Patents

Literature

40results about How to "Facilitate large-scale synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for cuprous oxide micron/nano crystal with controllable morphology

InactiveCN102583499AGood dispersionControl growth characteristicsNanotechnologyCopper oxides/halidesMicro nanoWatch glass

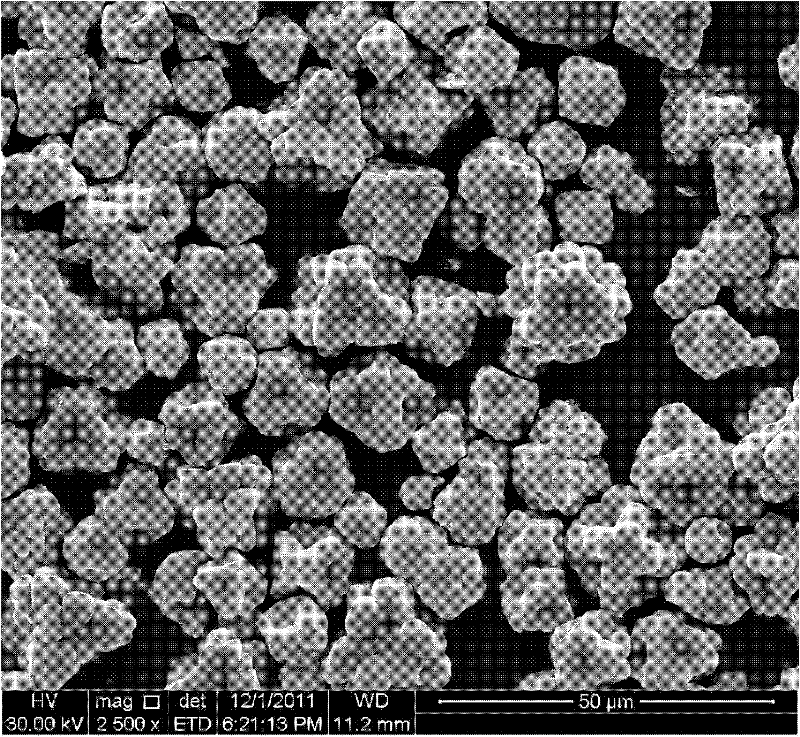

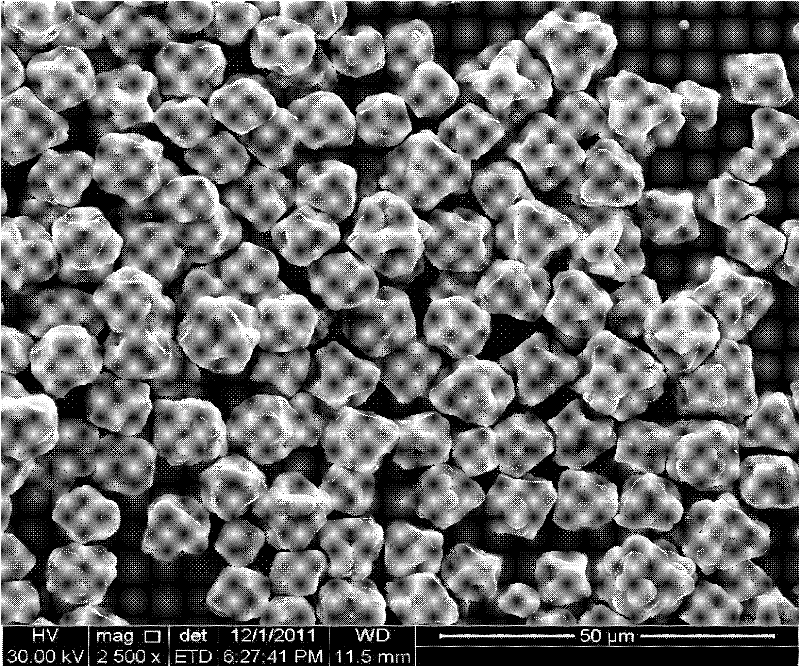

The invention relates to a preparation method for cuprous oxide micron / nano crystal with controllable morphology, relating to the preparation method for the cuprous oxide micron / nano crystal. The invention mainly solves the technical problems of high cost and environmental pollution in the preparation process of the micron / nano cuprous oxide. The method comprises the following steps of: 1, dissolving copper salt into ultrapure water, pouring lactic acid, continuously stirring, regulating a pH value, cooling to the temperature of 25 DEG C, keeping constant volume, measuring the pH value, and obtaining solution A; 2, moving the solution A to a hydrothermal reaction kettle, sealing the reaction kettle, putting the hydrothermal reaction kettle into a drying oven, keeping the temperature, naturally cooling to a room temperature, centrifugally washing by using the ultrapure water, centrifugally washing by using anhydrous ethanol, transferring the reaction kettle onto watch glass, and drying the reaction kettle in the drying oven; and thus obtaining the cuprous oxide micron / nano crystal. The preparation method for the cuprous oxide micron / nano crystal with the controllable morphology has the advantage of simpleness and practicability, simple equipment operation, low raw material price, easy synthesis, less pollution to environment and high synthetic concentration, the problem of the cost of the morphology control and industrialized large-scale synthesis in the prior art is solved, and the industrial production is facilitated.

Owner:HARBIN INST OF TECH

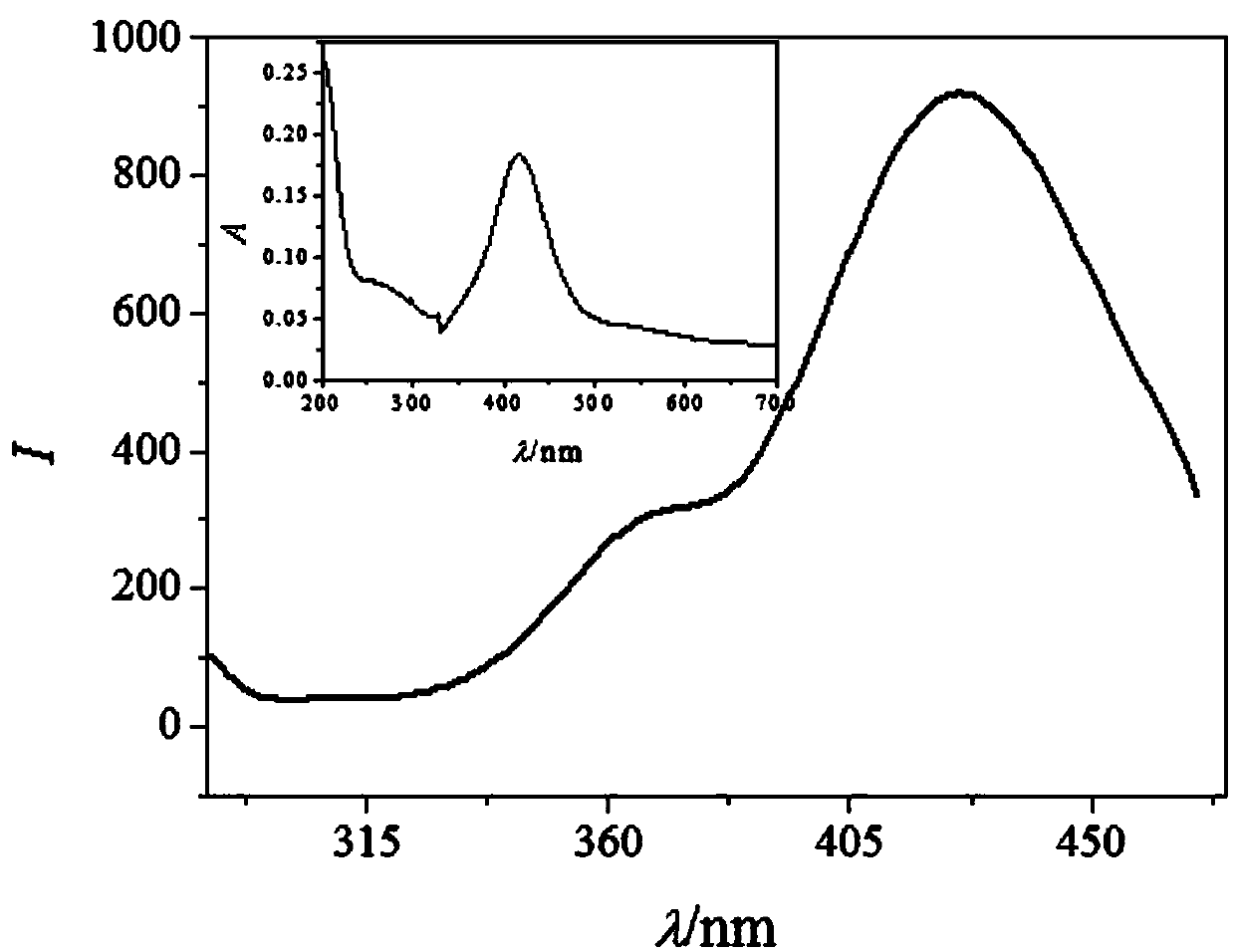

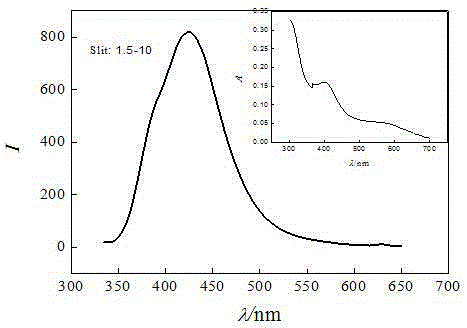

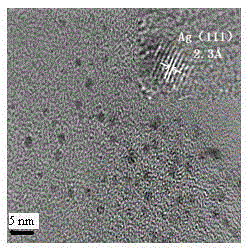

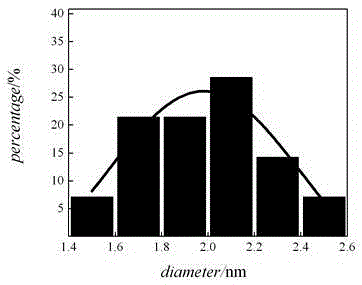

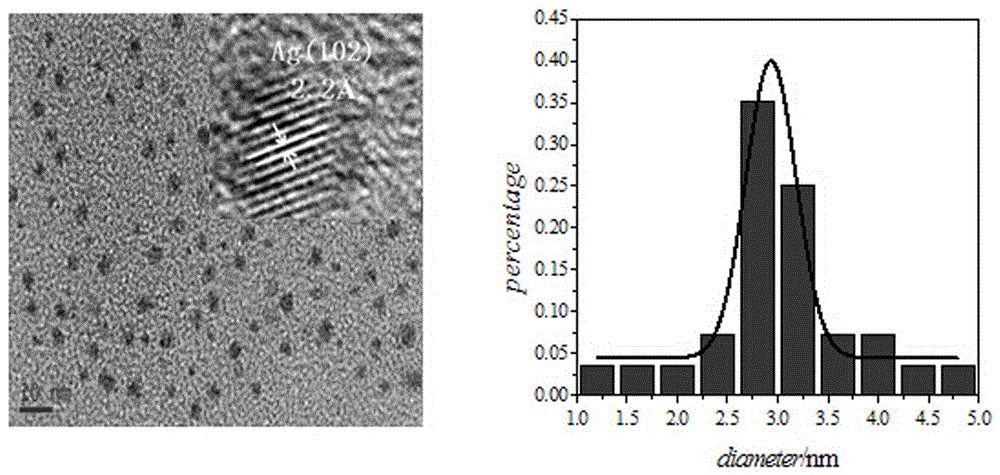

Method for synthesizing fluorescent silver nano clusters by taking general DNA (Deoxyribose Nucleic Acid) as stabilizer

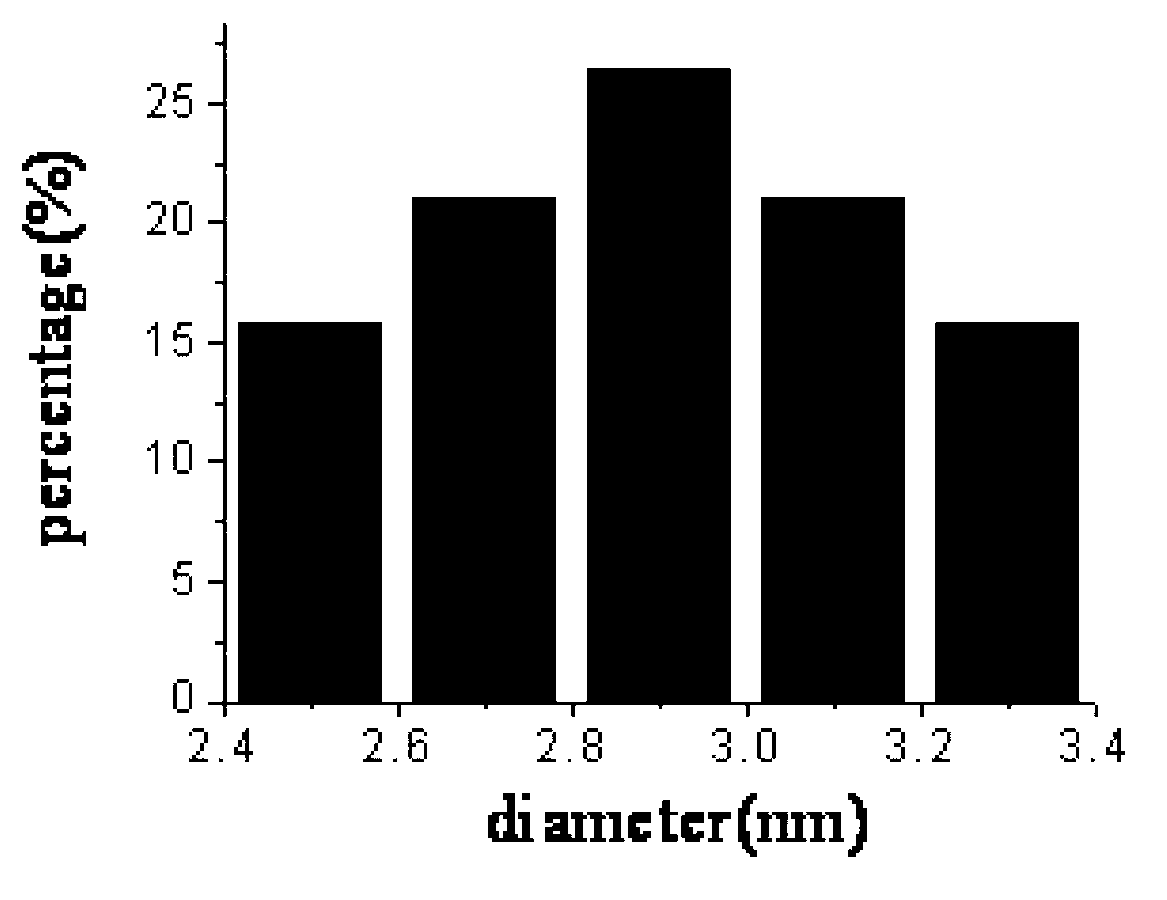

The invention belongs to the field of chemical engineering, and particularly relates to a method for large-scale synthesization of fluorescent silver nano clusters by taking general modified DNA (Deoxyribose Nucleic Acid) as a stabilizer. The method mainly comprises the following steps: (1) mixing the general modified DNA with a silver ion solution and reacting in a refrigerator of 4 DEG C for 24 h; and (2) adding a NaBH4 solution into a mixed solution in the step (1) and reacting for 3 h at the room temperature of 10-25 DEG C to obtain a silver nano cluster solution. According to the method, the general modified DNA is taken as the stabilizer for the convenience of large-scale synthesization of the fluorescent silver nano clusters; and the synthetic method is economic, the particle size is smaller, the particle distribution is uniform, and strong fluorescent light can be generated.

