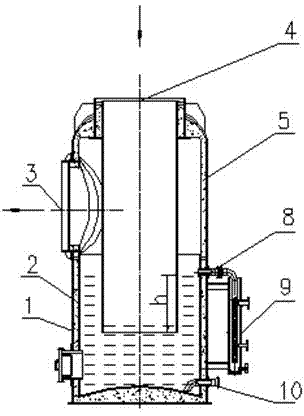

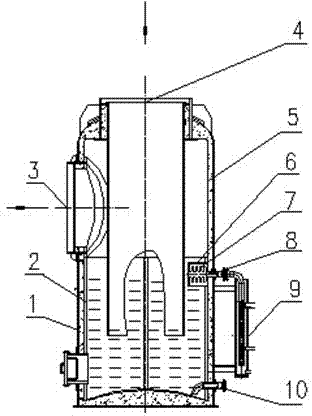

Catalytic cracking regeneration flue gas water-sealed tank and method for preventing inner barrel from deformation

A technology for regenerating flue gas and catalytic cracking, which is applied to engine components, mechanical equipment, valve devices, etc., can solve the problems of deformation of the inner cylinder, large deformation of the inner cylinder 2 due to thermal expansion, and the problem of expansion and absorption is not well considered. Avoid permanent deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] The specific implementation scheme is as follows,

[0039] Based on the analysis of the cause of the inner cylinder protruding inward due to thermal expansion during the use of the water-sealed tank, it is key to solve the problem of thermal expansion and absorption of the inner cylinder of the water-sealed tank. If the thermal expansion can be effectively absorbed, the deformation of the inner cylinder will be reduced. can be controlled. Since the thermal expansion of the inner cylinder is divided into two parts, the axial expansion and the circumferential expansion, the solution to the problem also starts from these two parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com