Low-cost niobium-titanium alloy electrode preparation method and niobium-titanium alloy electrode

A niobium-titanium alloy, low-cost technology, applied in the field of niobium-titanium alloy electrode, low-cost niobium-titanium alloy electrode preparation, can solve the problems of high cost, complicated process, a large amount of waste, etc., to achieve low manufacturing cost, low raw material cost, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A low-cost niobium-titanium alloy electrode preparation method, the low-cost niobium-titanium alloy electrode preparation method comprises the following steps,

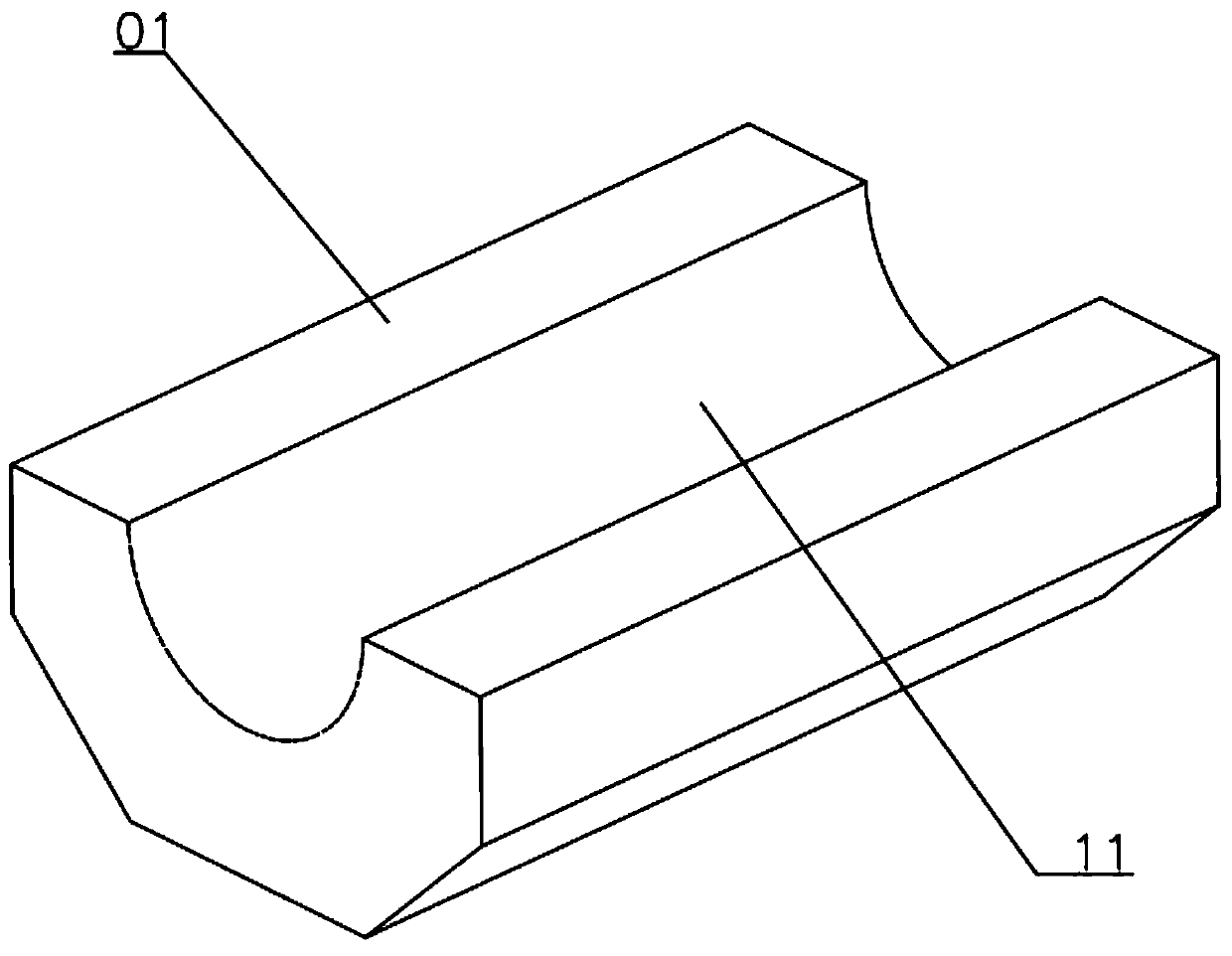

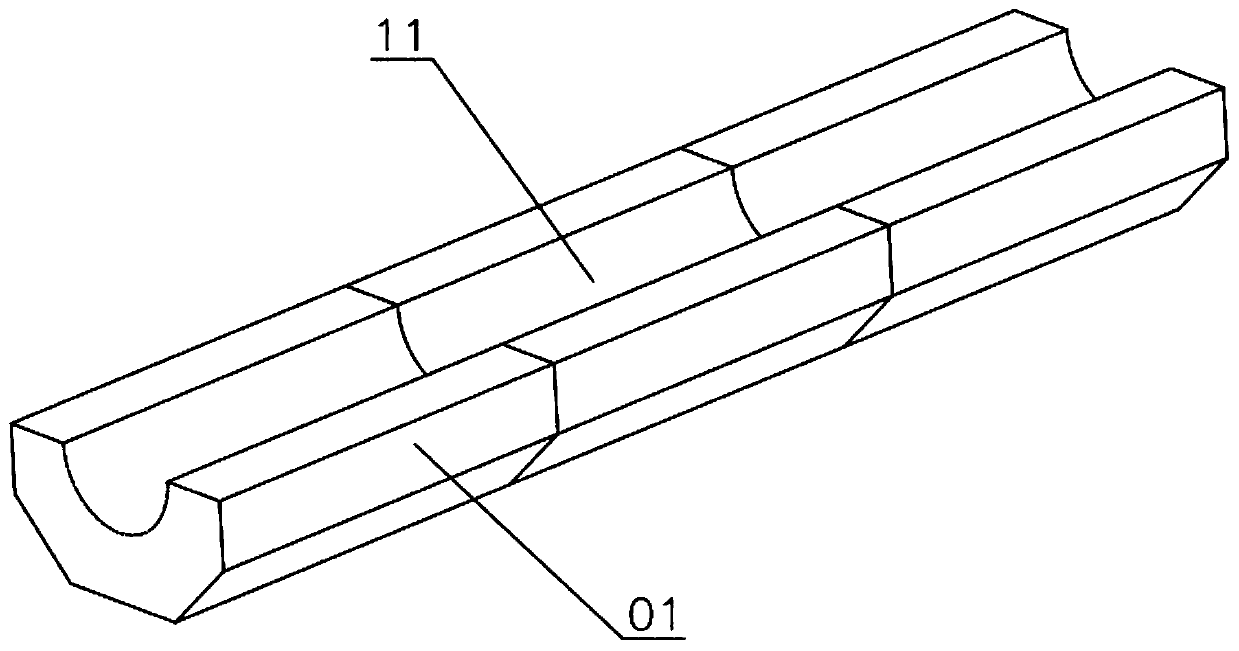

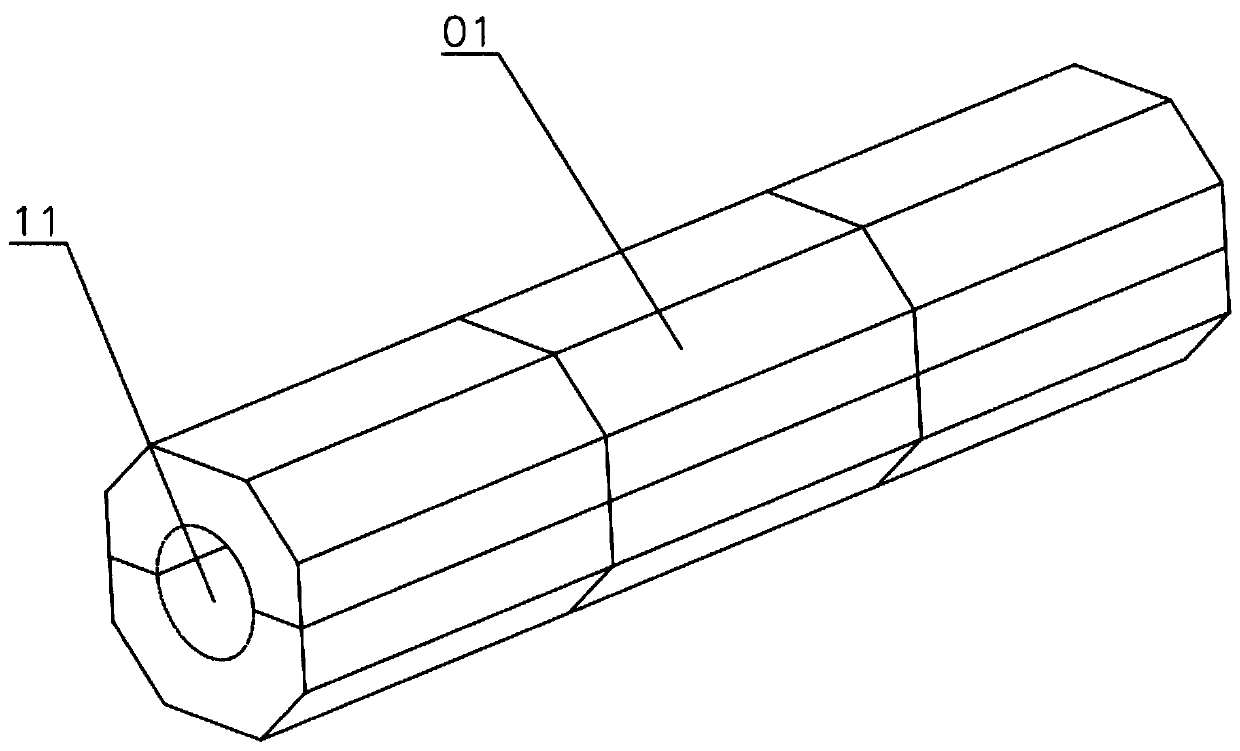

[0019] (1) Cloth: Weigh niobium chips with a mass fraction of 53% and titanium sponge with a mass fraction of 47%, and divide the weighed niobium chips evenly into m parts, and evenly divide the weighed titanium sponge into m+1 parts, Then put niobium chips and titanium sponge into the mold cavity alternately, first put a piece of titanium sponge into the bottom of the mold cavity, and then put a piece of niobium chips, the length direction of