Air sac mounting bracket for automobile co-pilot position

A technology for installing brackets and co-pilot seats, which is applied to vehicle safety arrangements, vehicle components, transportation and packaging, etc., can solve problems that affect the normal deployment of airbags, airbags fall off and fly out, and occupant injuries, etc., and achieve simple structure and enhanced Effects of strength and rigidity and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

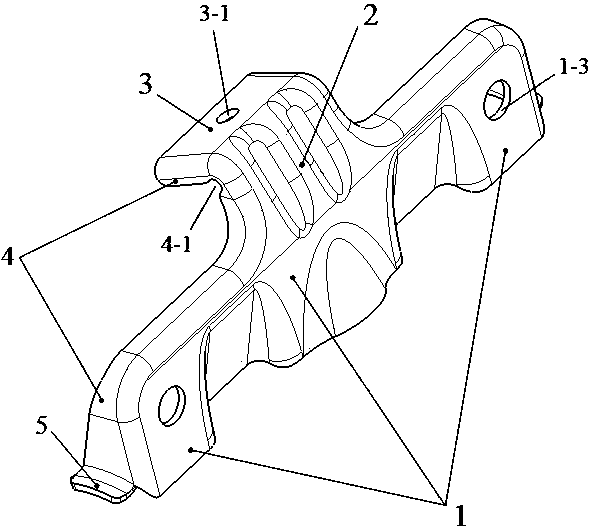

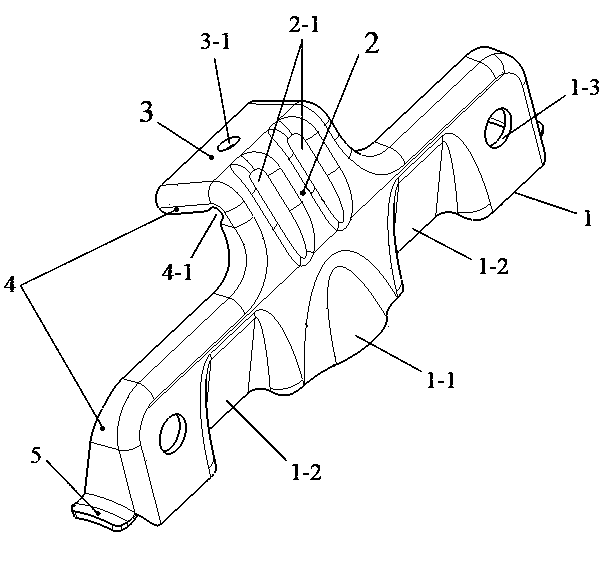

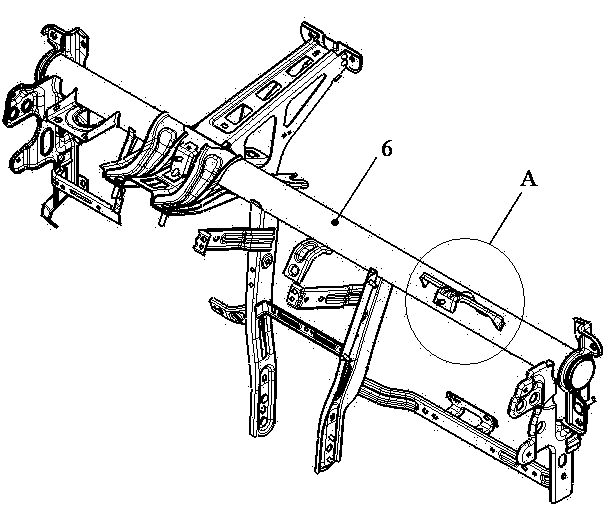

[0019] Such as figure 1 , figure 2 as well as image 3 As shown, the airbag mounting bracket for the passenger seat of the automobile is a sheet metal part stamped and formed as a whole, including a bracket body plate 1 that is horizontally adapted to the instrument panel beam 6, and extends upward from the middle section of the upper edge of the bracket body plate 1 The transition plate 2 is connected with the upper edge of the transition plate 2 and is bent towards the instrument panel connection plate 3 towards the rear side. The transition plate 2 and the instrument panel connection plate 3 are bent at an angle of 90 degrees (this angle can be determined according to According to the space requirements of different models, make appropriate adjustments). Airbag installation holes 1-3 are opened on the left and right sides of the bracket body plate 1, and instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com