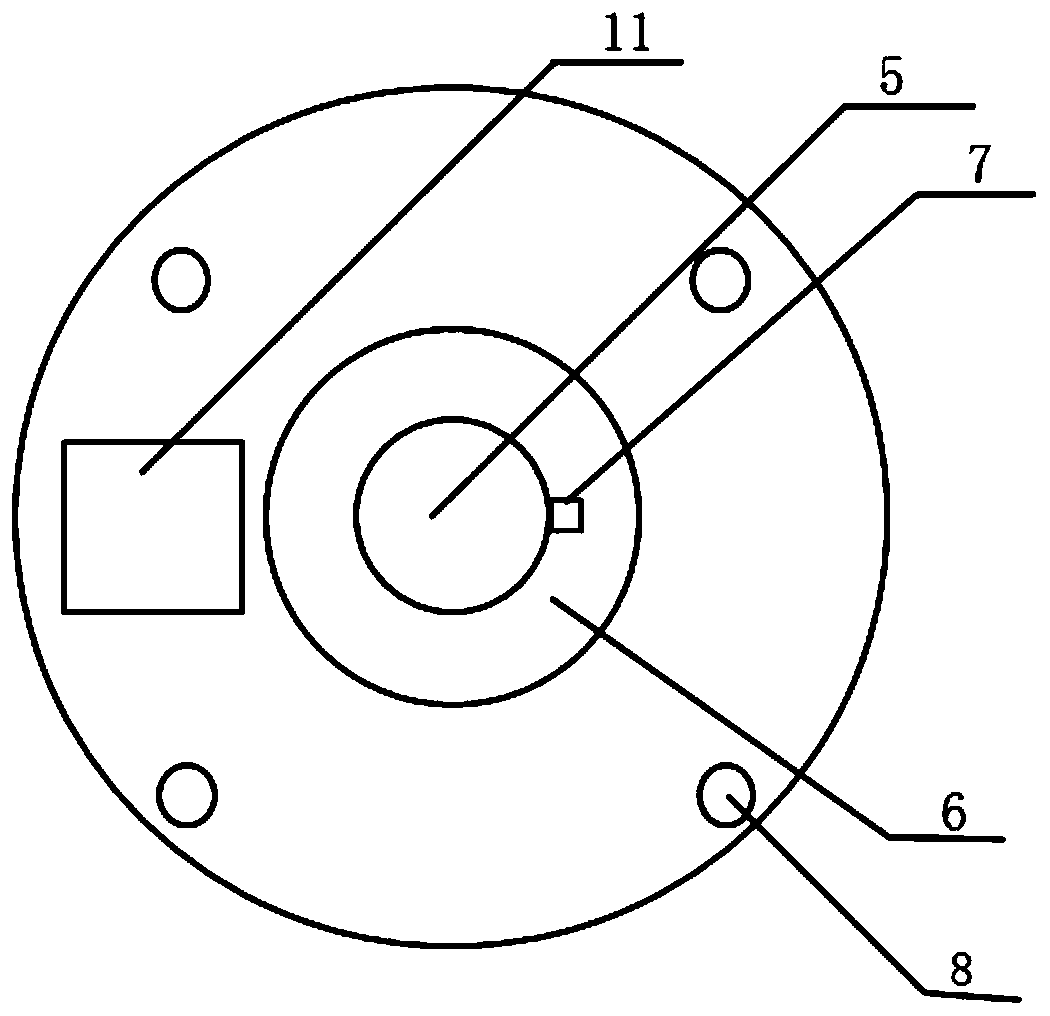

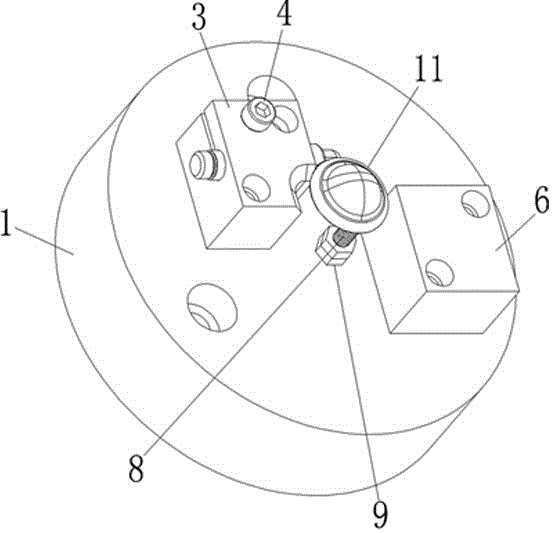

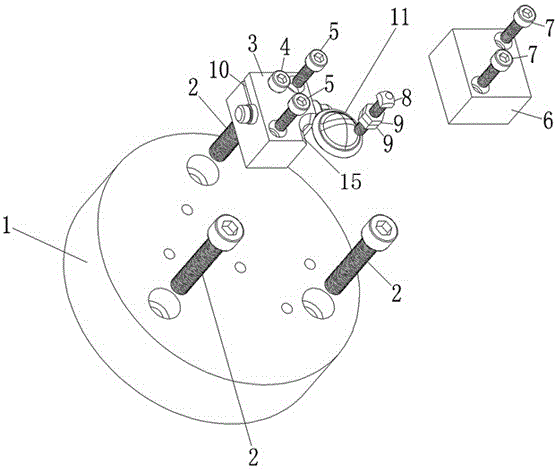

Special fixture for machining the round cap of special-shaped integrated parts

ActiveCN104191297BDimensionally stable and reliableSimple structurePositioning apparatusMetal-working holdersHigh volume manufacturingEngineering

The invention discloses a special machining fixture for round caps of special-shaped integrated components. The special machining fixture comprises a flat cylindrical fixture body, a positioning block, a balance bolt and a balance block. The positioning block, the balance bolt and the balance block are arranged on the upper surface of the fixture body, the positioning block and the balance block are respectively arranged on the left side and the right side of the balance bolt, a workpiece round cap accommodating station is formed between the positioning block and the balance block, the balance bolt is arranged in the middle of the upper surface of the fixture body and corresponds to a boss of a workpiece round cap, the positioning block comprises a block-shaped body, a workpiece shaft positioning hole and a seam, the workpiece shaft positioning hole is perforated through the block-shaped body in the left-right direction, the seam is perforated through the rear side surface of the workpiece shaft positioning hole and the rear side surface of the block-shaped body, a clamping screw hole which is perpendicularly perforated through the seam is formed in the block-shaped body, and a clamping bolt is arranged in the clamping screw hole. The special machining fixture has the advantages that the special machining fixture is reasonable and simple in structure, low in cost, high in clamping force, easy to maintain in follow-up procedures and applicable to large-scale production, and brings convenience for clamping operation, to-be-machined workpieces can be quickly clamped by the special machining fixture, machined workpieces are dimensionally stable and reliable, and the production cost can be effectively reduced.

Owner:上海华验精密机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com