Connecting structure of side wall stand column and underframe boundary beam, vehicle body and rail vehicle

A technology for connecting structures and columns, applied in the field of rail vehicles, can solve problems such as reducing connection strength, and achieve the effect of improving stress conditions, meeting structural strength requirements, and solving connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

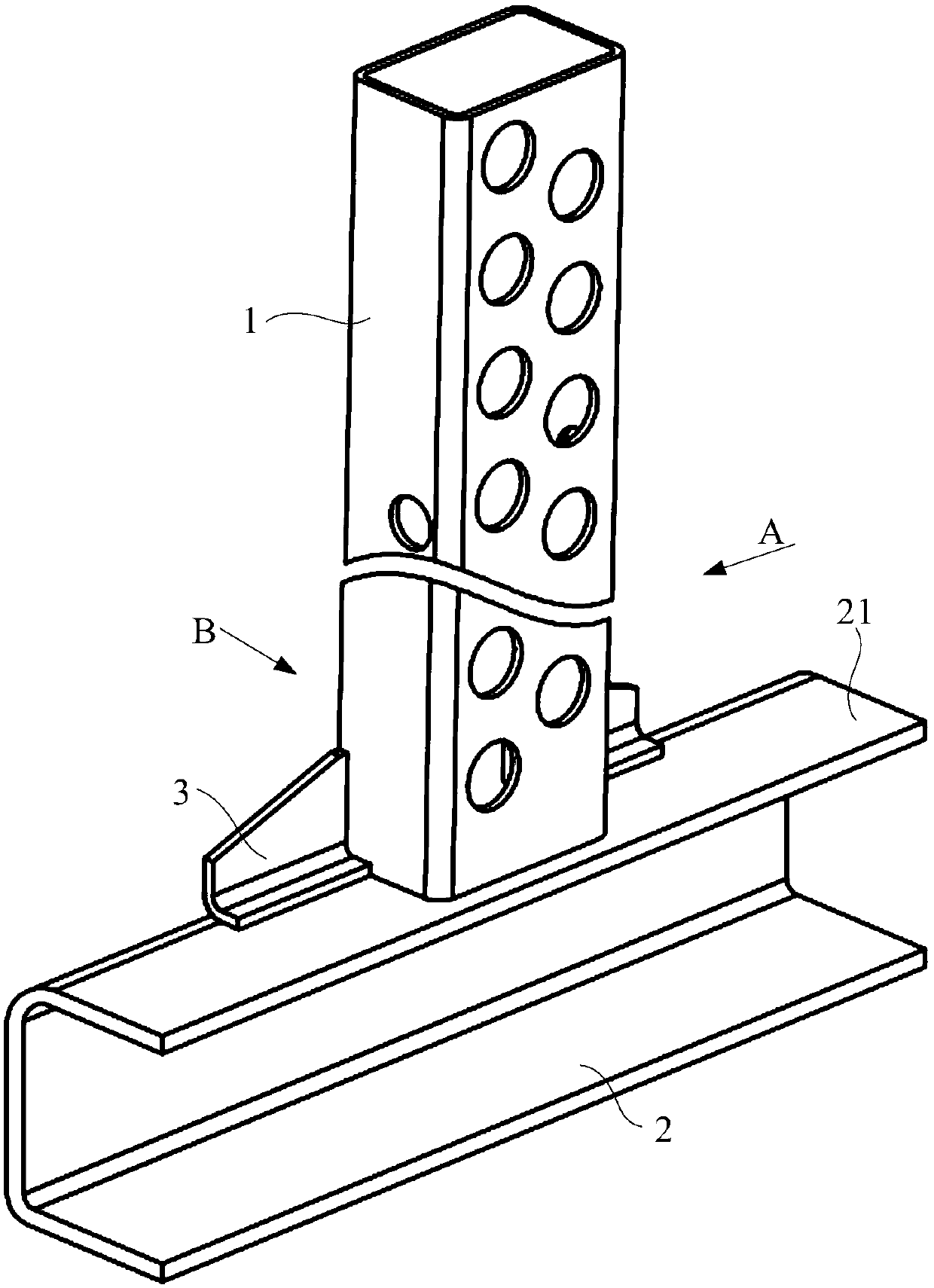

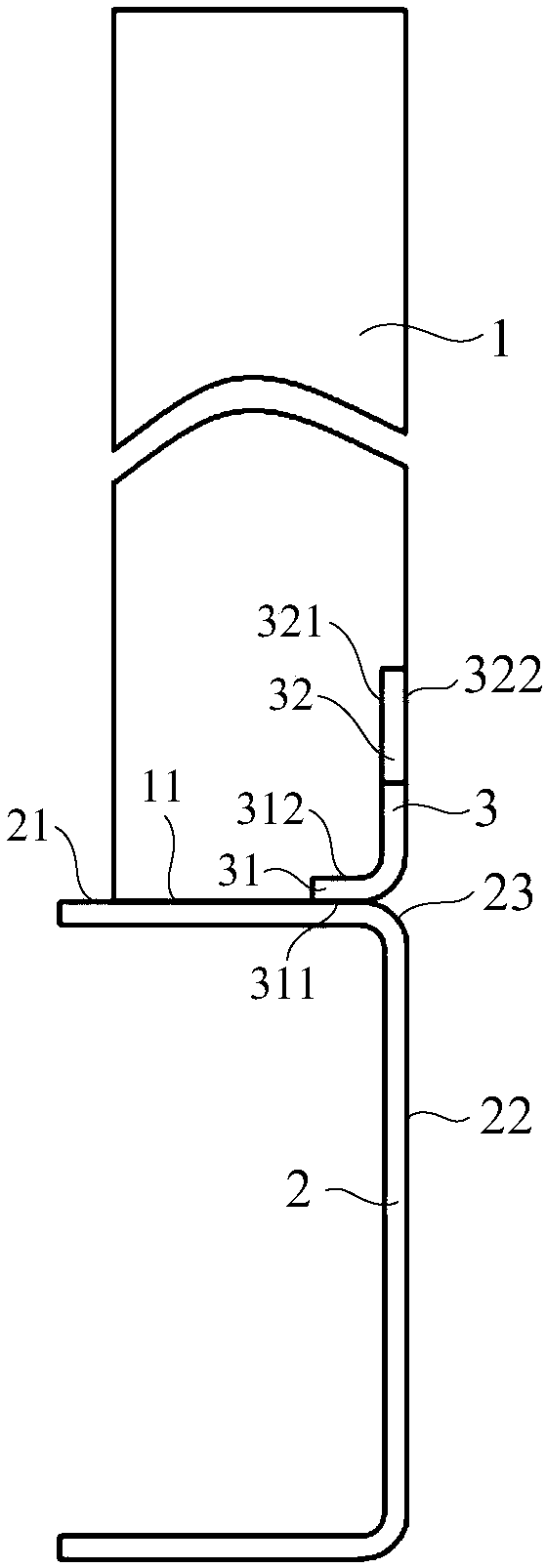

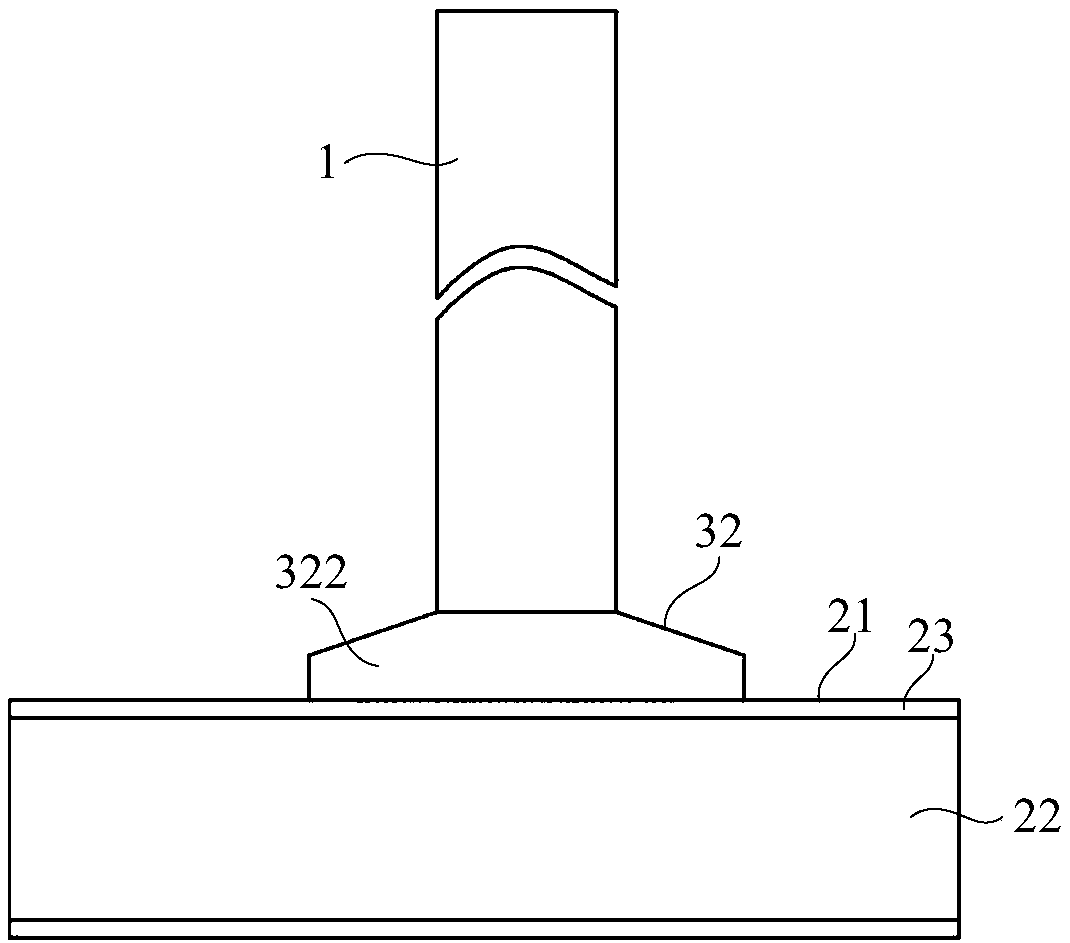

[0032] The embodiment of the present application provides a connection structure between the side wall column 1 and the underframe side beam 2, such as figure 1 with Figure 5 As shown in the structure, the connection structure includes a side wall column 1 and an underframe side beam 2, and the underframe side beam 2 is provided with a