Owner:HUNAN UNIV OF SCI & TECH

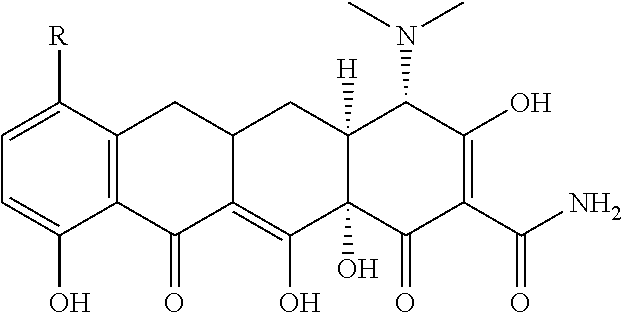

Tigecycline and methods of preparing intermediates

InactiveUS20090099376A1Facilitate large scale synthesisReduce the presence of impuritiesOrganic compound preparationCarboxylic acid amides preparationTigecyclineMedicinal chemistry

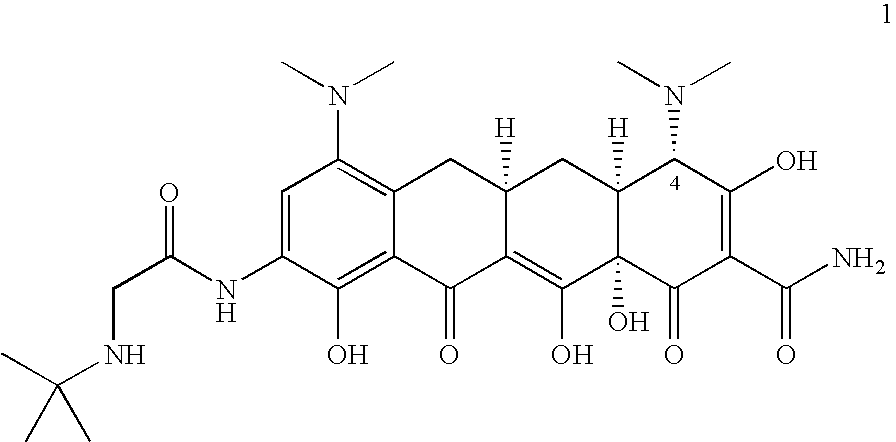

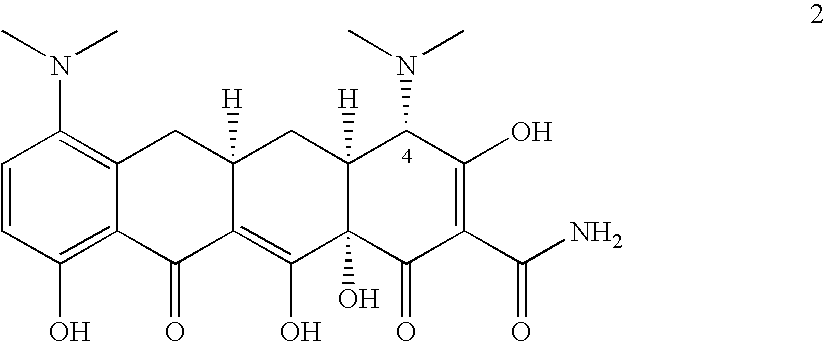

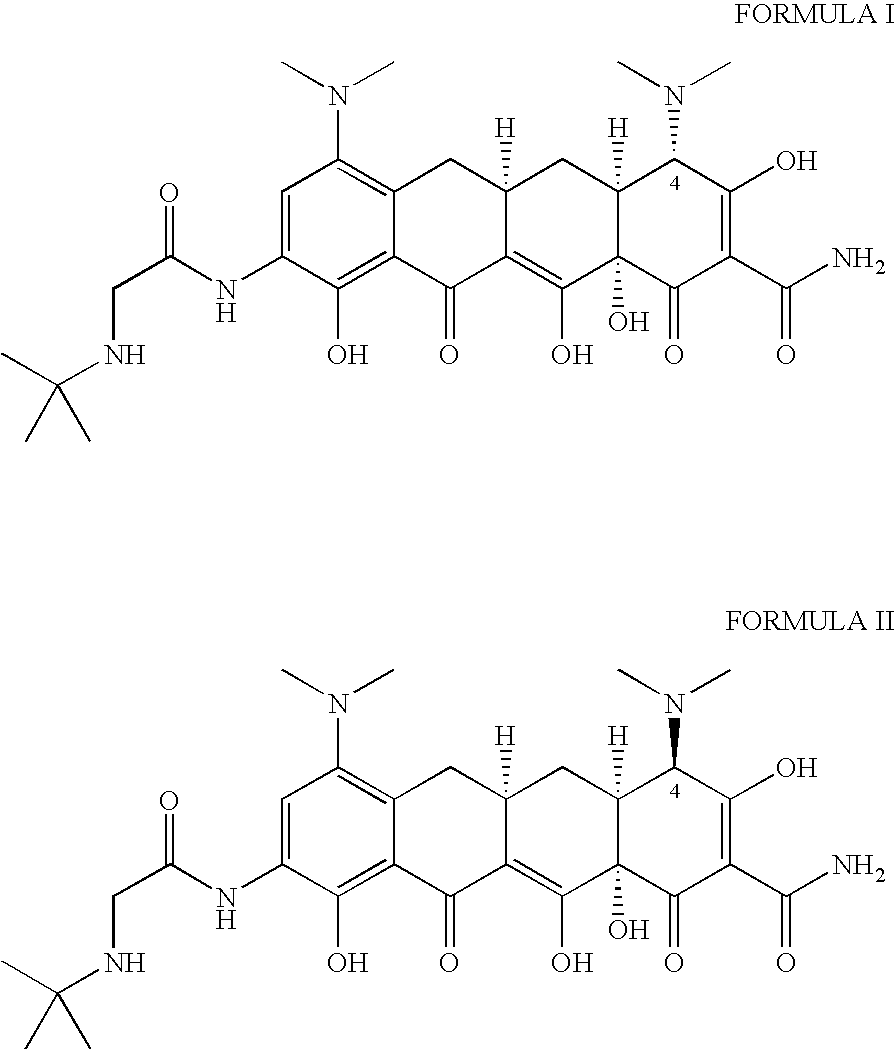

Methods of preparing and purifying 9-nitrominocycline and 9-aminominocycline and salts thereof used in the process of making tigecycline, are disclosed. In one embodiment, the invention is directed to a method of preparing the compound of formula 1or a pharmaceutically acceptable salt thereof, comprising:(a) reacting nitric acid with the compound of formula 2,or a salt thereof, to produce a reaction mixture comprising an intermediate; and(b) further reacting the intermediate to form the compound of formula 1, wherein the intermediate is isolated from the reaction mixture, the method further comprising sparging with an inert gas prior to step (a).

