Shipping container and method of construction thereof

a technology of shipping containers and containers, applied in the field of shipping containers, can solve the problems of many problems still affecting the performance of containers, no longer meeting the loading/stacking/handling requirements, and likely affecting the performance of some current containers, so as to increase the length of the weld interface and therefore the strength. the effect of increasing the strength of the header assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

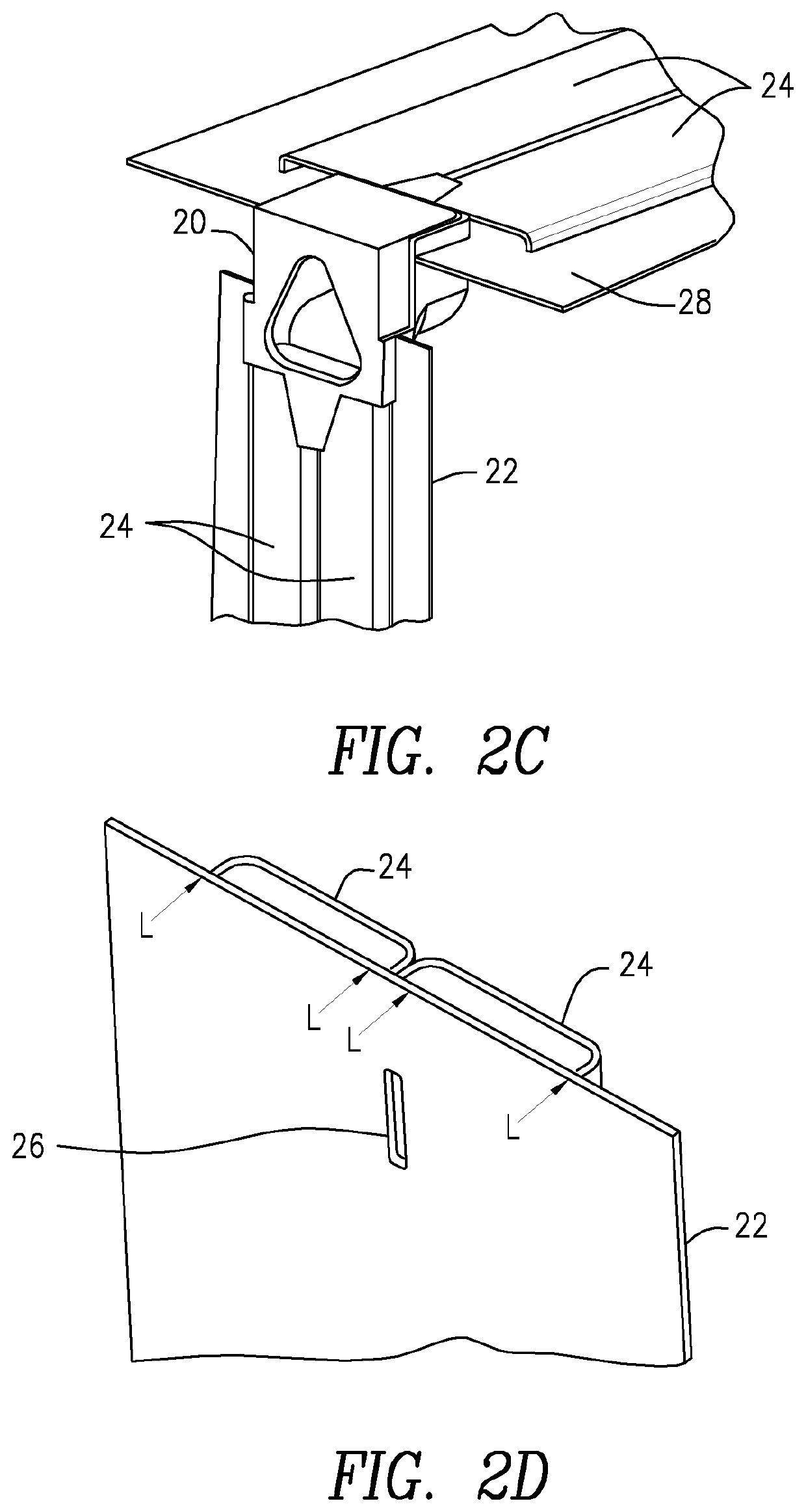

[0034]The following terminology can be defined interchangeably: 40′ gable (or just “gable”), intermediate stacking post, and stacking frame; Gable header, gable upper (or top) channel and plate assembly, intermediate header and intermediate frame upper (or top) member; Rear intermediate bolster, rear 40′ gable (or rear intermediate stacking post / frame), lower (or bottom) channel and plate assembly, and lower (or bottom) cross member; Upper casting and upper handling fitting; Lower rear casting, lower 53′ rear casting, and lower rear corner casting. The same terminology is also applicable to all size shipping containers including 60′, for example.

[0035]There are four bolsters in the floor of a container. The front bolster is the lower structural member of the front facing wall which engages with the front bolster of the associated chassis. The two, intermediate bolsters connect the lower, intermediate 40′ castings, respectively and form the lower portions of the structural “ring” of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com