Special-shaped tooth groove small tooth type bimetal saw blade

A special-shaped tooth and bimetal technology, which is applied in the field of bimetal saw blades, can solve the problems of easy springback of the divided teeth and reduce the stress concentration of the tooth groove, so as to achieve low tolerance of the difference of the divided teeth, reduce the stress concentration of the tooth groove, The effect of avoiding tooth pulling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

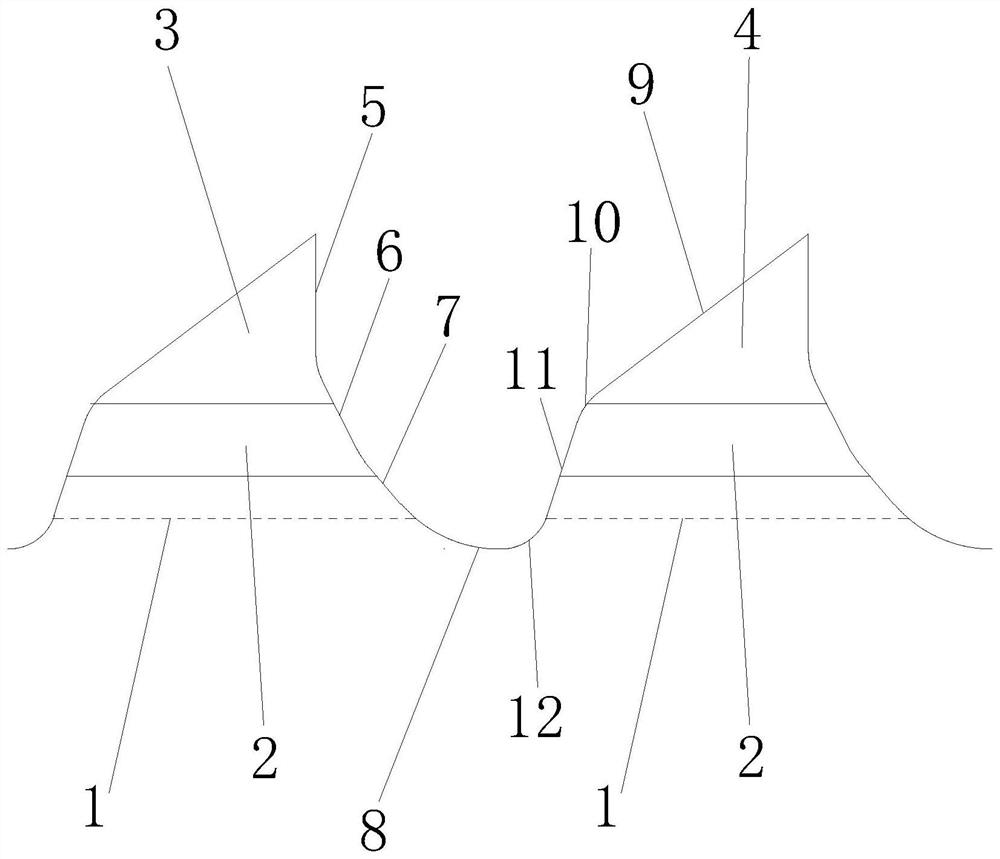

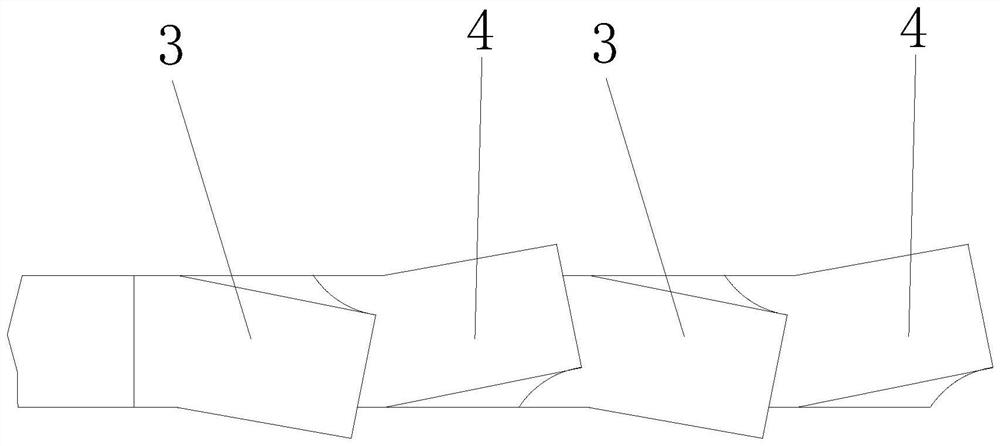

[0024] Such as Figure 1 to Figure 2 As shown, the bimetal saw blade with special-shaped tooth groove and small teeth includes a saw blade band, and a number of teeth in a continuous arrangement are fixed on one edge of the saw blade band through a weld 2, and the teeth are all inclined in the same direction to form a straight line Extended sawing edge, one side of the teeth is the rake face, the other side is the flank face, a tooth groove 8 is set between adjacent teeth, the tooth groove 8 is located below the weld 2, and the rake face is The vertical blade 5, the vertical blade 5 is located above the weld 2, the flank is a slanted blade 9, the slanted blade 9 is located above the weld 2, and the vertical blade 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com