Patents

Literature

57results about How to "Increase weld length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost niobium-titanium alloy electrode preparation method and niobium-titanium alloy electrode

The invention relates to a low-cost niobium-titanium alloy electrode preparation method and a niobium-titanium alloy electrode. The niobium-titanium alloy electrode preparation method comprises the steps of material distribution, electrode block pressing, electrode assemble welding and electrode smelting. According to the low-cost niobium-titanium alloy electrode preparation method, compared witha traditional niobium-titanium alloy electrode preparation method, the raw material cost is low, the manufacturing cost is low, and the yield is high; by using the method, the length of an electrode block joint welding seam can be increased, the strength of the electrode is improved, the problem of niobium inclusion caused by block falling of a core during smelting of the niobium-titanium electrode prepared by the common titanium and titanium alloy electrode preparation method can be solved, and a cast ingot obtained after smelting of the prepared electrode is free of niobium inclusion.

Owner:宁夏中色金航钛业有限公司

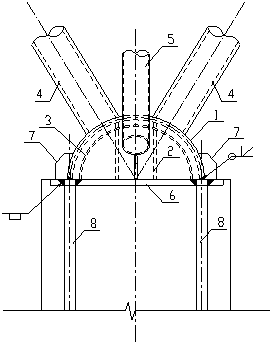

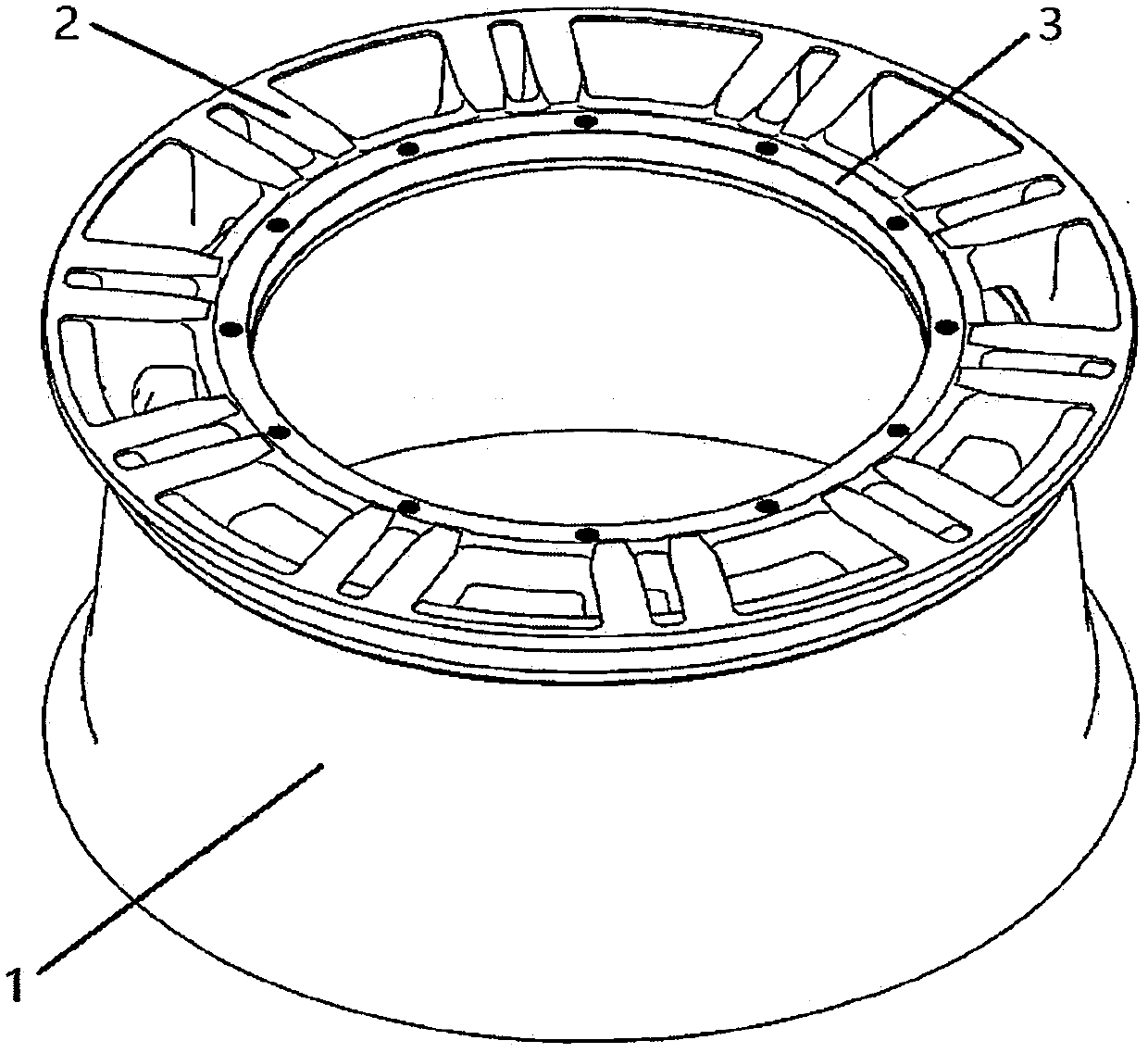

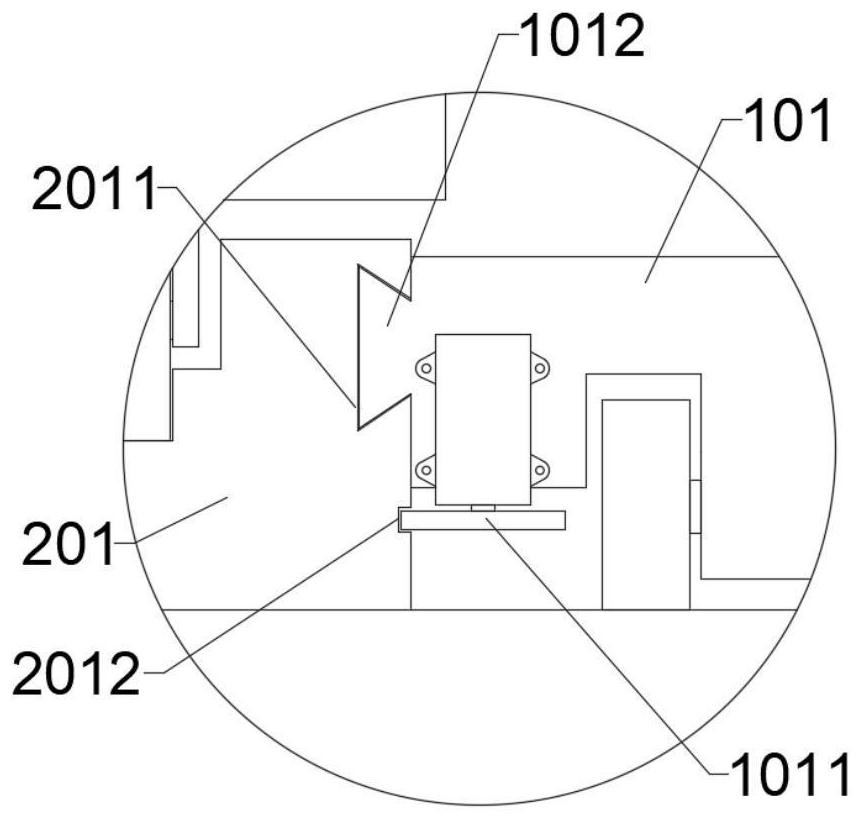

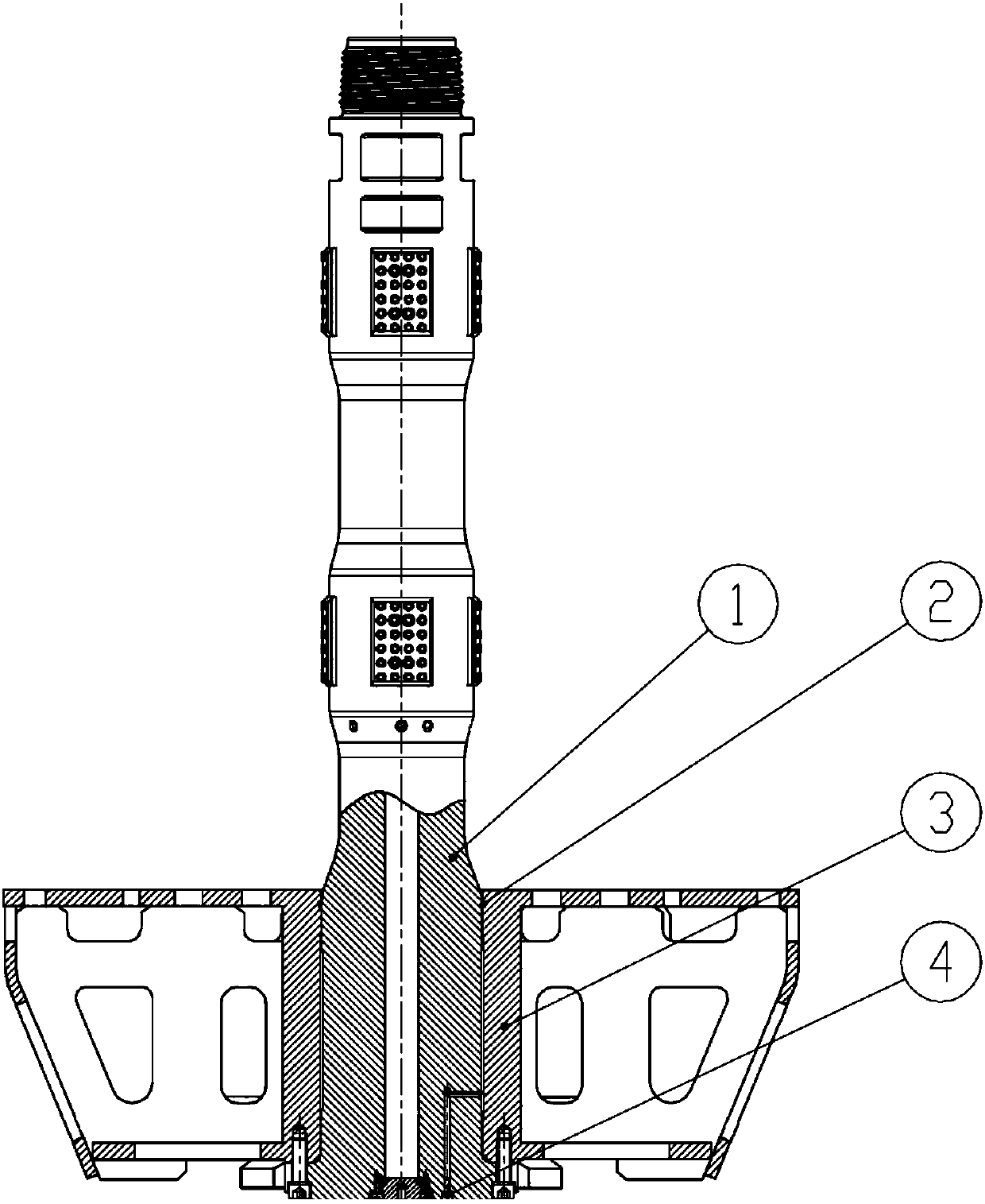

Hemispherical hollow welding sphere joint for large-span space steel structure support

InactiveCN104110072ALower the altitudeTensile benefitsBuilding constructionsEngineeringSteel structures

The invention provides a hemispherical hollow welding sphere joint for a large-span space steel structure support. The hemispherical hollow welding sphere joint at least comprises four foundation bolts which are connected with at least two embedded plates. At least one outer stiffening plate is welded to each embedded plate. A hemispherical case is respectively connected with the embedded plates and the outer stiffening plates in a welded mode. The hemispherical case is used as a sphere joint, at least one main pipe and one branch pipe are welded to the hemispherical case, and a transverse semicircular stiffening plate and a longitudinal semicircular stiffening plate are further welded to the hemispherical case. The hemispherical hollow welding sphere joint has the following advantages that a novel joint form is designed for the large-span space steel structure support, and the defects of the joint form in the application field are effectively made up; the height of the steel support is reduced, the length of the welding joint is increased, larger horizontal shearing force can be borne, and the tensile strength of the foundation bolts is benefited; the hemispherical case, the transverse semicircular stiffening plate, the longitudinal semicircular stiffening plate, the outer stiffening plates and the embedded plates are connected, and therefore the safety of the joint is ensured.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

