Rail type welding device for pipeline

A welding device and orbital technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to use the axial and circumferential welding of pipelines, poor versatility, etc., and achieve reduced strength, long welding length, and ease of use. cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

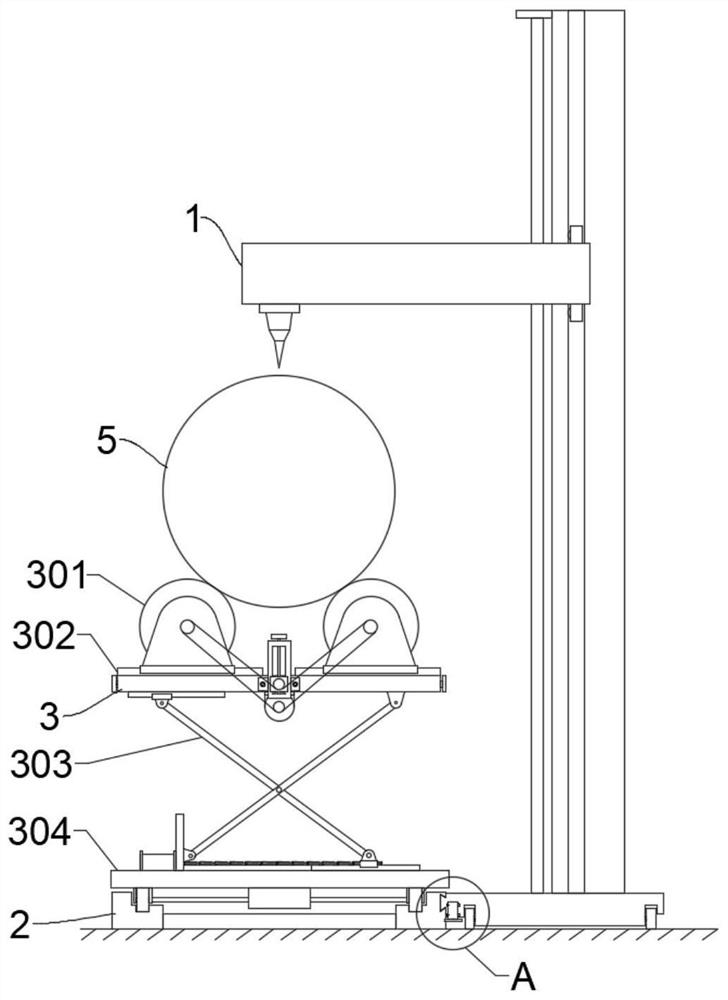

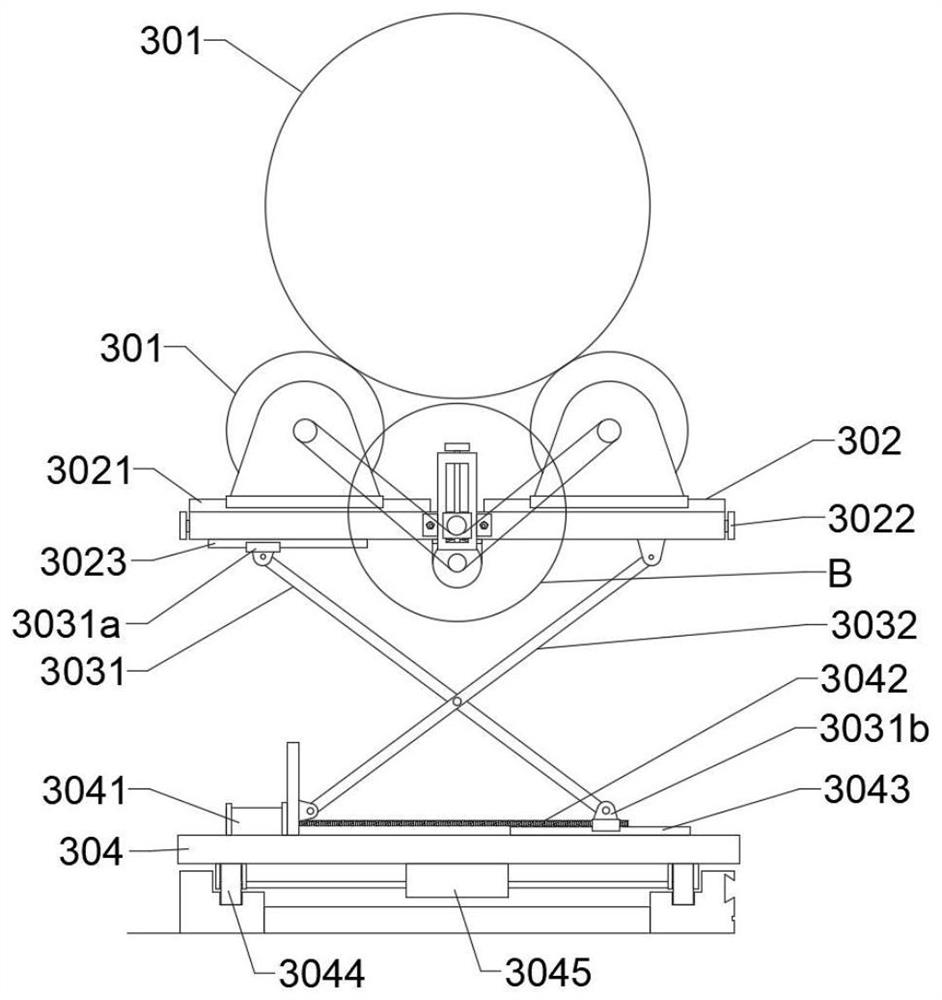

[0034] Such as Figure 1-9 As shown, this embodiment discloses an orbital welding device for pipelines, including a welding machine 1, an orbital assembly 2, an anti-oxidation mechanism 4 and multiple sets of carrying mechanisms 3, and the welding machine 1 is located on the side of the orbital assembly 2 square, and the welding machine is slidably connected with the track assembly 2;

