Method for welding upper rail of seat track for vehicle seat and adaptor bracket

A vehicle seat and welding method technology, which is applied to vehicle seats, seat frames, special positions of vehicles, etc., can solve problems such as insufficient welding strength, excessive man-hours, and connection strength limitations, and achieve increased welding length and welding Strength, the effect of reducing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

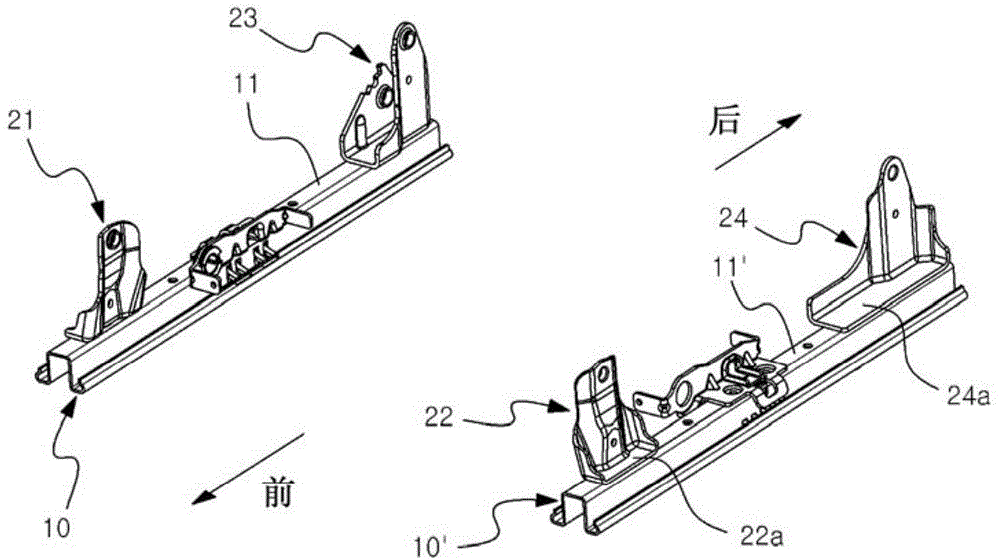

[0027] Like the prior art, the welding method of the upper rail and the joint bracket in the seat rail of the vehicle seat according to the exemplary embodiment of the present invention is applied to figure 1 Seat rail shown.