Owner:WYETH

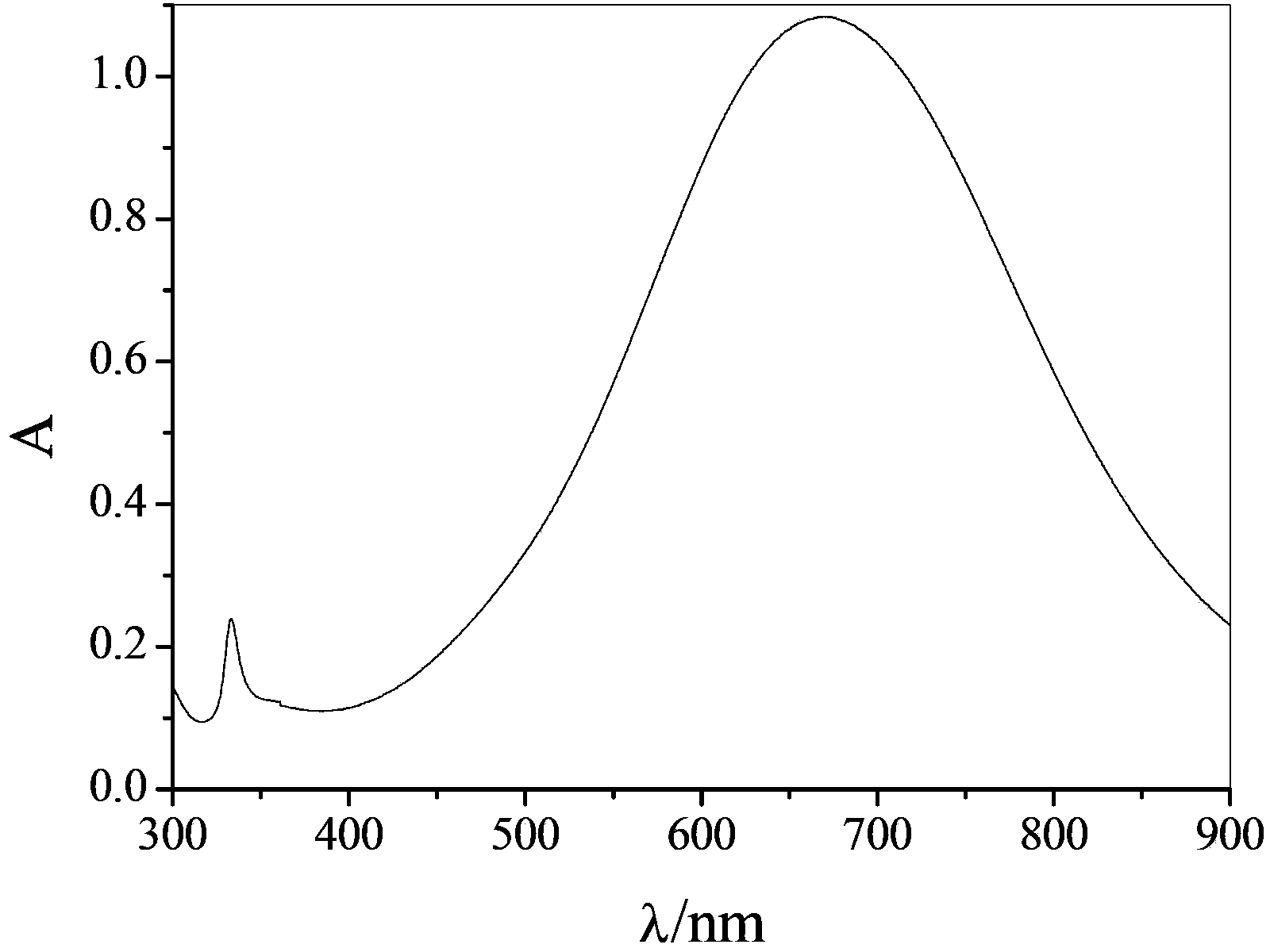

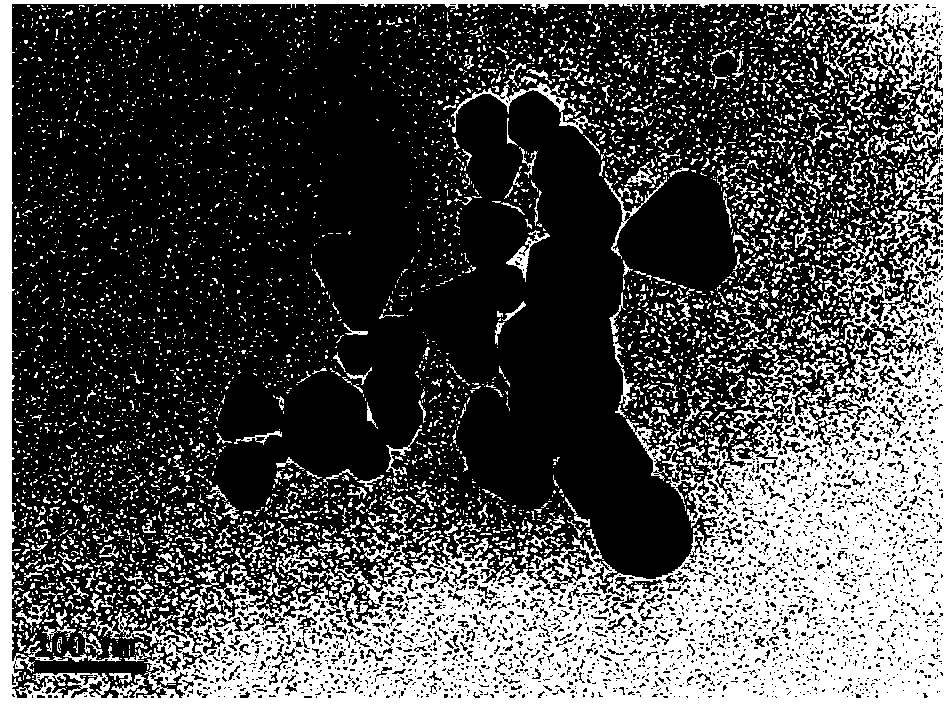

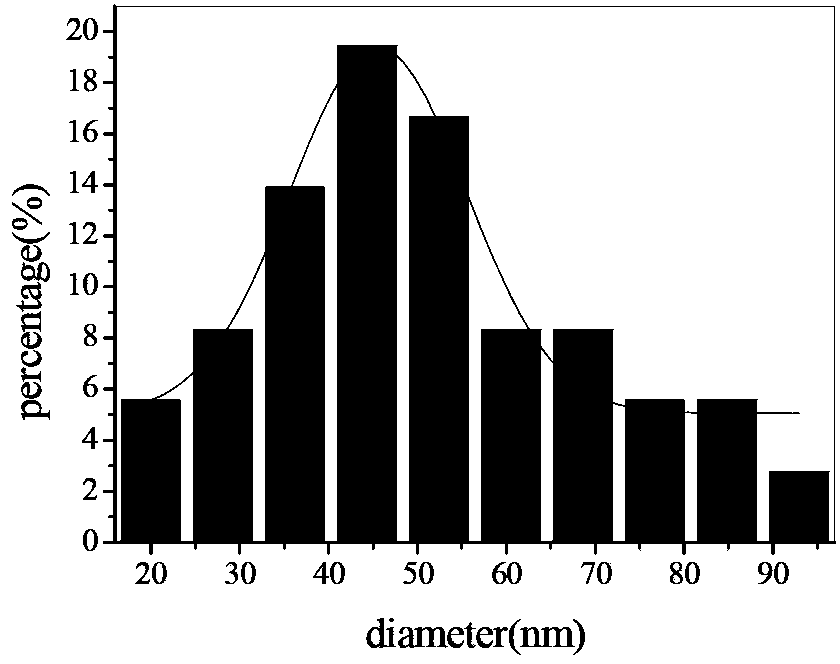

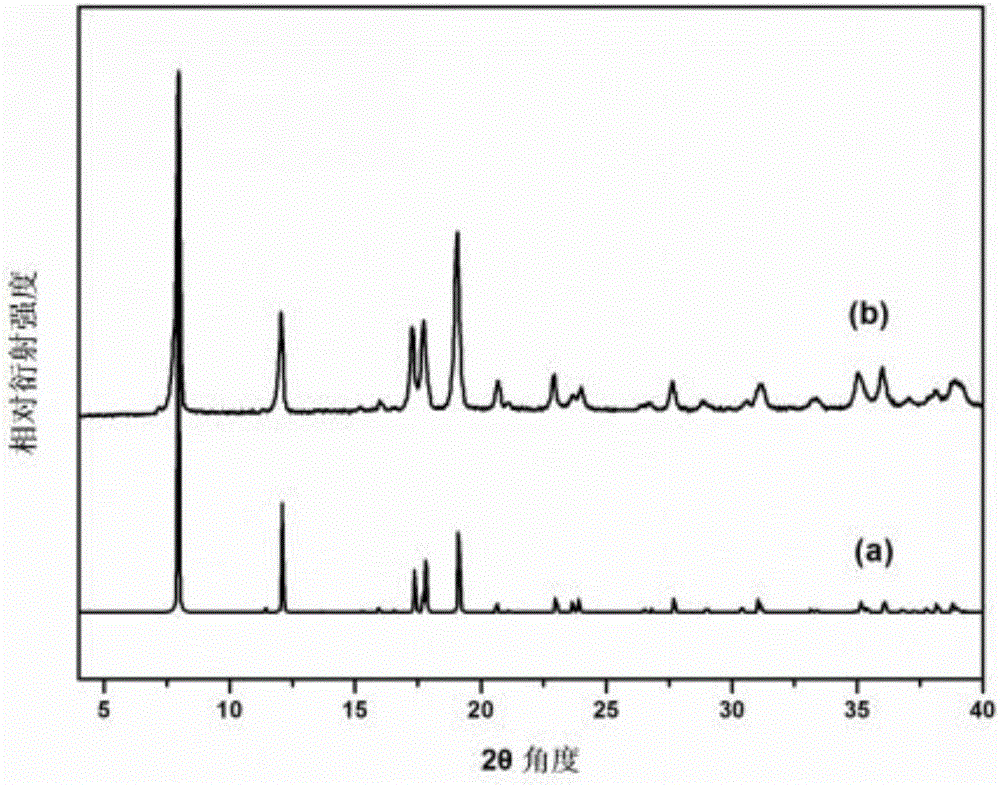

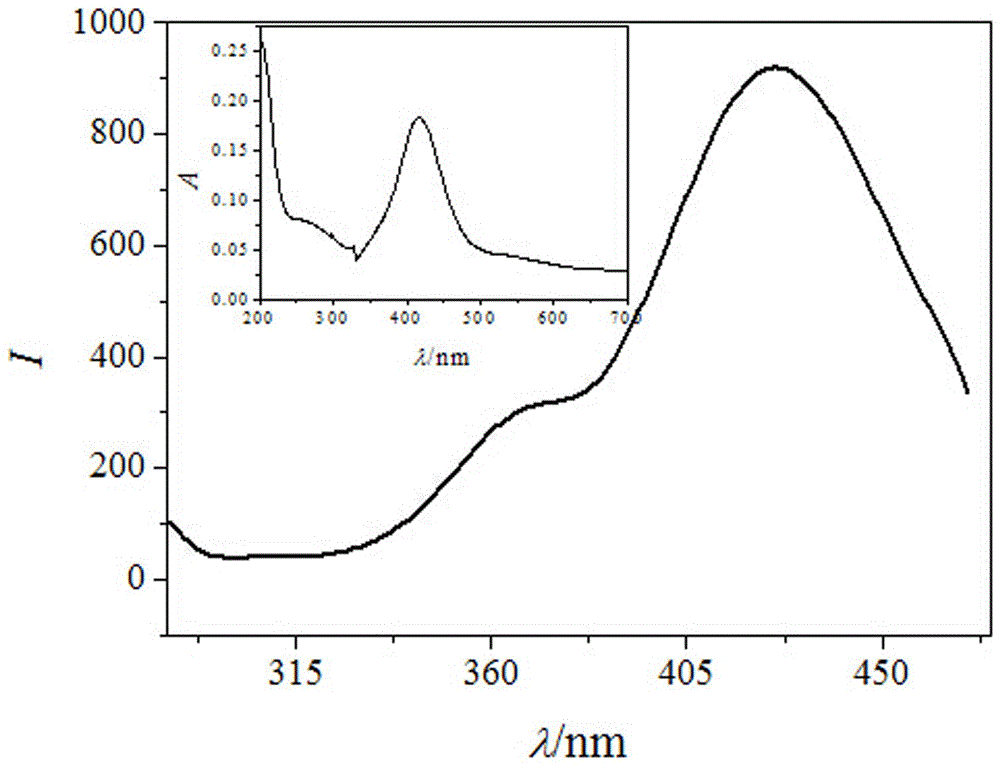

Method for compounding hexagon silver nanosheet

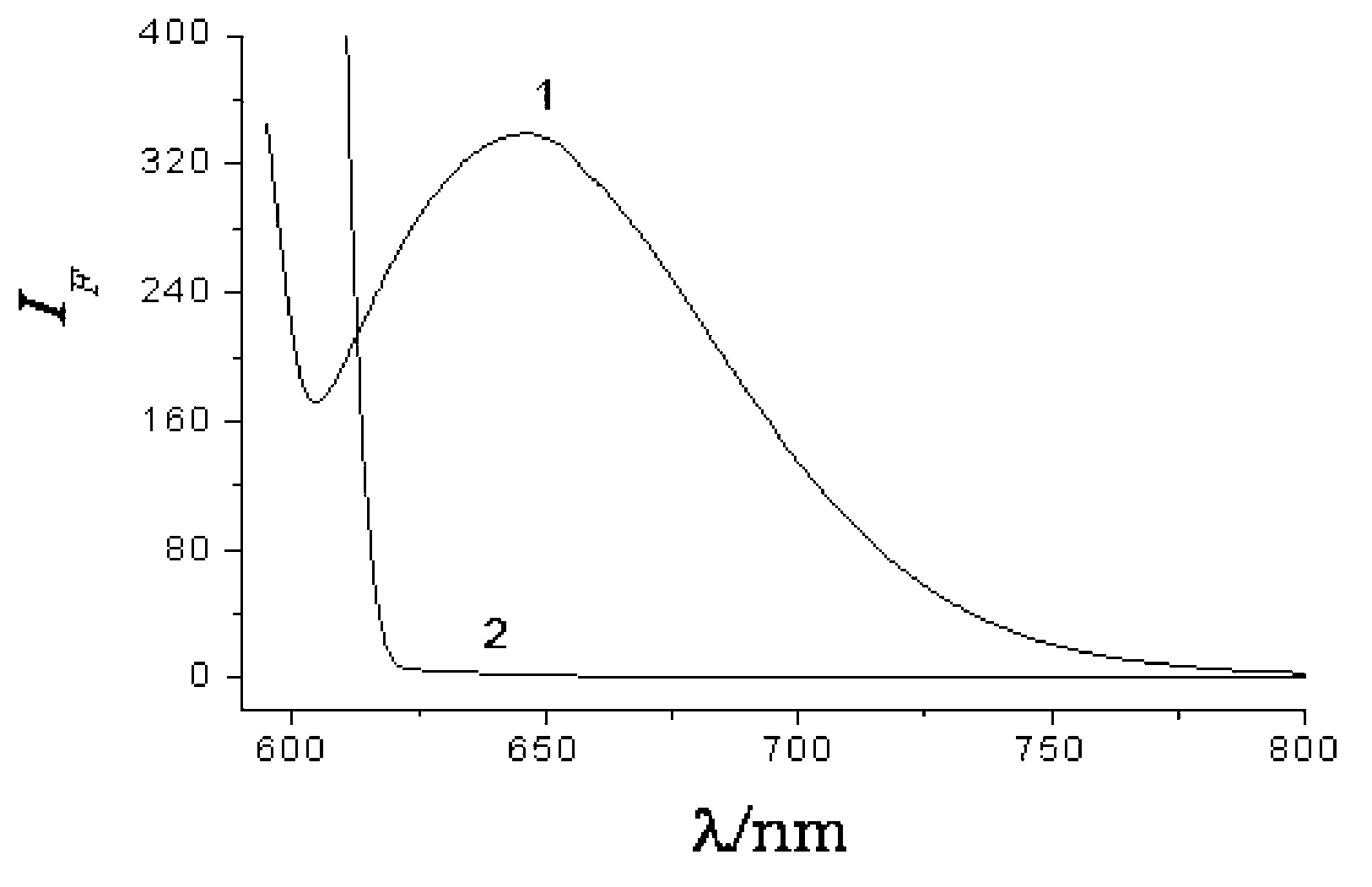

The invention belongs to the field of chemical engineering, and particular relates to a method for compounding a hexagon silver nanosheet. The method for compounding the hexagon silver nanosheet takes carboxymethyl glucan as stabilizing agents and sodium borohydride as reducing agents and uses an ammoniacal silver solution. According to the method for compounding the hexagon silver nanosheet, a prepared Ag(NH3)2OH solution is added in a conical flask, redistilled water and stirrers are further added, and the conical flask is placed in a magnetic stirring apparatus; trisodium citrate, hydrogen peroxide, carboxymethyl glucan, newly prepared NaBH4 are added in the solution in sequence under stirring, reaction is carried out for 3-5min at room temperature, and a blue hexagon silver nanosheet solution is simply obtained. Compared with other silver nanosheet compounding methods, the method for compounding the hexagon silver nanosheet has the advantages of being short in compounding cycle, simple in operation, low in cost, convenient to compound in large scale and the like. The maximum absorption peak position of the method for compounding the hexagon silver nanosheet is around 680nm, and the average particle diameter is around 45nm.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of magnetic carbon-covering nano material