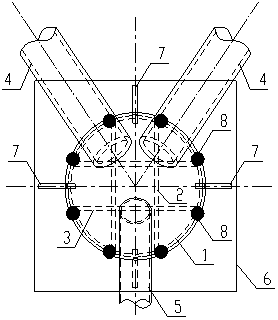

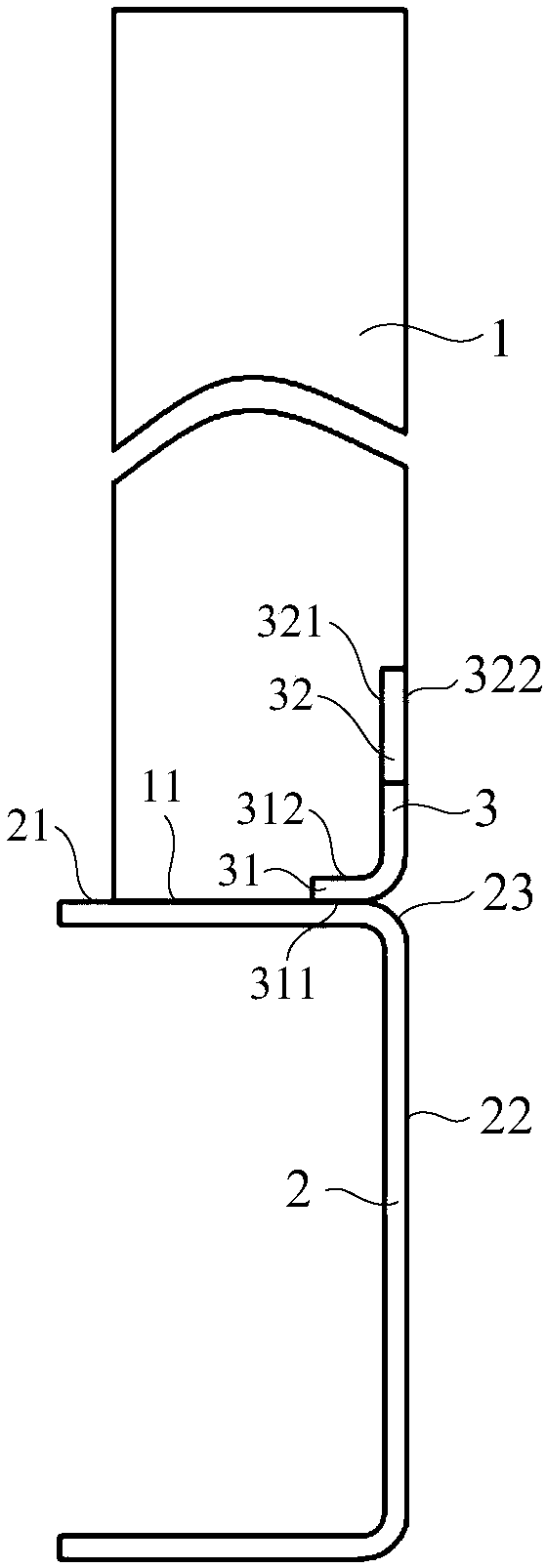

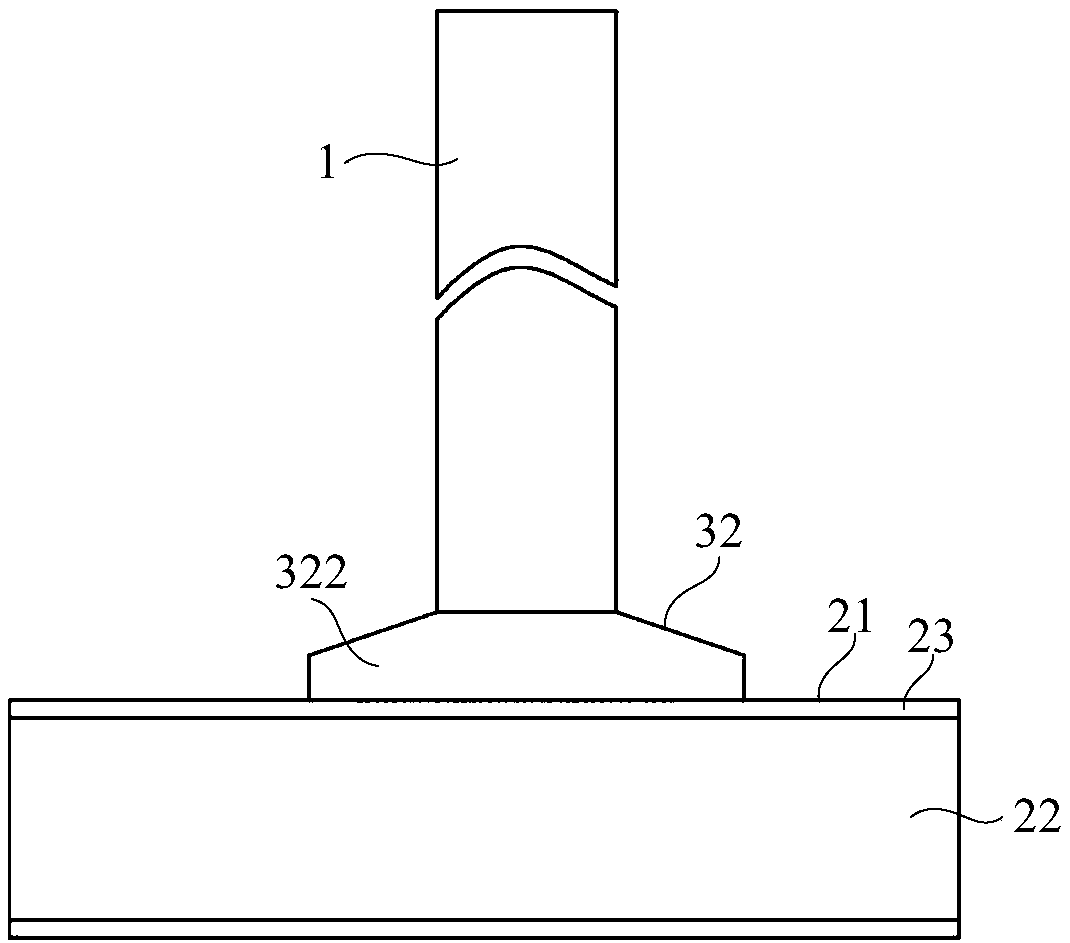

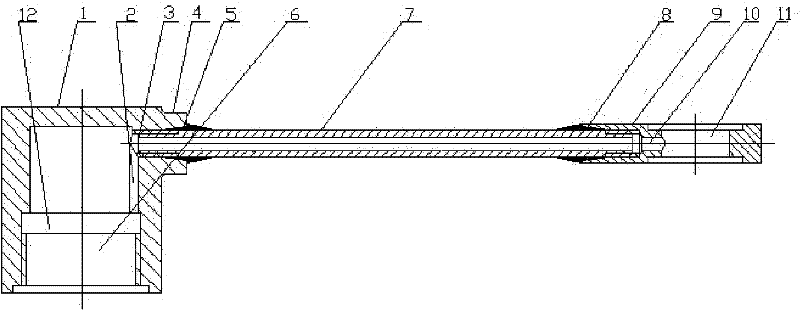

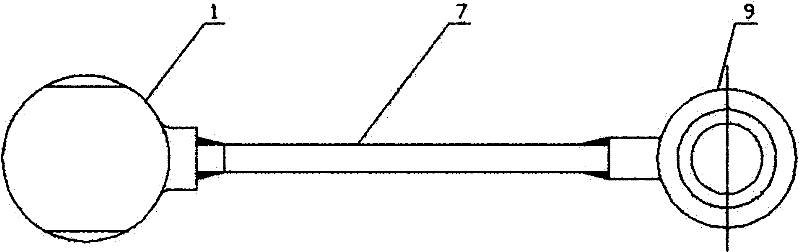

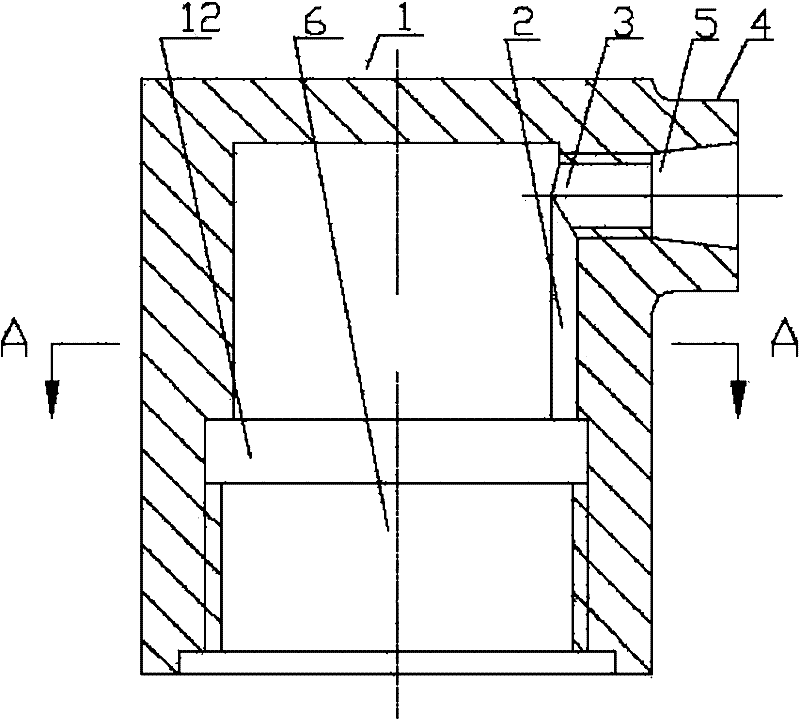

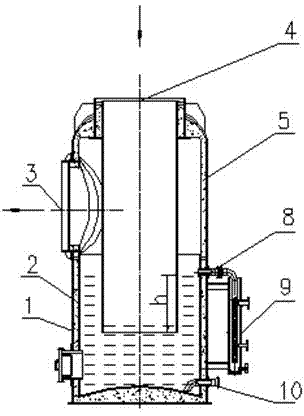

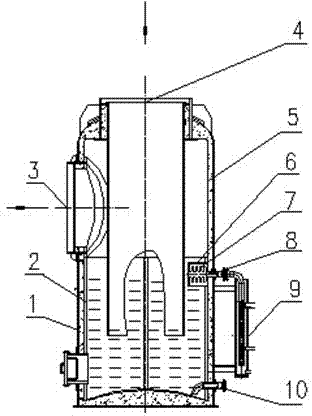

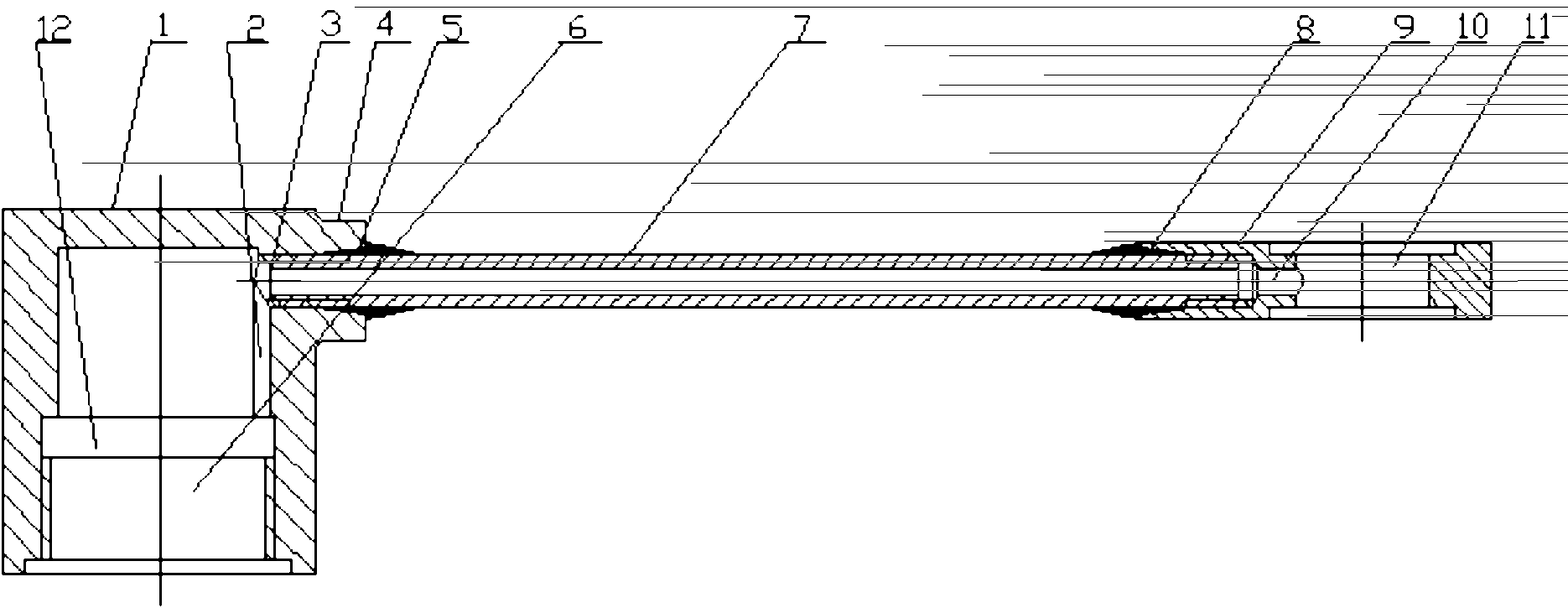

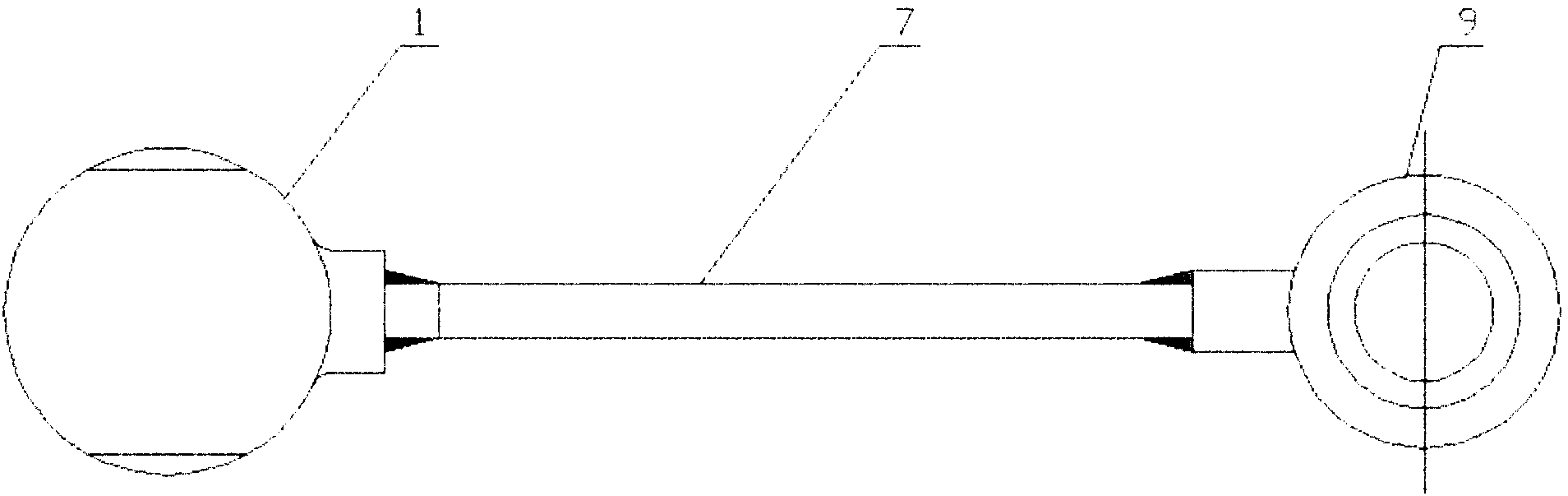

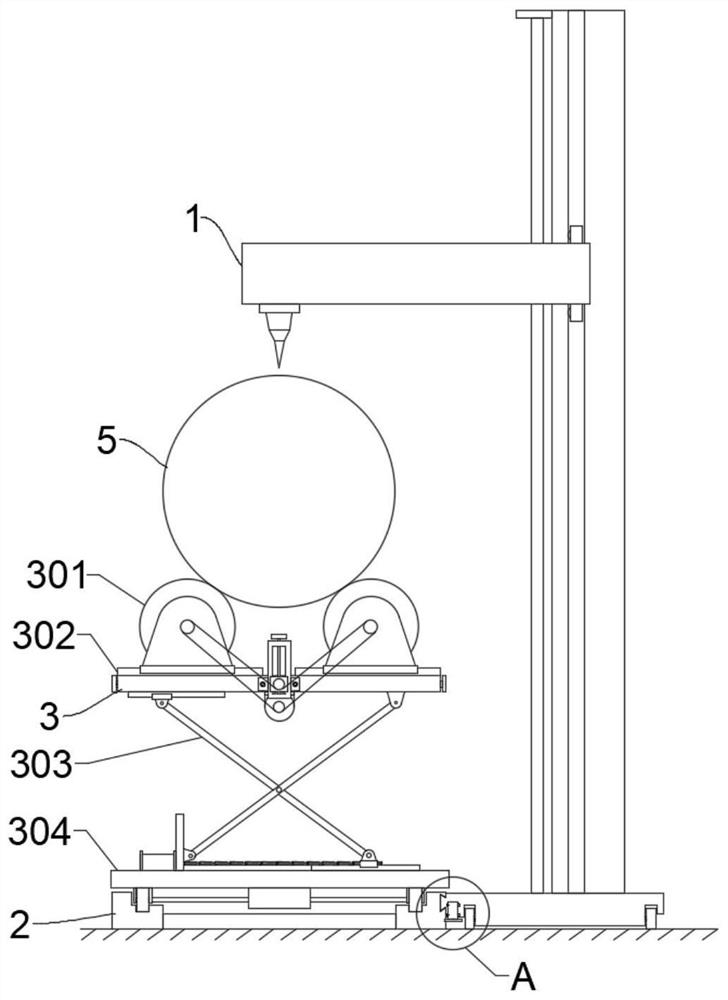

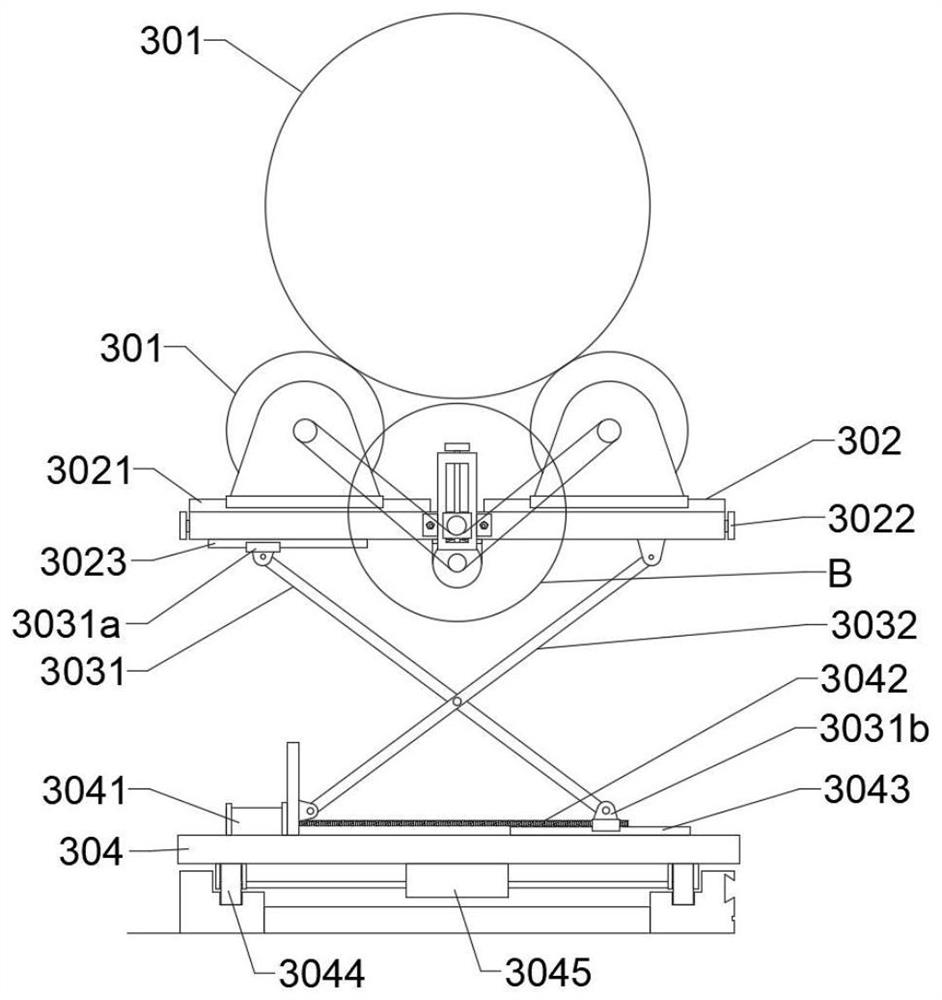

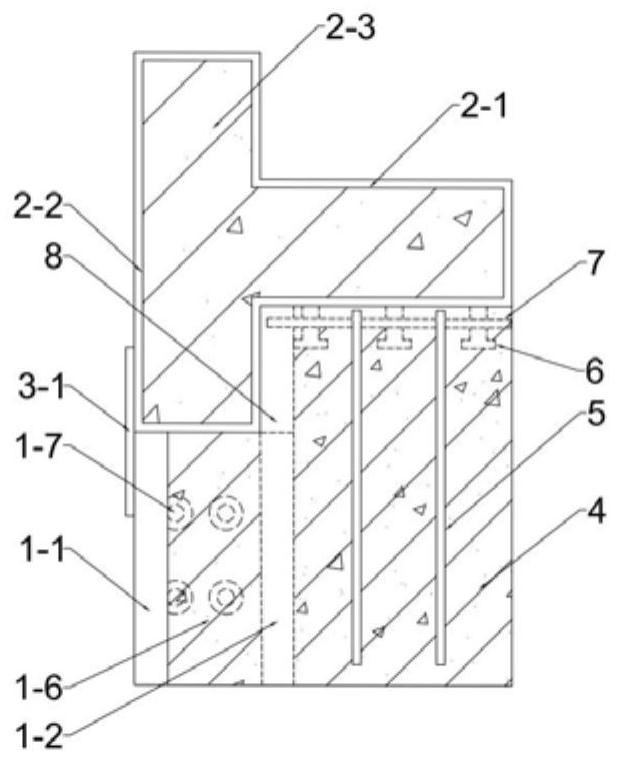

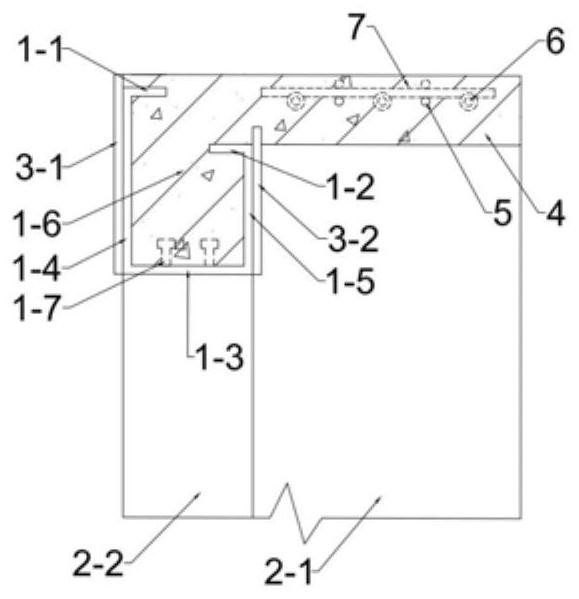

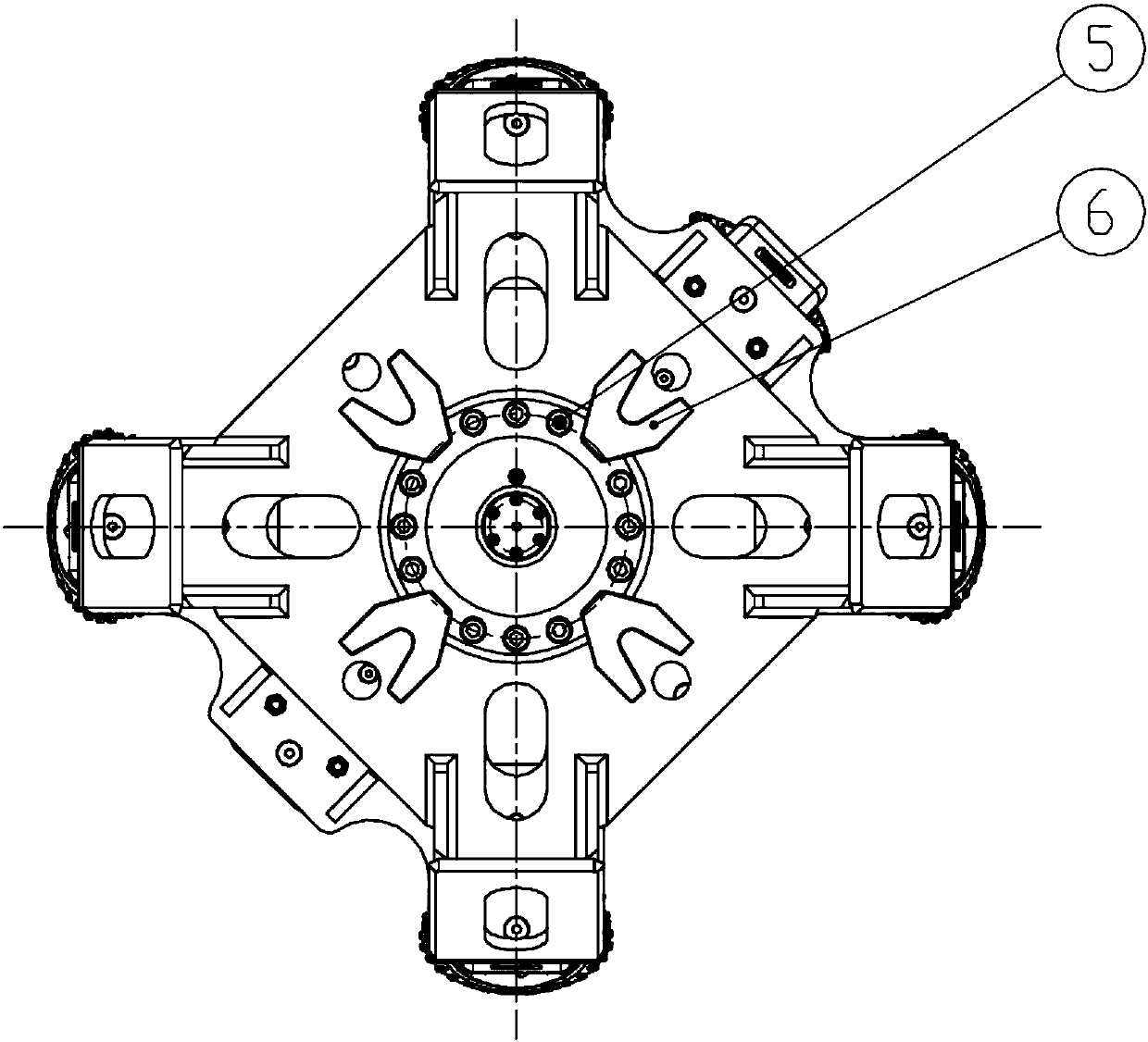

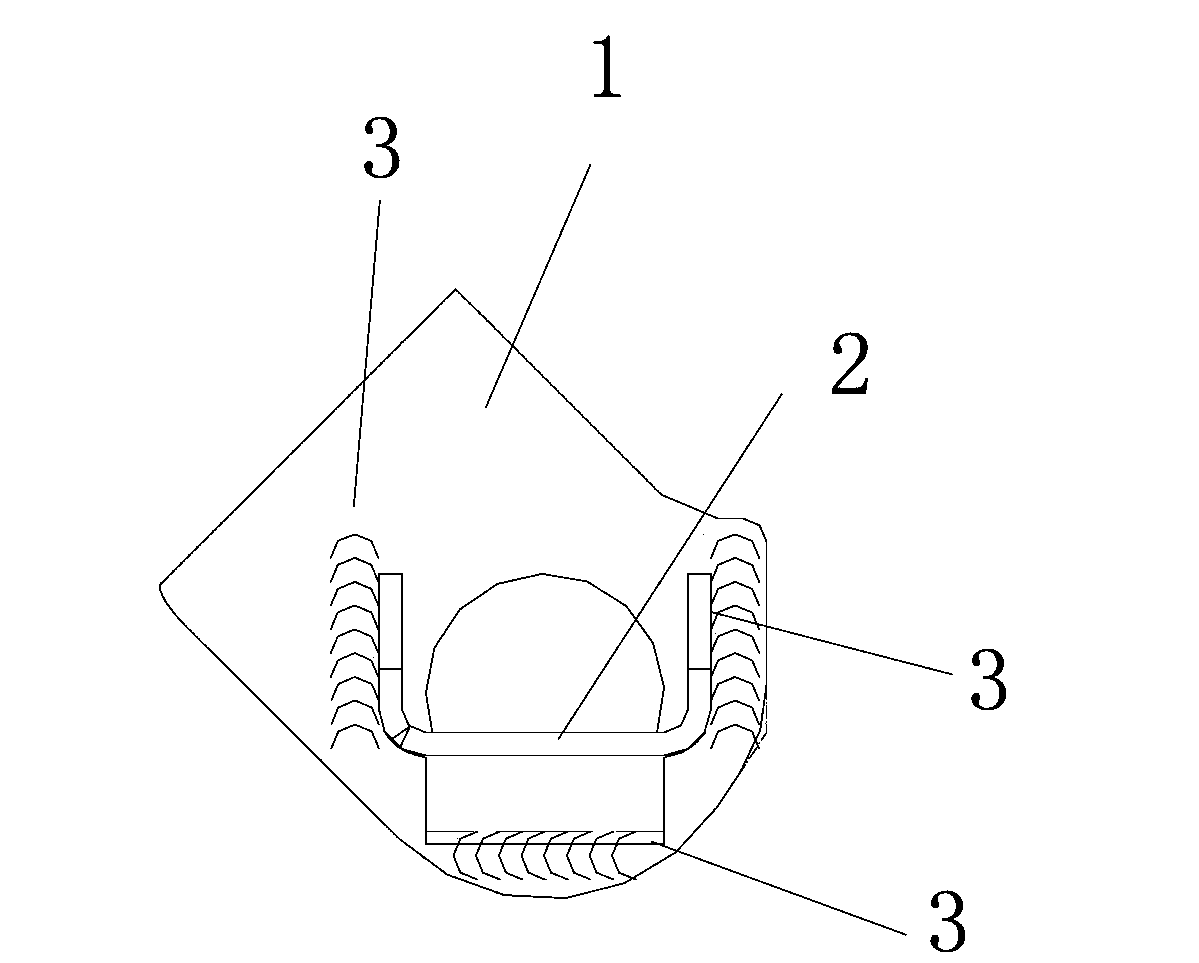

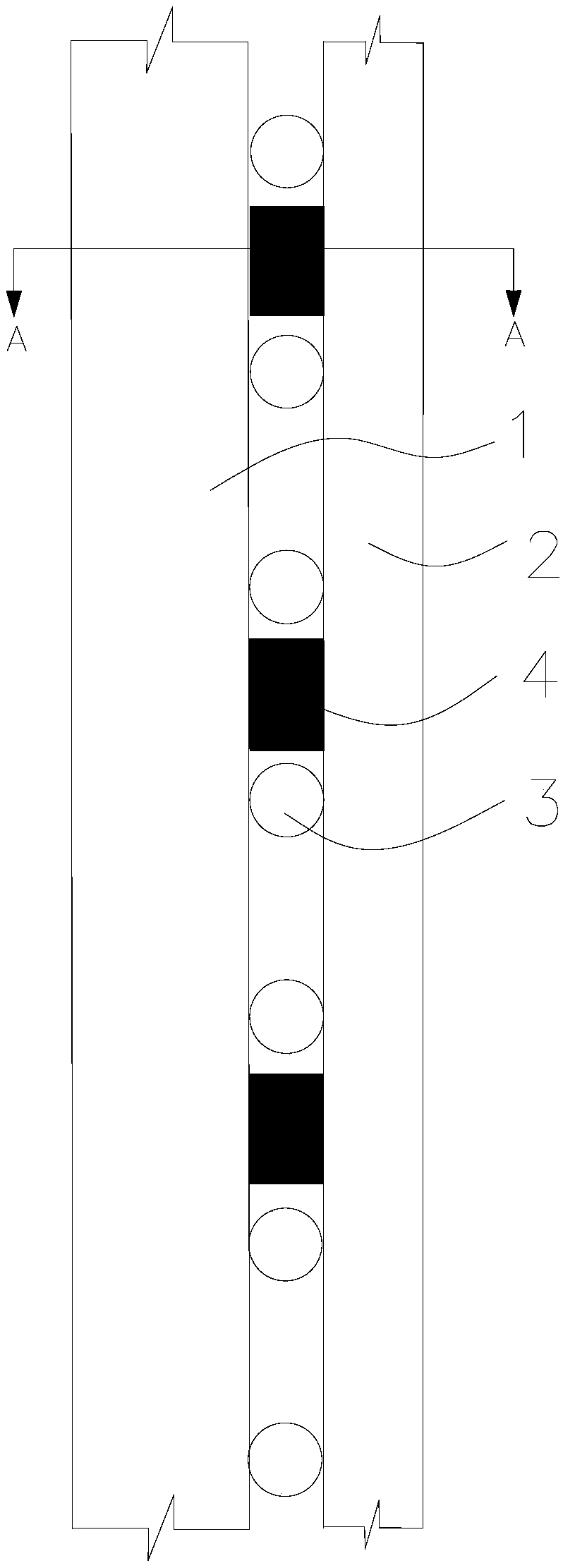

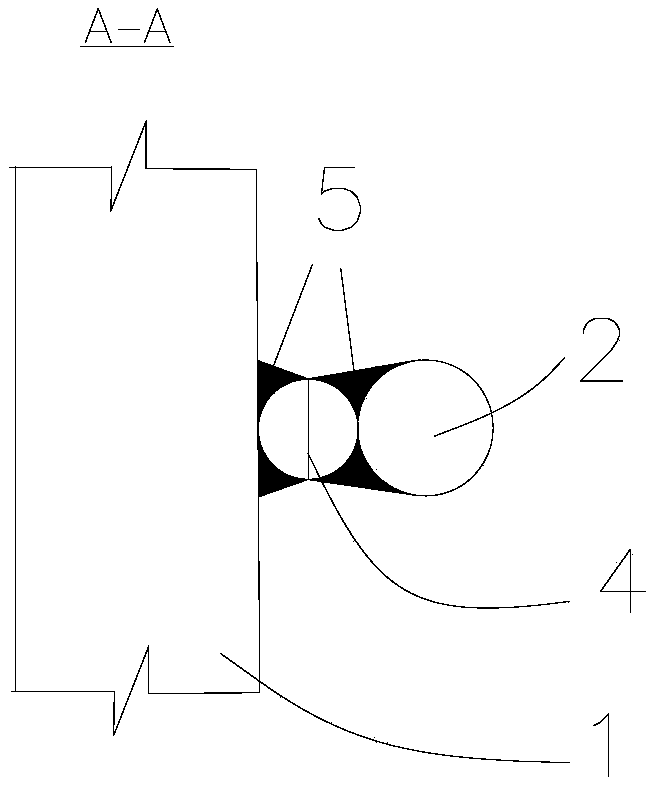

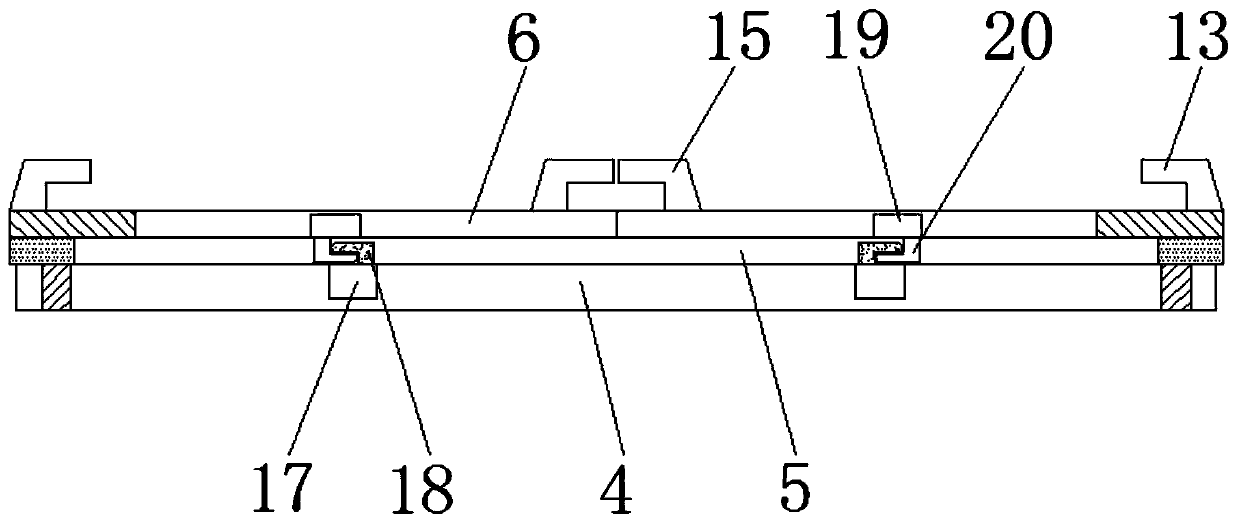

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steam insulation pipe is DN 600-DN 700. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels arranged on the upper steel hoop and distributed symmetrically, and four lower idler wheels arranged on the lower steel hoop and distributed symmetrically, wherein the four lower idler wheels are evenly divided into two groups; the end parts of the upper steel hoop and the lower steel hoop are connected by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the four lower idler wheels and the inner wall of the outer sleeve steel pipe are contacted in a rolling friction way, and gaps are left between the two upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steaminsulation pipe comprises the rolling supporting mechanism and also comprises insulation material positioned between the rolling supporting mechanism and the inner sleeve steel pipe, heat-preservation material with the external diameter smaller than the internal diameter of the outer sleeve steel pipe, an air evaporation valve arranged on the outer sleeve steel pipe, and erosion resistant coatingsleeved outside the outer sleeve steel pipe. The rolling supporting mechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