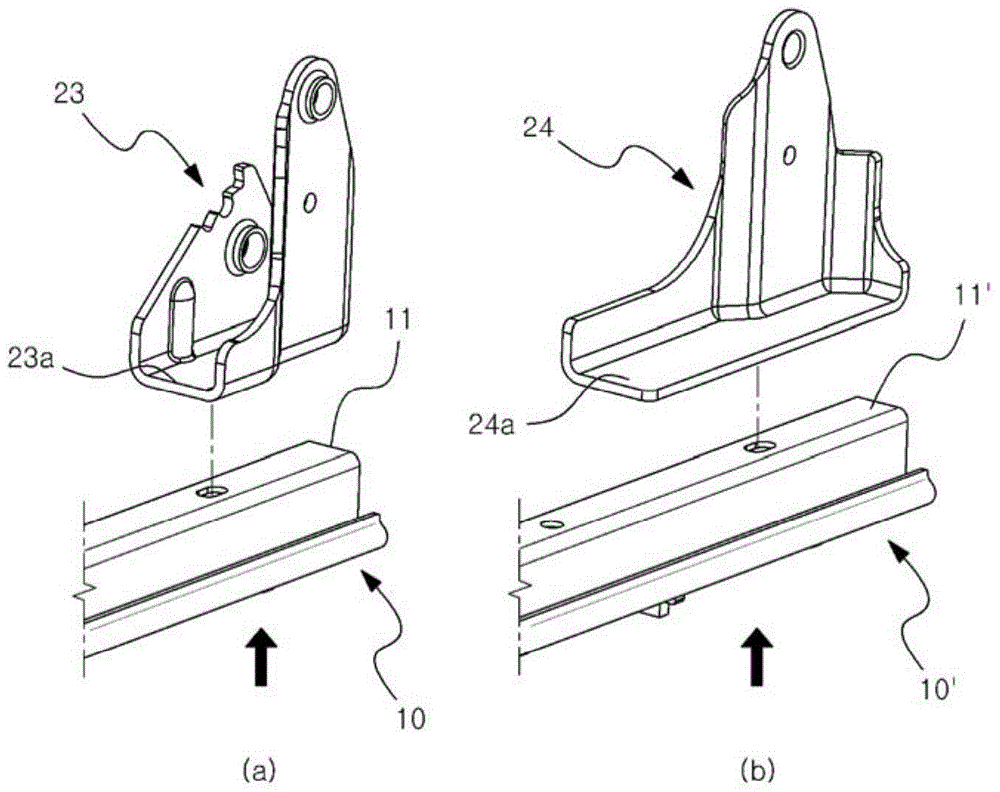

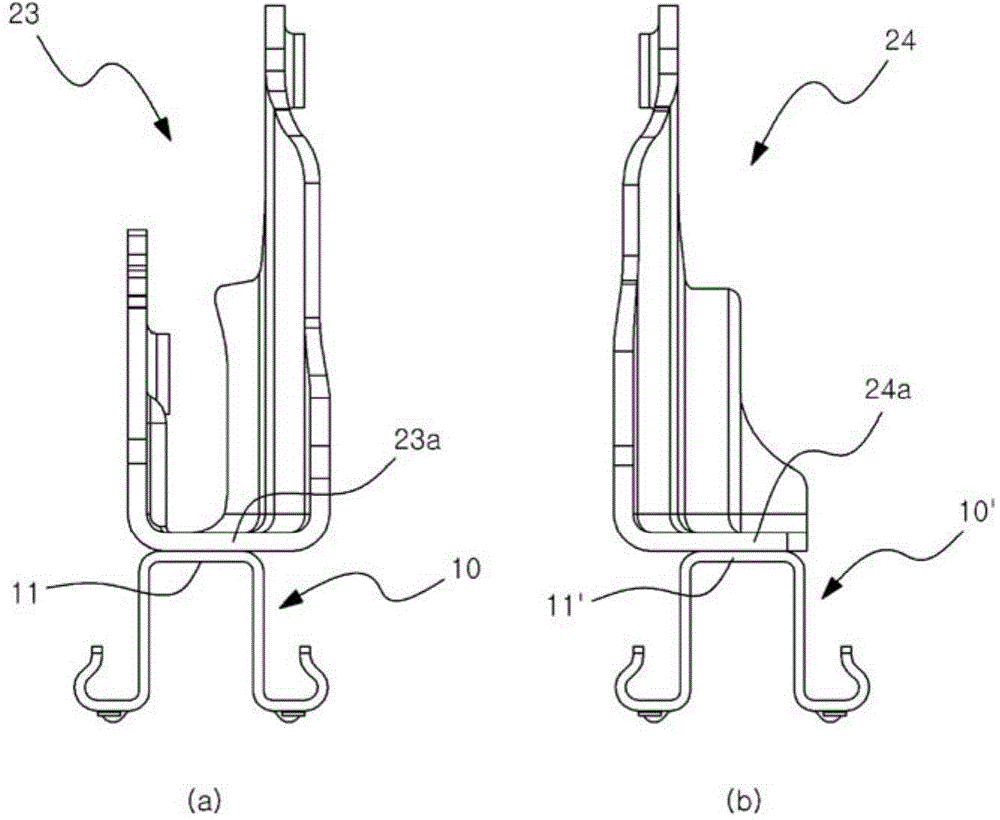

[0028] Such as figure 2 and image 3 As shown, the rear left and right rear engagement brackets 23, 24 have a relatively large surface contact area with the upper rails 10, 10'. The flat connecting surface portions 23a, 24a form the lower end portions of the engagement brackets 23, 24 and are in longitudinal face-to-face contact with the upper surfaces of the flat horizontal surface portions 11, 11', which form the respective upper rails 10, the upper end of 10'.

[0029] Then, if figure 2 As indicated by the arrows in , the laser welding is directly performed on the horizontal surface portion 11, 11' from below the upper rail 10, 10' and upward.

[0030] Laser welding is performed in overlapping areas between the horizontal surface portions 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com