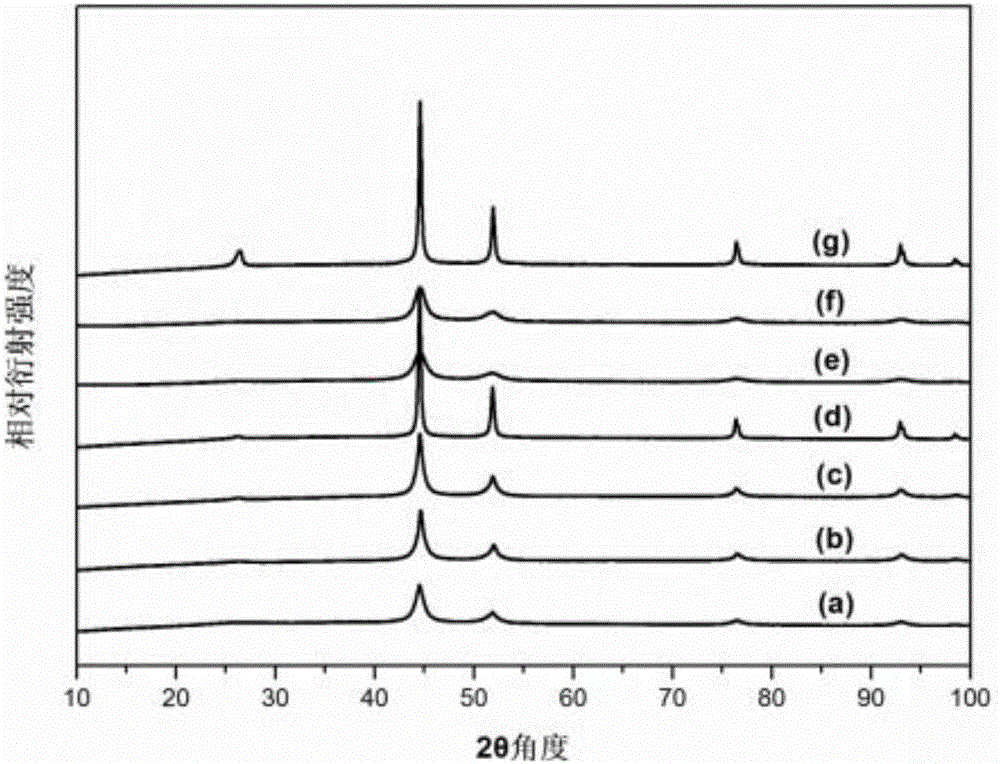

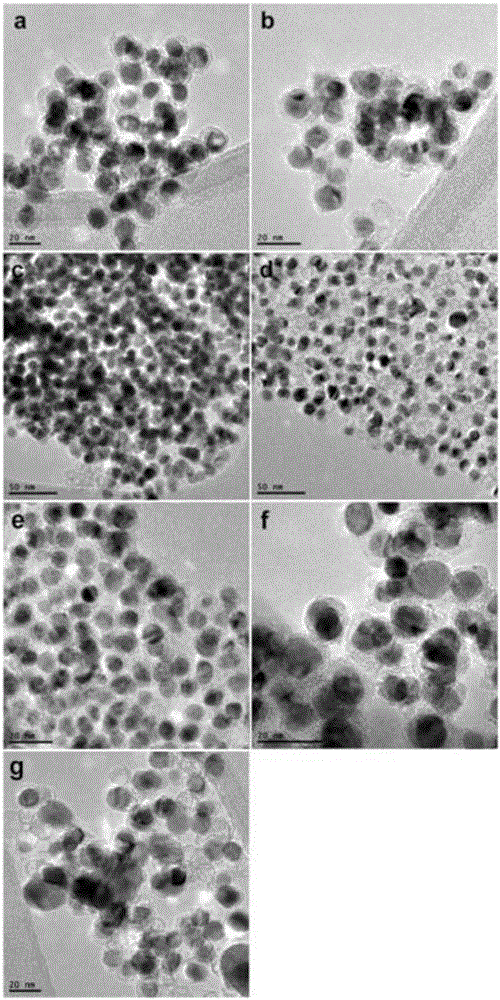

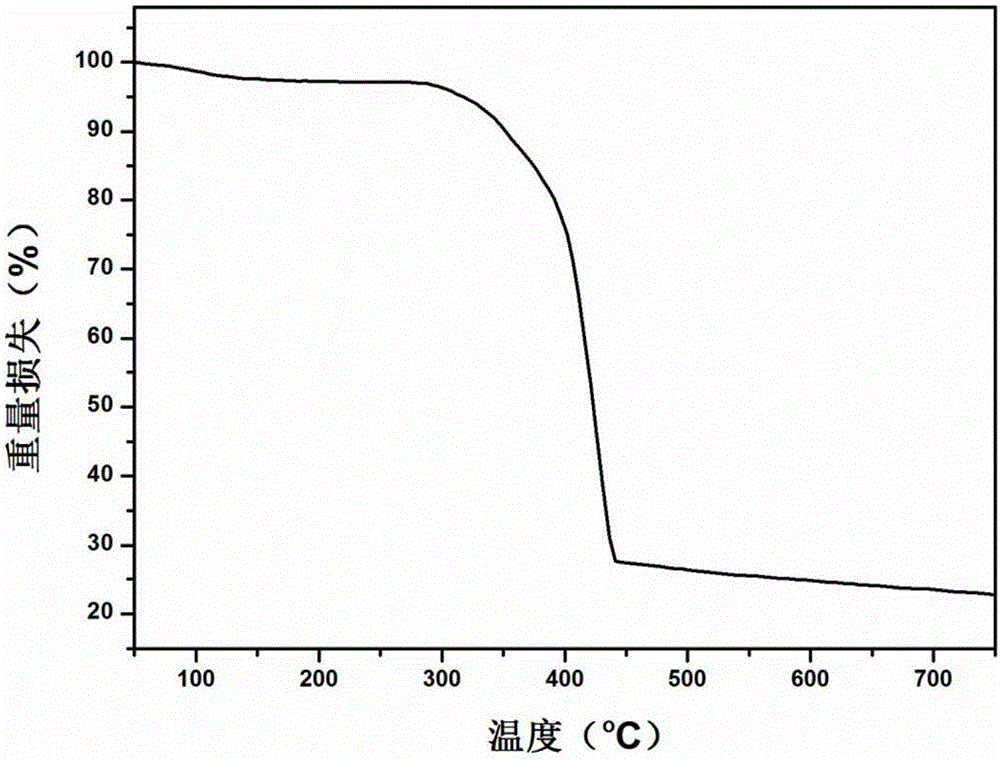

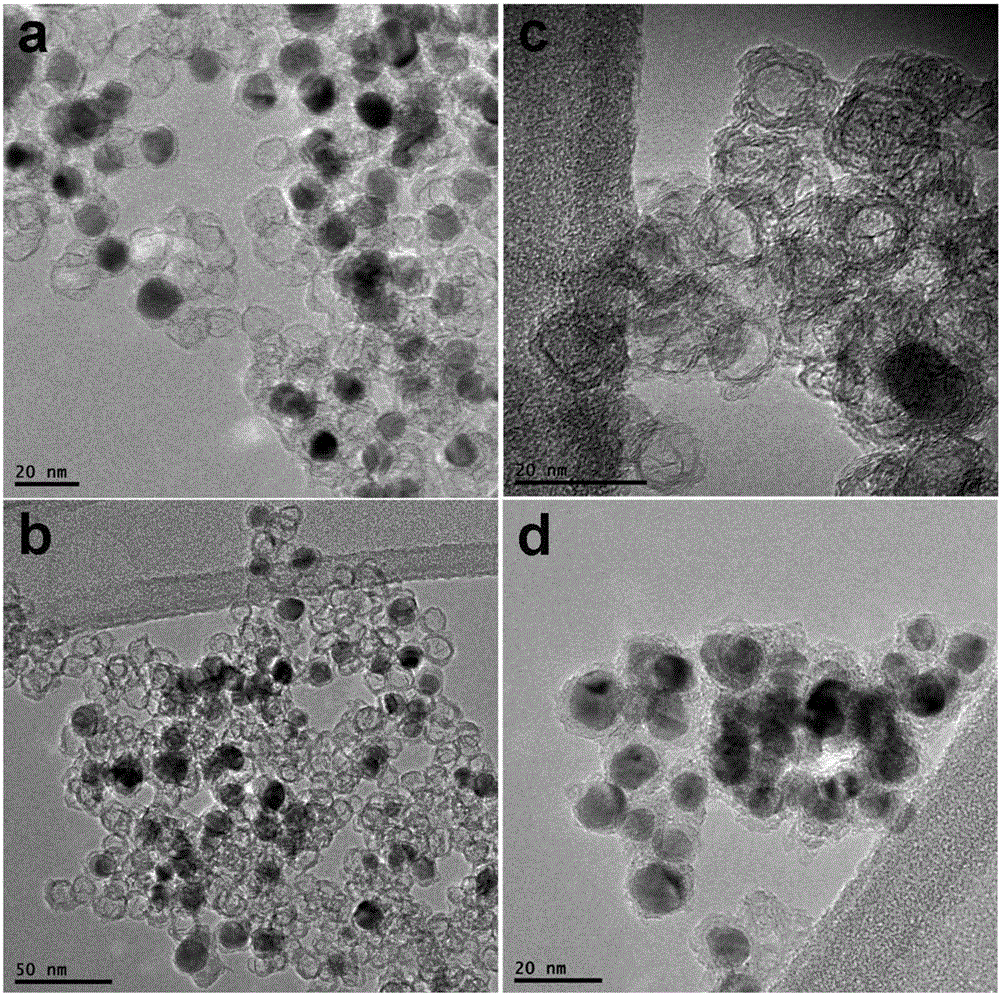

InactiveCN105965009AIncrease productionHigh saturation magnetizationMaterial nanotechnologyTransportation and packagingDispersityHysteresis

The invention discloses a preparation method of a magnetic carbon-covering nano material, and belongs to the field of preparation of nanocarbon@metal composites. The preparation method of the magnetic carbon-covering nano material is characterized in that the magnetic carbon-covering nano material is obtained through carrying out high-temperature pyrolysis on a metal-organic framework compound in the atmosphere of inert protection. According to the preparation method, the metal-organic framework compound is utilized as a precursor, and the carbon-covering nano material with a uniform size is prepared through a one-step high-temperature pyrolysis process; and according to a product obtained through the method, the phase is single, the impurities are extremely few, the collection is particularly easy, the yield is high, the large-scale synthesis is facilitated, the product has quite good ferromagnetism, the dispersity is quite good, the response time is short, and the magnetic carbon-covering nano material has quite typical ferromagnetism hysteresis loop and relatively high saturation magnetization intensity, and is a kind of quite potential biomagnetic nano material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

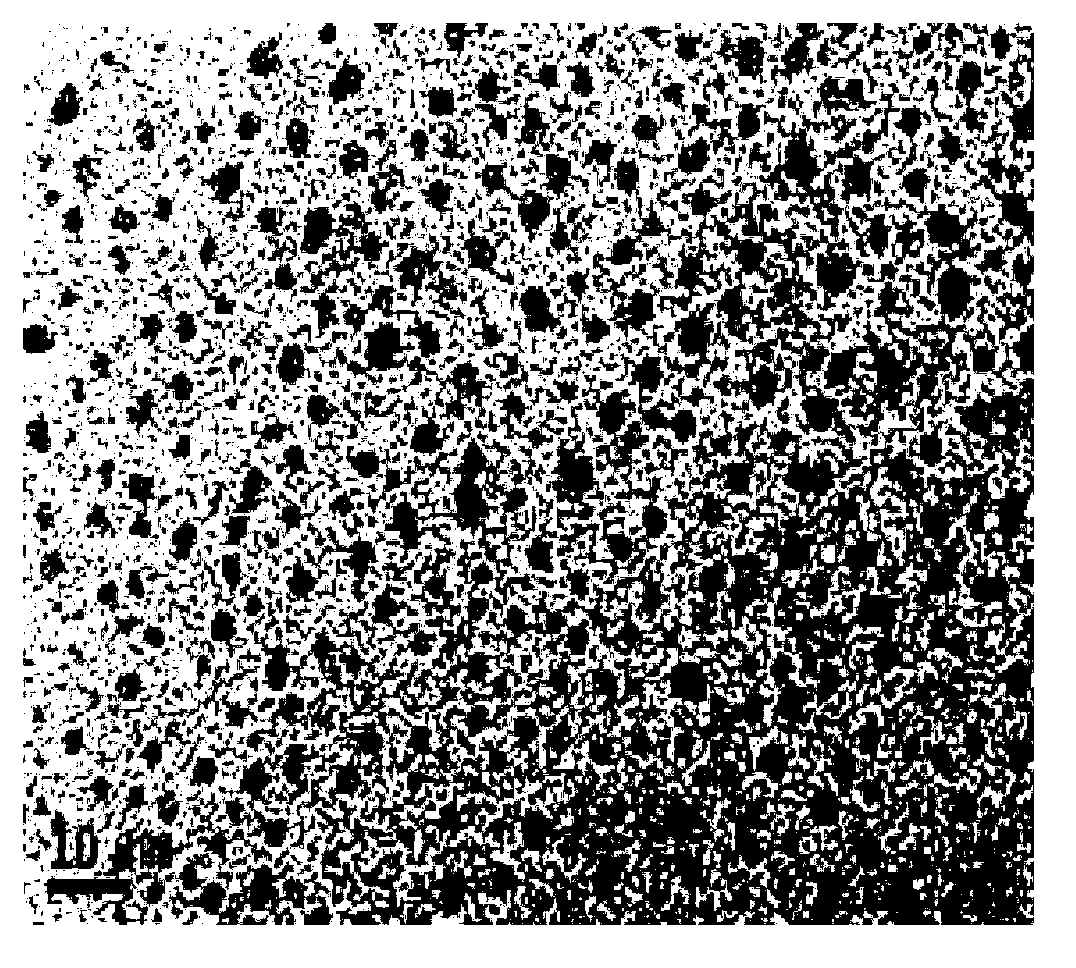

Method for restoring silver ammonia solution with ultraviolet light to prepare water-soluble silver nano-clusters

ActiveCN104174868ASimple reaction systemEasy to operateMaterial nanotechnologyFluorescenceUltraviolet lights

The invention provides a method for restoring a silver ammonia solution with ultraviolet light to prepare water-soluble silver nano-clusters. The method includes: adding an AgNO3 solution to a reaction vessel, slowly adding a NaOH solution to the vessel in oscillation, after sediment is generated, dropwise adding NH3.H2O to the vessel in oscillation till the sediment is fully dissolved, and adding redistilled water to prepare a silver ammonia stock solution with the concentration of 5.0*10<-3>M; dropwise adding carboxymethyl dextran to a weighing bottle, adding the silver ammonia stock solution in stirring, adding secondary water till volume of the solution reaches 5 to 10 times of that of the carboxymethyl dextran, stirring the solution with a magnetic stirrer for 5 to 10 minutes, and placing the solution in an exposure manner at the normal temperature under an ultraviolet lamp prior to stirring while light the solution for 2 to 4 hours. The carboxymethyl dextran is taken as a stabilizer and a reducing agent, and the water-soluble silver nano-clusters can be synthesized from the silver ammonia solution under irradiation of the ultraviolet light.

Owner:HUNAN UNIV OF SCI & TECH

Method for preparing arylboronic acid neopentyl glycol ester

ActiveCN105732684AEasy to purifyClear structureOrganic-compounds/hydrides/coordination-complexes catalystsNickel organic compoundsPotassiumCarbene

The invention discloses a method for preparing arylboronic acid neopentyl glycol ester.The method includes the steps that a mixed-type nickel (II) complex with Ni(P(OR1)3)((R2NCH2CH2NR2)C)X2 as the chemical formula serves as a catalyst, and a cross coupling reaction of phenyl chlorine substitutes and bis(neopentyl glycolato) diboron is efficiently catalyzed in potassium methoxide to prepare the arylboronic acid neopentyl glycol ester.The method is the first case that the mixed-type nickel (II) complex catalyzes the cross coupling reaction with phosphite ester and n-heterocyclic carbine as auxiliary ligands.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