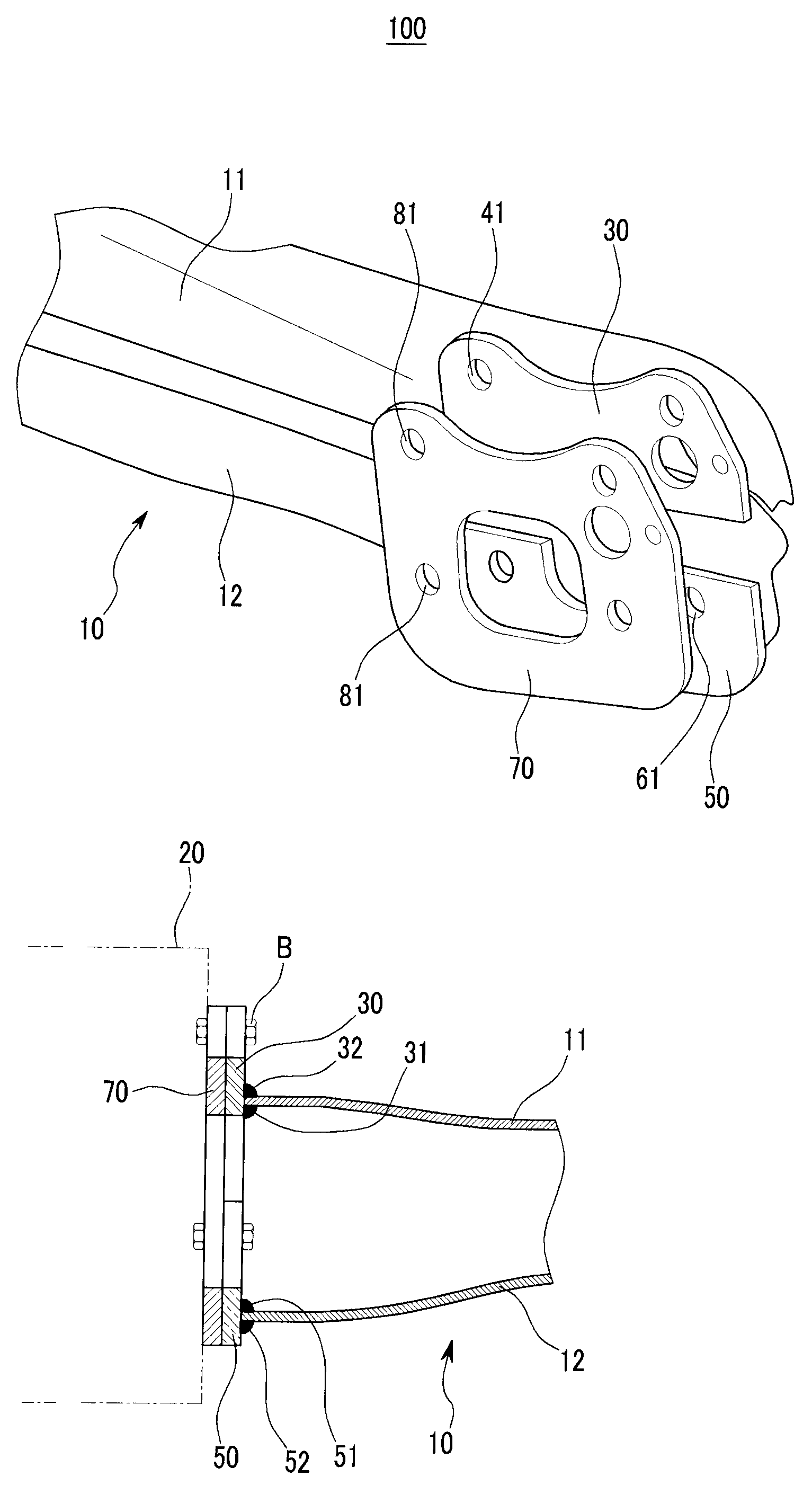

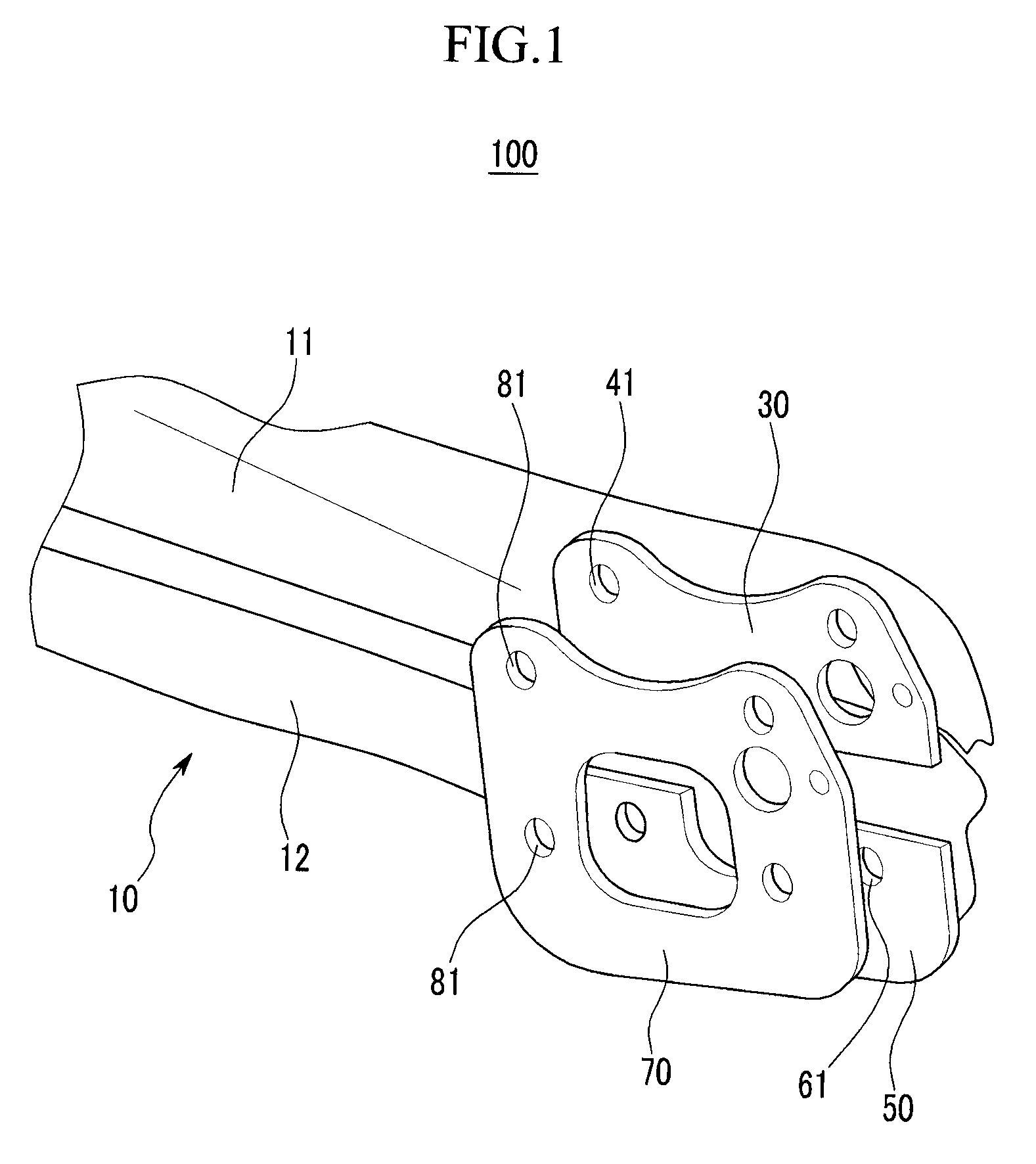

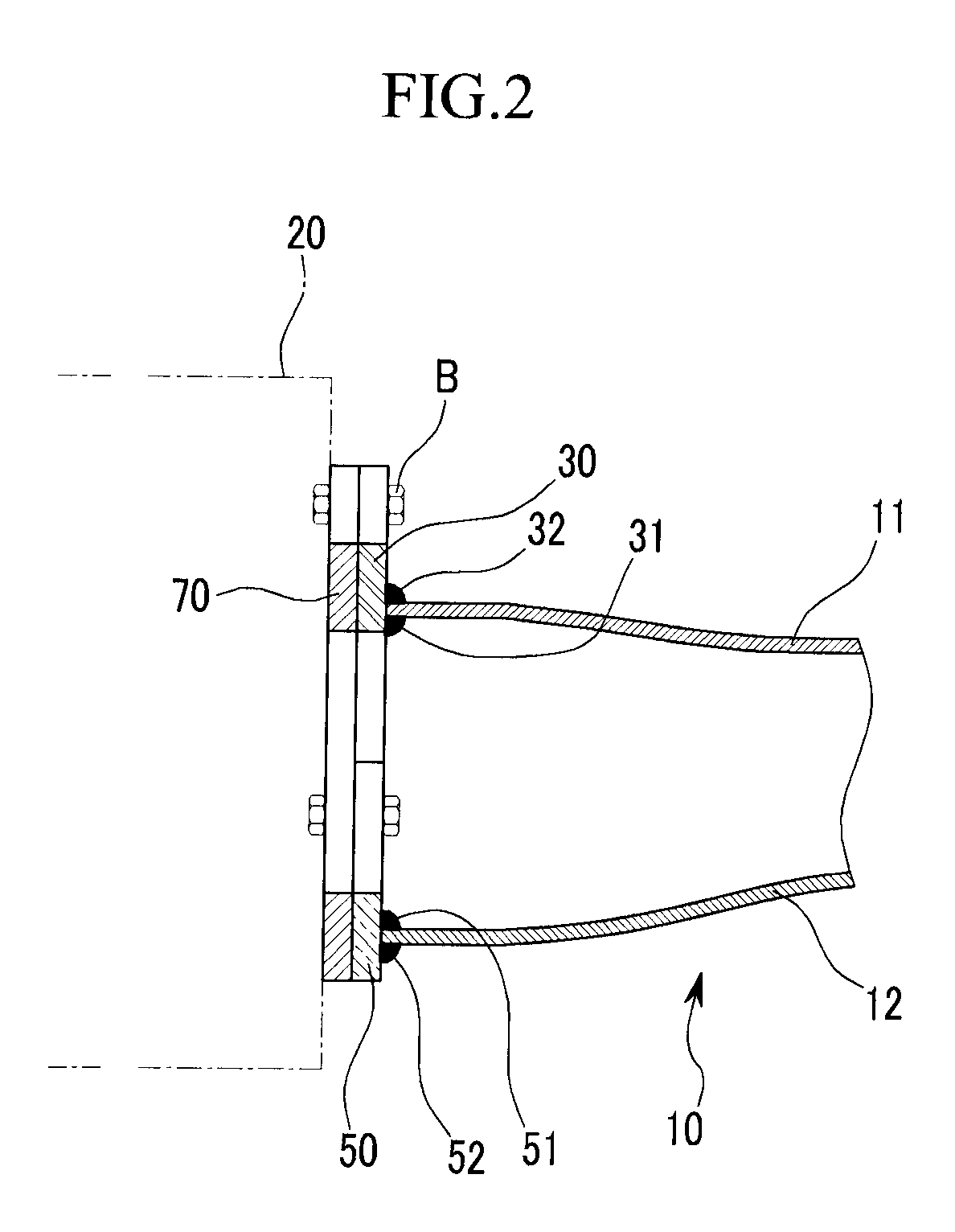

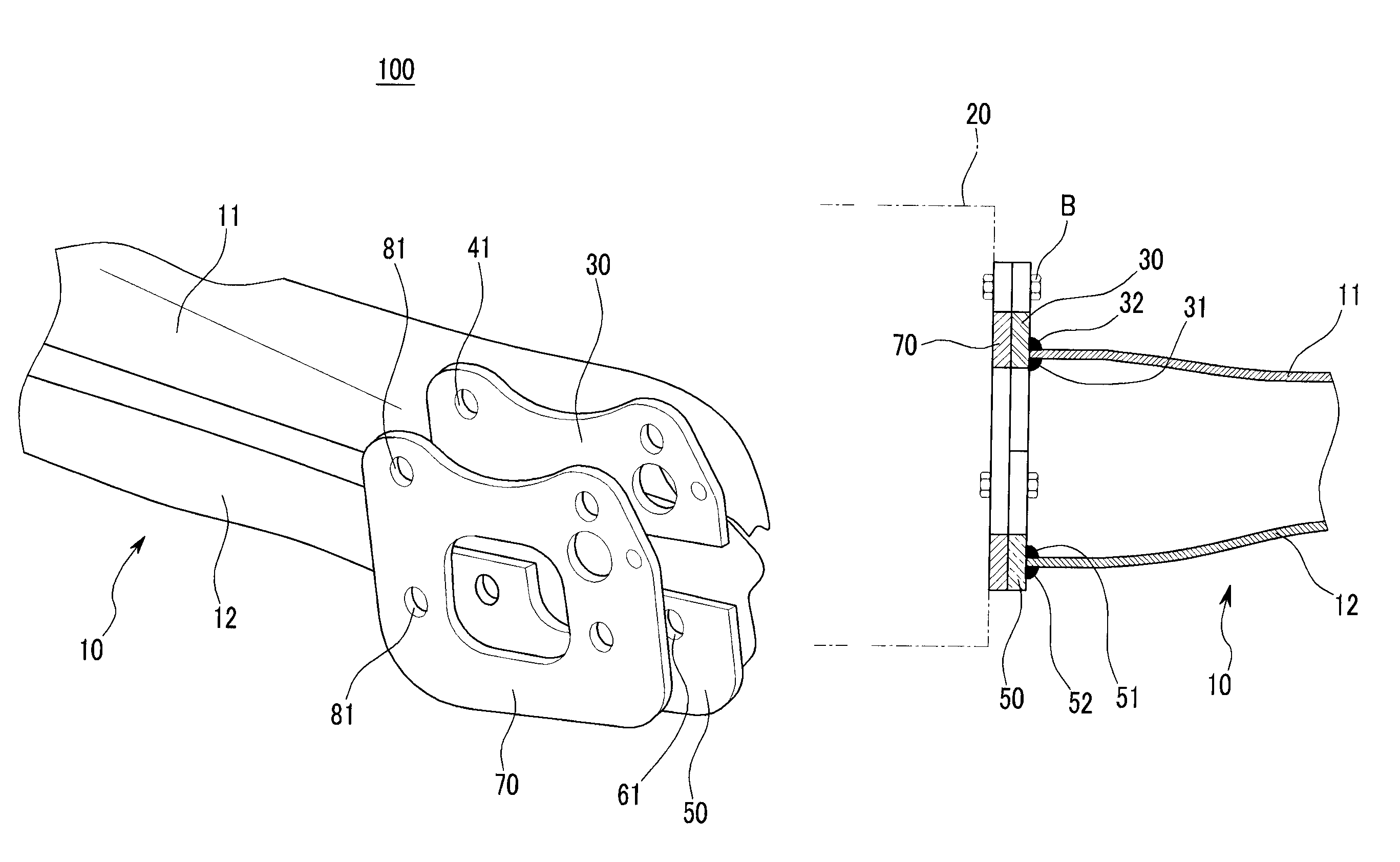

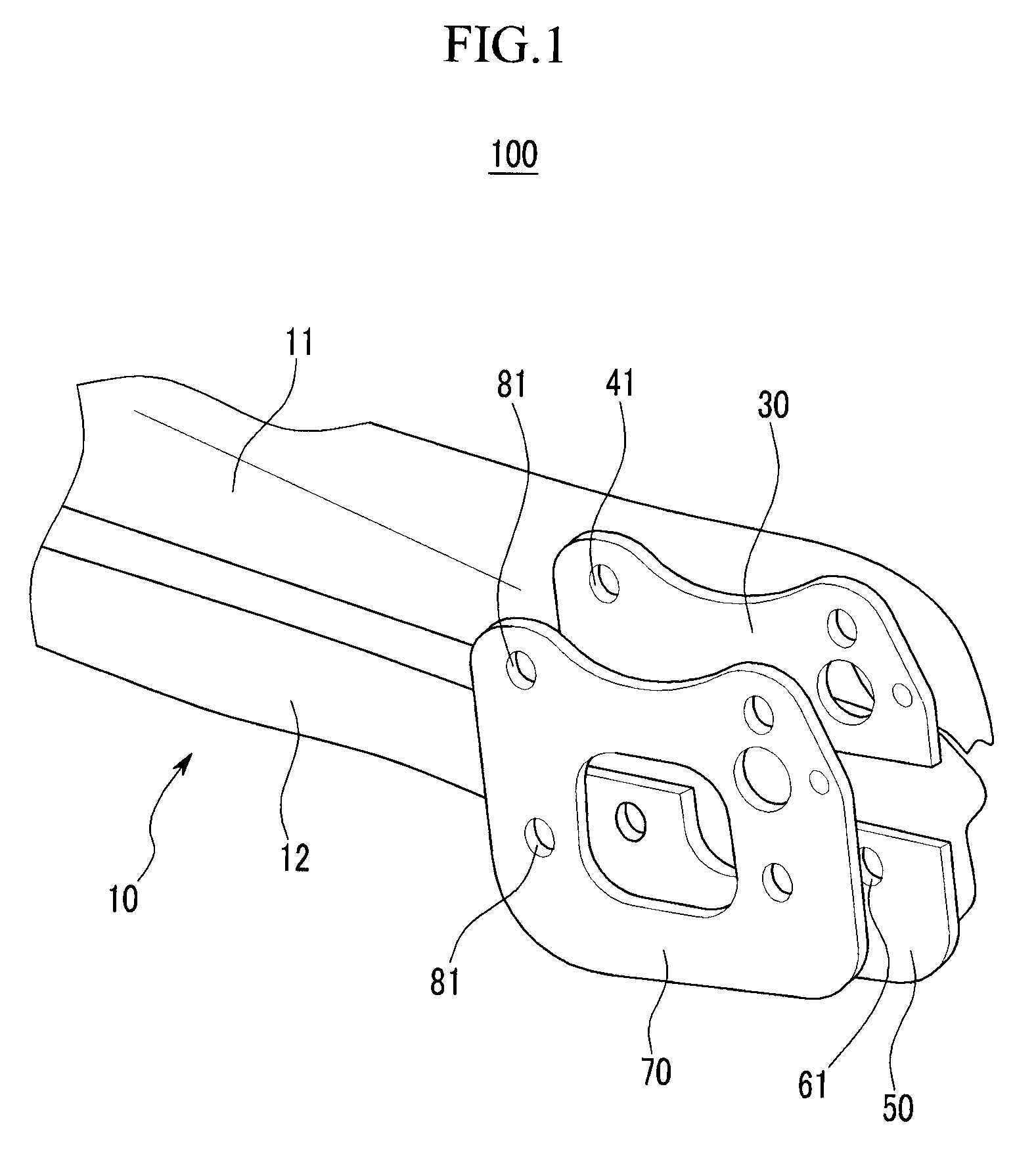

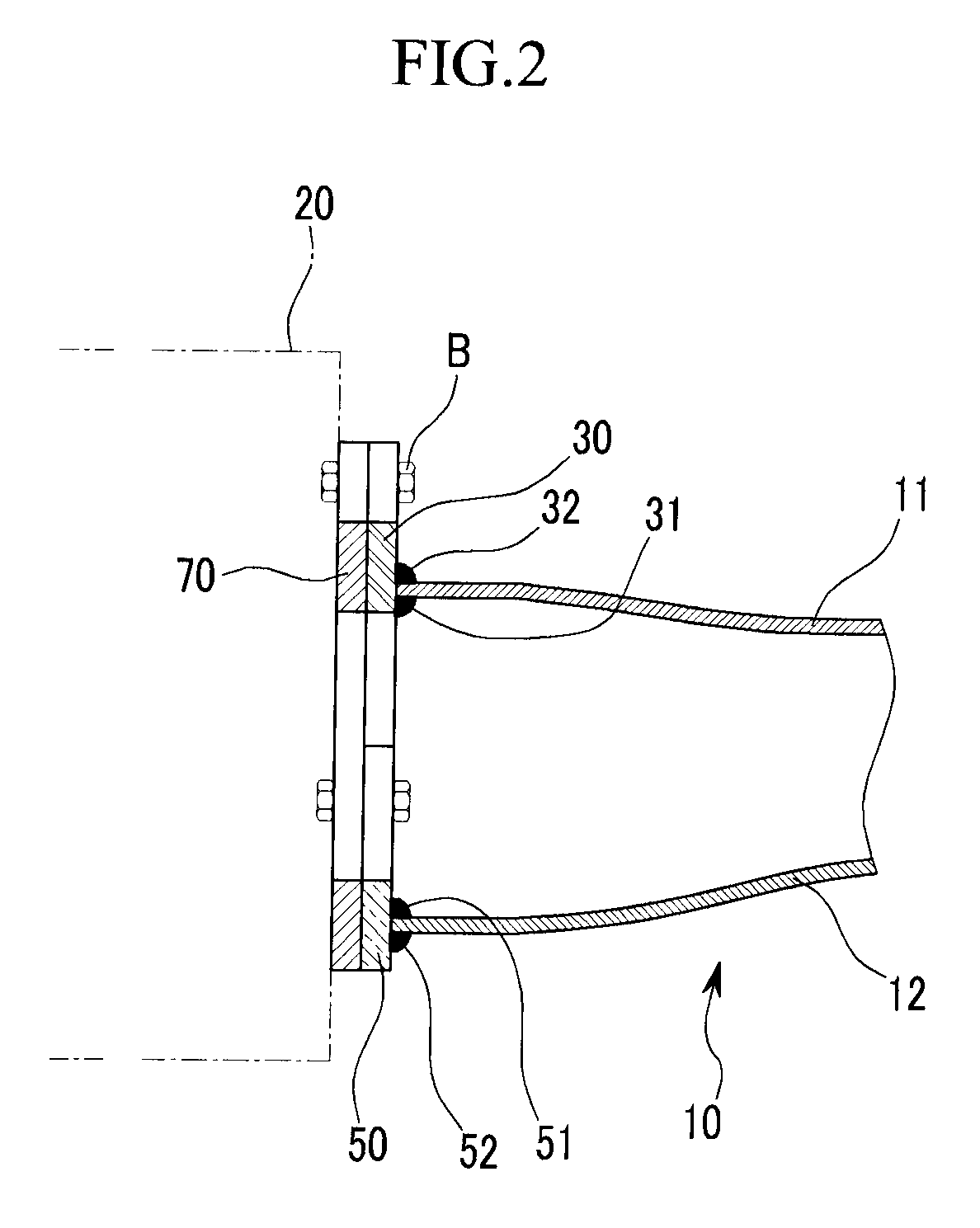

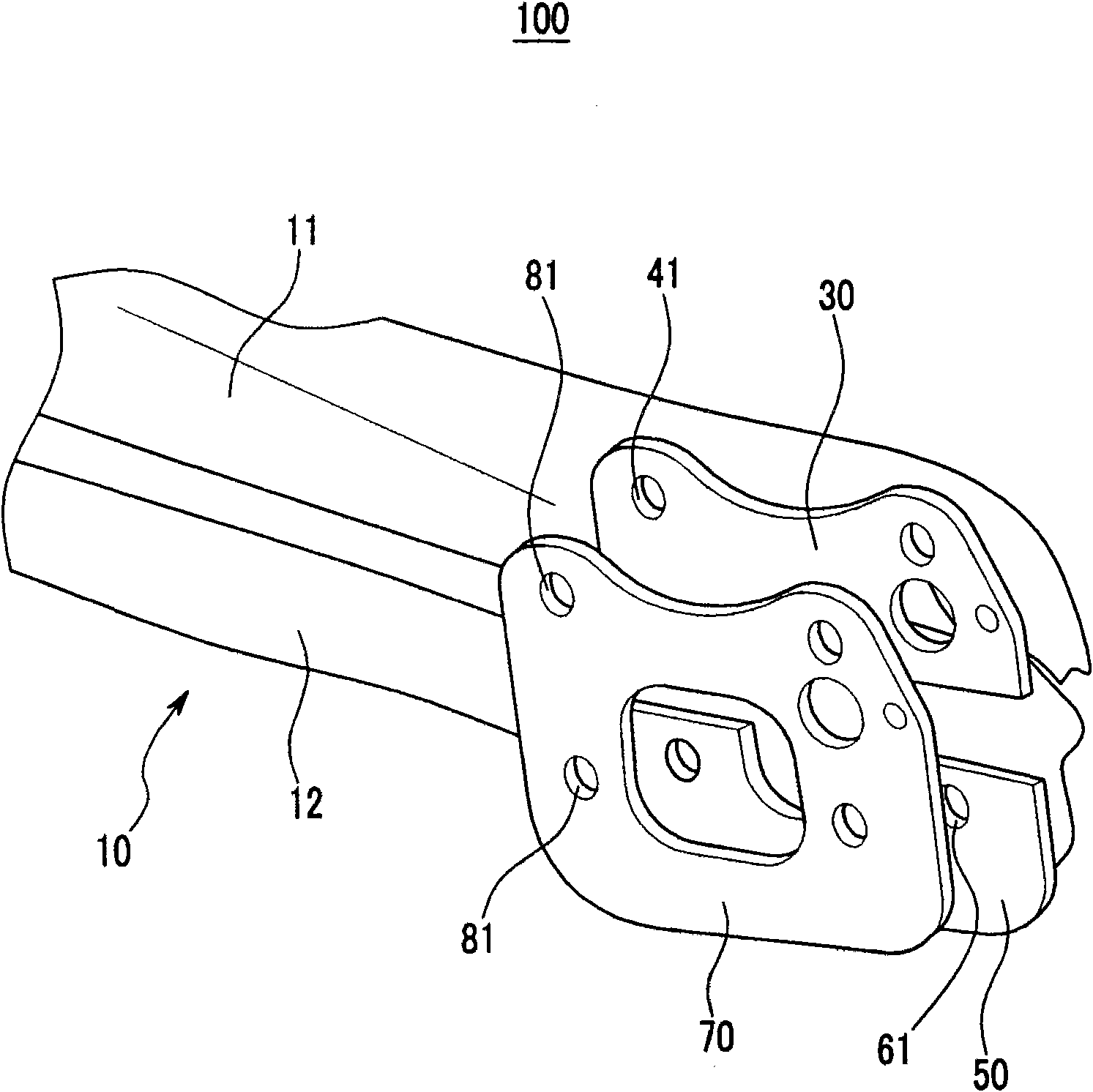

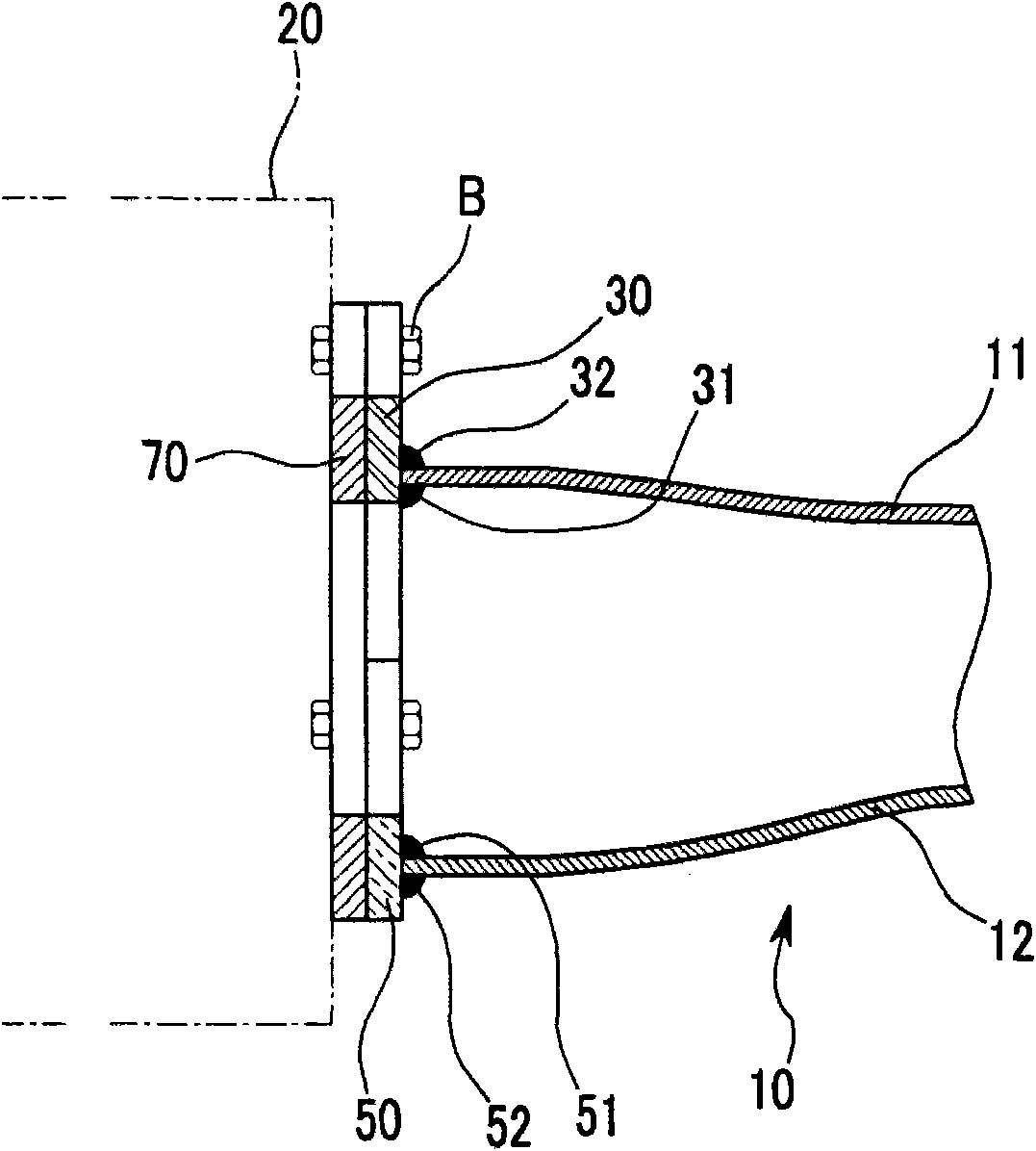

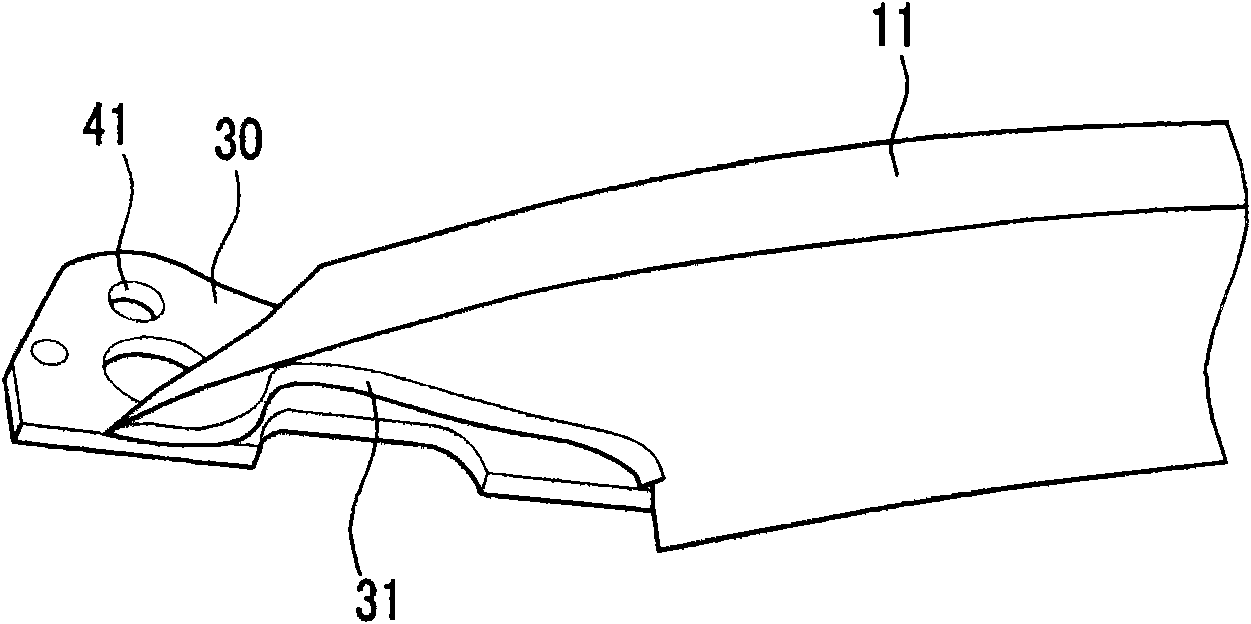

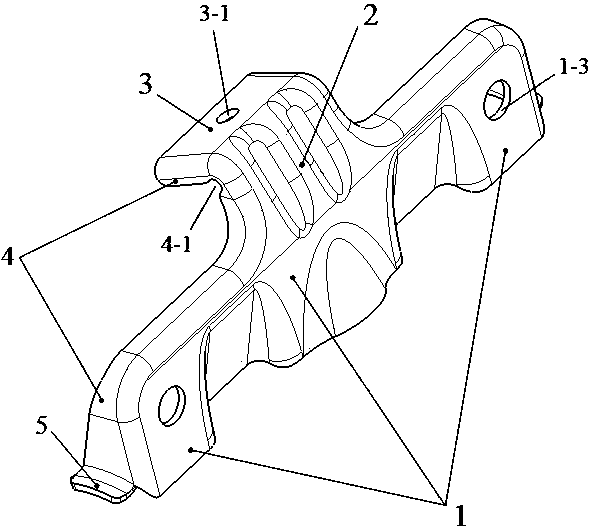

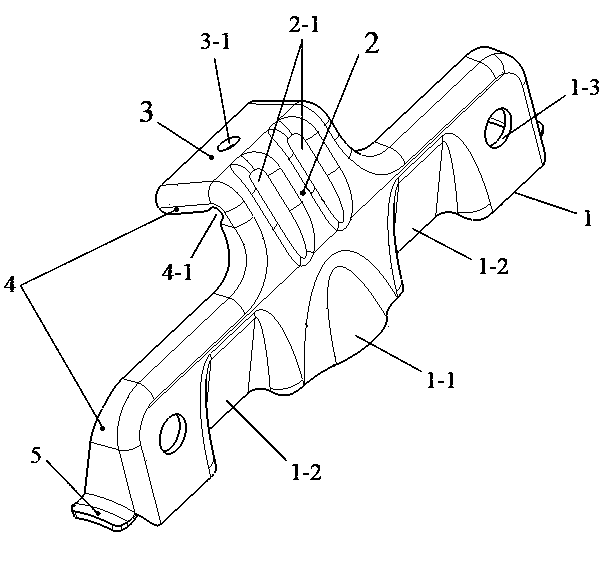

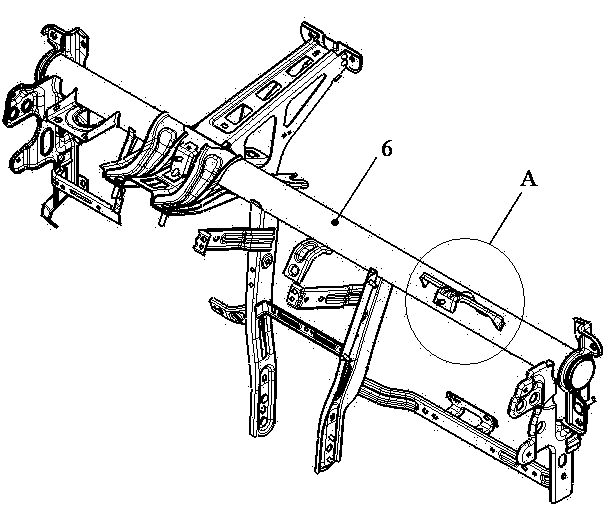

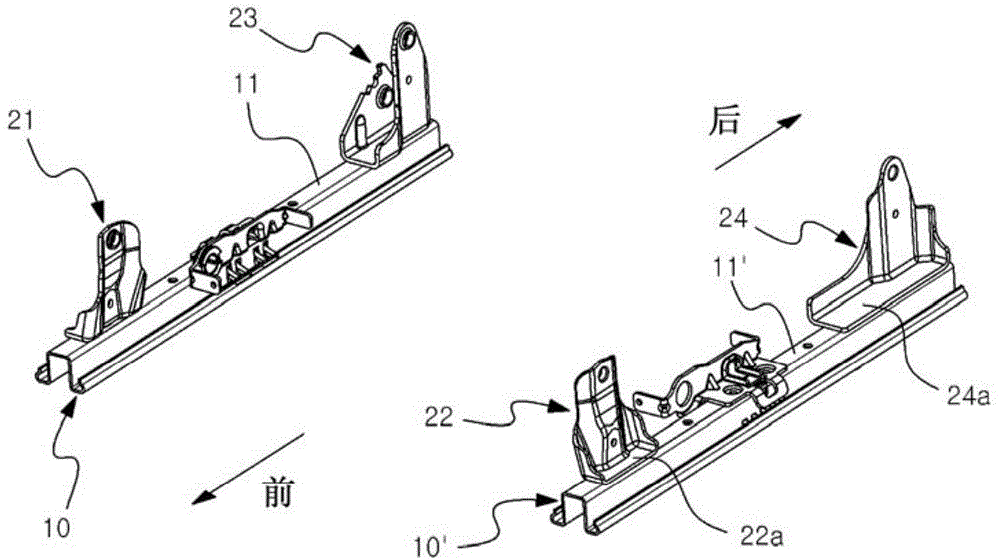

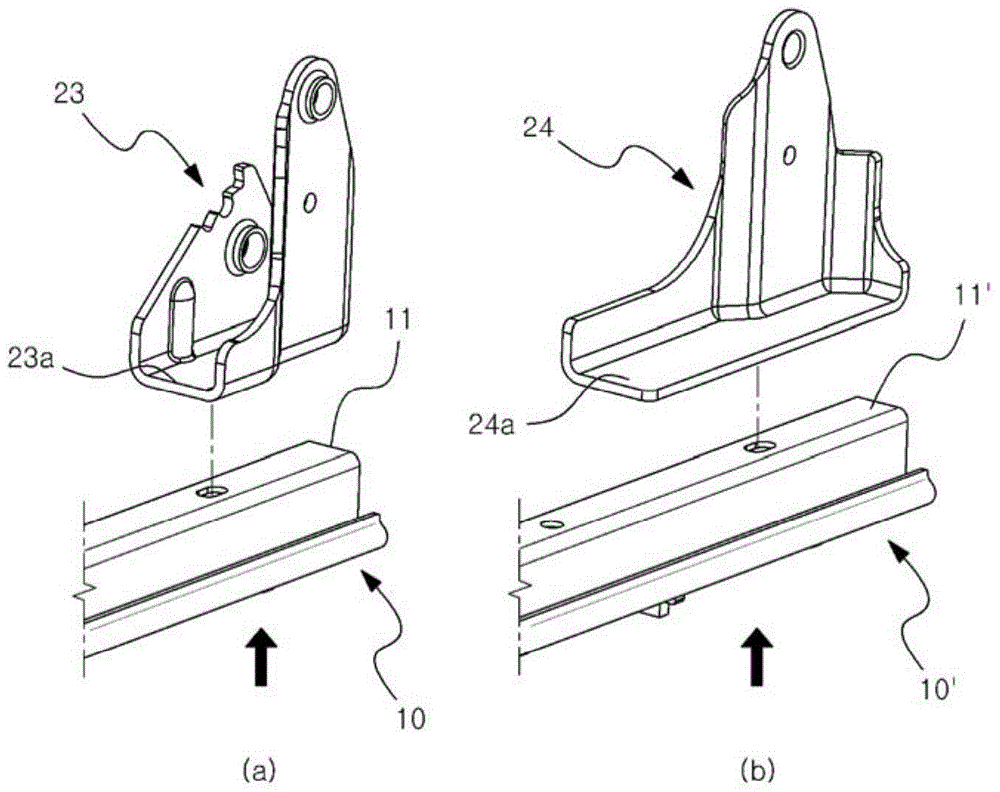

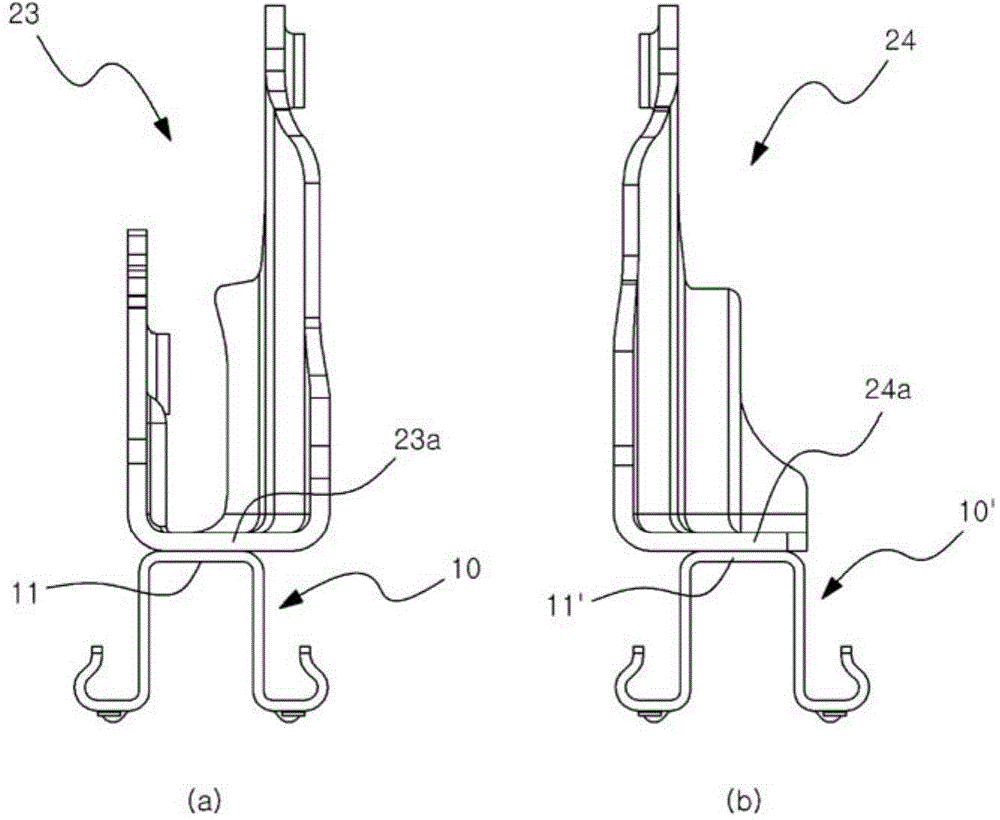

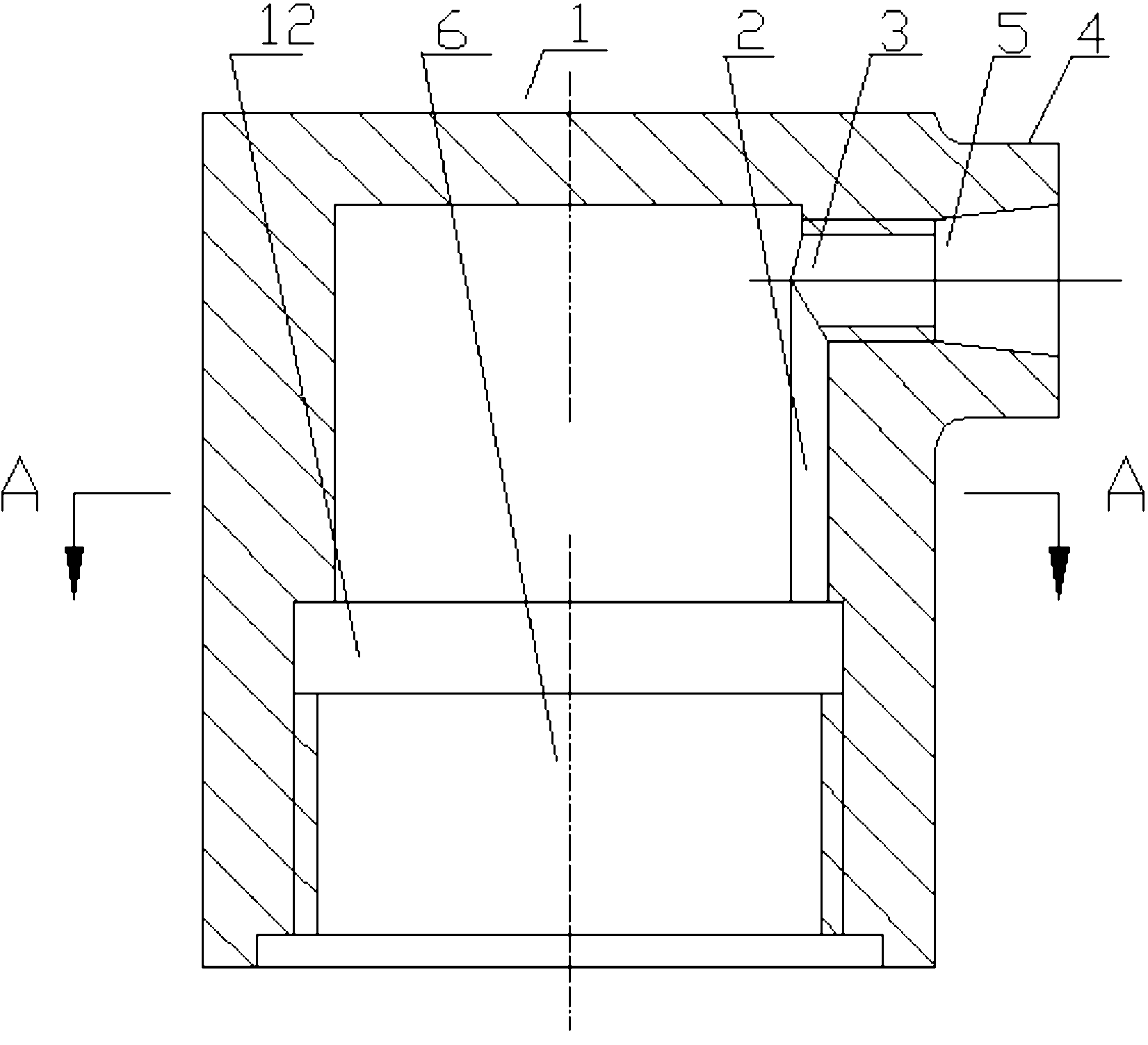

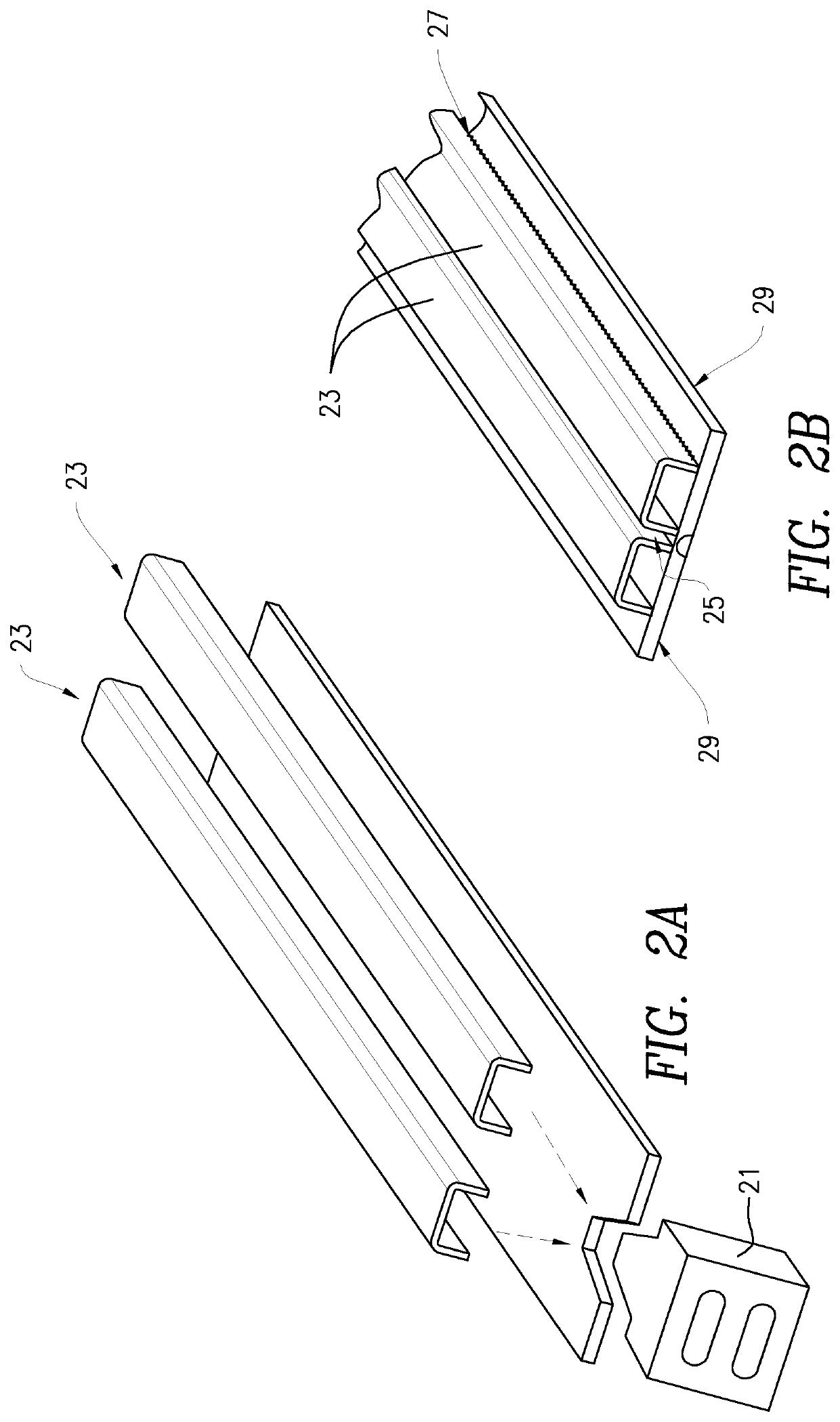

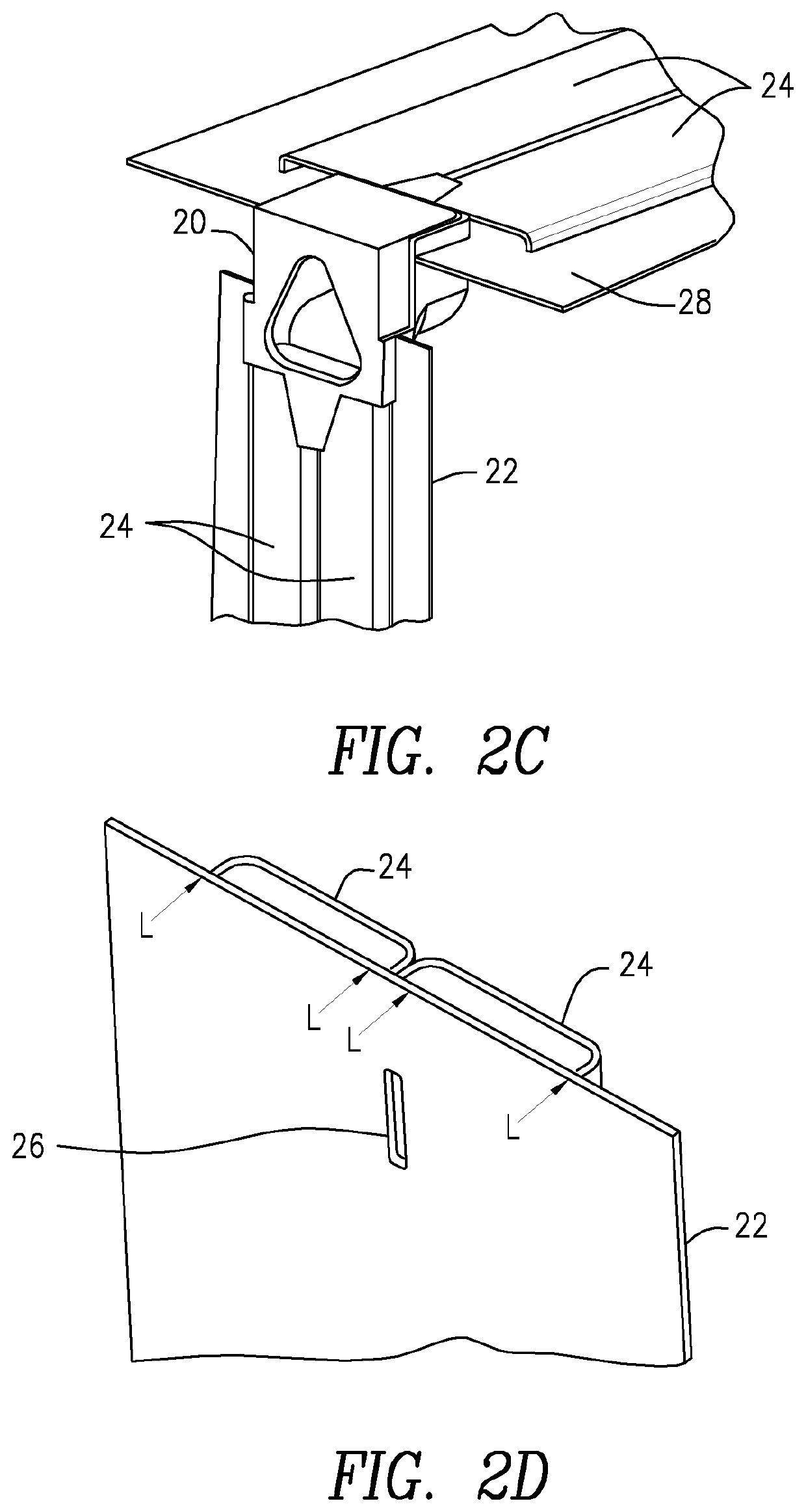

Spindle bracket of torsion beam axle suspension

ActiveUS20100019466A1Increase weld lengthIncreased durabilityInterconnection systemsResilient suspensionsMechanical engineeringBeam axle

A spindle bracket of a torsion beam axle suspension system is defined on an end portion of a trailing arm to be connected to a hub assembly on which a wheel and a tire are mounted. The spindle bracket may include a first inner bracket that is welded to an inner side and an outer side of an end portion of a upper member of the trailing arm, a second inner bracket that is welded to an inner side and an outer side of an end portion of a lower member of the trailing arm, and an outer bracket that is attached to the first and second inner brackets to be engaged with the hub assembly in company with the first and second inner brackets.