the niobium chips is along the axis of the electrode block 01 , until the cloth is completed, so that titanium sponge and niobium chips are alternately put into the mold cavity in turn; using this cloth method, titanium sponge is used to separate niobium chips to reduce the agglomeration of niobium chips during smelting;

[0020] (2) Electrode block pressing: Use the punc...

Embodiment 2

[0024] A low-cost niobium-titanium alloy electrode preparation method, the low-cost niobium-titanium alloy electrode preparation method comprises the following steps,

[0025] (1) Cloth: weigh 20% niobium chips and 80% titanium sponge respectively, divide the weighed niobium chips into m parts, and divide the weighed titanium sponge into m+1 parts, Then put niobium chips and titanium sponge into the mold cavity alternately, first put a piece of titanium sponge into the bottom of the mold cavity, and then put a piece of niobium chips, the length direction of the niobium chips is along the axis of the electrode block 01 , until the cloth is completed, so that titanium sponge and niobium chips are alternately put into the mold cavity in turn; using this cloth method, titanium sponge is used to separate niobium chips to reduce the agglomeration of niobium chips during smelting;

[0026] (2) Electrode block pressing: Use the punching head of the punching machine to squeeze the cavi...

Embodiment 3

[0030] A low-cost niobium-titanium alloy electrode preparation method, the low-cost niobium-titanium alloy electrode preparation method comprises the following steps,

[0031] (1) Cloth: weigh 45% niobium chips, 54.9% titanium sponge, and 0.1% titanium dioxide, respectively, divide the weighed niobium chips into m parts, and divide the weighed titanium sponge into m parts + 1 part, then put niobium chips and titanium sponge into the mold cavity alternately, first put a part of titanium sponge into the bottom of the cavity, and then put a part of niobium chips, when the niobium chips are clothed, its length direction is along the electrode Block 01 axis direction, until the cloth is completed, so as to form sponge titanium and niobium chips and put them into the mold cavity sequentially; using this cloth method, use sponge titanium to separate niobium chips, and reduce the agglomeration of niobium chips during smelting;

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com