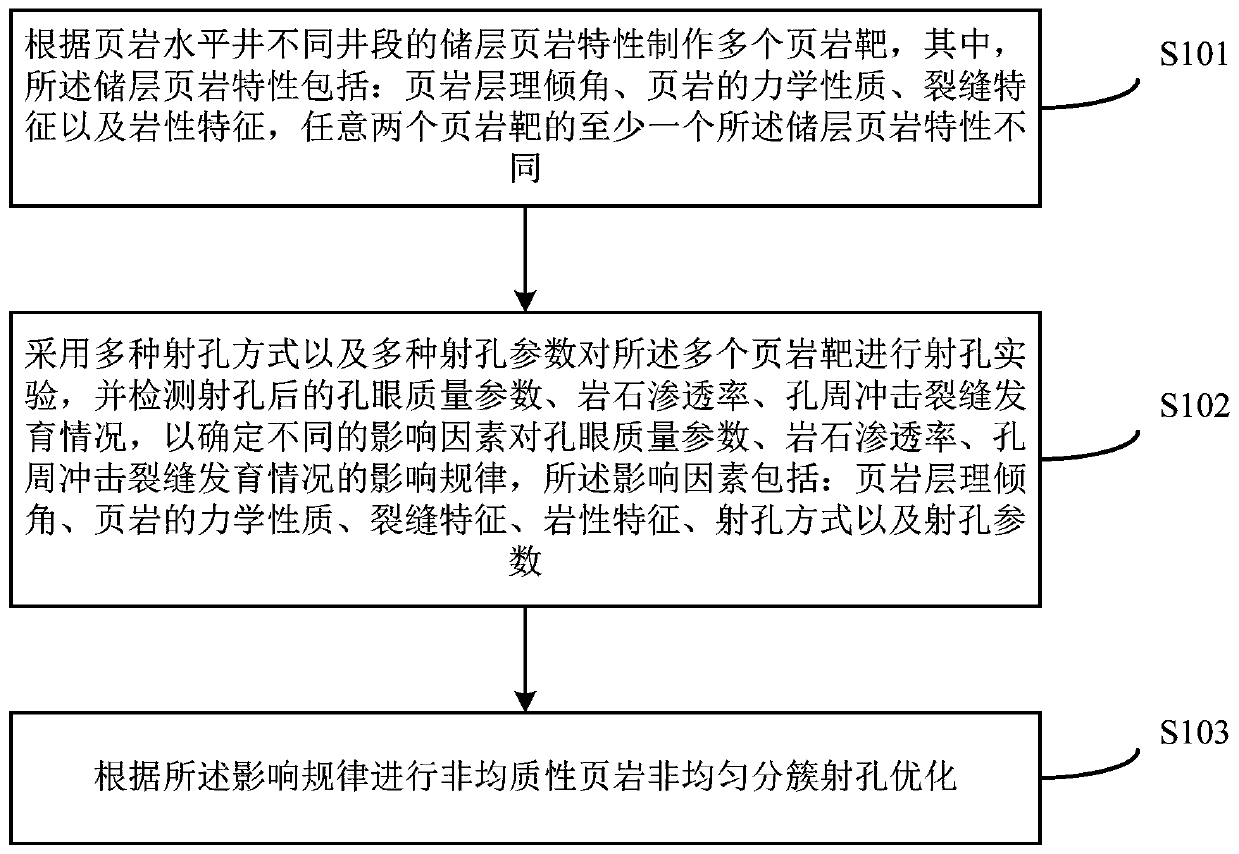

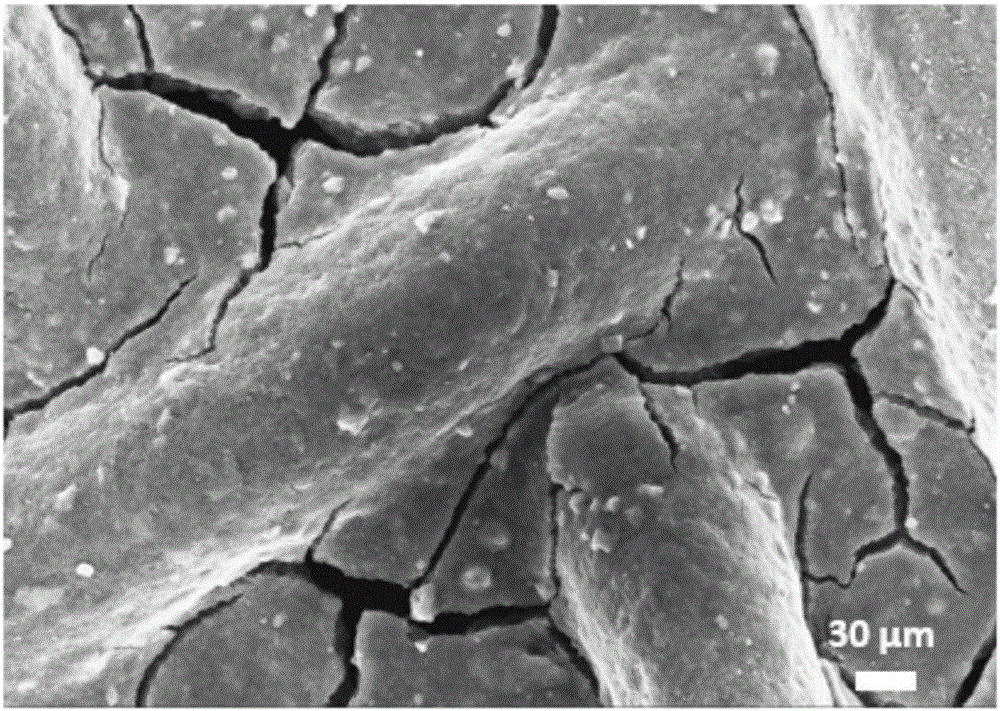

Non-uniform clustering perforation optimization method for non-homogeneous shale

ActiveCN110005380AMeet the experimental needsThe method is simple and fastSurveyFluid removalLithologyHorizontal wells

The invention discloses a non-uniform clustering perforation optimization method for non-homogeneous shale. The non-uniform clustering perforation optimization method comprises the steps that a plurality of shale targets are manufactured according to the reservoir shale characteristics of different well segments of shale horizontal wells, wherein the reservoir shale characteristics comprise the shale bedding inclination angle, the mechanical properties of the shale, the crack characteristics and the lithologic characteristic, and one or more reservoir shale characteristics of any two shale targets are different; and the multiple shale targets are subjected to a perforation test through multiple perforation modes and multiple perforation parameters, and the hole quality parameters, the rockpermeability and the development situation of impact cracks around a hole after perforation are detected so as to determine the influence law of different influence factors on the hole quality parameters, the rock permeability and the development situation of impact cracks around the hole; and non-uniform clustering perforation optimization of the non-homogeneous shale is conducted according to the influence law. According to the non-uniform clustering perforation optimization method, the technical problem that a non-uniform clustering perforation optimization method of the non-homogeneous shale is difficult to realize in the prior art is solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Carbon-based nanocomposite material for electrode

InactiveCN105977483AImprove stabilityIncrease productionMaterial nanotechnologyCell electrodesCarbon nanocompositeLithium-ion battery

The invention discloses a carbon-based nanocomposite material for an electrode, and belongs to the field of preparation of metal@carbon nanocomposite materials. According to a preparation method, the carbon-based nanocomposite material for the electrode is obtained by high-temperature pyrolysis of a metal-organic skeleton compound in an inert protective atmosphere. The metal-organic skeleton compound [Ni2(L-asp)2(bpy)] is utilized as a precursor; and the carbon-based nanocomposite material with a uniform dimension is prepared through a one-step high-temperature pyrolysis process. The product obtained by the method is single in phase, very few in impurities, especially easy to collect, high in yield and beneficial to large-scale synthesis; and the microstructure of the carbon-based nanocomposite material prepared by the method has excellent properties of high stability and the like in application of the electrode material of a lithium-ion battery.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

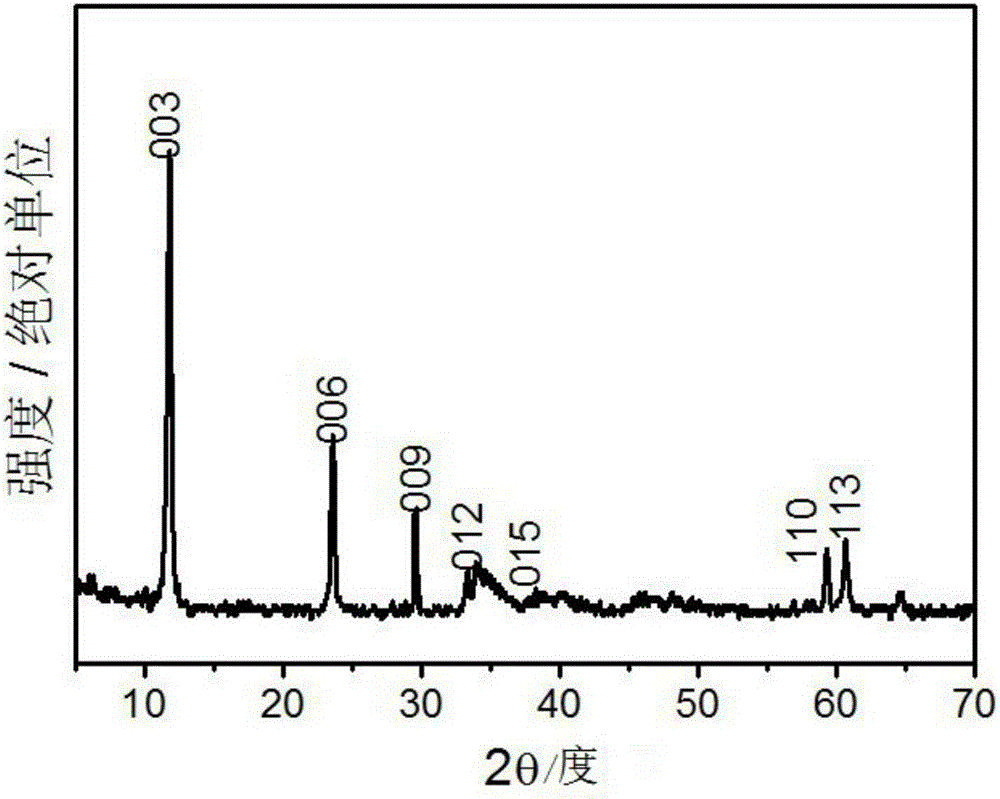

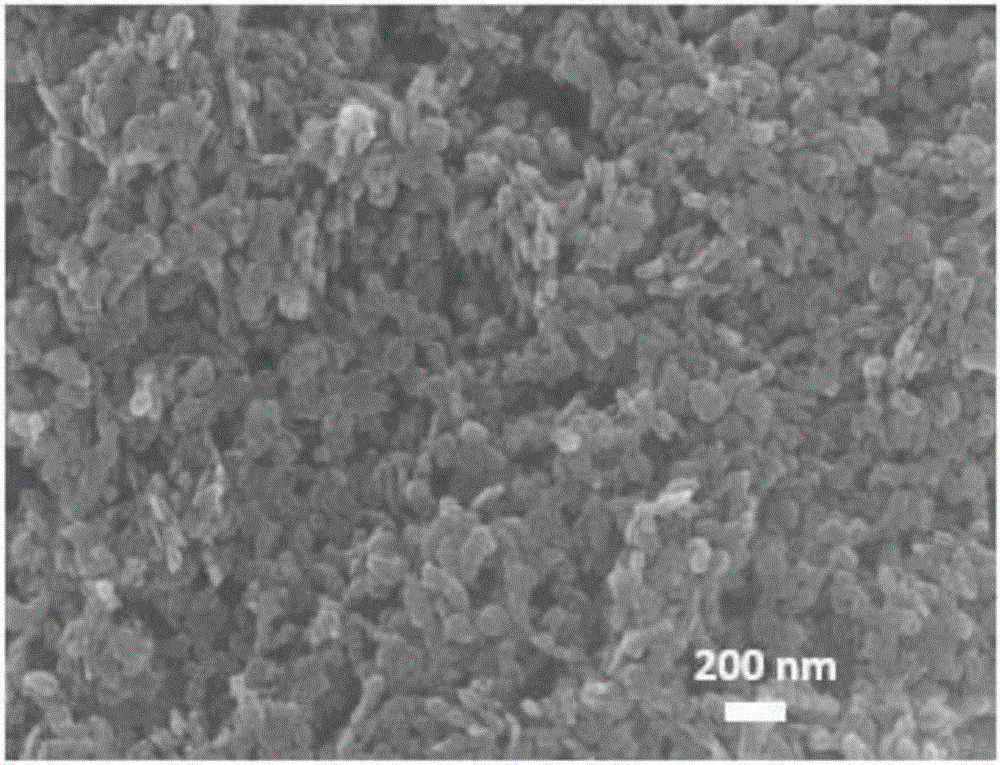

High efficiency water splitting oxygen electrode suitable for natural water and preparation method

Belonging to the field of water splitting new energy technologies, the invention provides a high efficiency water splitting oxygen electrode suitable for natural water and a preparation method. In the electrode, Co-Fe hydrotalcite has a mass percentage content of 3-5%, a particle diameter of 50-00 nm, and a specific surface area of 30-50m<2> / g; the used conductive carbon black is Vulcan XC-72 type, and has a mass percentage content of 7-16%; the used titanium mesh is a plain titanium mesh with equal warp and weft wire diameter density, has a thickness of 0.2-0.5mm and a mass percentage of 79%-90%. According to the preparation method, the Co-Fe hydrotalcite, carbon black and a metal titanium mesh substrate for loading are integrated into the composite electrode. The electrode can carry a simple three-electrode system to be used for oxygen evolution reaction in natural water and neutral non-buffer solutions, including natural seawater and neutral sodium chloride solutions, etc. The preparation method is simple and is easy to realize industrial production, and has no side reaction influence.

