Automobile lower lining limiting support

A bushing and automotive technology, applied in the field of auto parts, can solve the problems of short stroke of robot welding torch, difficulty in ensuring product size, large welding deformation of parts, etc., and achieve uniform welding heat dissipation, simple and practical structure, and reduced deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

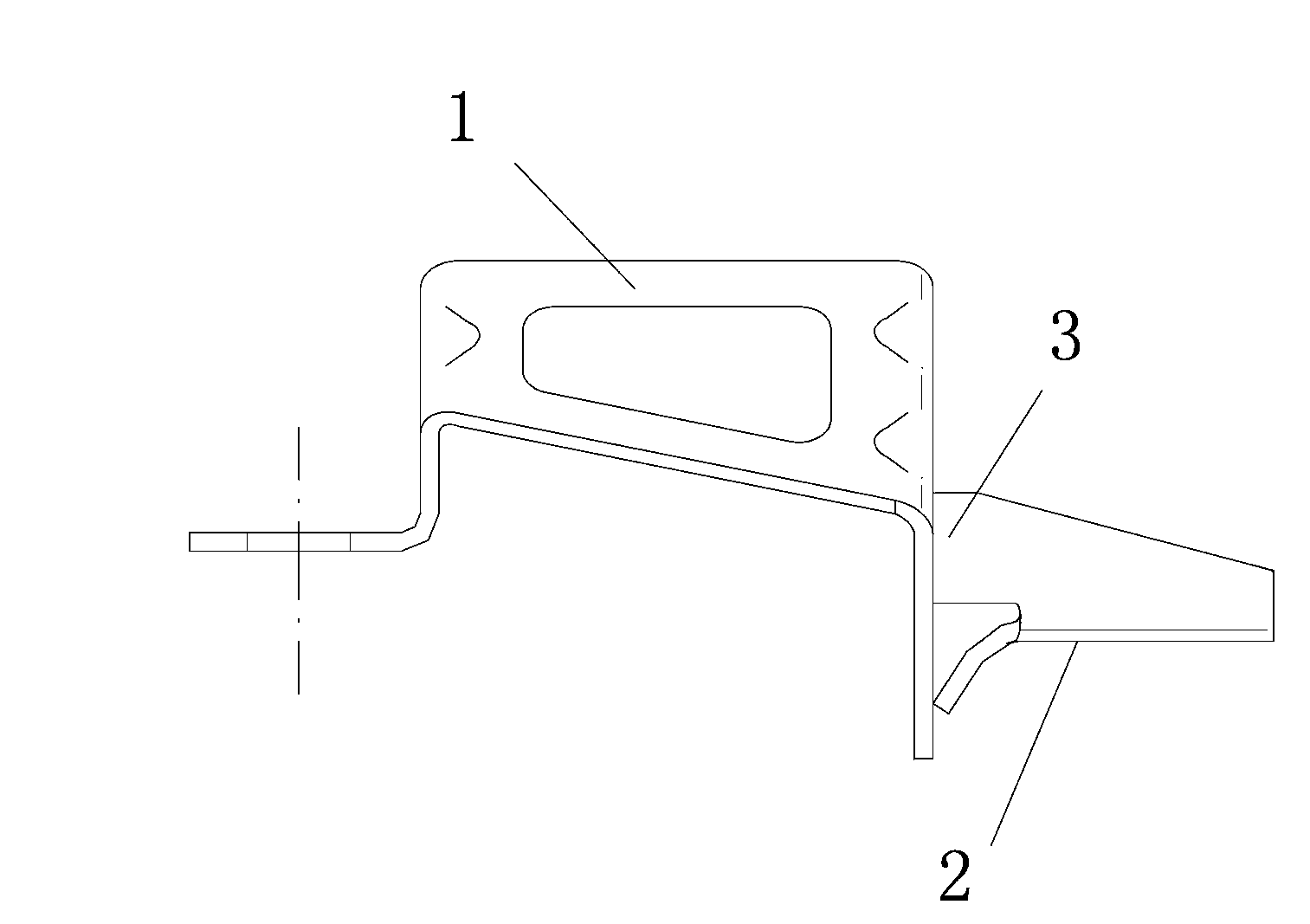

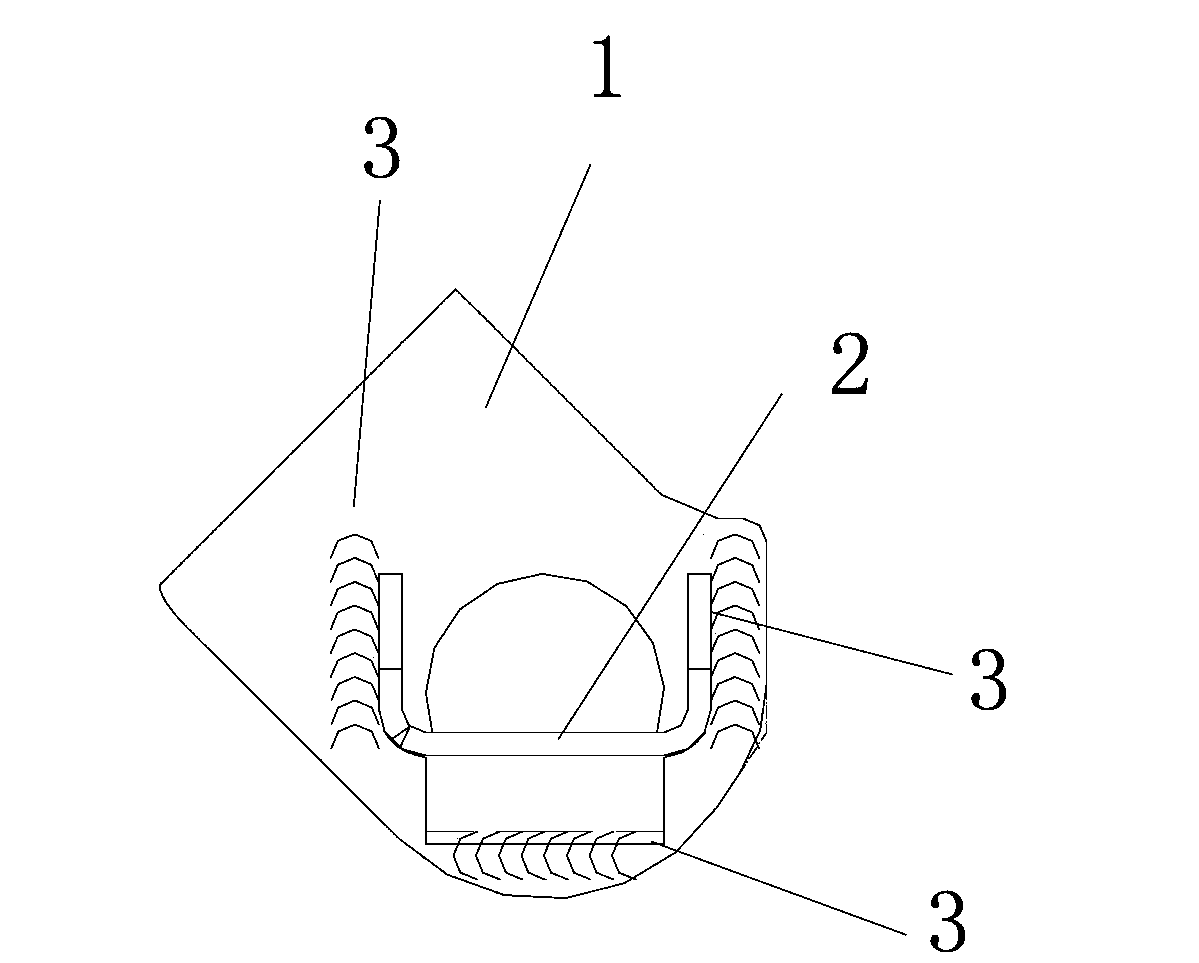

[0010] see figure 1 , figure 2 It can be seen that the automobile lower bush limit bracket of the present invention includes a lower bush limit bracket body 1 and a lower bush limit bracket sub-piece 2, and the lower bush limit bracket sub-piece 2 is located at the right end of the lower bush limit bracket body 1 And welded together with the lower bush limit bracket body 1, there are three welding flanges 3 on the lower bush limit bracket part 2, two of which are arranged side by side at the upper end, and one at the lower end, and two welding flanges are arranged side by side at the upper end. The length of the flange 3 is 27mm. Wherein the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com