Coil for magnetic-pulse welding of flat parts and related welding method

A technology of magnetic pulses and parts, applied in the direction of coil devices, welding equipment, electrical components, etc., can solve problems such as difficult to maintain welding windows, achieve the effect of reducing stress and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

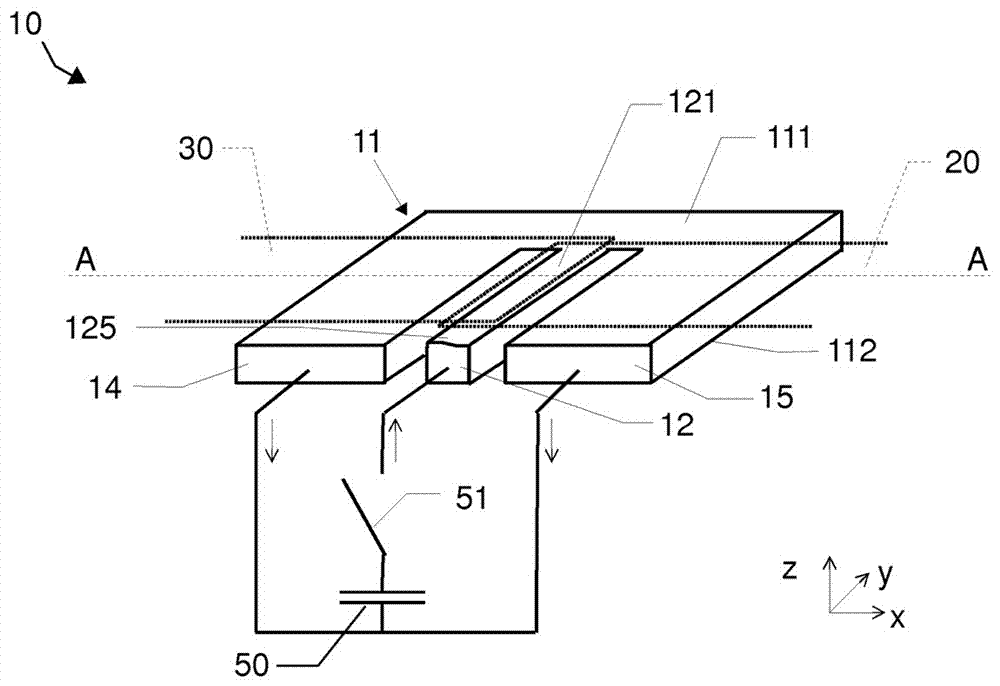

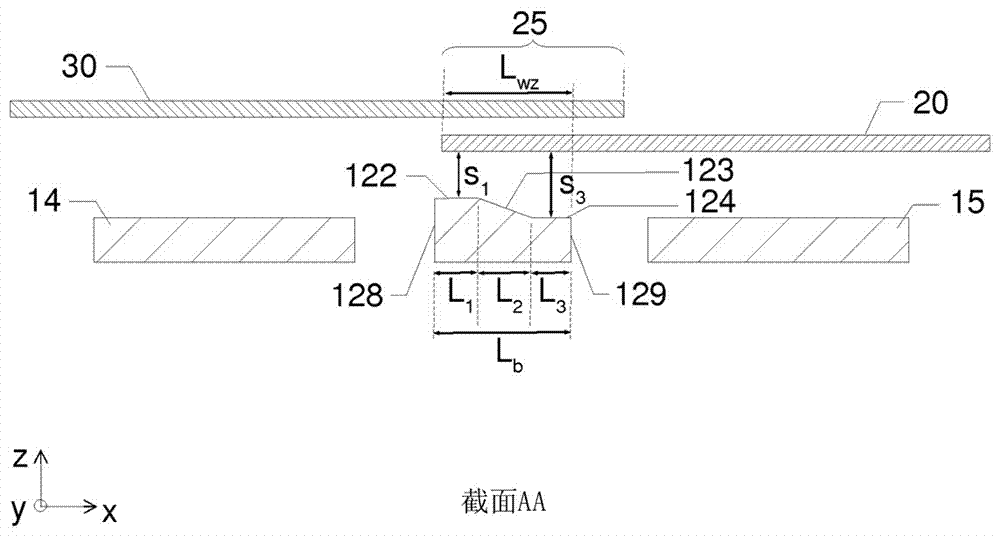

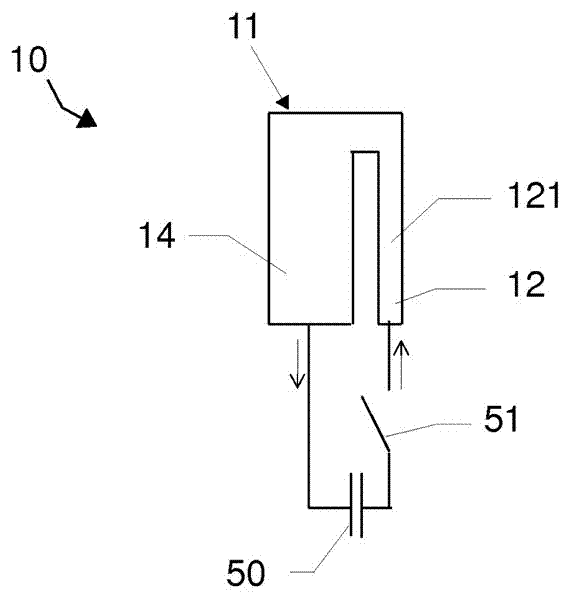

[0045] figure 1 and figure 2 Shown is a coil 10 according to a first embodiment for magnetic pulse welding of two parts 20 , 30 . Both parts 20, 30 are made of metallic material.

[0046] The coil 10 constitutes the main part of the magnetic pulse welding equipment, and the magnetic pulse welding equipment further includes a storage unit 50 and one or more switches 51 .

[0047] The storage unit 50 is suitable for storing high energy, for example on the order of tens of kilojoules (KJ).

[0048] In a preferred embodiment, the storage unit is a discharge capacitor battery.

[0049] The coil is adapted to generate a magnetic field concentrated in a defined space, which will be described later.

[0050] Two parts, called inner part 20 and outer part 30, are arranged one above the other to form a so-called overlapping area 25 in their superimposed position, which is then welded by means of coil 10 in all or part of the overlapping area . The two parts 20 , 30 are arranged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com