top surface 21, a side surface 22, and an arc surface 23 connecting the top surface 21 and the side surface 22; The beam 2 is a channel beam, and the top surface 21 is used to weld and connect a plurality of side wall columns 1. In order to prevent the stress concentration of the side beam 2 of the bottom frame, a rounded transition is adopted at the junction of the top surface 21 and the side surface 22, and an arc is formed. Surface 23;

[0033] The connection structure also includes a connecting piece 3 welded on the top surface 21 of the side beam 2 near the arc surface 23, the connecting piece 3 is used to enhance the connection strength ...

Embodiment 2

[0049] The embodiment of the present application provides a car body of a rail vehicle, the car body includes an underframe provided with an underframe side beam 2 and a side wall provided with a side wall column 1, and the connection between the side wall column 1 and the underframe side beam 2 Use any one of the connection structures provided in the above-mentioned embodiments for connection.

[0050] Since the above connection structure is adopted between the side wall and the chassis of the car body, a connecting piece 3 is added between the side wall column 1 and the side beam of the chassis 2, and the connection between the side wall column 1 and the chassis edge can be enlarged through the connecting piece 3. The welding area and length of the welding seam between the beams 2 can improve the connection strength between the side wall column 1 and the side beam 2 of the underframe.

Embodiment 3

[0052] An embodiment of the present application provides a rail vehicle, and the rail vehicle includes the vehicle body provided in the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com