Owner:HYUNDAI MOTOR CO LTD

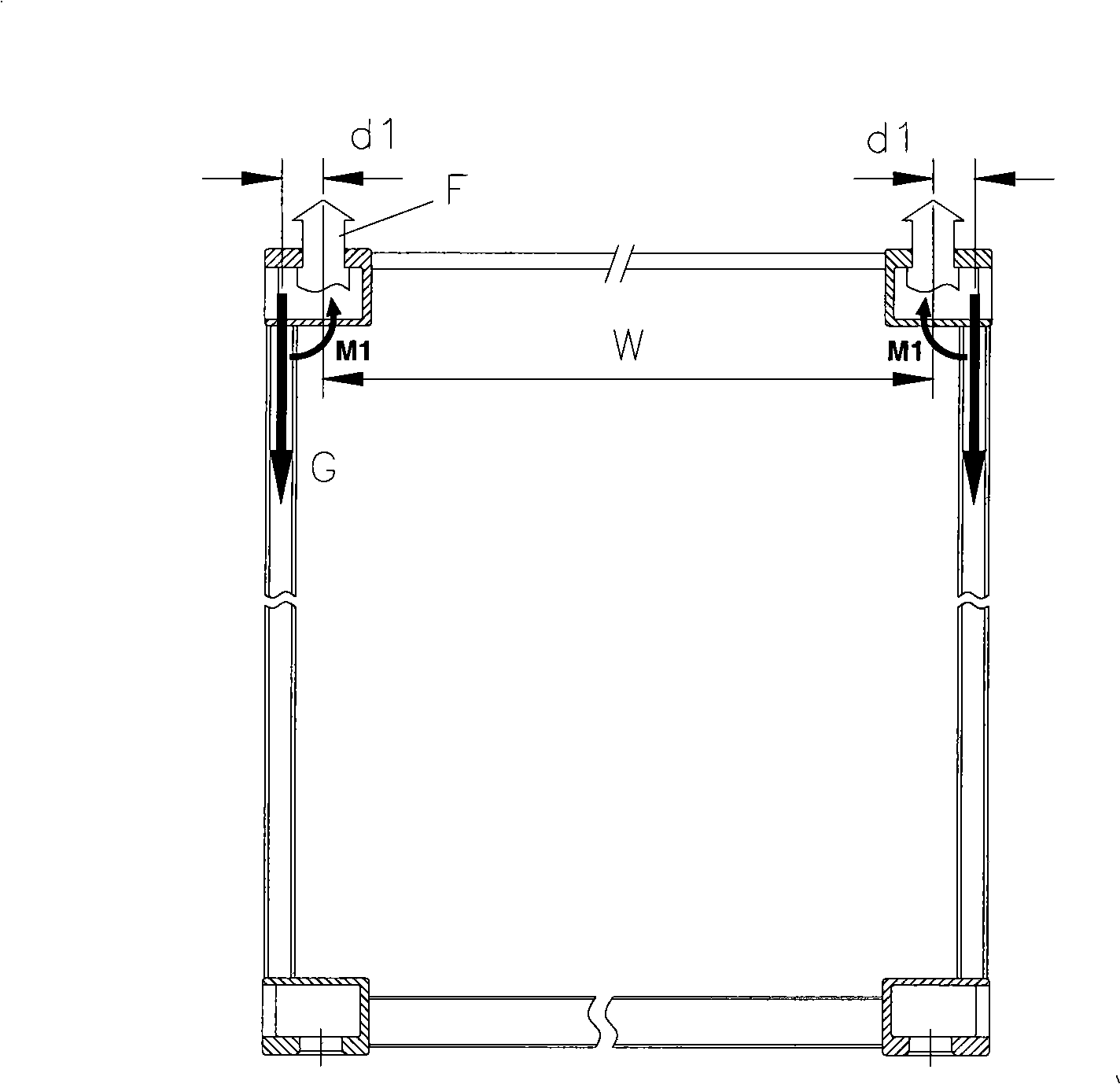

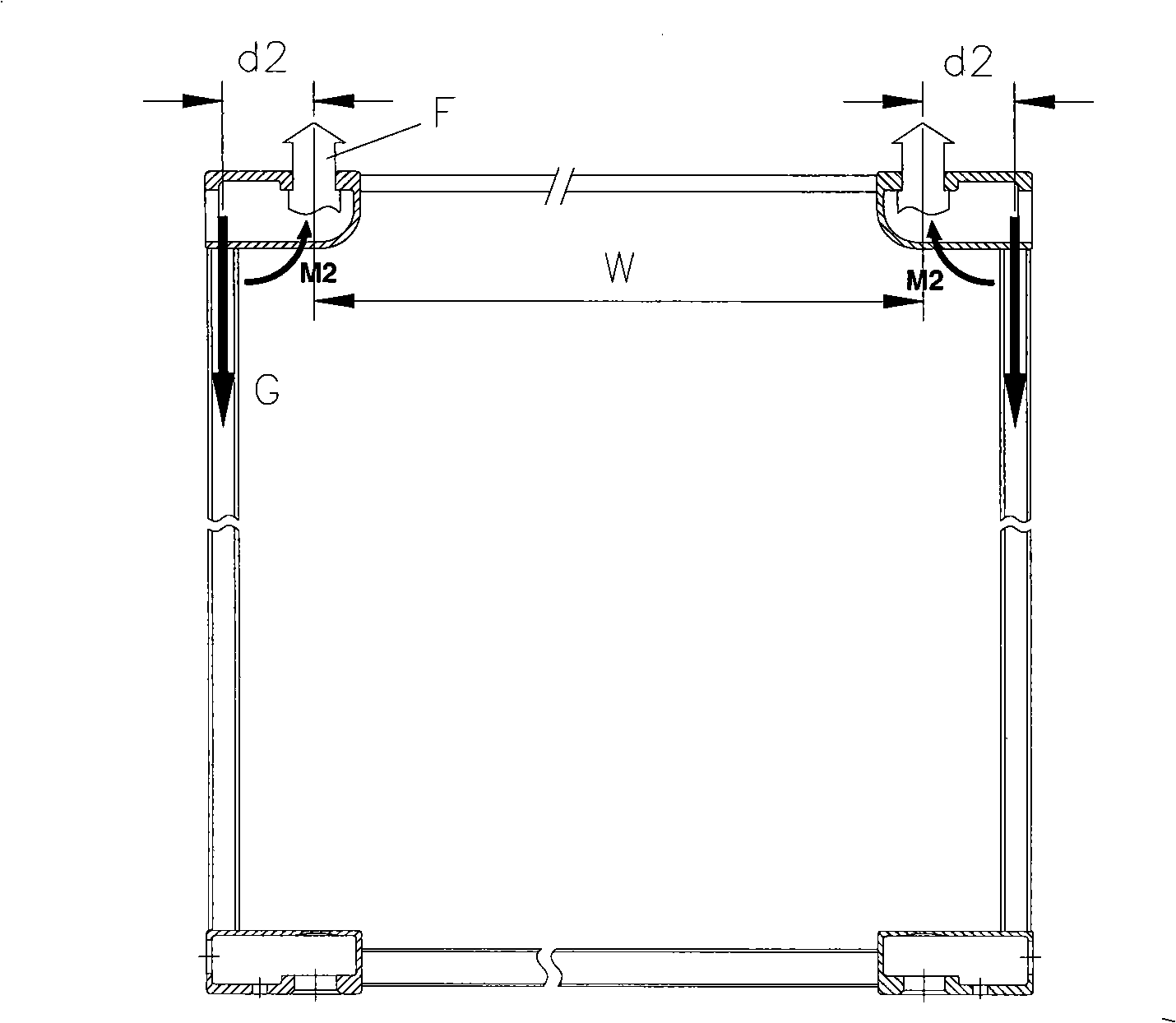

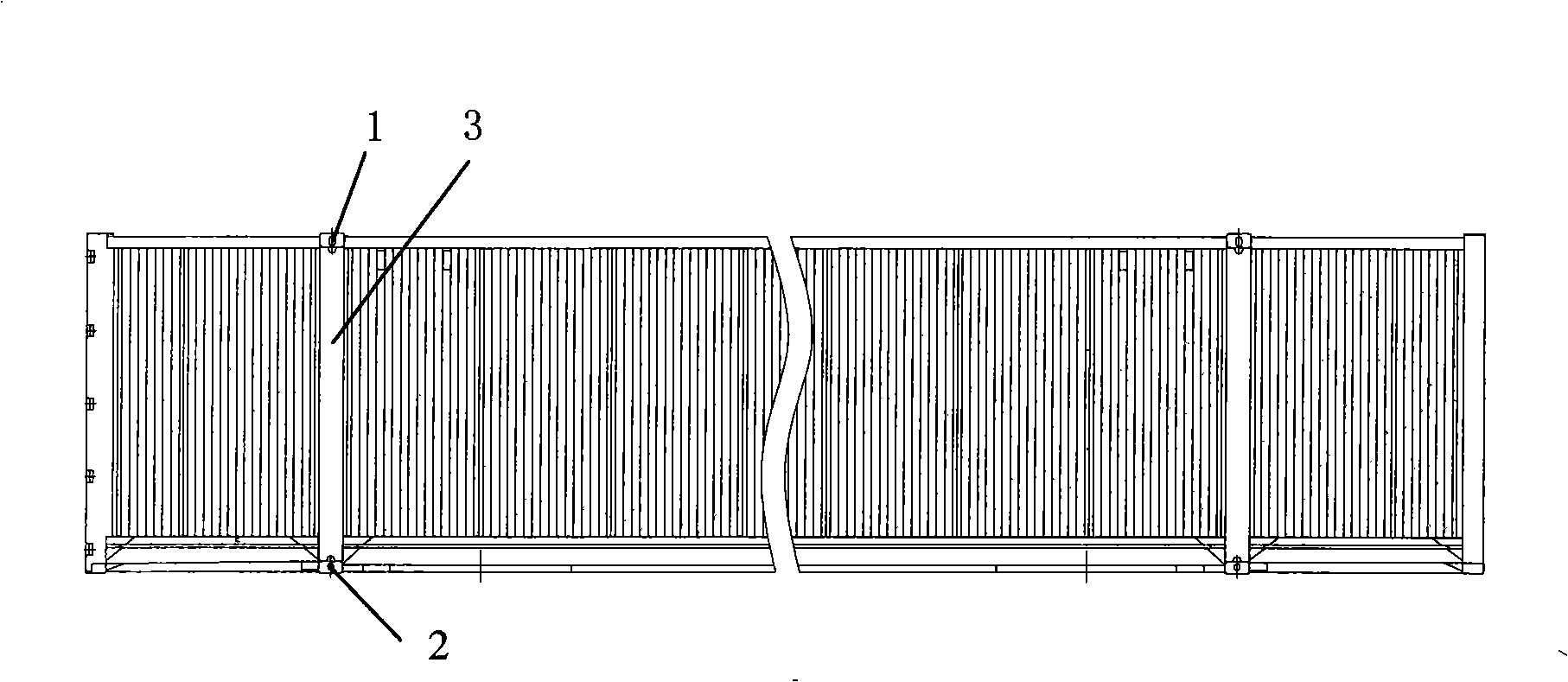

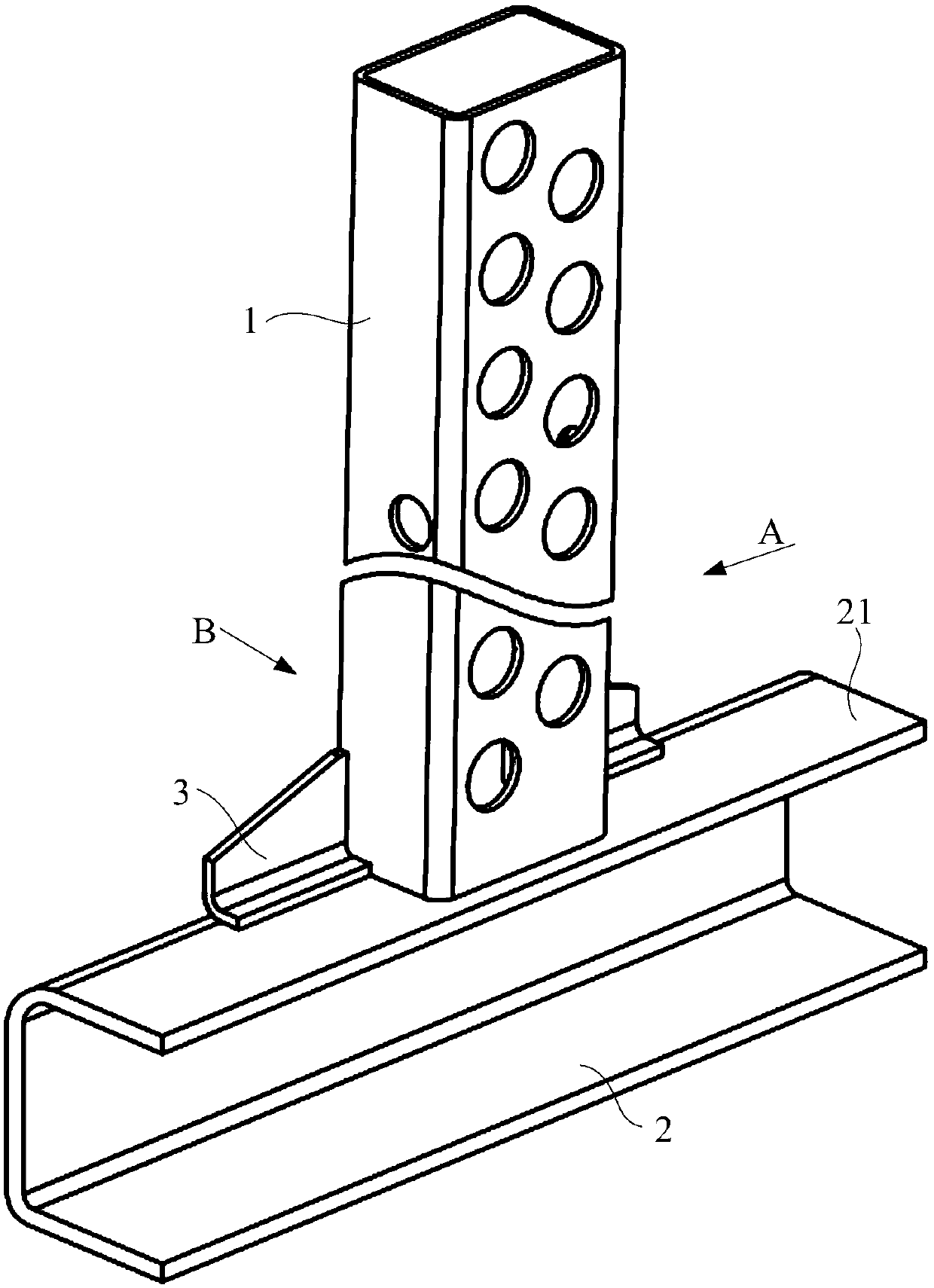

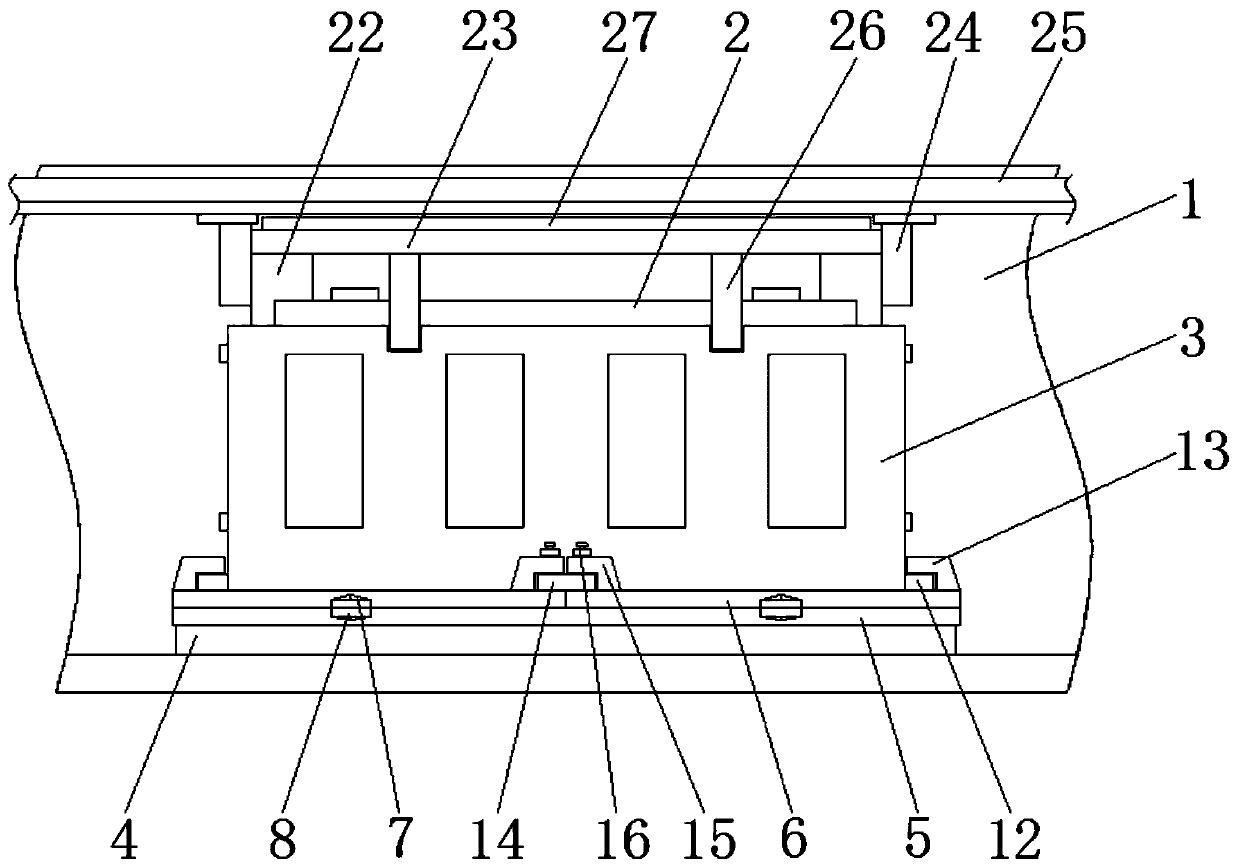

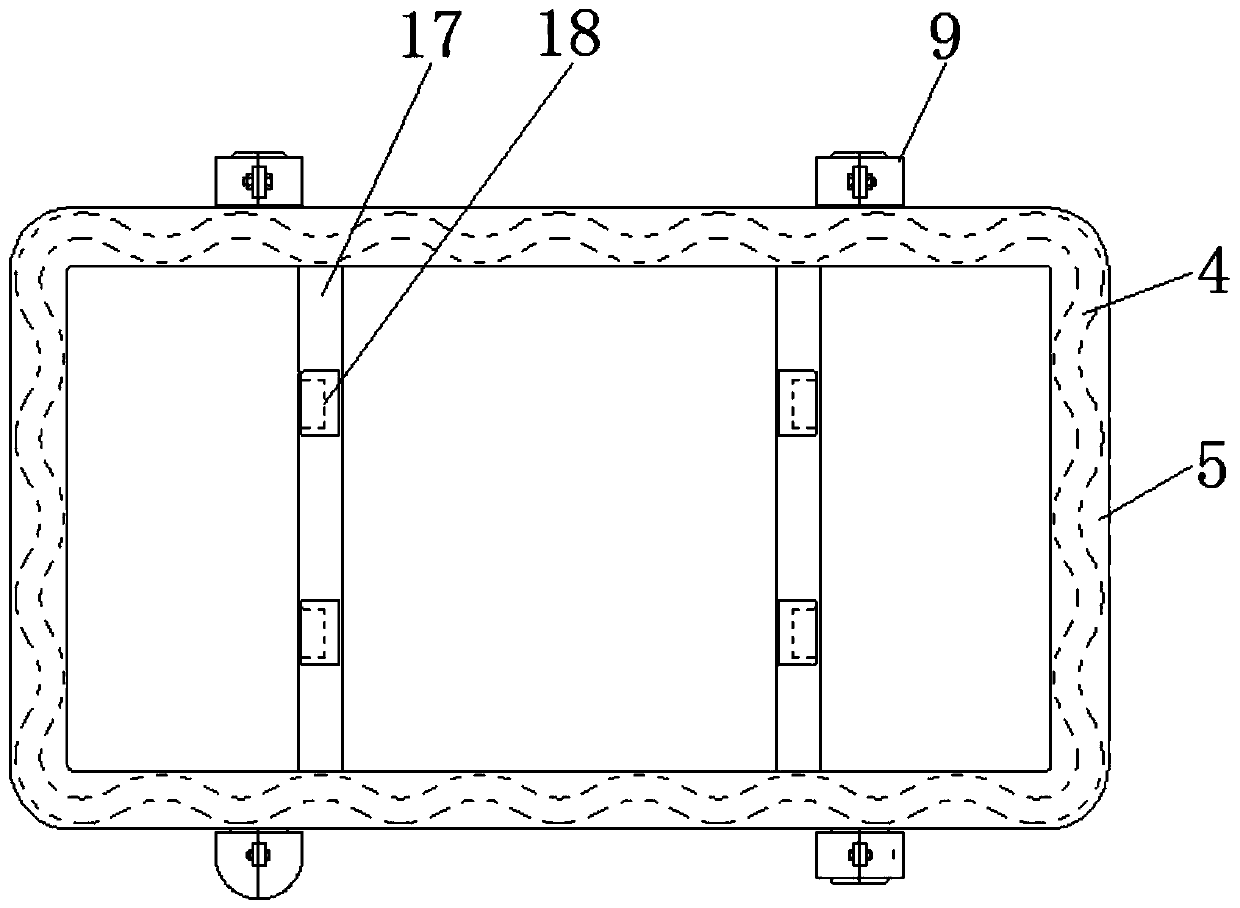

Hoisting and piling structure of container

ActiveCN101402414AStrengthen connectionAvoid assembly process problemsLarge containersEngineeringMechanical engineering

The invention relates to a hoisting and stacking structure of a container, which comprises a corner post, a top angle piece and a bottom angle piece arranged on the top and the bottom of the corner post respectively, wherein a first ear is arranged on the top angle piece extending downwardly; a second ear is arranged on the bottom angle piece extending upwardly; and the first ear and the second ear both extend into the corner post and are welded with the inner surface of the corner post. The hoisting and stacking structure of the container increases the weld length between the corner post and the top angle piece, as well as the bottom angle piece, so as to strength the connecting between among the corner post and the top angle piece as well as the bottom angle piece. Because of the simple plane fit between the first ear together with the second ear and the corner post, the problem of imprecise assembly can not happen; moreover, even if the precisions of the top angle piece and bottom angle piece are reduced, the assembly of the corner post can not be affected, thereby avoiding the problem of the assembly process caused by the difference of casting the angle piece, and ensuring the convenient and simply assembly of the angle piece with ears and the corner post.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

Connecting structure of side wall stand column and underframe boundary beam, vehicle body and rail vehicle

ActiveCN111348063AIncrease weld lengthImprove connection strengthRailway transportAxle-box lubricationWeld seamChassis

Owner:CRRC TANGSHAN CO LTD

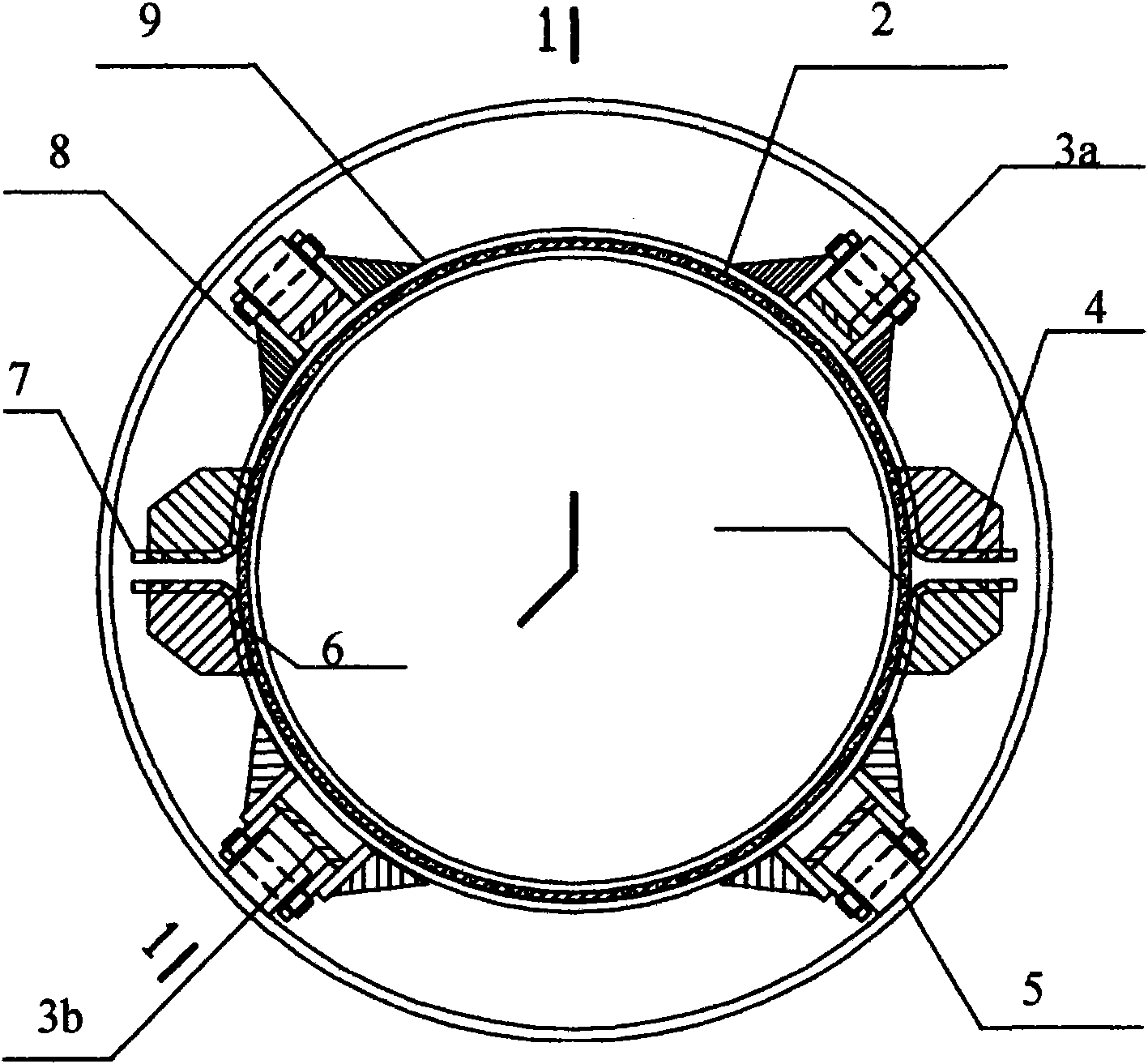

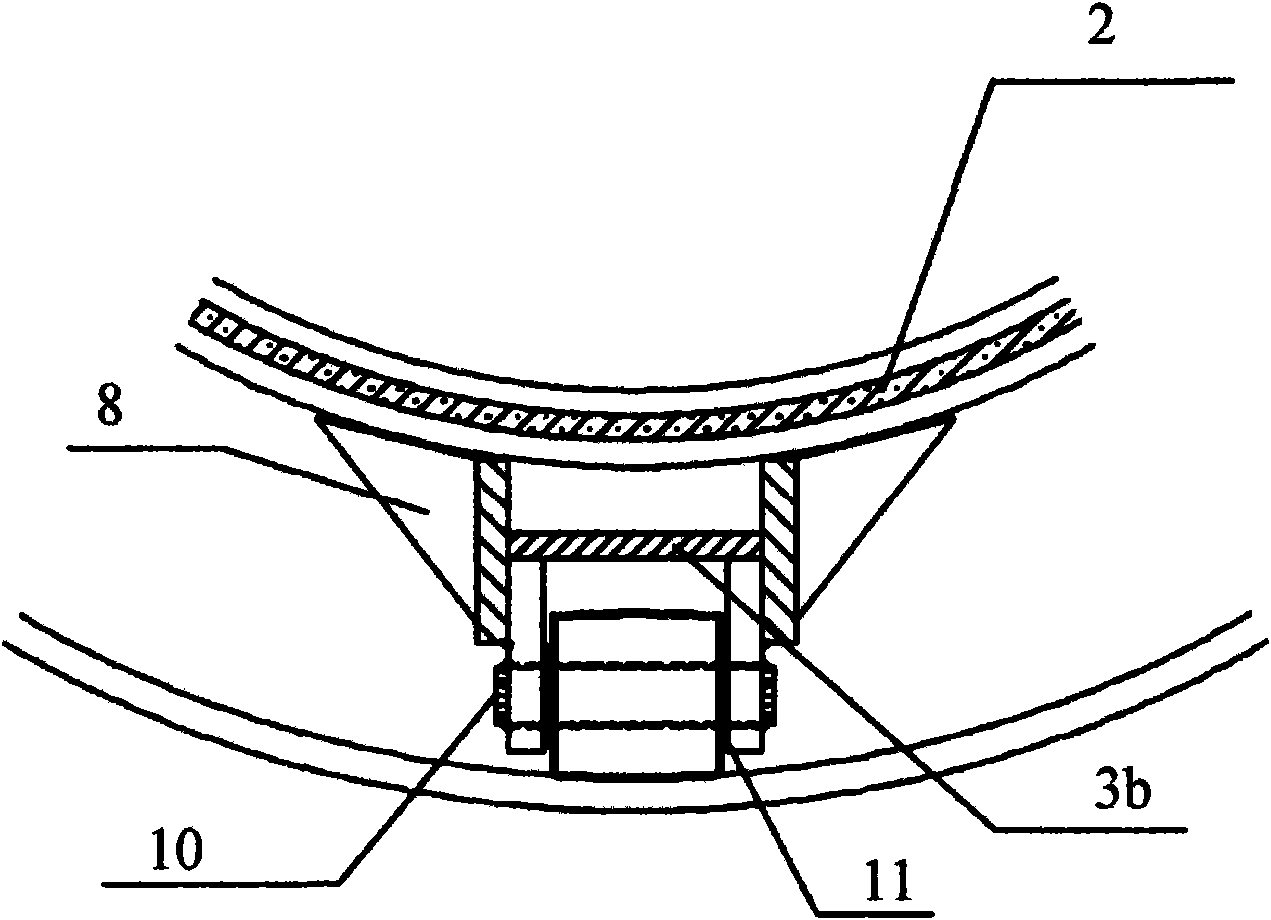

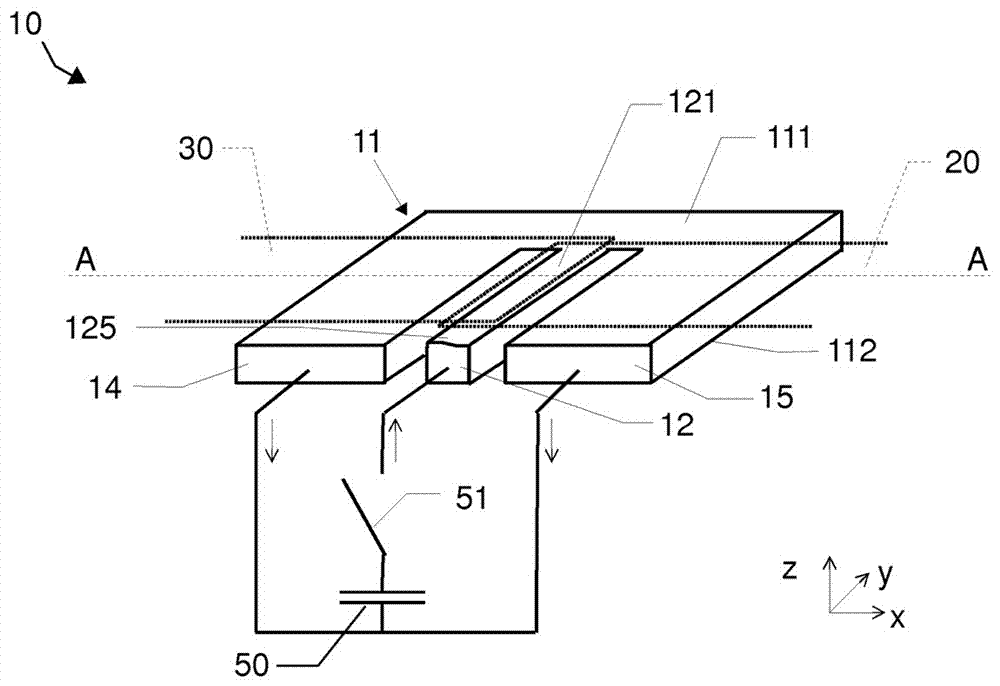

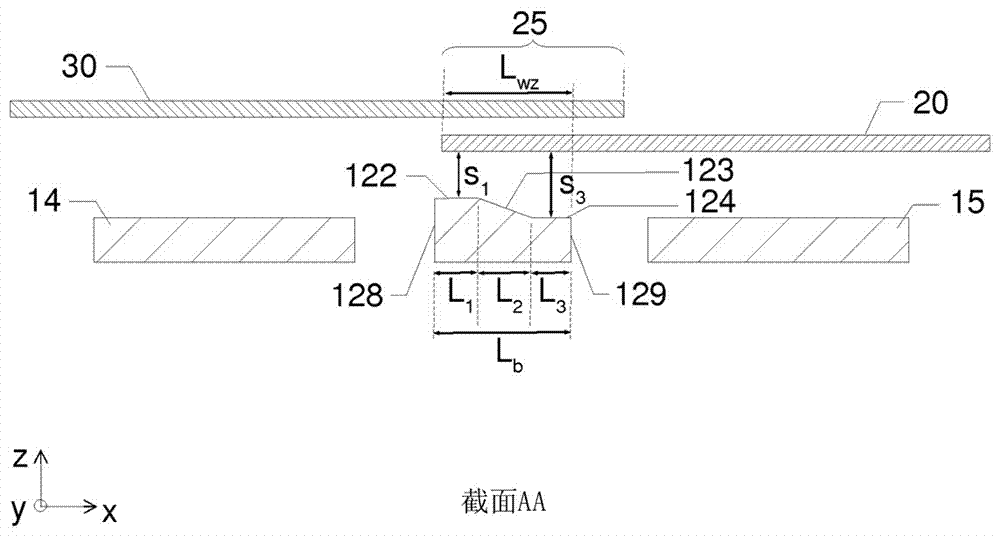

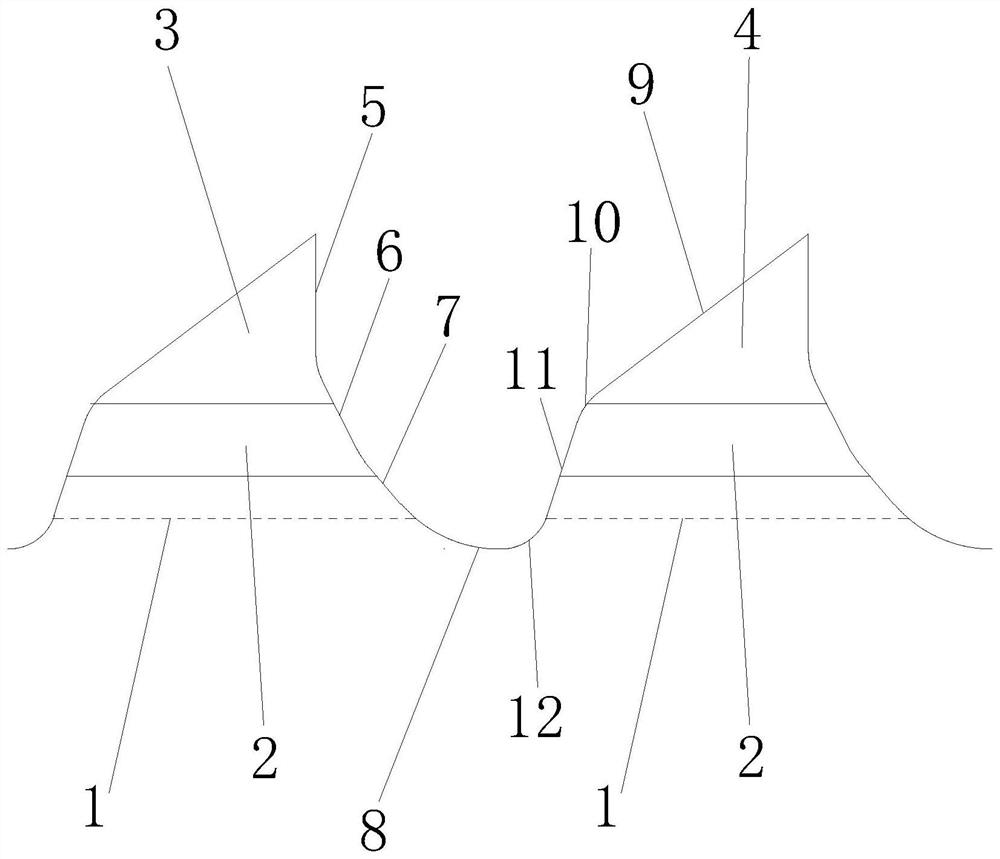

Coil for magnetic-pulse welding of flat parts and related welding method

InactiveCN107000113AIncrease weld lengthHigh mechanical strengthCoil arrangementsMetal working apparatusEngineeringMaterials science

The invention relates to a coil (10) for magnetic-pulse welding of parts comprising an active portion (125), one surface, referred to as the active surface (121), of which is intended to be arranged opposite one of the parts, at an area of overlap between the parts. The active surface (121) has, across the width thereof Lb, an angled profile such that the active surface is intended to have a non-zero angle in relation to a plane (XY) along which, at least at the working area, the part nearest to the active surface extends, when the parts are positioned at the coil for welding. The invention also relates to a related magnetic-pulse welding method.

Owner:ADM28有限责任公司

Spindle bracket of torsion beam axle suspension

ActiveUS7832749B2Increase weld lengthIncreased durabilityInterconnection systemsResilient suspensionsEngineeringMechanical engineering

A spindle bracket of a torsion beam axle suspension system is defined on an end portion of a trailing arm to be connected to a hub assembly on which a wheel and a tire are mounted. The spindle bracket may include a first inner bracket that is welded to an inner side and an outer side of an end portion of a upper member of the trailing arm, a second inner bracket that is welded to an inner side and an outer side of an end portion of a lower member of the trailing arm, and an outer bracket that is attached to the first and second inner brackets to be engaged with the hub assembly in company with the first and second inner brackets.

Owner:HYUNDAI MOTOR CO LTD

Manufacturing method of combustion chamber for silver-zinc battery

InactiveCN102544557AIncrease the installation locationOptimize the installation methodFuel cellsCombustion chamberEffective length

The invention relates to a manufacturing method of a combustion chamber for a silver-zinc battery. The manufacturing method comprises the manufacturing steps of manufacturing a combustion chamber body with a partial-thread air inlet and a full-thread air outlet; manufacturing a joint of a full-thread air inlet and a full-thread air outlet; adjusting the threaded connection position of an air guide tube with two ends in threaded connection with the air outlet of the combustion chamber body and the air inlet of the joint according to a mounting position, and then welding the connection parts between the air guide tube and the combustion chamber as well as the joint by silver brazing; and then bluing to complete the manufacturing of the combustion chamber for the silver-zinc battery. According to the invention, the two ends of the air guide tube are in threaded connection with the air outlet of the combustion chamber body and the air inlet of the joint respectively, so that the adjustability of the mounting position and the mounting mode are improved; a lug boss is adopted at the outer end of the air outlet of the combustion chamber body, so that the effective length of the threaded connection is increased; the ports of the air outlet of the combustion chamber body and the air inlet of the joint are conical, so that the welding length of the silver brazing is increased; and the reliability of the combustion chamber is improved when a gas generator works.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Spindle bracket of torsion beam axle suspension

InactiveCN101633298AIncreased durabilityIncrease weld lengthInterconnection systemsResilient suspensionsMechanical engineeringBeam axle

A spindle bracket of a torsion beam axle suspension system is defined on an end portion of a trailing arm to be connected to a hub assembly on which a wheel and a tire are mounted. The spindle bracket may include a first inner bracket that is welded to an inner side and an outer side of an end portion of a upper member of the trailing arm, a second inner bracket that is welded to an inner side and an outer side of an end portion of a lower member of the trailing arm, and an outer bracket that is attached to the first and second inner brackets to be engaged with the hub assembly in company with the first and second inner brackets.