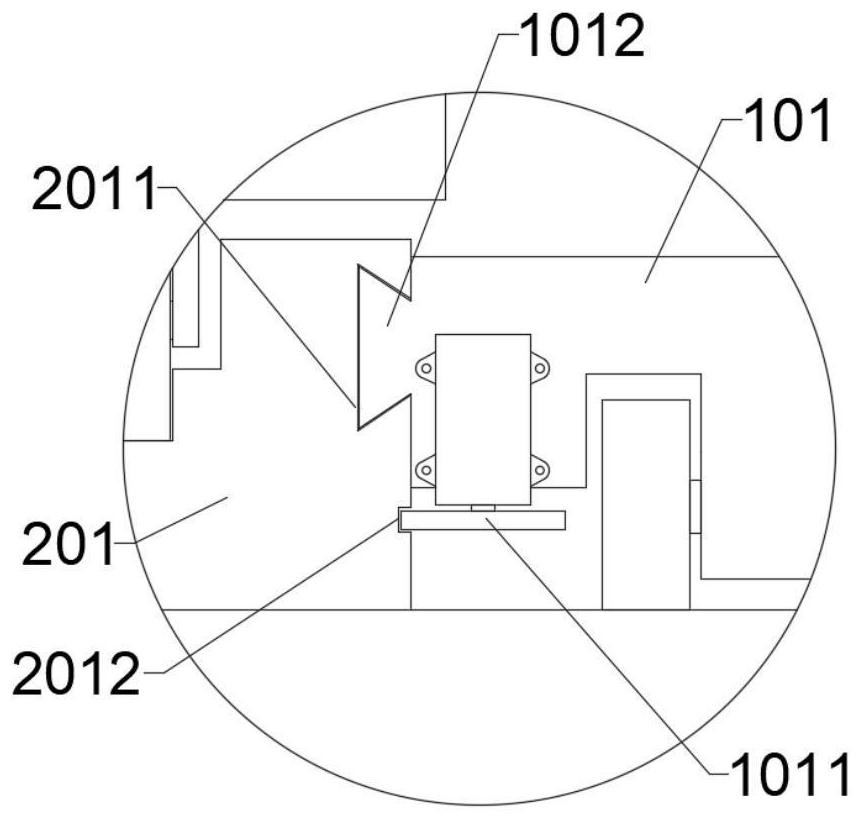

[0035] Specifically, combine figure 1 and image 3 As shown, the track assembly 2 includes a first straight track and a second straight track 201, wherein the first straight track and the second straight track 201 are arranged in parallel, and the first straight track and the second straight track 201 is provided with track grooves along the length direction, and the side of the second linear track 201 close to the welding machine 1 is provided with dovetail grooves 2011 and rack driving grooves 2012 . The carrying mechanism 3 limits the direction of travel through the first linear track and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com