Owner:BEIJING UNIV OF CHEM TECH

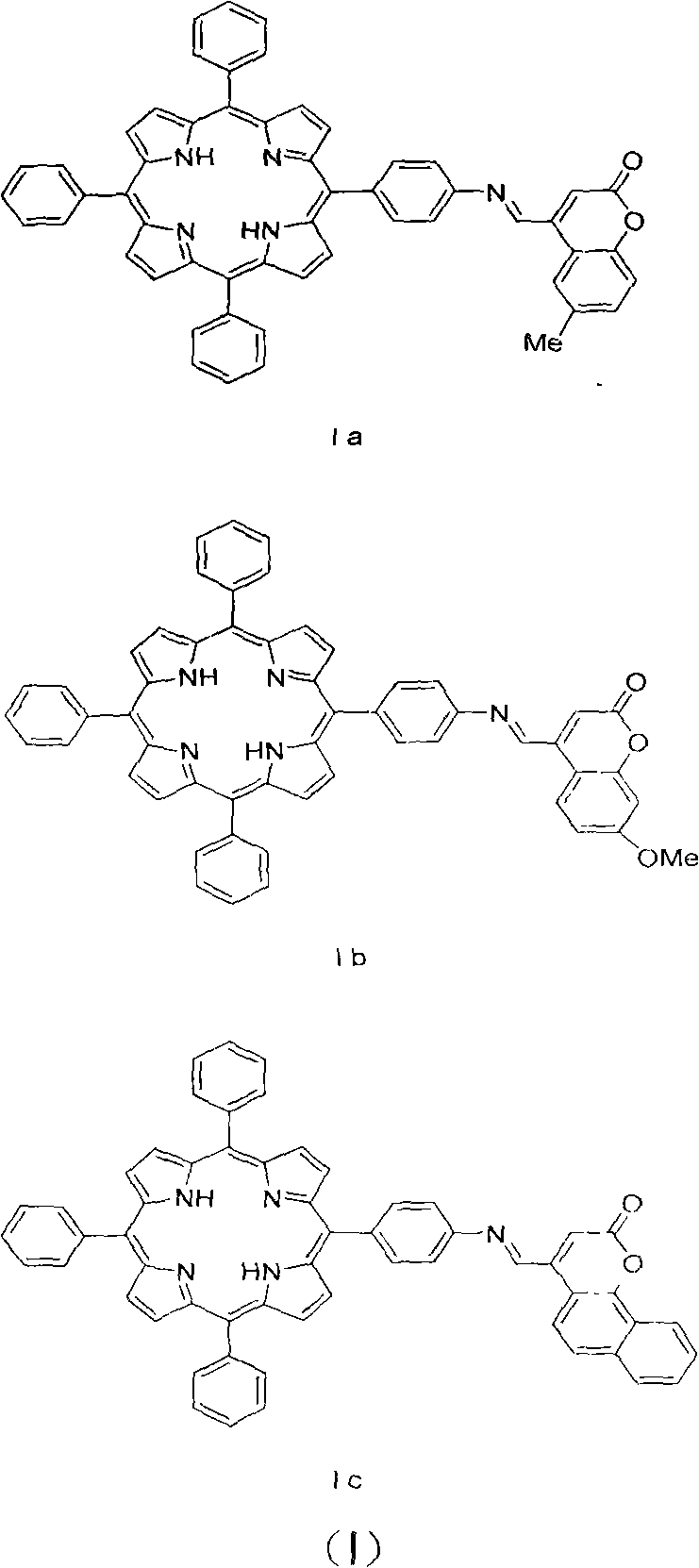

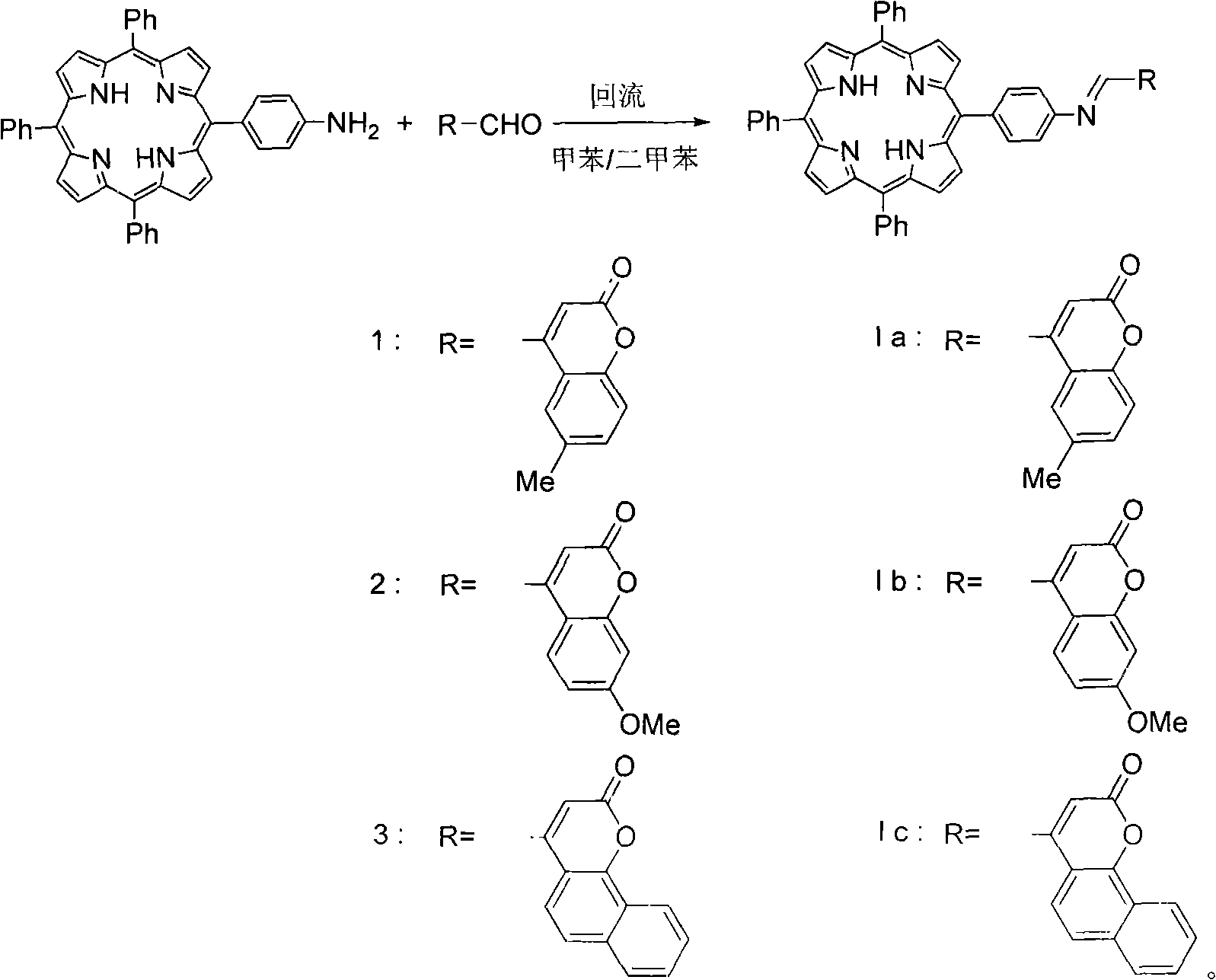

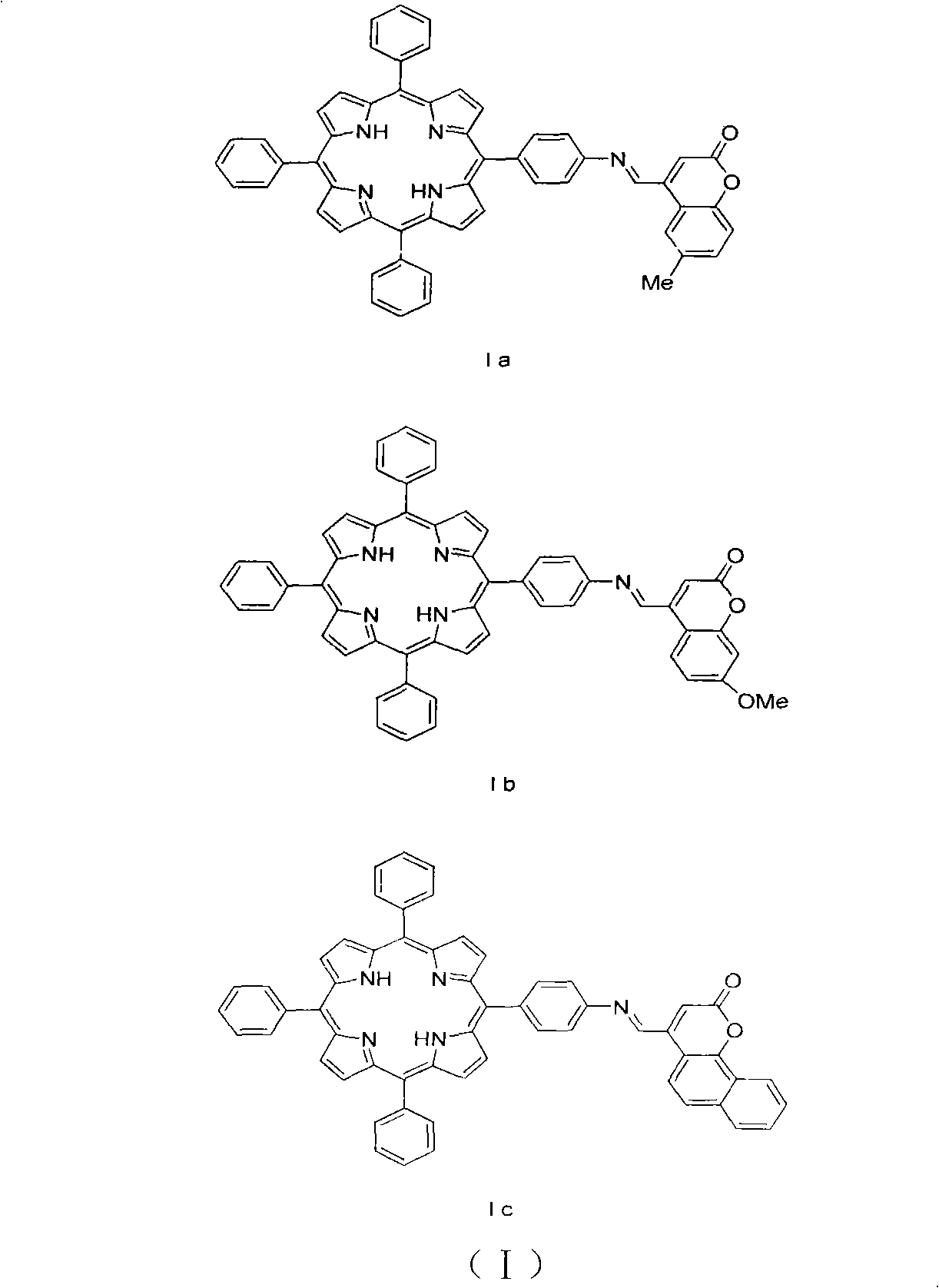

Coumarin-porphyrin schiff base compounds and preparation method

The invention relates to a coumarin-porphyrin Schiff alkali compound and a preparation method thereof. 5-(4-aminophenyl)-10, 15, 20-triphenyl porphyrin and coumarin aldehyde are dissolved in inertia solvent and heated until refluxing under the protection of nitrogen. A thin-layer chromatography is used for monitoring the reaction liquid. After the 5-(4-aminophenyl)-10, 15, 20-triphenyl porphyrin reacts fully, the reaction is stopped. Decompression is carried out for steaming out the solvent. After the recrystal purification, corresponding coumarin-porphyrin Schiff alkali is obtained. With the structure shown in formula (I), the porphyrin Schiff alkali compound has the advantages of high yield and simple separation and purification, and the product yield can reach 60-70 percent.