Owner:HYUNDAI MOTOR CO LTD

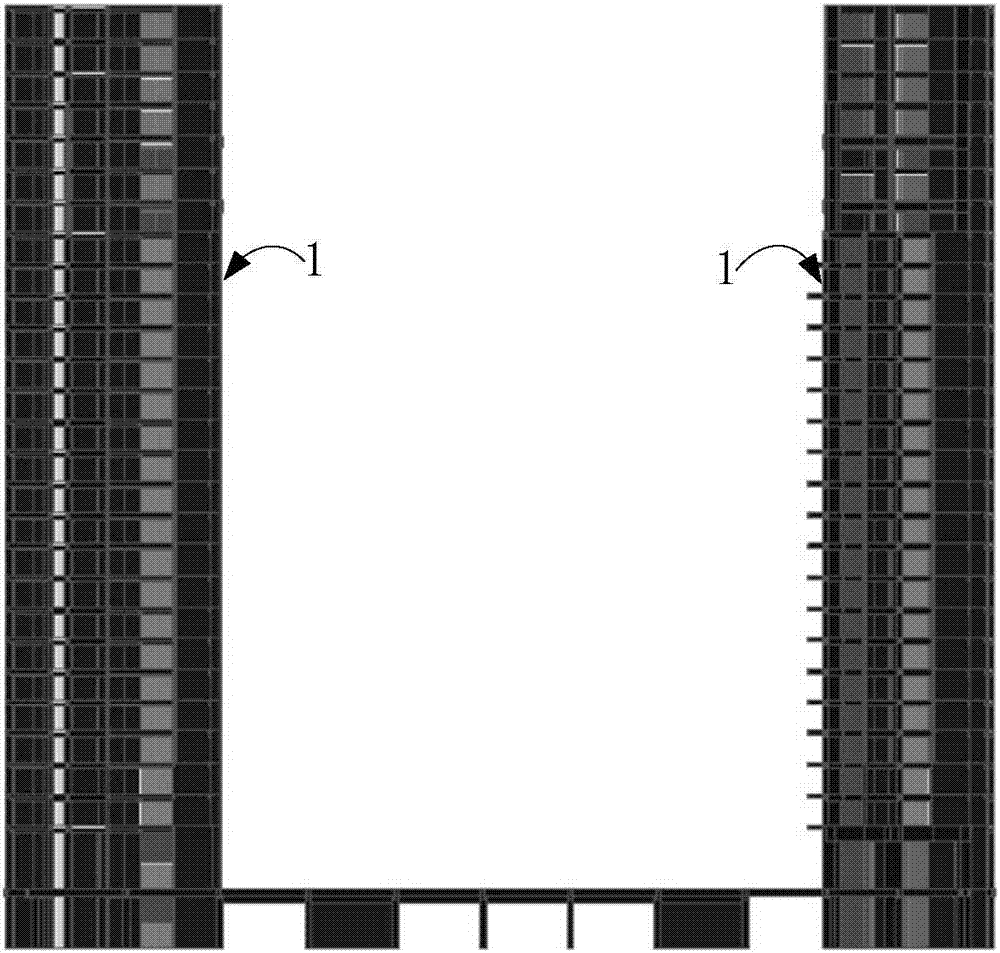

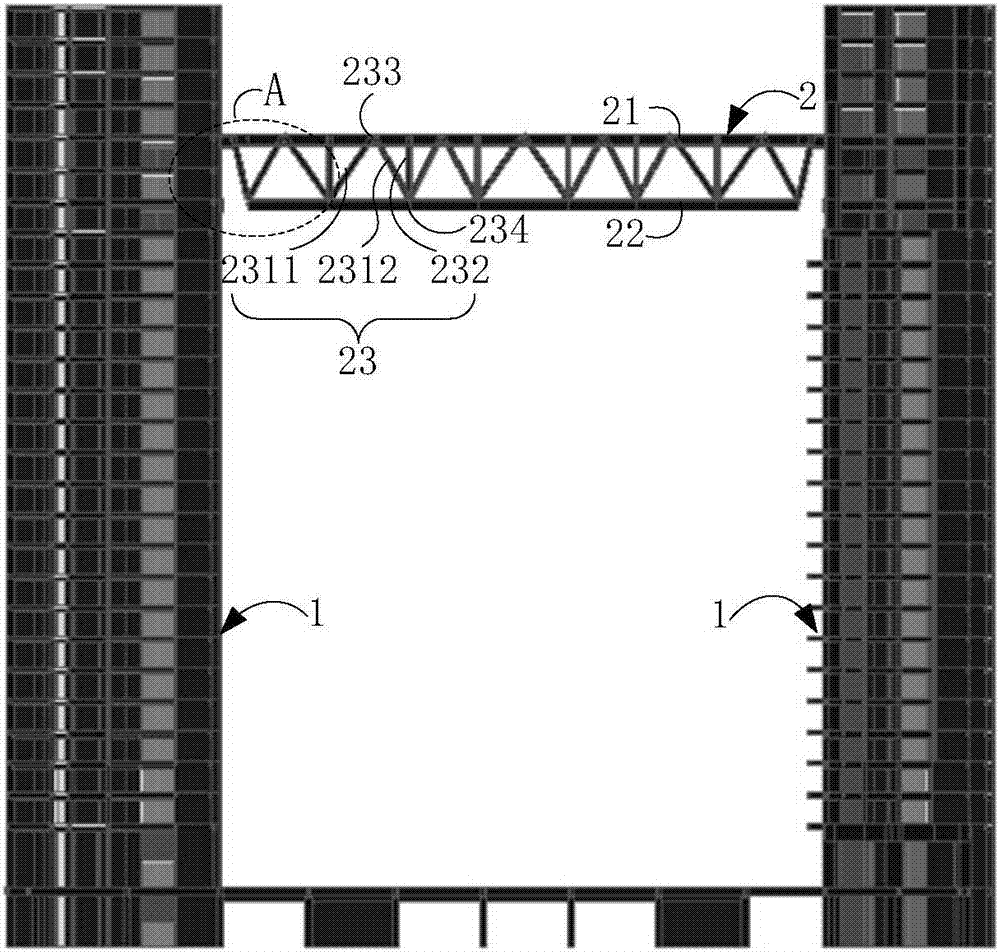

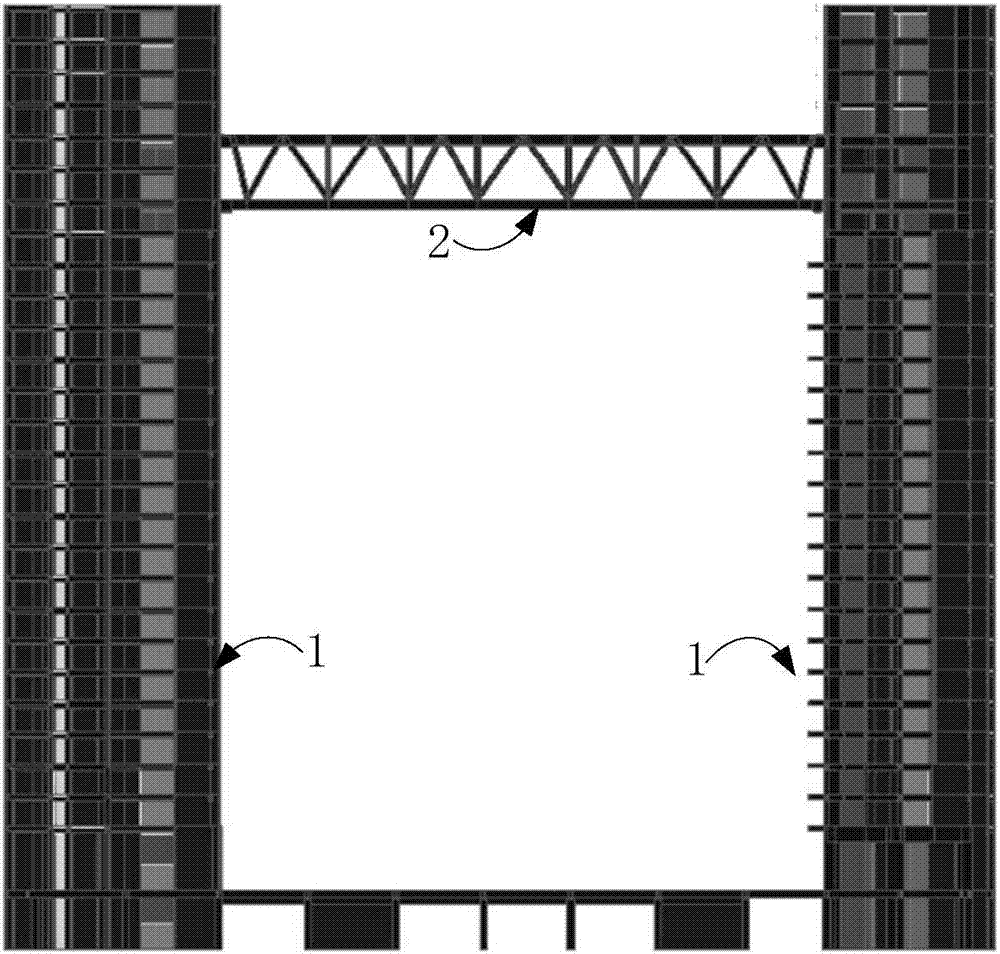

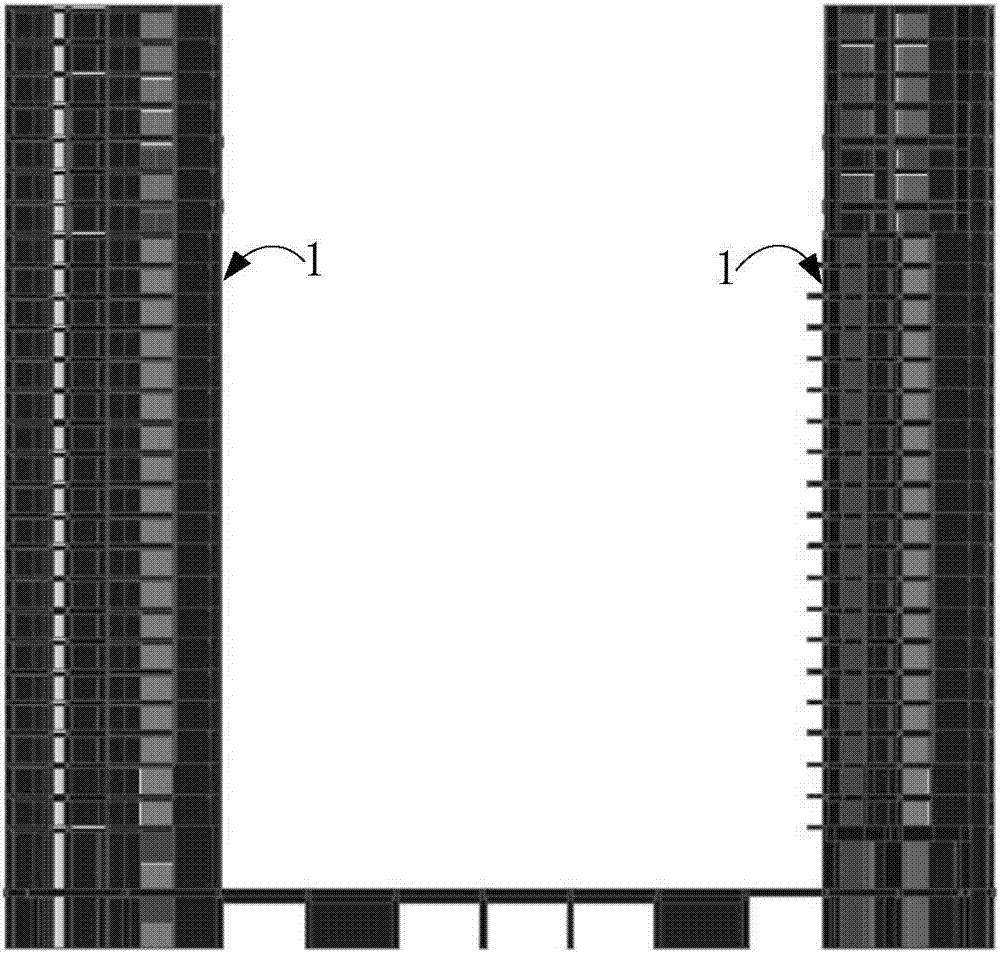

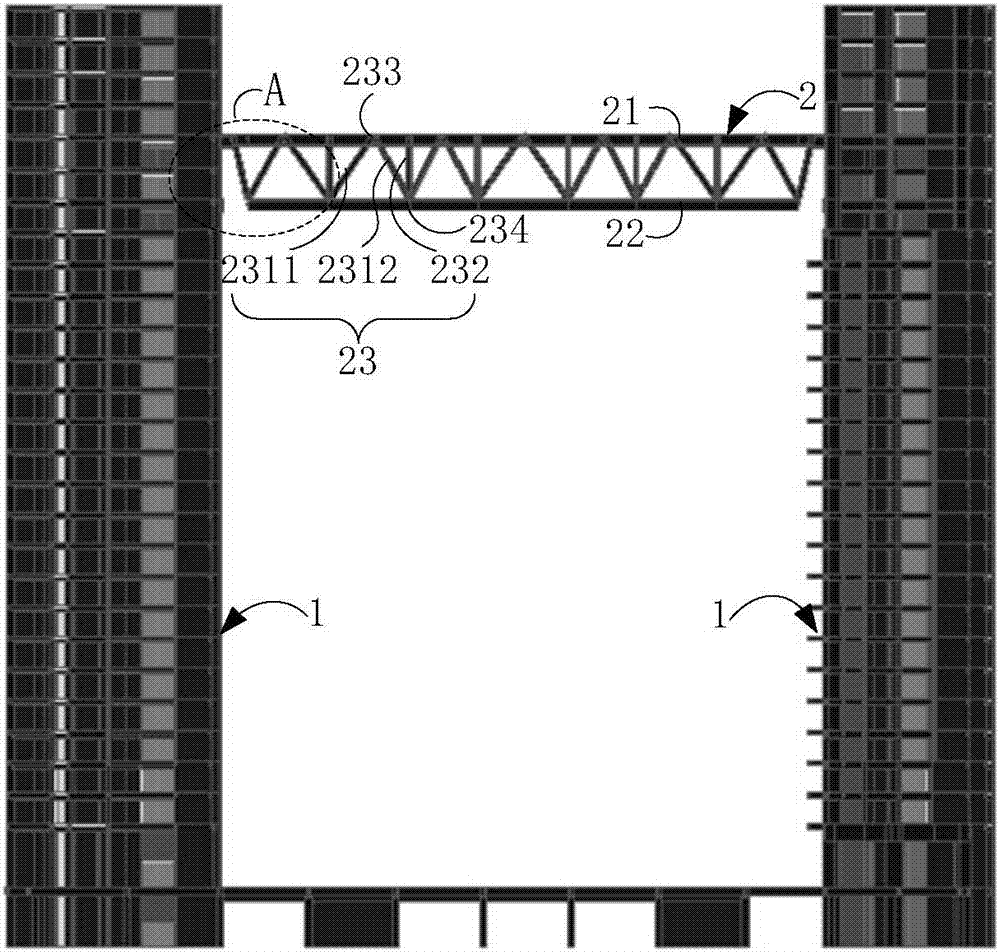

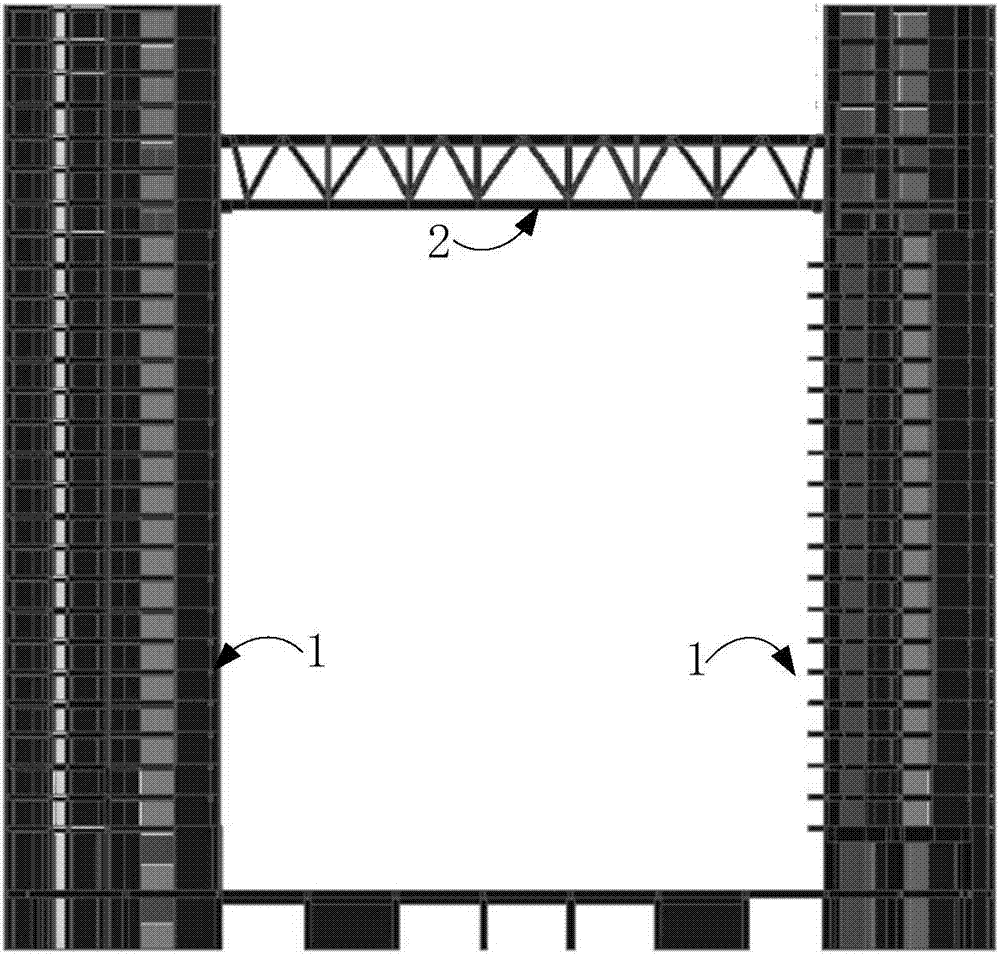

Connected structure building

ActiveCN106930557ATake advantage ofImprove securitySpecial buildingProtective buildings/sheltersStructure building

The invention relates to the technical field of building structure engineering, in particular to a connected structure building. The connected structure building comprises at least two main structures arranged in a spaced mode, and a connection body truss fixedly connected between the main structures, wherein the connection body truss comprises an upper chord member, a lower chord member and a web member connected between the upper chord member and the lower chord member. The connected structure building is obtained according to the following construction method. The method comprises the steps that end parts on the two sides of the upper chord member are hinged to to-be-connected portions on the main structures correspondingly; the end portions of the two sides of the lower chord member are disengaged from the to-be-connected portions on the main structures correspondingly; standing is conducted, the connection body truss is bent and deformed under the action of gravity loads, and the end portions of the two sides of the upper chord member rotate; and the end portions, finishing rotation, of the two sides of the upper chord member are rigidly connected with the to-be-connected portions on the main structures, and the end portions of the two sides of the lower chord member are rigidly connected with the to-be-connected portions on the main structures correspondingly. The connected structure building has the excellent anti-seismic property and can sufficiently use truss materials.

Owner:深圳华森建筑与工程设计顾问有限公司

Catalytic cracking regeneration flue gas water-sealed tank and method for preventing inner barrel from deformation

InactiveCN103899794AIncrease weld lengthGood for axial thermal expansionValve arrangementsFlue gasThermal expansion

The invention belongs to the technical field of petroleum processing, and discloses a catalytic cracking regeneration flue gas water-sealed tank and a method for preventing an inner barrel from deformation. The method is characterized in that an axial thermal expansion device is arranged on an overflow port tube of the inner barrel of the water-sealed tank and is composed of a cylindrical inner sleeve, an annular plate plug and a metal bellows, one end of the cylindrical inner sleeve is connected with the inner barrel of the water-sealed tank, the other end of the cylindrical inner sleeve is connected with the annular plate plug with an inner hole, and the inner hole of the annular plate plug is fixedly connected with the outer wall of the metal bellows communicated with the overflow port tube; a circumferential thermal expansion device which deforms under stress to absorb heating circumferential expansion of the inner barrel is arranged on the circumference of a wallboard of the inner barrel of the water-sealed tank. By the adoption of the catalytic cracking regeneration flue gas water-sealed tank and the method for preventing the inner barrel from deformation, axial expansion caused by heating of the inner barrel can be effectively absorbed, circumferential expansion caused by heating of the inner barrel can also be effectively absorbed, the problems that an inner barrel of an existing water-sealed tank expands and deforms under heat and can only be forced to protrude inwards, and then permanent deformation is generated are solved, the inner barrel is prevented from damage, and the service life of the inner barrel is prolonged.

Owner:洛阳汇通石化工程有限公司

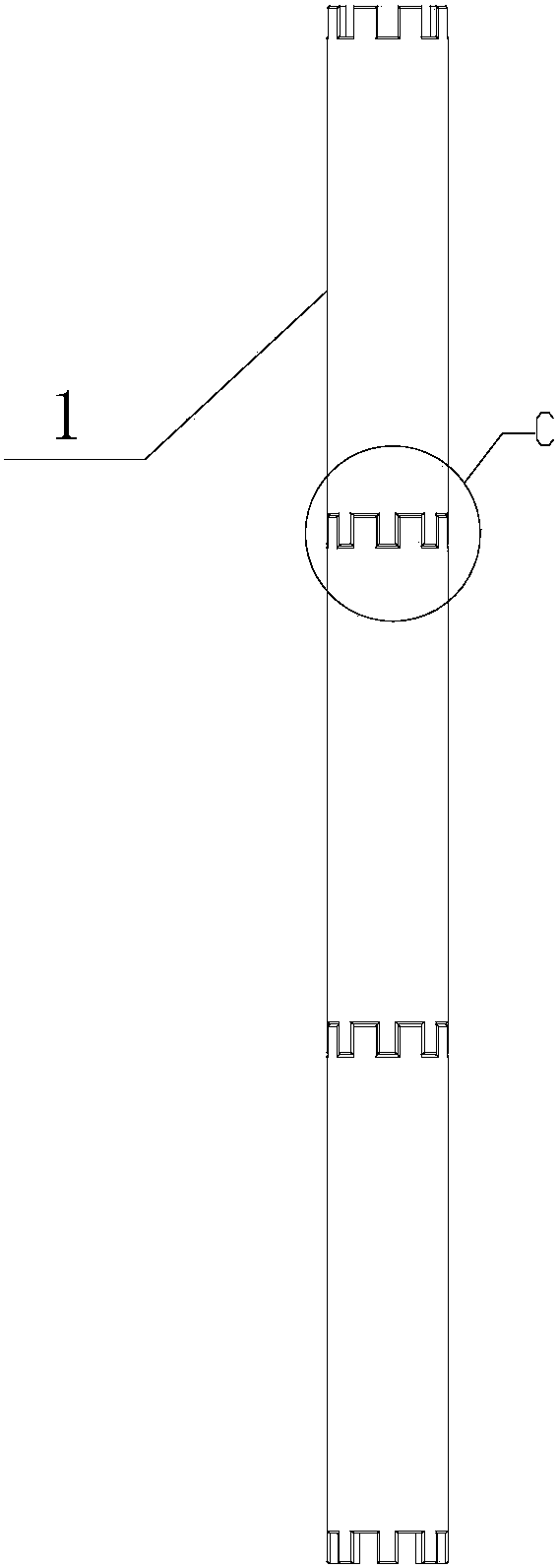

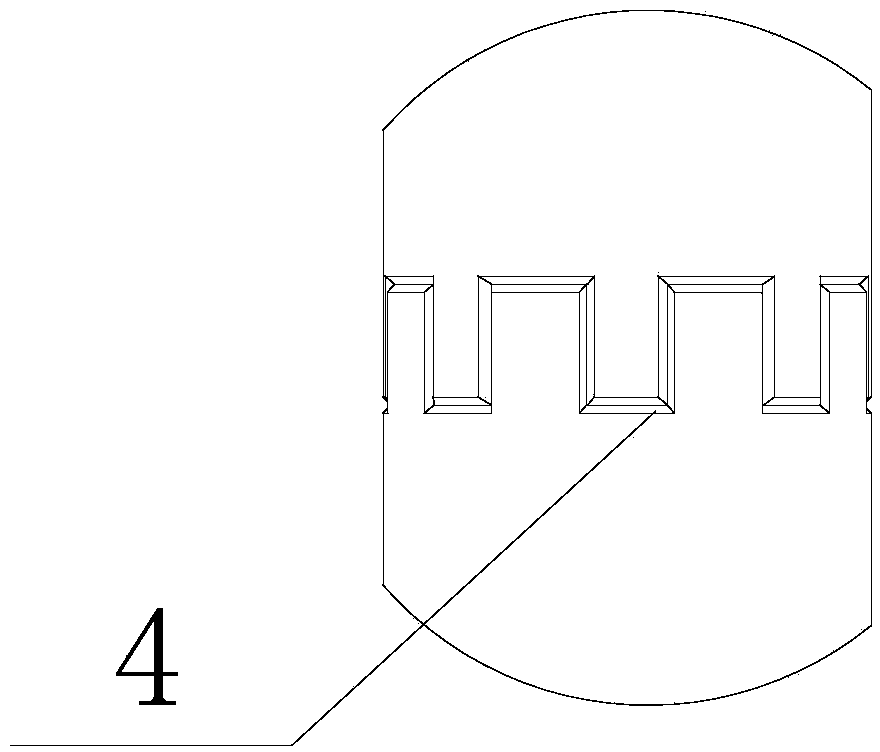

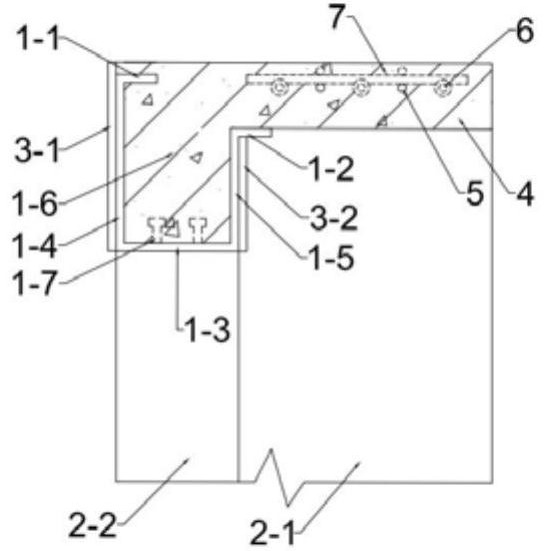

Rectangular butt-welded seam steel pipe for communication tower

The invention discloses a rectangular butt-welded seam steel pipe for a communication tower. The rectangular butt-welded seam steel pipe comprises at least two steel pipes sequentially arranged in the axial direction of the steel pipes; the adjacent steel pipes are welded at a butt part; rectangular grooves are formed in one of the two ends of each steel pipe in the axial direction, and rectangular lug bosses are arranged at the other end of the steel pipe; the rectangular grooves and the rectangular lug bosses are uniformly distributed in the circumferential direction of each steel pipe; the rectangular lug bosses at a connecting part of any two adjacent steel pipes can be inserted into the rectangular grooves; a rectangular connector at the connecting part of the two adjacent steel pipes is welded in the edge direction of the connector. According to the technical scheme of the rectangular butt-welded seam steel pipe, the weld seam length is increased, the welding strength is increased, the tightness is good, the overall strength is high through the meshing of the grooves and the lug bosses, the assembling is simple and convenient, the working efficiency is improved, and the appearance is aesthetic; the rectangular butt-welded seam steel pipe is safer and more reliable, simple in processing, low in dimensional precision requirement and convenient to maintain, and lowers the cost.

Owner:NANJING JOOZ INFORMATION SCI & TECH

Construction method of connected structure building

ActiveCN106906896ATake advantage ofImprove securityBuilding material handlingStructure buildingCivil/structural engineers

The invention relates to the technical field of building structure engineering, in particular to a construction method of a connected structure building. The connected structure building comprises at least two major structures which are arranged in a spaced mode and a connective truss fixedly connected between the major structures; and the connective truss comprises an upper chord member, a lower chord member and a web member connected between the upper chord member and the lower chord member. The construction method of the connected structure building comprises the following steps that the ends of the two sides of the upper chord member are hinged to to-be-connected parts on the major structures correspondingly, and the ends of the two sides of the lower chord member break away from the to-be-connected parts on the major structures correspondingly; still standing is conducted, the connective truss is bent and transformed under the gravity load effect, and the ends of the two sides of the upper chord member rotate; and the ends of the two sides of the upper chord member after rotating are connected with the to-be-connected parts of the major structures in a rigid mode, and the ends of the two sides of the lower chord member are connected with the to-be-connected parts of the major structures in a rigid mode correspondingly. Through the construction method of the connected structure building, the connected structure building with an excellent anti-seismic property can be obtained, and a truss material can be sufficiently used.

Owner:深圳华森建筑与工程设计顾问有限公司

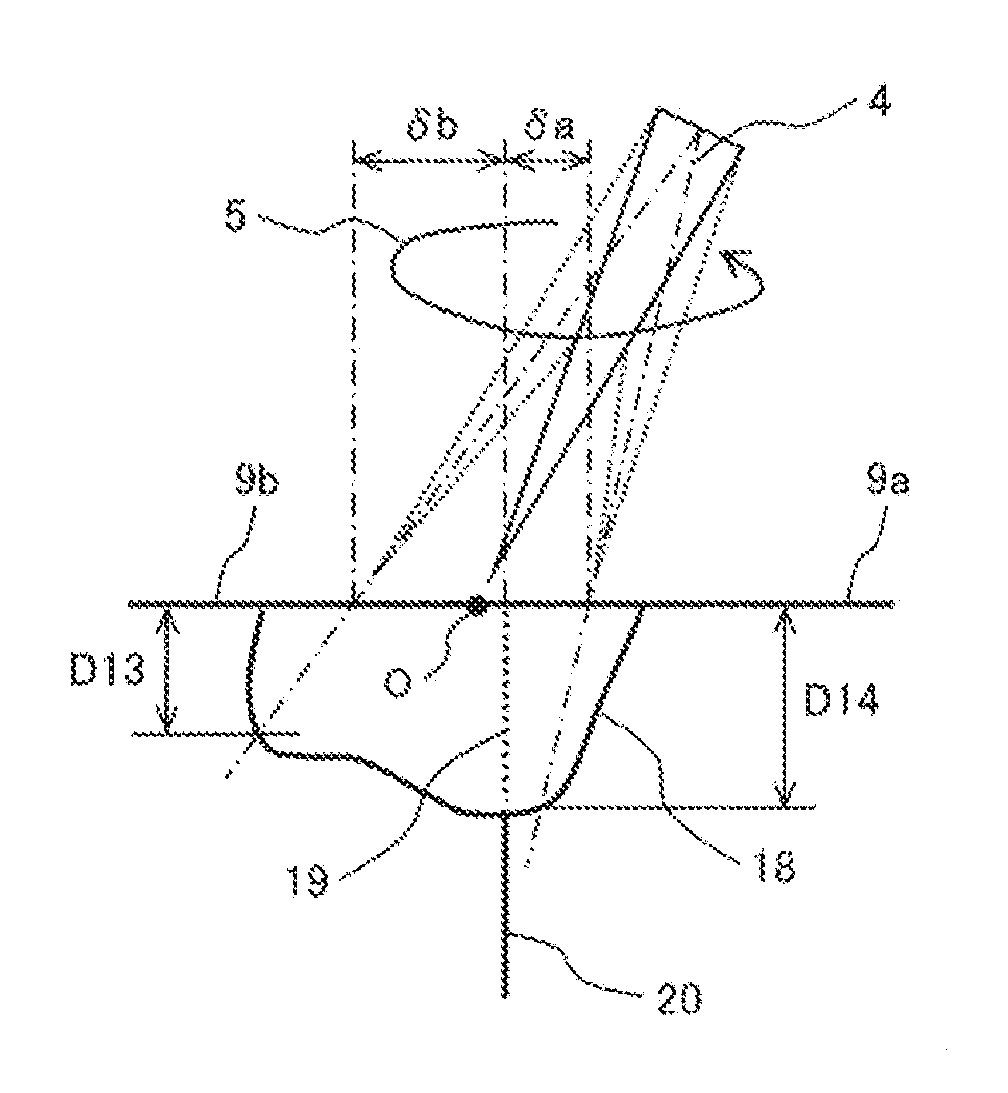

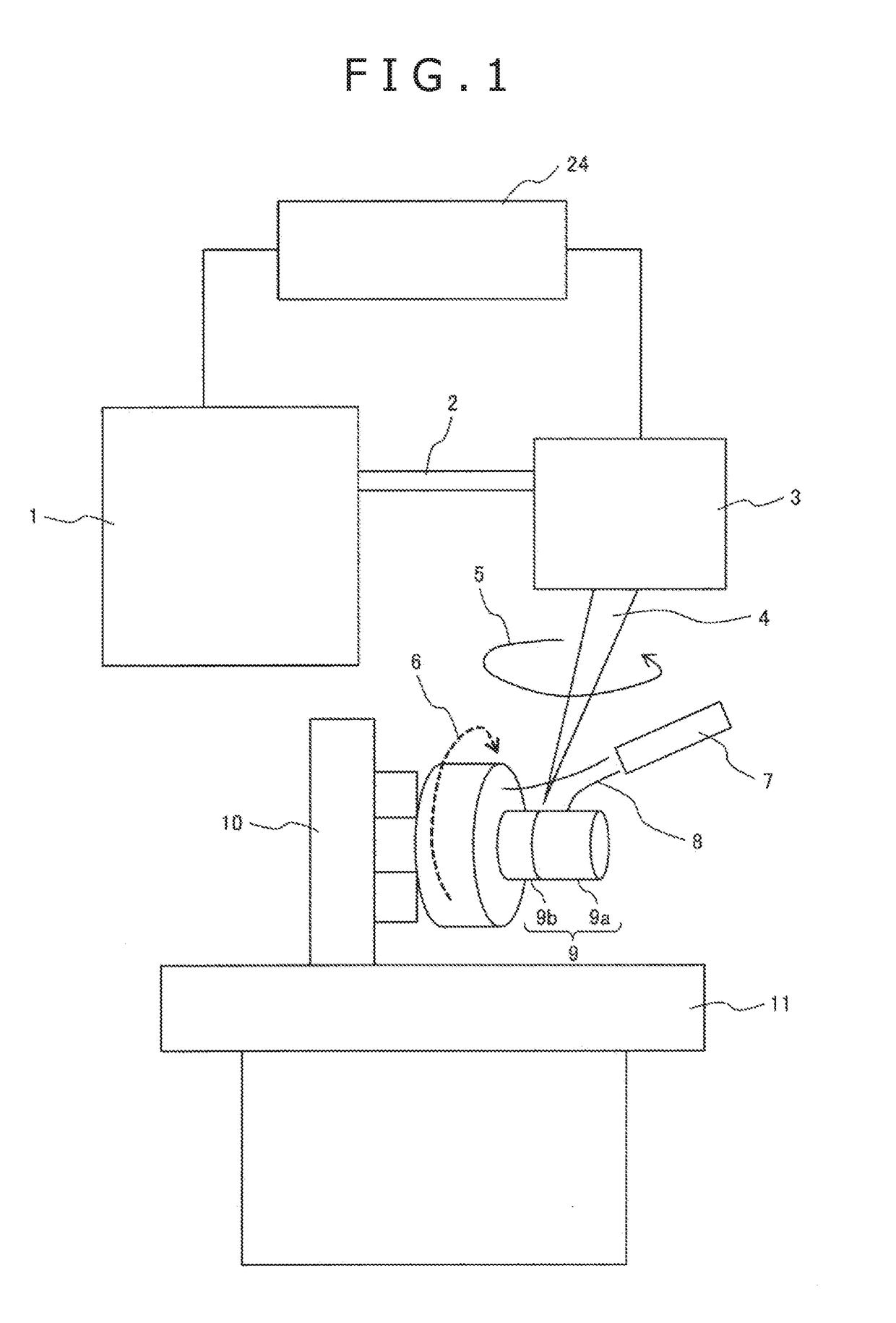

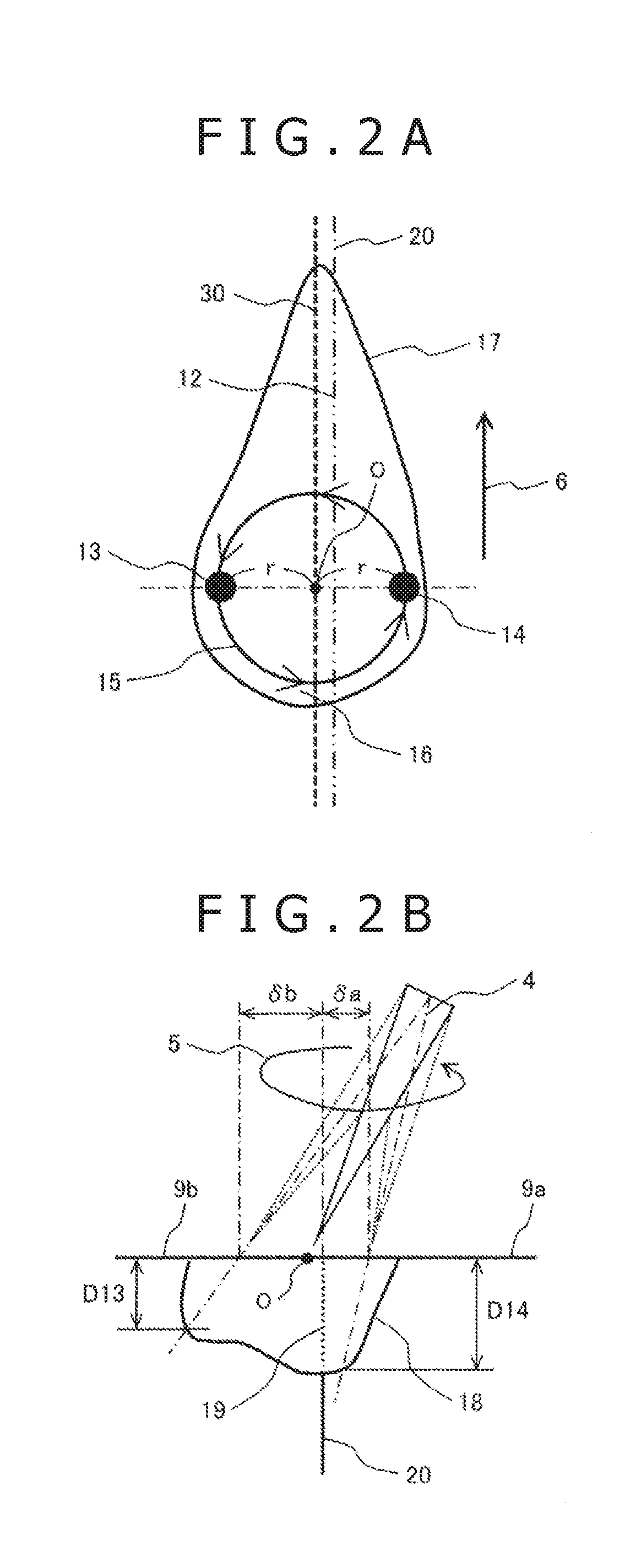

Laser welding method, high pressure fuel supply pump, and fuel injection valve

InactiveUS20180193951A1Increase weld widthImprove position toleranceVehicle componentsMetal working apparatusEngineeringHigh pressure

It is an object of the present invention to provide a laser welding method making it possible to secure the effective welding length when the laser beam is applied obliquely. In a laser welding method in which oscillation scanning is periodically effected with a laser beam 4 while moving an object of welding 9 to apply the laser beam to a surface of the object of welding 9 to perform welding, at least one of the output of the laser beam 4, a scanning speed, and a scanning track is controlled, whereby welding is effected with input heat amounts on both left and right sides with respect to the welding progressing direction being substantially different from each other.