Owner:TIANJIN UNIV

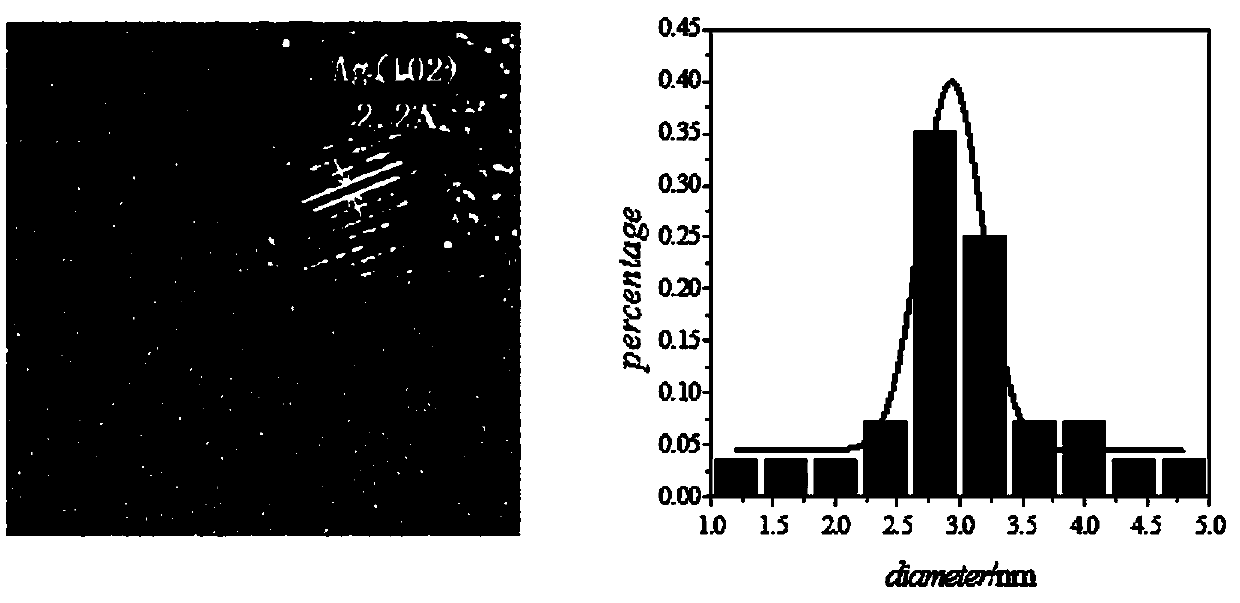

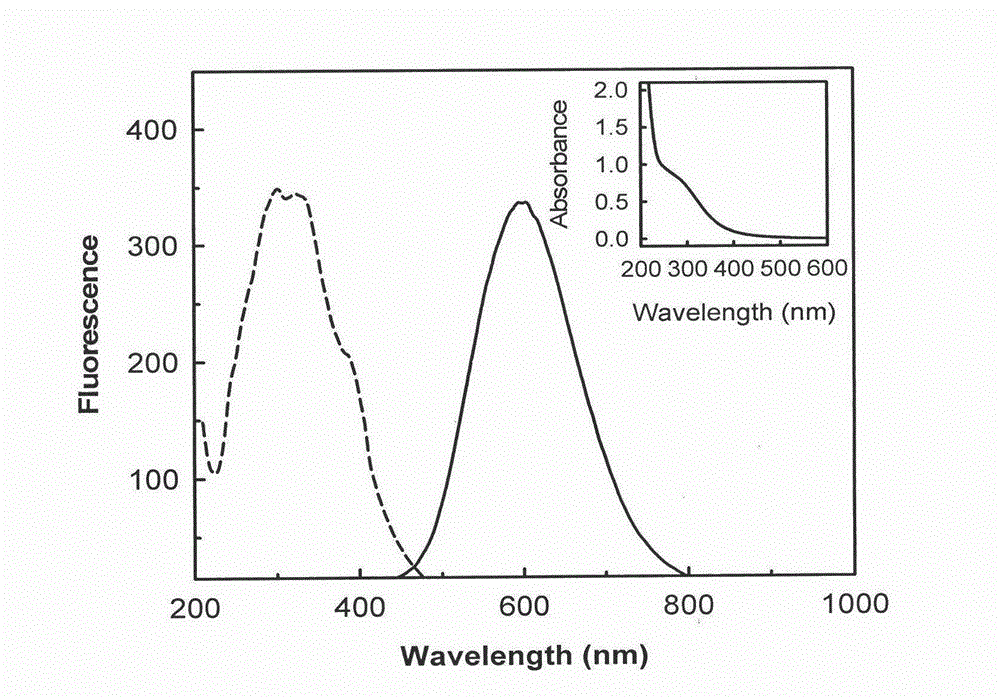

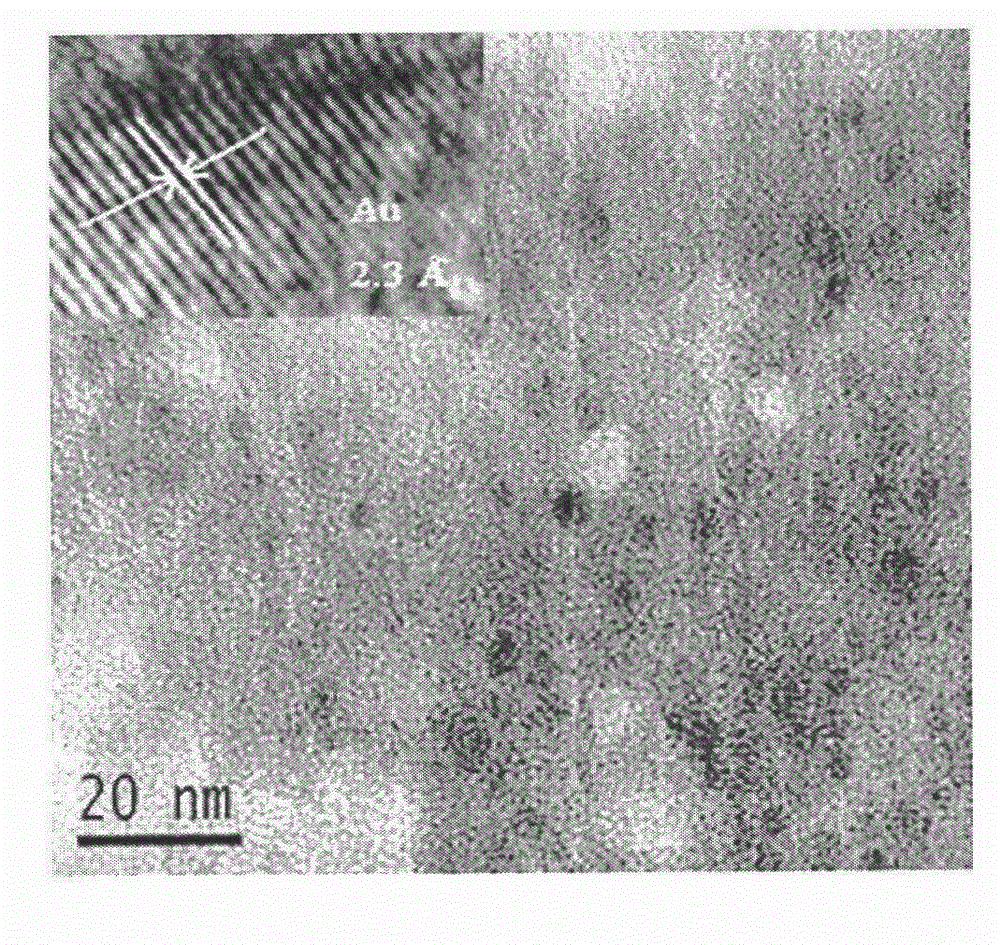

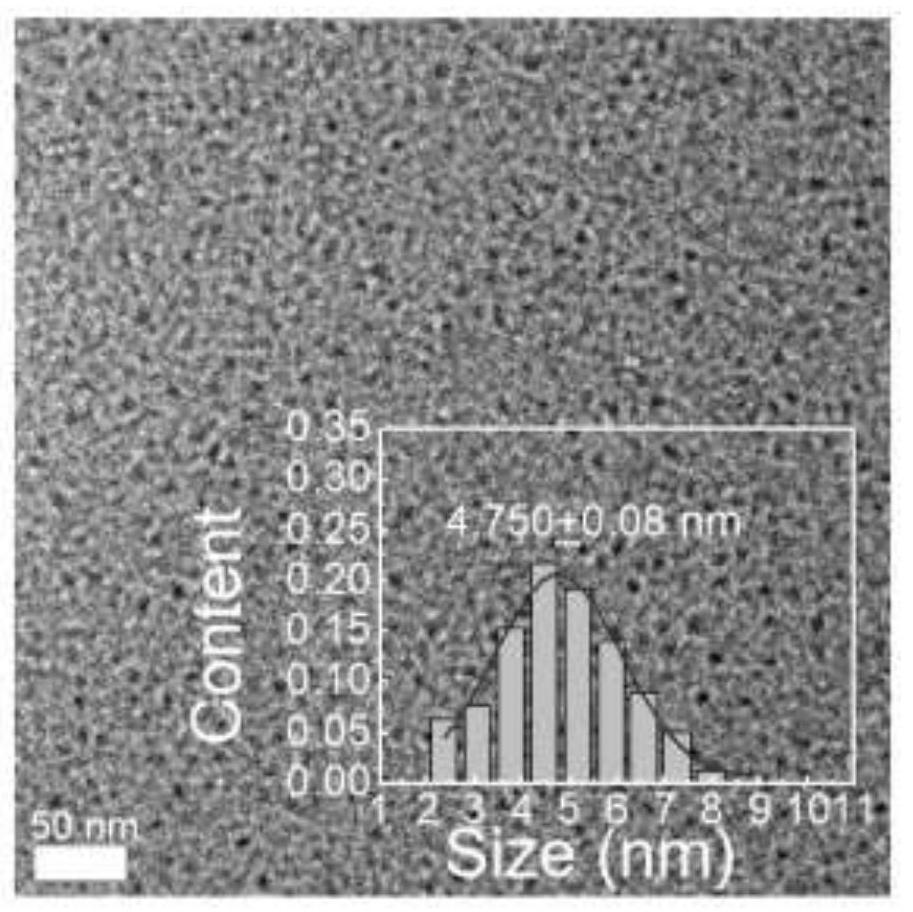

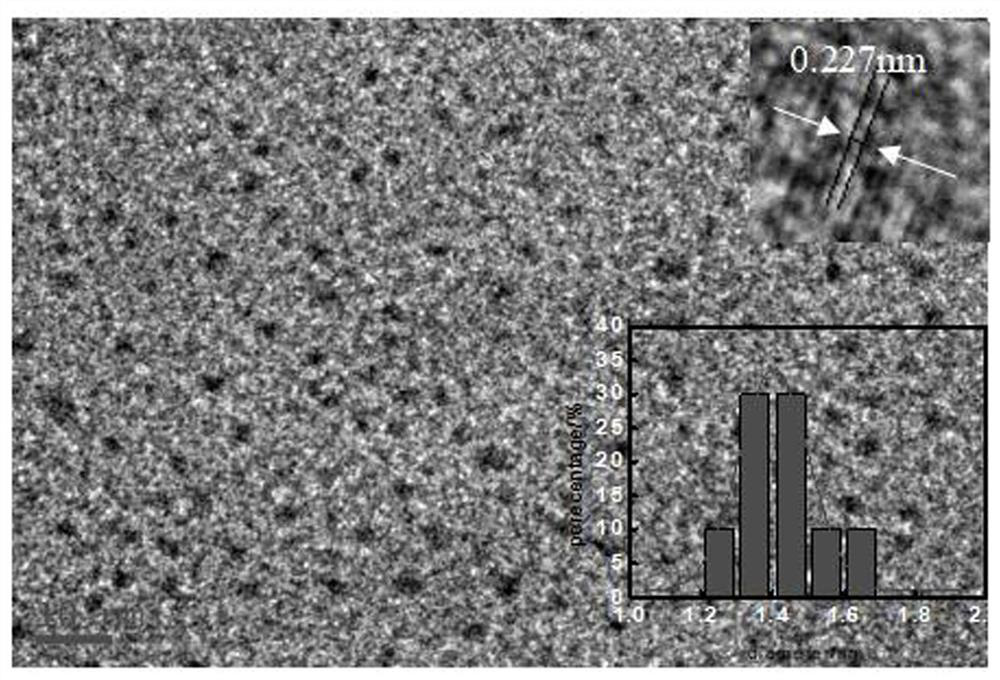

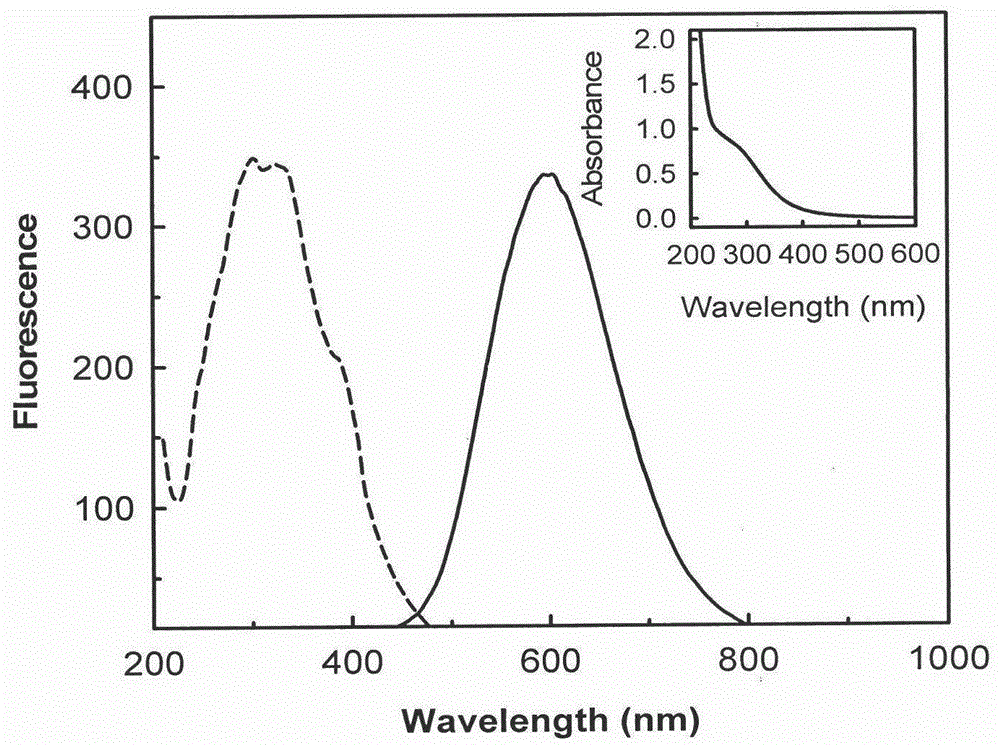

Method for synthesizing fluorogold nanometer quantum dots by taking micromolecules as stabilizer

InactiveCN102861922ASmall particle sizeFacilitate large-scale synthesisNanotechnologyLuminescent compositionsFluorescenceTrisodium citrate

The invention discloses a method for synthesizing fluorogold nanometer quantum dots by taking micromolecules as a stabilizer. The method is characterized by comprising the following steps: (1) preparing a SnCl2 solution which utilizes trisodium citrate as the stabilizer; and (2) synthesizing fluorogold nanometer quantum dots by taking the SnCl2 solution, an HAuCl4 solution, an H202 solution and an H3PO4 solution as raw materials and adopting a hydrothermal method. The method can be used for facilitating large-scale synthesis by adopting conventional micromolecules as the stabilizer; the synthesis period is short and only lasts for two hours, the particle size is small, and strong fluorescence can be produced.