Owner:HITACHI AUTOMOTIVE SYST LTD

Air sac mounting bracket for automobile co-pilot position

ActiveCN103640544AIncrease weld lengthImprove reliabilityPedestrian/occupant safety arrangementEngineeringMechanical engineering

The invention relates to an air sac mounting bracket for an automobile co-pilot position. The air sac mounting bracket is a stamping part molded by integral punch forming and comprises a transverse bracket body plate adapted to an instrument board beam, a transition plate extending upwards from the middle section of the upper edge of the bracket body plate, and an instrument board connecting plate connected with the upper edge of the transition plate and bent to face towards the rear side, wherein the bracket body plate is provided with an air sac mounting hole, the instrument board connecting plate is provided with instrument board connecting holes, the left side edge and the right side edge of the air sac mounting bracket are provided with a turning edge facing towards the rear side respectively, each turning edge extends from the end of the lower edge of the bracket body plate to the end of the upper edge of the instrument board connecting plate, and a weakening notch is formed in a position, adjacent to a bent part between the transition plate and the instrument board connecting plate, of each turning edge. The air sac mounting bracket has proper strength and stiffness. Not only can enough strength and stiffness of the air sac mounting bracket be guaranteed, but also overlarge stiffness of internal protruding objects of automobiles can be avoided, and requirements of laws and regulations of nations for internal protruding objects of passenger vehicles are met.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method for welding upper rail of seat track for vehicle seat and adaptor bracket

InactiveCN104602861AImprove welding strengthSave man hoursSeat framesWelding/soldering/cutting articlesCouplingEngineering

The present invention relates to a method for welding an upper rail of a seat track for a vehicle seat and an adaptor bracket for fixing a seat frame, the method comprising the steps of: surface contacting a bottom surface of a plate-shaped coupling face, which forms the lower end part of the adaptor bracket and which is extended to a predetermined length in the longitudinal direction, with a top surface of a plate-shaped horizontal face, which forms the upper end part of the upper rail and which is extended in the longitudinal direction; and welding a bottom surface of the horizontal face that overlaps the coupling face to bond the coupling face and the horizontal face. Accordingly, it is possible to improve the welding hardness of the upper rail of the seat track and the adaptor bracket, and to significantly reduce the time required for welding, compared to conventional welding methods in which welding is performed along the edge of the coupling face.

Owner:AUSTEM CO LTD

Integrated wheel type six-component sensor adaptive wheel rim

InactiveCN107757248AHigh precisionHigh dimensional accuracyRimsWeighing apparatus detailsData acquisitionUltimate tensile strength

An integral wheel-type six-component force sensor is adapted to a wheel rim. Consists of rim sensor mounting flange and spokes (optional). The product is formed by forging, spinning or casting process, and the finished product is a continuous, uniform and dense whole, with no internal interface and seam. Compared with the welded wheel type six-component force sensor adapted rim, the integral wheel type six-component force sensor adapted rim has the characteristics of high precision, high strength, heat dissipation and beauty. The use of an integral wheel-type six-component force sensor to adapt the rim can improve the accuracy of vehicle road load data measurement and collection; expand the range of road data measurement and collection to more severe road conditions with greater load; at the same time, it is also important for sensors and braking systems. Provides better protection.

Owner:上海守衡机械设备有限公司

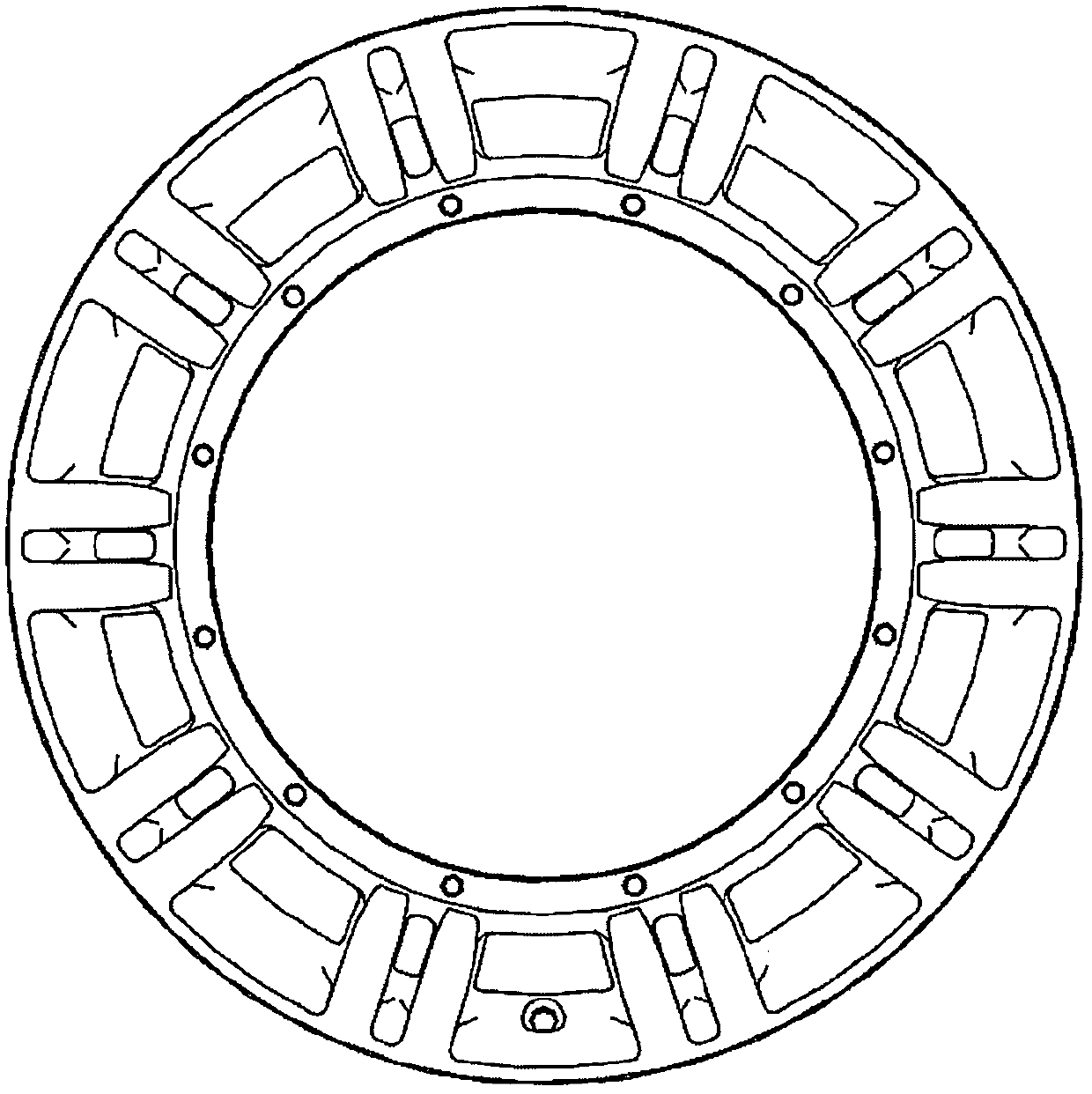

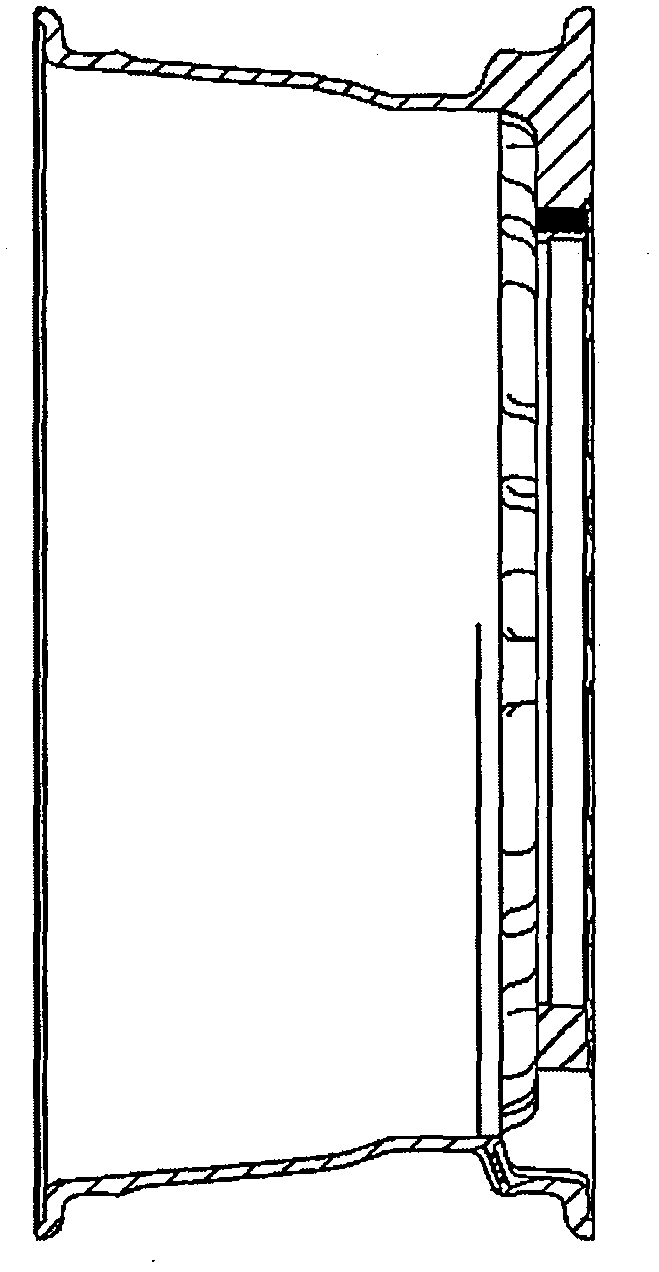

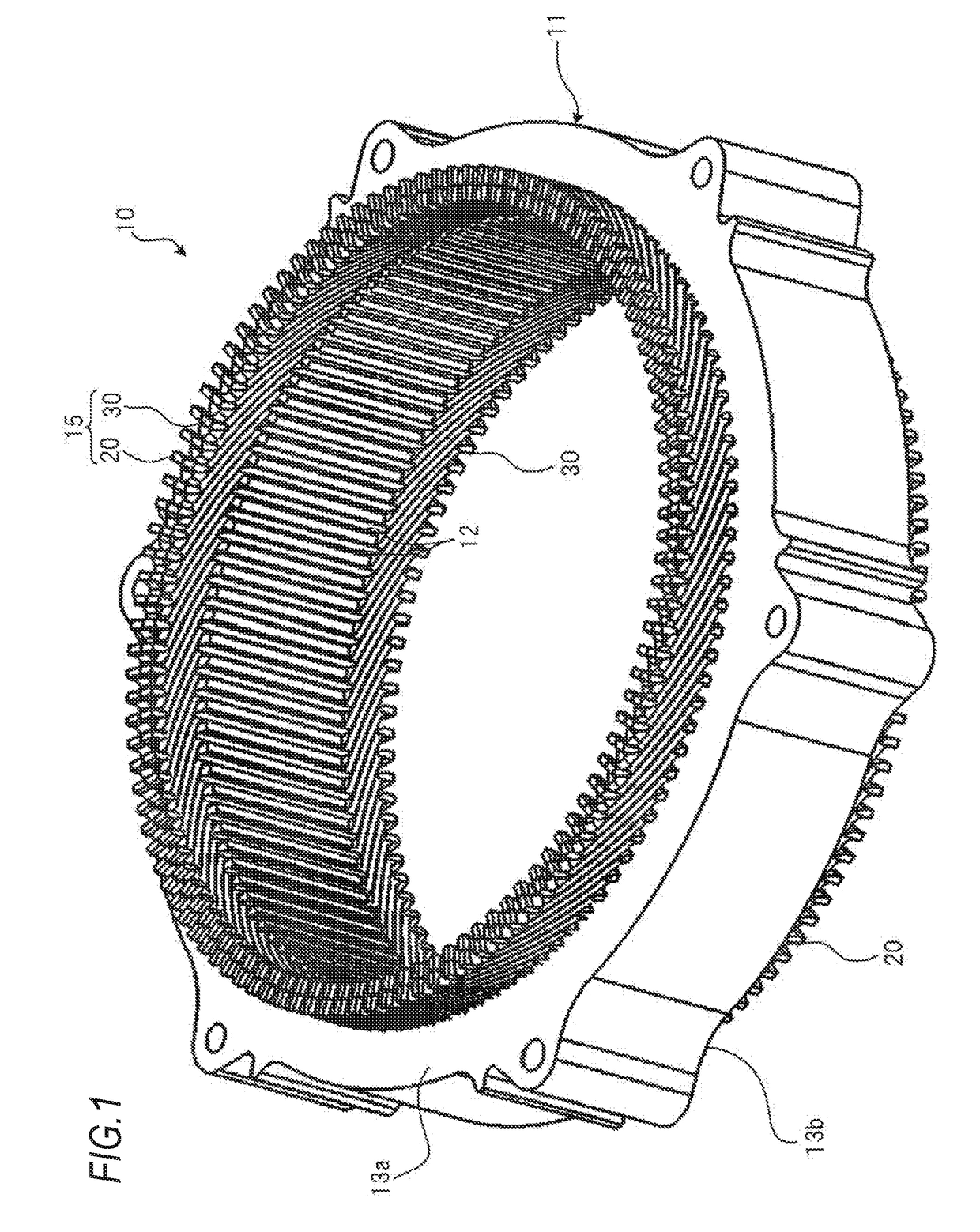

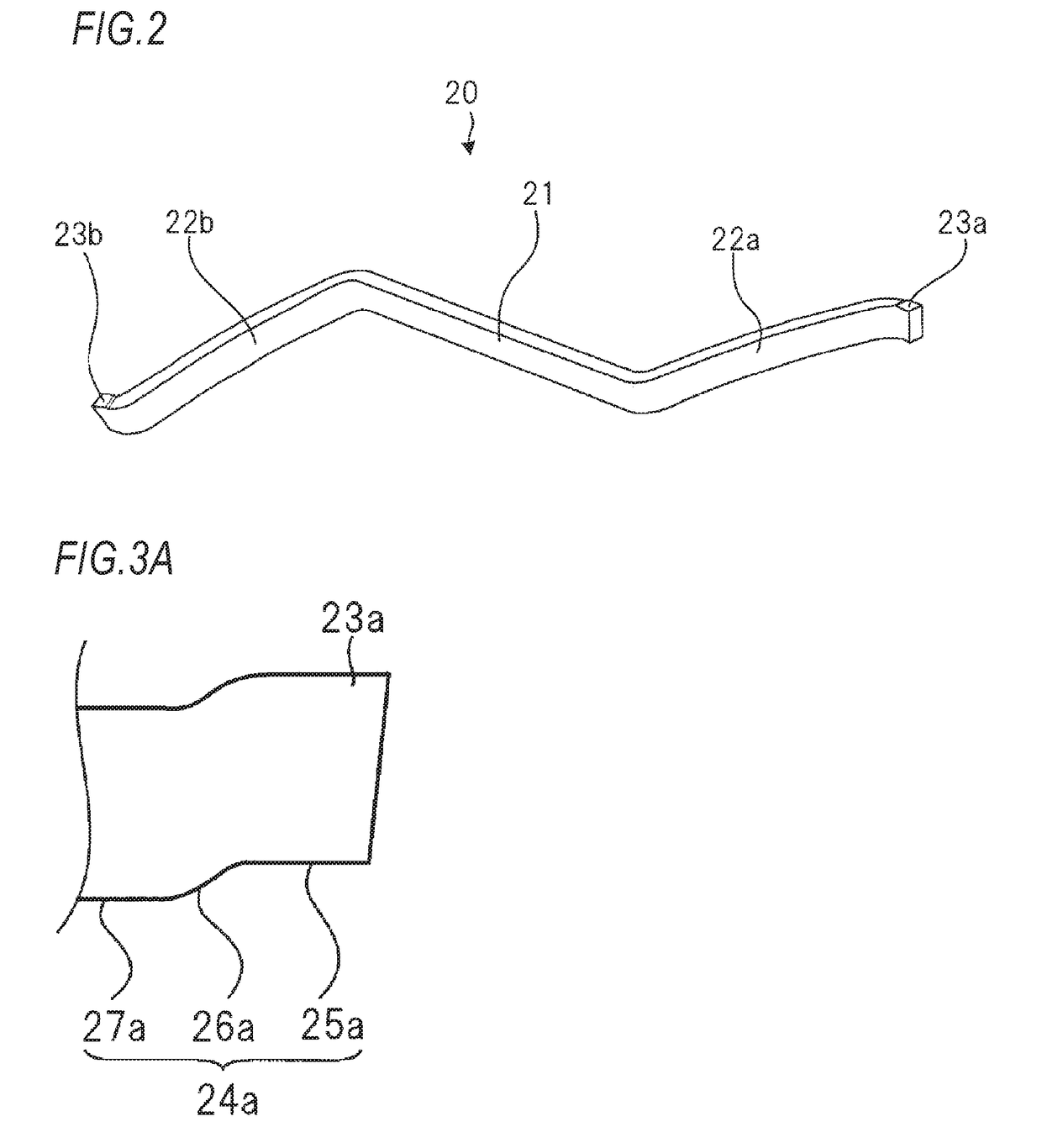

Stator for rotary electric machine

InactiveUS20190013704A1Increase weld lengthReduce resistanceMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineEngineering

A stator for a rotary electric machine includes: a stator core; and a coil including a plurality of first coil segments and a plurality of second coil segments; a first coil segment of the plurality of first coil segments includes an insertion portion and a protrusion portion; a second coil segment of the plurality of second coil segments includes an insertion portion and a protrusion portion; the end portion of the protrusion portion of the first coil segment is joined with the end portion of the protrusion portion of the second coil segment; and abutting surfaces, abutting on each other at the protrusion portion of the first coil segment and the protrusion portion of the second coil segment, include: joining surfaces joined to each other; and bent surfaces that are bent in the same direction with respect to the joining surfaces.

Owner:HONDA MOTOR CO LTD

Manufacturing method of combustion chamber for silver-zinc battery

InactiveCN102544557BIncrease the installation locationOptimize the installation methodFuel cellsCombustion chamberEffective length

The invention relates to a manufacturing method of a combustion chamber for a silver-zinc battery. The manufacturing method comprises the manufacturing steps of manufacturing a combustion chamber body with a partial-thread air inlet and a full-thread air outlet; manufacturing a joint of a full-thread air inlet and a full-thread air outlet; adjusting the threaded connection position of an air guide tube with two ends in threaded connection with the air outlet of the combustion chamber body and the air inlet of the joint according to a mounting position, and then welding the connection parts between the air guide tube and the combustion chamber as well as the joint by silver brazing; and then bluing to complete the manufacturing of the combustion chamber for the silver-zinc battery. According to the invention, the two ends of the air guide tube are in threaded connection with the air outlet of the combustion chamber body and the air inlet of the joint respectively, so that the adjustability of the mounting position and the mounting mode are improved; a lug boss is adopted at the outer end of the air outlet of the combustion chamber body, so that the effective length of the threaded connection is increased; the ports of the air outlet of the combustion chamber body and the air inlet of the joint are conical, so that the welding length of the silver brazing is increased; and the reliability of the combustion chamber is improved when a gas generator works.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Rail type welding device for pipeline

ActiveCN113977148AIncrease weld lengthReduce intensityWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingStructural engineering

The invention relates to a rail type welding device for a pipeline, which comprises a welding machine, a rail assembly, an anti-oxidation mechanism and a plurality of sets of bearing mechanisms, and is characterized in that the welding machine is located on the side of the rail assembly, and the welding machine is in sliding connection with the rail assembly; the bearing mechanism is connected to the upper portion of the rail assembly in a sliding mode, the anti-oxidation mechanism is located at one end of the rail assembly, the height of the bearing mechanism in the device can be automatically adjusted, the distance between two bearing wheels of the bearing mechanism can be adjusted, and the welding device can be suitable for welding pipelines with different diameters. And axial and circumferential welding of the pipeline can be achieved, and the equipment universality is high.

Owner:GUANGDONG JINYISHENG SPECIAL MATERIAL CO LTD

Steel-concrete composite beam and concrete filled steel tubular column joint and construction method

PendingCN113216380AConvenient and effective heat preservationConvenient and effective decorationBuilding constructionsFloor slabWeld seam

The invention discloses a steel-concrete composite beam and concrete filled steel tubular column joint and a construction method, relates to a composite joint and a joint construction method, and aims to solve the problems that when a U-shaped steel-concrete composite beam is connected with a T-shaped or L-shaped concrete filled steel tubular column in an existing frame joint, an outer side upper flange is turned outwards, and the use function is seriously influenced; and meanwhile, when the U-shaped steel-concrete composite beam is connected with the T-shaped or L-shaped concrete filled steel tubular column, the end of a longitudinal stressed steel bar in a reinforced concrete floor is directly welded to the concrete filled steel tubular column, a steel tube has relatively large residual stress, the plasticity is reduced, when the stress is relatively large, the steel bar transmits force to a welding seam, the concrete filled steel tubular column is torn and damaged at the welding position, and the huge potential safety hazard is brought. The concrete filled steel tubular column is vertically arranged, one end of the steel-concrete composite beam and one end of a reinforced concrete plate are both fixed to the outer side wall of the concrete filled steel tubular column, and two connecting end plates are installed on the steel-concrete composite beam and the concrete filled steel tubular column. The invention belongs to the field of building structures.

Owner:HARBIN INST OF TECH

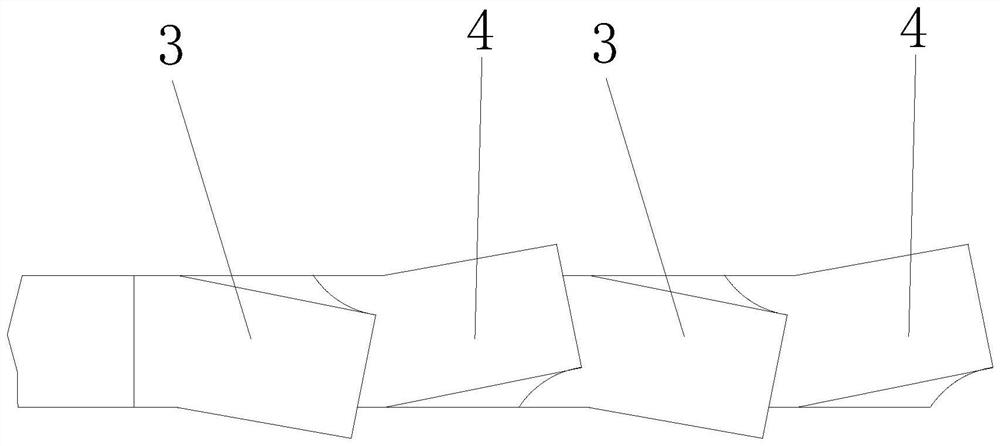

Special-shaped tooth groove small tooth type bimetal saw blade

PendingCN112355401APreserve stress distribution characteristicsReduce stress concentrationMetal sawing toolsSmall toothSmall teeth

The invention provides a special-shaped tooth groove small tooth type bimetal saw blade which comprises multiple teeth on a saw blade band, the multiple teeth deflect towards the same direction to form saw cutting edges extending linearly, one side of each tooth is a front cutter face, the other side of each tooth is a rear cutter face, a tooth groove is formed between every two adjacent teeth, and the tooth grooves are located below a weld joint. The front cutter faces are vertical cutter edges, the vertical cutting edges are located above the weld joint, the rear cutter faces are oblique line cutting edges, the oblique line cutting edges are located above the weld joint, the vertical cutting edges and the tooth grooves are connected through at least two straight line sections and / or arcline sections, first front line sections connected with the vertical cutting edges deflect forwards to expand the front end of the weld line, and second front line sections connected with the first front line sections deflect forwards to be in transition connection with the tooth grooves. The oblique line cutting edges are connected with the tooth grooves through at least three straight line sections and / or arc sections, first rear line sections connected with the oblique line cutting edges are bent downwards, second rear line sections connected with the first rear line sections deflect backwards to extend the rear end of the weld line, and third rear line sections connected with the second rear line sections are bent backwards to be in transition connection with the tooth grooves.

Owner:浙江思普锯业有限公司

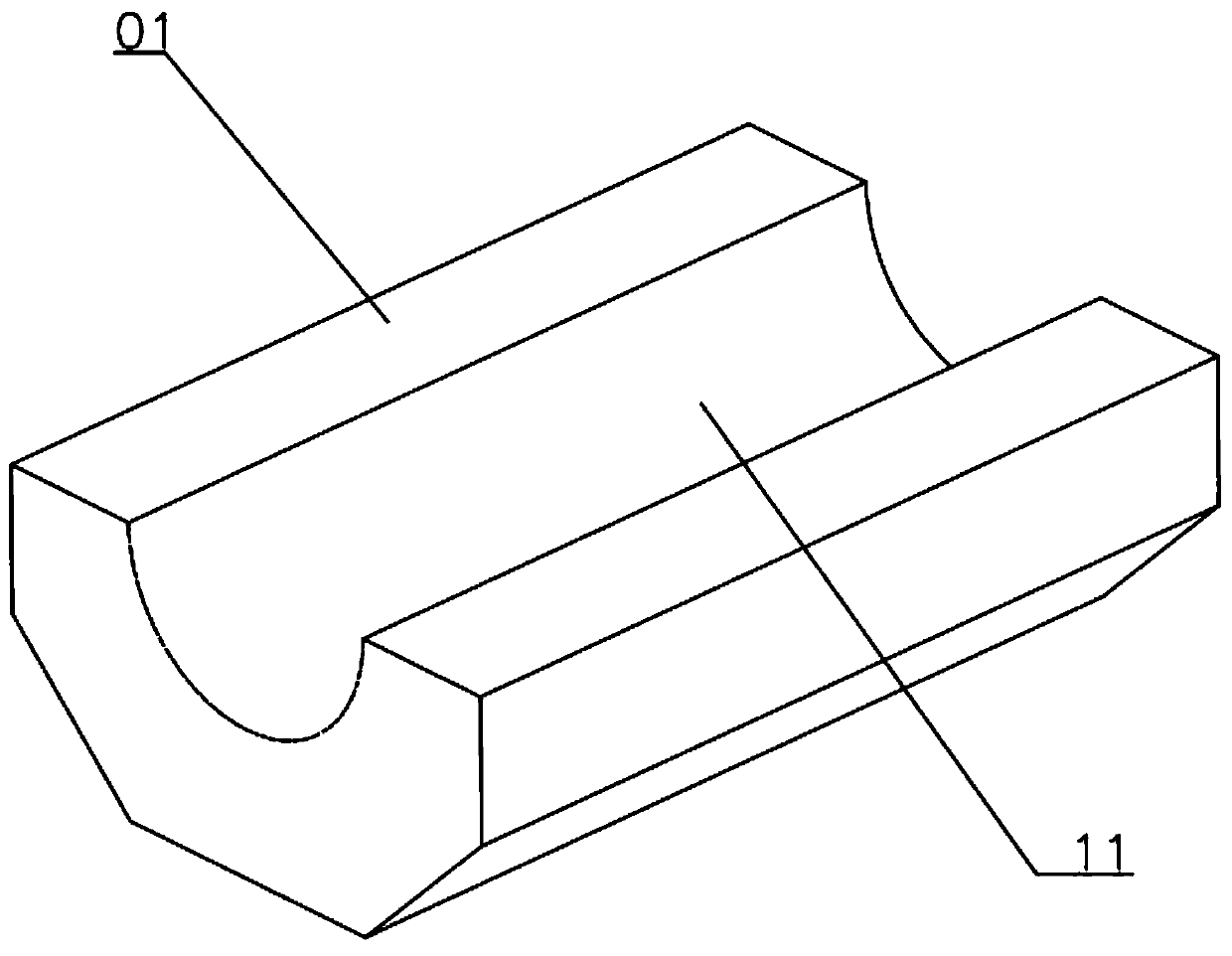

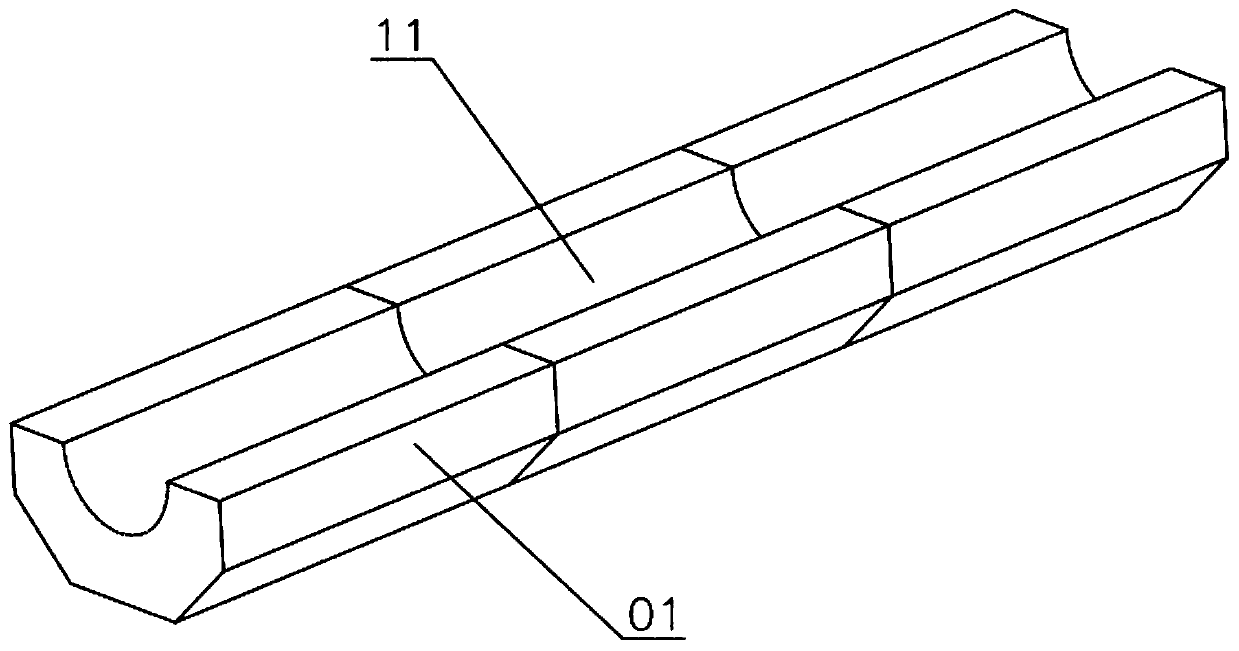

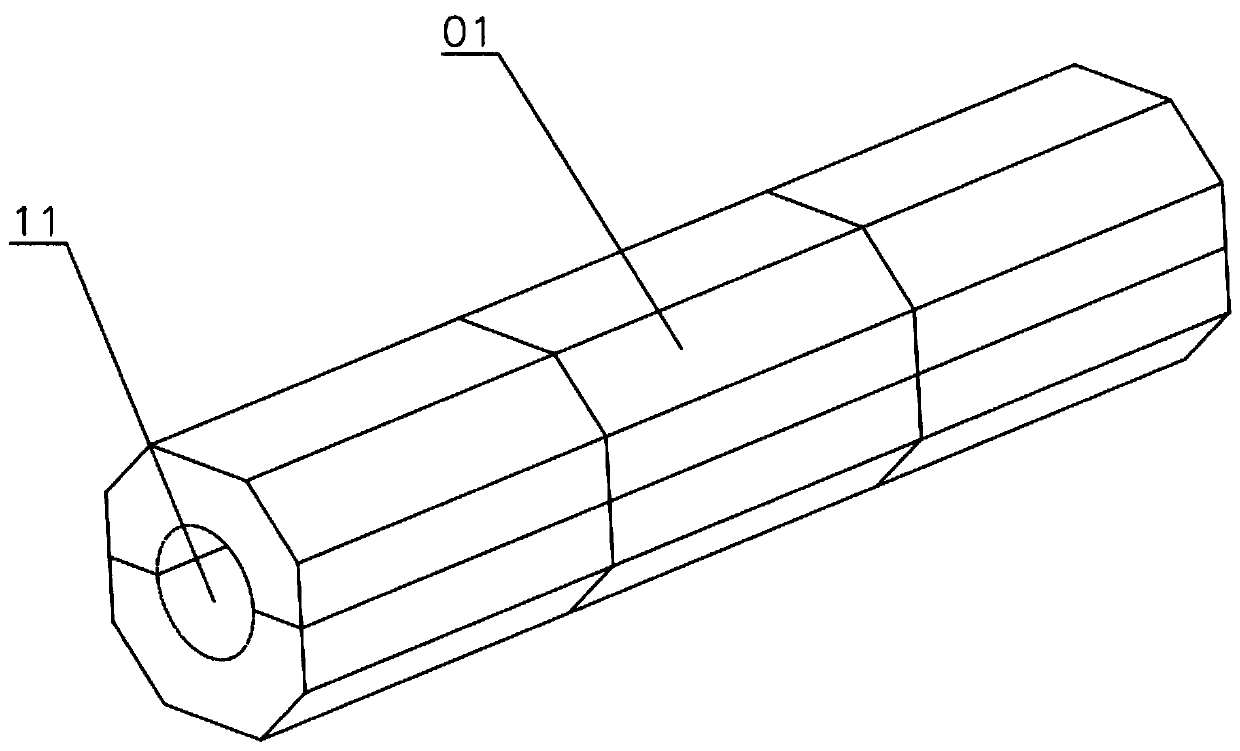

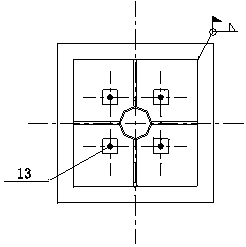

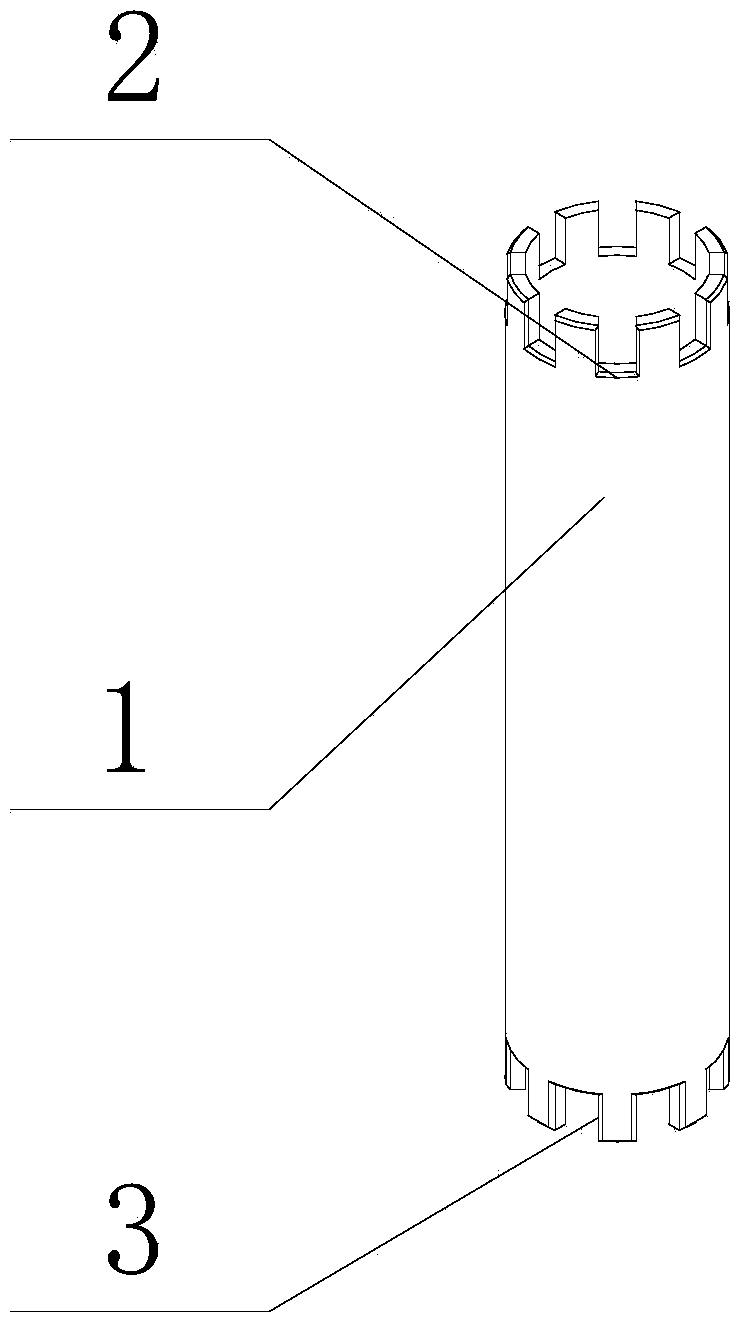

Key-type connection structure between the cutter head box and the pull rod of the patio drilling rig

ActiveCN105735904BStable structureReduce manufacturing costEarth drilling toolsDrill bitsEngineeringDrill

The invention discloses a clamping key type connecting structure for a cutter disc case and a pull rod of a raise boring machine. The connecting structure comprises the pull rod, the cutter disc body and clamping keys, wherein the cutter disc case is arranged on the outer surface of the pull rod in a sleeving manner; the pull rod is connected with the cutter disc case through a flange at an end part of the pull rod; grooves are formed in the flange at the end part of the pull rod; after the clamping keys are aligned with the grooves, the cutter disc case is assembled and welded with the clamping keys; a gap is formed between the inner surface of the cutter disc case and the outer surface of the pull rod; an oil channel is formed in the pull rod, and is communicated with the gap. The connecting structure is reliable in structure, low in manufacturing cost, convenient to mount, dismount and maintain, economic and practical.

Owner:湖南创远矿山机械有限责任公司

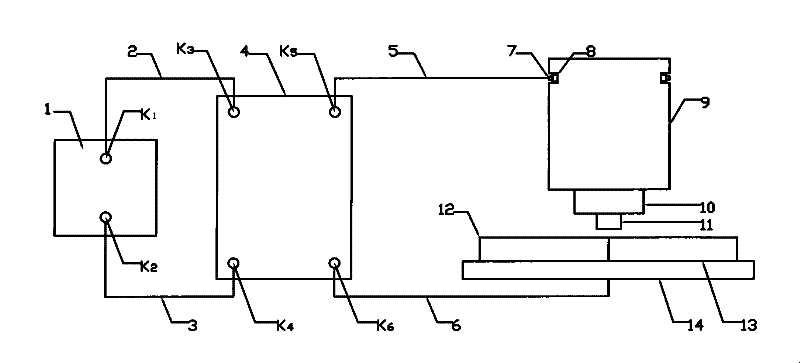

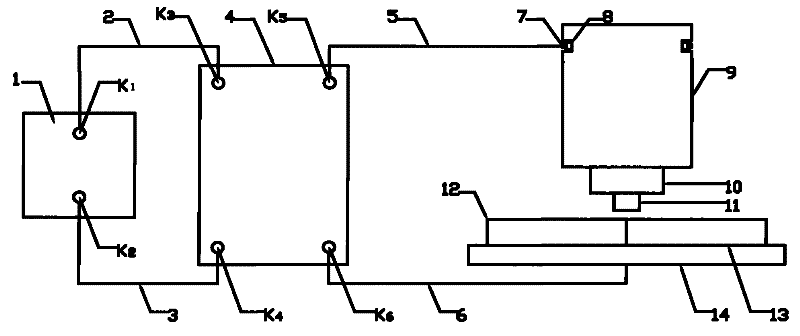

Stir friction composite welding stainless steel device with resistor heat and method thereof

InactiveCN101474718BReduce difficultyReduce wearNon-electric welding apparatusHigh resistanceTransformer

The invention discloses a device for welding stainless steel by resistance heat as well as stirring and friction, comprising an electric power source, a transformer and a stirring head, wherein, two output terminals of the electric power source are connected with the input terminal of the transformer by an electric cable, one output terminal of the transformer is connected with a cushion plate by the electric cable, the cushion plate is used for placing work pieces, the other output terminal of the transformer is connected with an electric brush by the electric cable, the electric brush is contacted with a copper ring arranged in a groove at the upper end of the stirring head. When the device of the invention is adopted for welding, the transformer is adjusted to form low voltage heavy current; driven by an electric motor, a mixing needle is screwed in the space between two work pieces, a low voltage heavy current circuit is conducted and generates relatively high resistance heat on the work pieces, materials at the welding lines are plasticized under high temperature effect of the resistance heat and friction heat, and welding lines form at the rear part of the mixing needle. Stirring friction welding of stainless steel can be realized, abrasion of the stirring head can be reduced, weld length of the stirring head can be increased, service life of the stirring head can be prolonged; in addition, the device of the invention has simple structure and relatively low cost, and is easy to manufacture.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

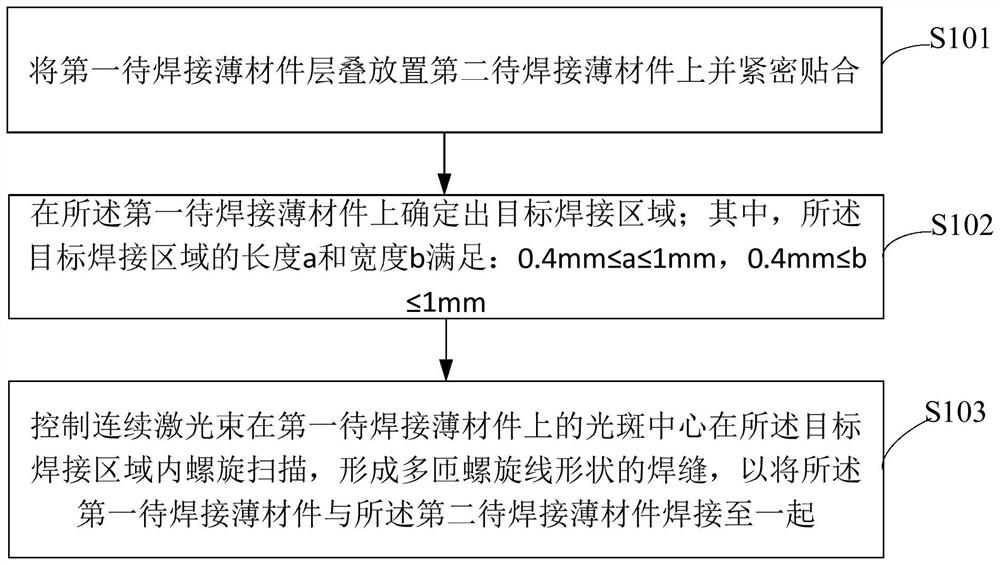

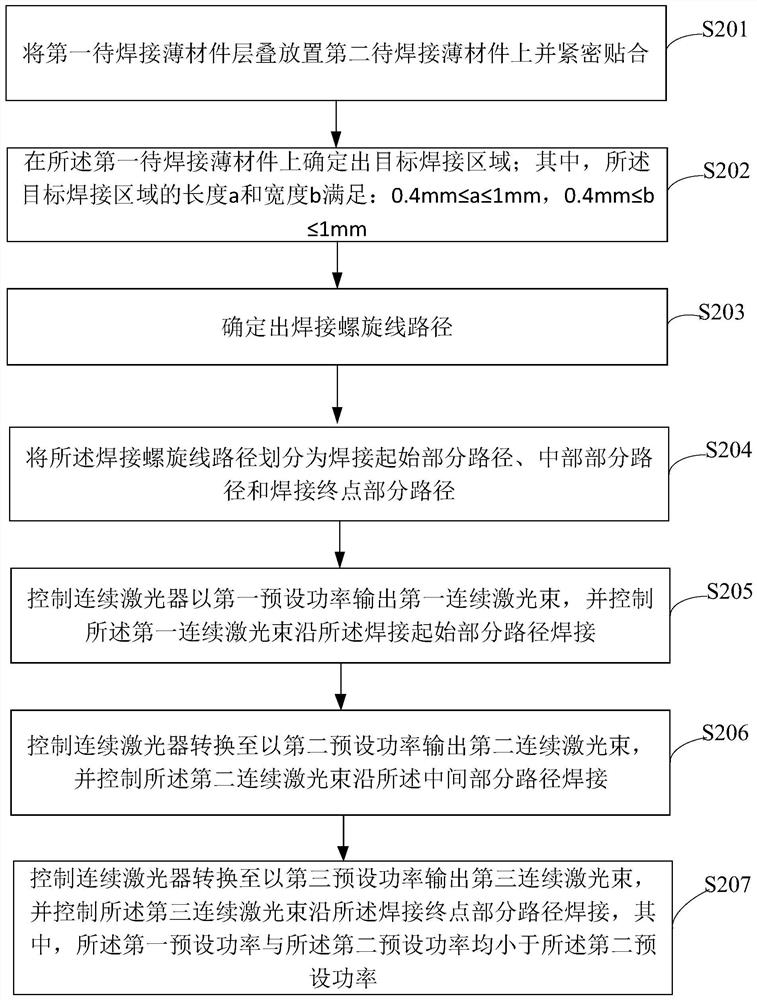

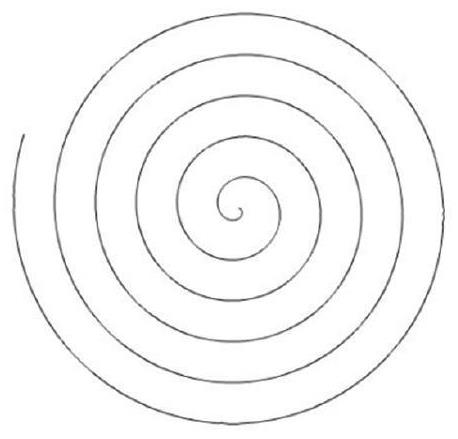

Thin material laser welding method

PendingCN114346429AIncrease fusion areaIncrease weld lengthLaser beam welding apparatusLight spotWeld seam

The invention discloses a thin material laser welding method, and belongs to the technical field of welding. The method comprises the steps that a first to-be-welded thin material piece is stacked on a second to-be-welded thin material piece and tightly attached to the second to-be-welded thin material piece; a target welding area is determined on the first thin material piece to be welded; wherein the length a and the width b of the target welding area meet the conditions that a is larger than or equal to 0.4 mm and smaller than or equal to 1 mm, and b is larger than or equal to 0.4 mm and smaller than or equal to 1 mm; and a continuous laser beam is controlled to spirally scan in the target welding area in the light spot center of the first to-be-welded thin material piece, a welding seam in a multi-turn spiral line shape is formed, and the first to-be-welded thin material piece and the second to-be-welded thin material piece are welded together. According to the method, scanning is carried out along the spiral line in the extremely small target welding area, so that the length of the welding seam is increased, the fusion area of the first to-be-welded thin material piece and the second to-be-welded thin material piece is increased, and welding is firmer.

Owner:SHENZHEN TETELASER TECH CO LTD

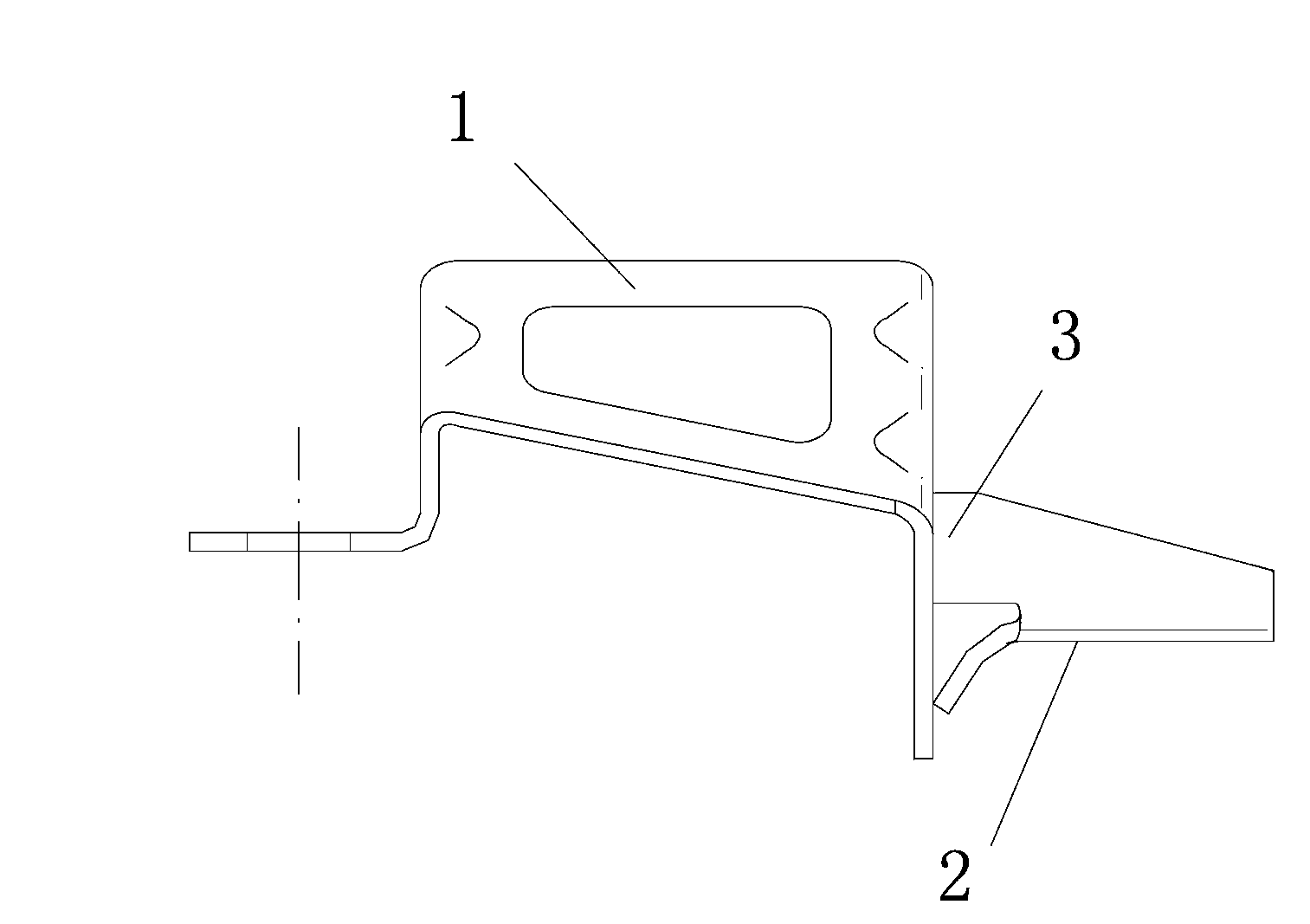

Automobile lower lining limiting support

InactiveCN103832235AIncrease weld lengthWelding heat spreads evenlyResilient suspensionsEngineeringWelding deformation

Disclosed is an automobile lower lining limiting support. The automobile lower lining limiting support is characterized by comprising a lower lining limiting support body (1) and a lower lining limiting support division part (2), the lower lining limiting support division part (2) is located at the right end of the lower lining limiting support body (1) and welded with the lower lining limiting support body (1), three welding flanges (3) are arranged on the lower lining limiting support division part (2), two welding flanges are arranged at the upper end of the lower lining limiting support division part (2) side by side, the other one welding flange is arranged at the lower end of the lower lining limiting support division part (2), and the length of the two welding flanges (3) arranged at the upper end of the lower lining limiting support division part (2) side by side is 27 mm. According to the automobile lower lining limiting support, due to the fact that the flanges on the two sides of the automobile lower lining limiting support division part (2) are lengthened by 10 mm, the welding length of a welding robot is increased, welding heat can be effectively diffused evenly, the welded deformation quantity is greatly reduced, the size is more easily ensured, and working efficiency is improved.

Owner:WUHAN HUIHENG IND

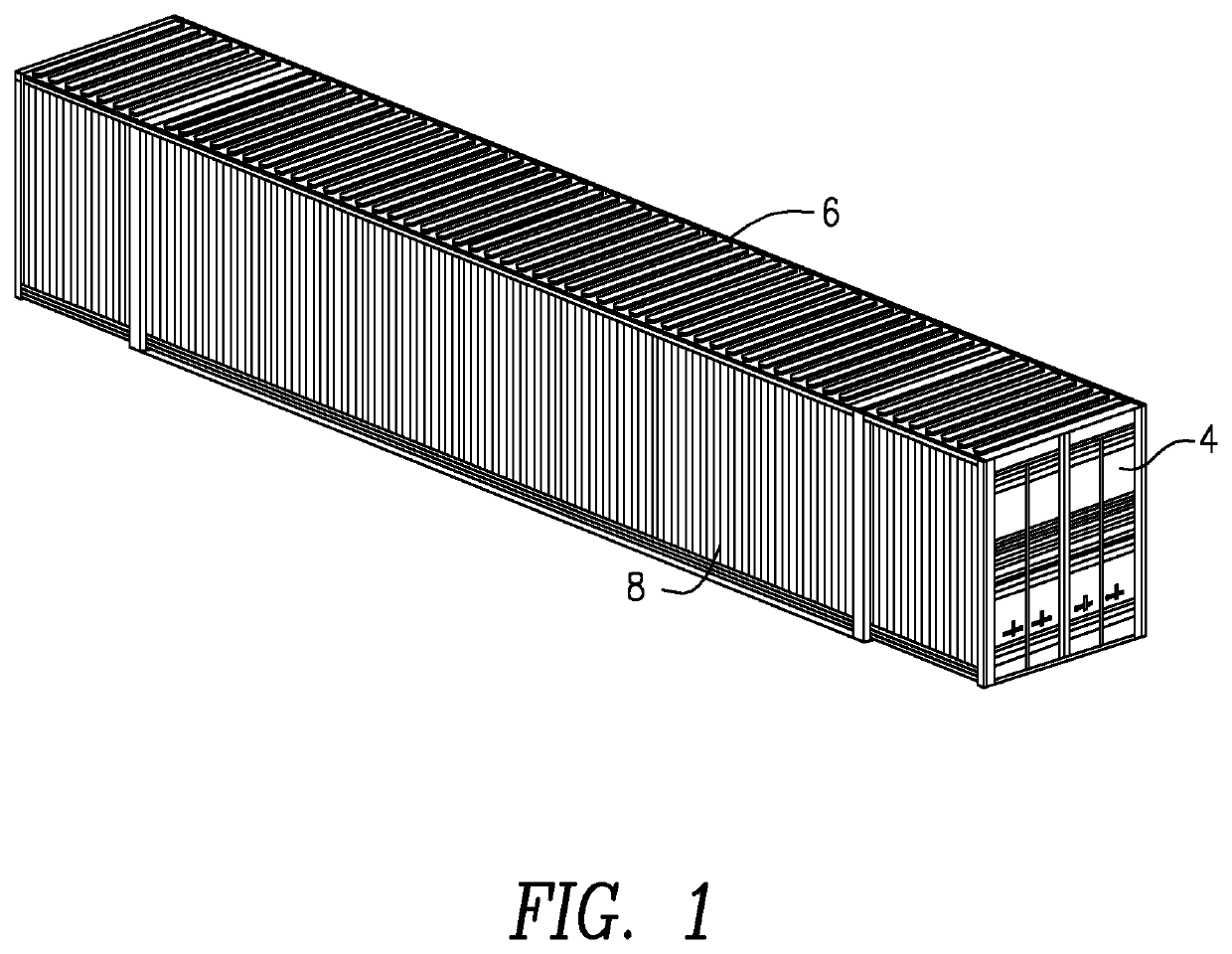

Shipping container and method of construction thereof

An intermodal shipping container including one or more improvements such as intermediate gable posts or gable headers adapted to increase an internal width and strength of the container, wherein the gable posts or the gable headers include twin channels having at least two internal flanges welded to a gable post plate or gable header plate, one or more upper castings having an integral top rail ledge, wherein a top rail of a side wall hangs on the integral top rail ledge, “C” channel style beam main frame cross members, a one-piece continuous top plate including an integral lip connecting the top plate and a roof, one or more rear lower castings, wherein the one or more rear lower castings are an integral interlocking interface, a bolster including an integral seating and fastening surface and slots, and / or one or more nested rear corner posts subassemblies, the one or more nested rear corner posts having a notch and protrusion connection, wherein a protrusion in a lower rear casting engages with a corresponding notch in the rear corner post.

Owner:IPA PATENTS LLC

Welding structure and welding method of metal plate and main rib

PendingCN109024244AAchieve welding fixationReduce the difficulty of pre-preparationBridge structural detailsWorkpiece edge portionsEngineeringMetal

The invention provides a welding structure and a welding method of a metal plate and a main rib, The welding structure comprises a plurality of main bars arranged in parallel combination, a pluralityof stirrups arranged perpendicularly to the main bars and around which the main bars are fixed, a metal plate arranged in parallel with the main bars, and a plurality of welding pieces sandwiched between the metal plate and a single main bar at intervals along an extension direction of the main bars; The welding piece is respectively welded with the metal plate and the main bar, and the outer diameter of the welding piece is greater than or equal to the outer diameter of the stirrup. The structure solves the problem that the metal plate and the main rib cannot be fixedly connected due to the separation of the stirrups in a simple manner.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Aircraft wing capable of loading solar cell

InactiveCN111086621AEasy to installGuaranteed connection strengthSpars/stringersCell component detailsStructural engineeringSolar battery

The invention discloses an aircraft wing capable of loading a solar cell, which comprises a wing shell, a solar storage cell and a cell frame, wherein the bottom of the inner cavity of the wing shellis fixedly connected with a corrugated fixed underframe. According to the aircraft wing capable of loading a solar cell, which relates to the technical field of aircraft wings, the wavy edge of the corrugated fixed underframe is used to increase the perimeter, namely, the welding length with the surfaces of the wing shell and the annular plate is increased; the material increment is not large; meanwhile, the connection strength is improved; a hoop is matched with a first fixing block and a second fixing block; the mounting plate for mounting the cell frame and the annular plate can be firmly fixed together; by utilizing the contact between the hoop and the inclined surfaces of the first fixing block and the second fixing block, the stress can be decomposed into two directions to be matchedwith bolts for use, and the fixing strength is far greater than that of the bolt for fixing, so that the cell is firmer to install, and the cell can be prevented from loosening due to the breakage ofthe bolt.

Owner:芜湖市极星航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com