Owner:HUNAN UNIV OF SCI & TECH

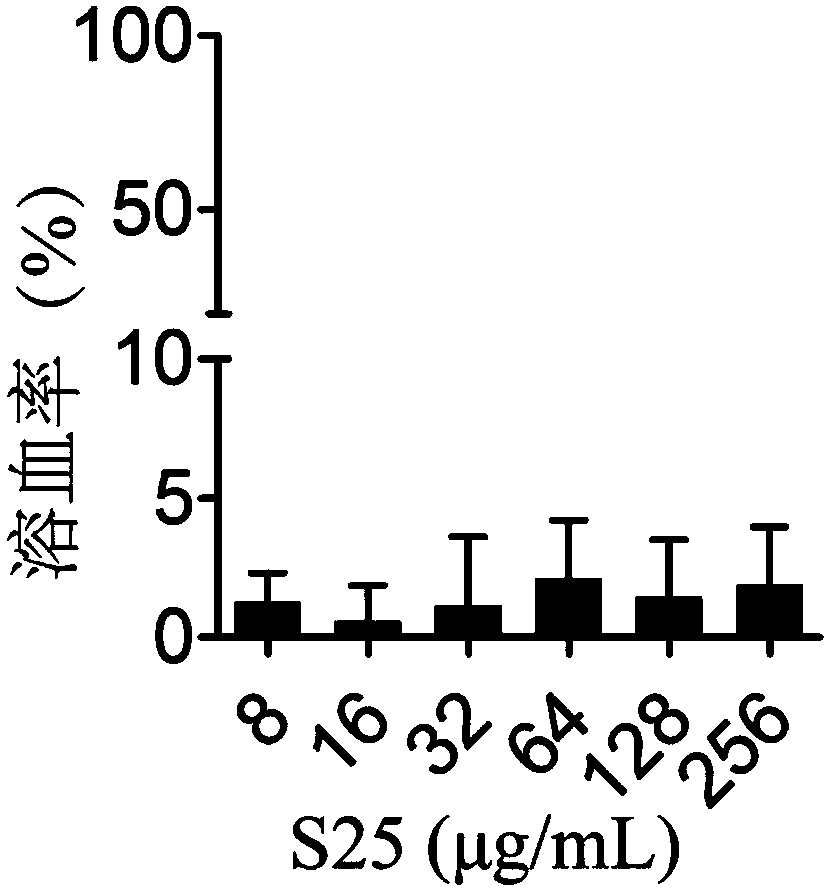

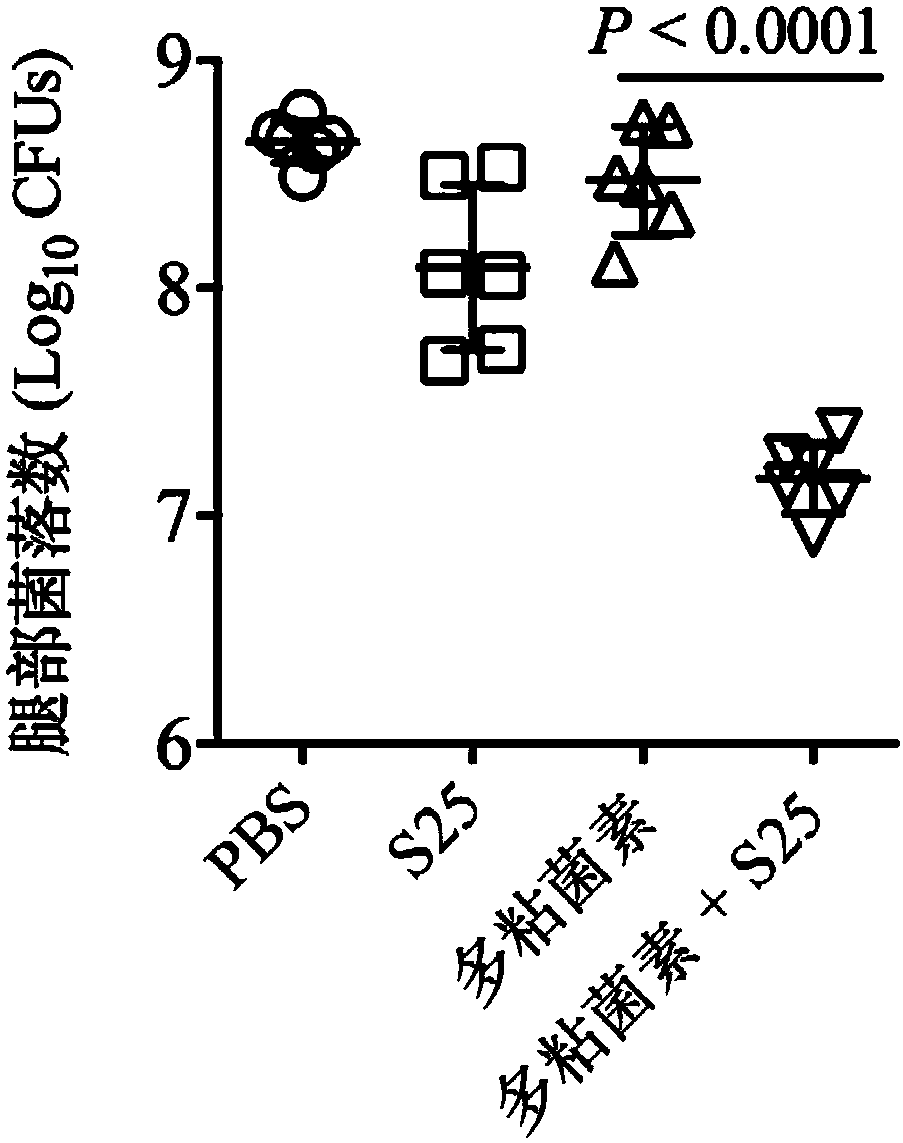

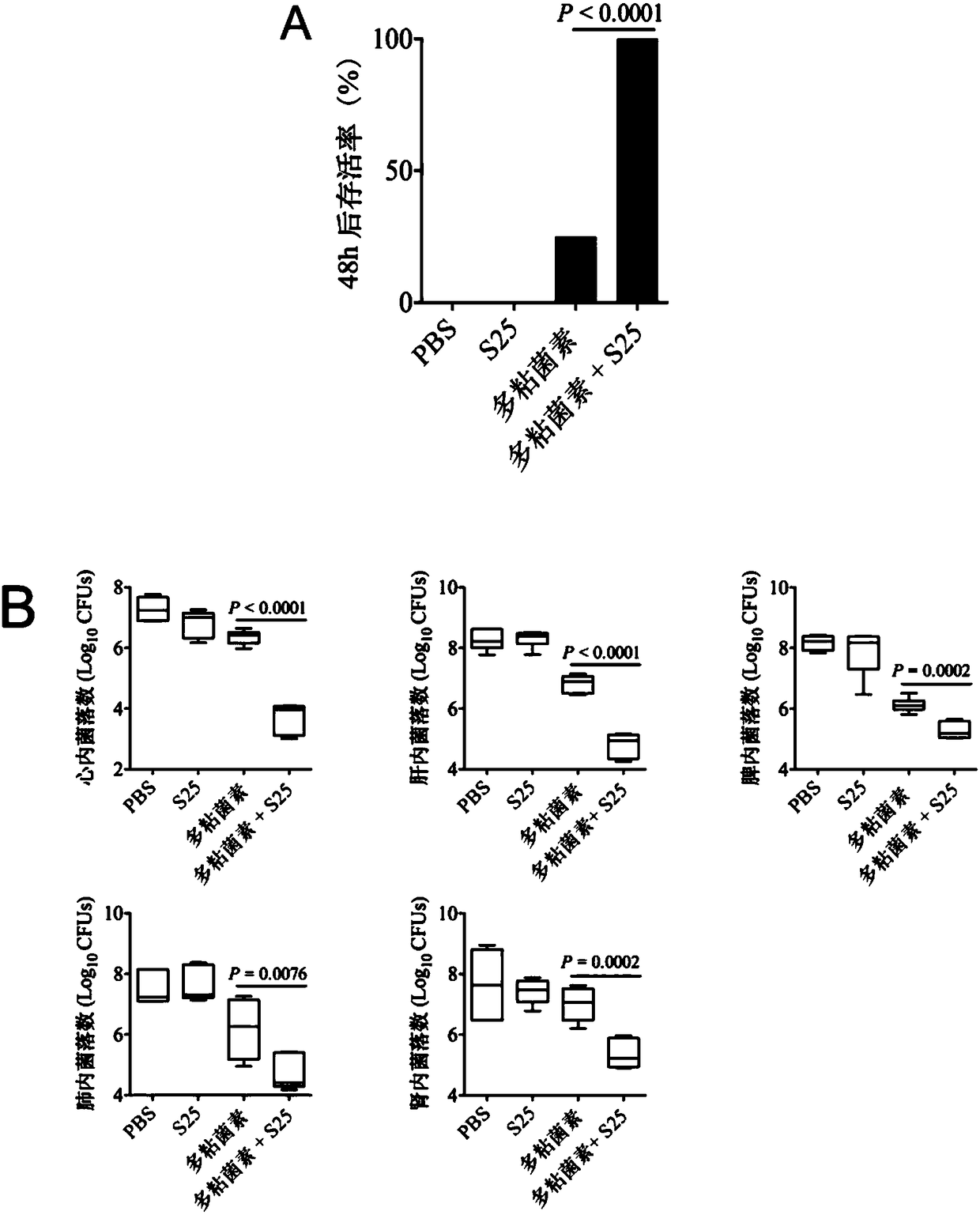

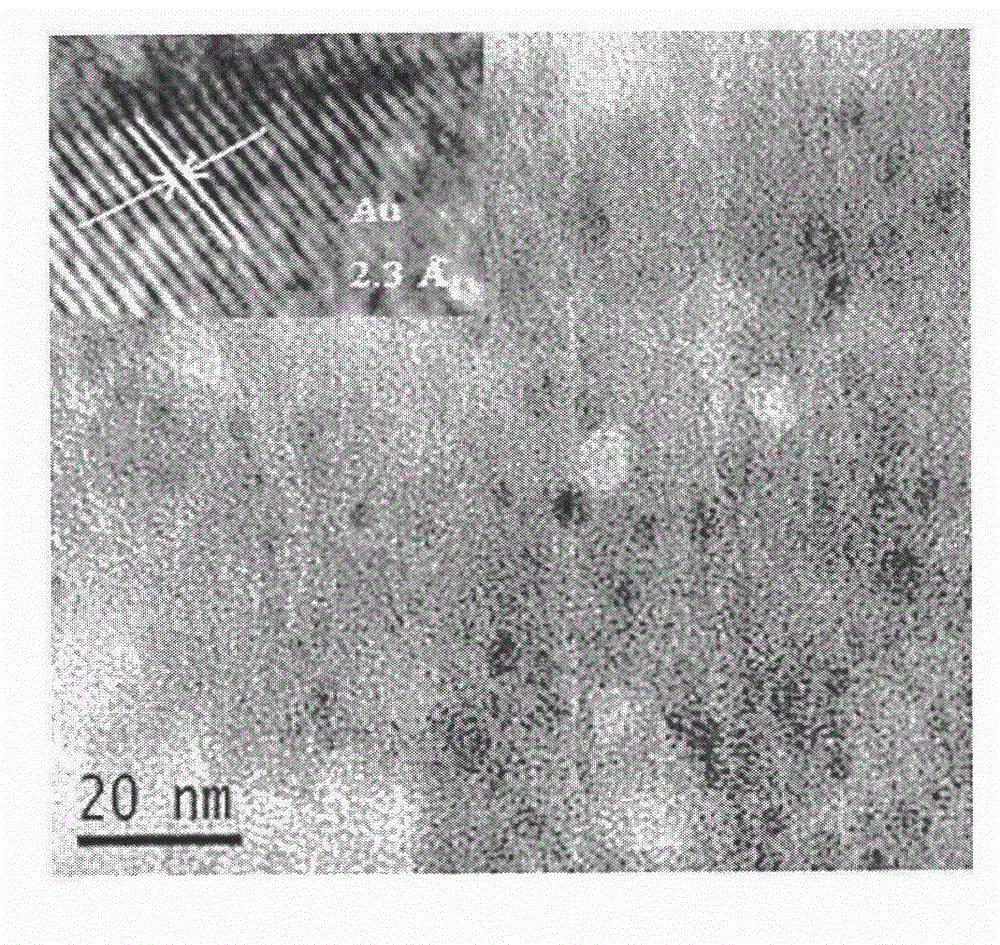

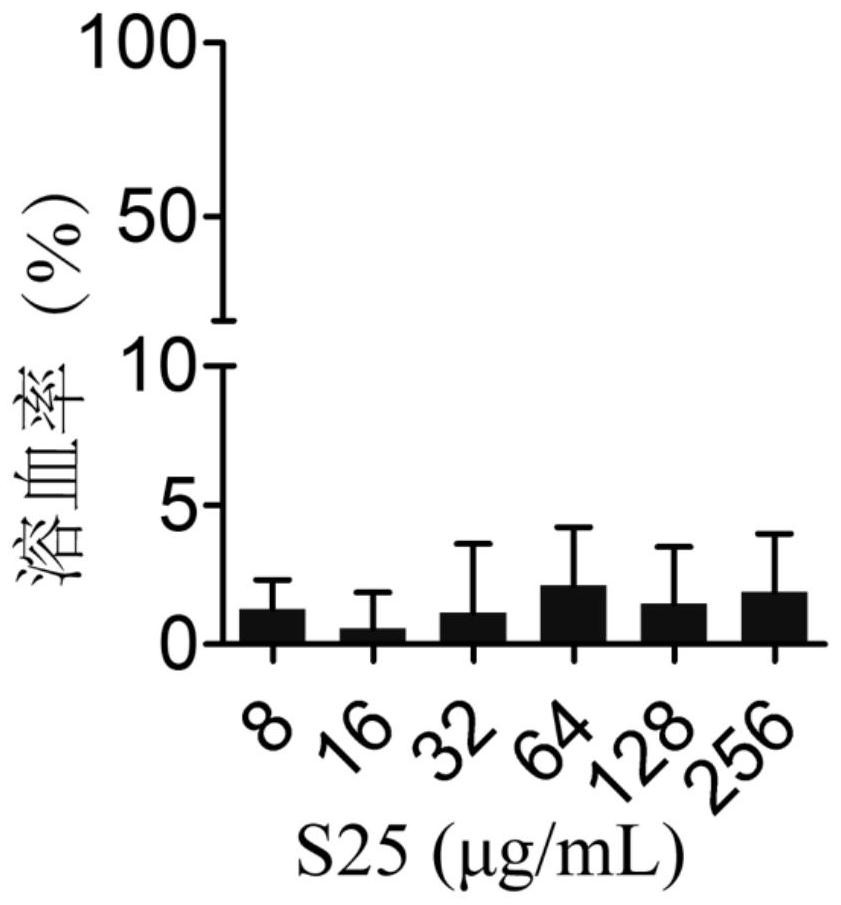

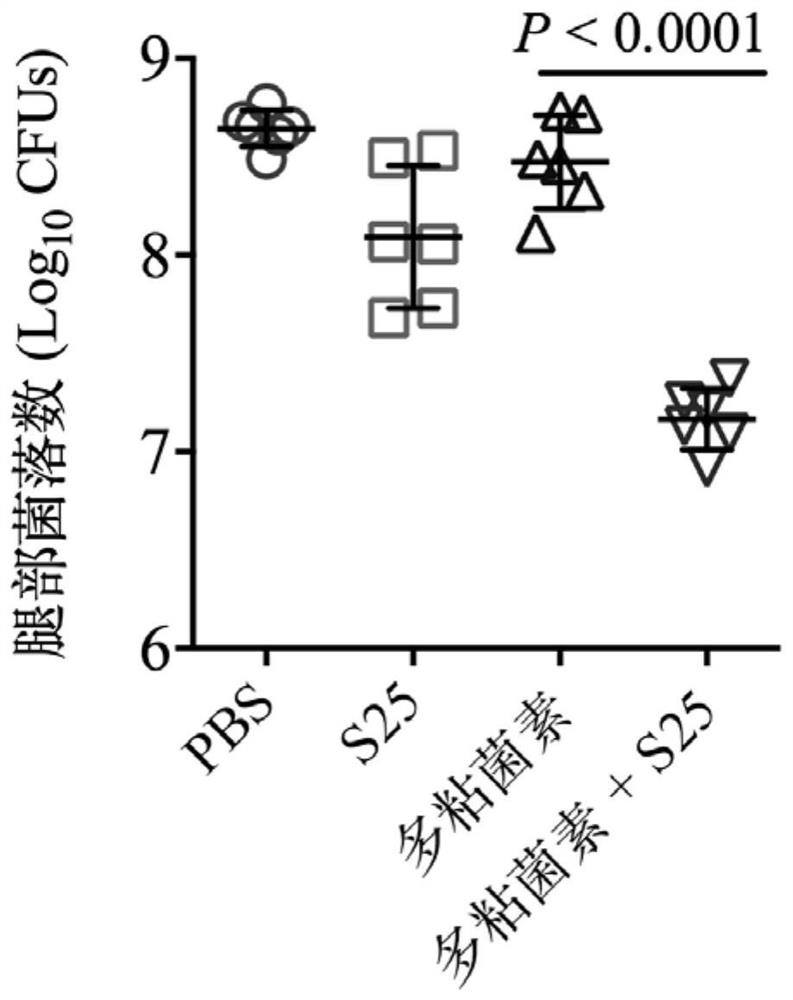

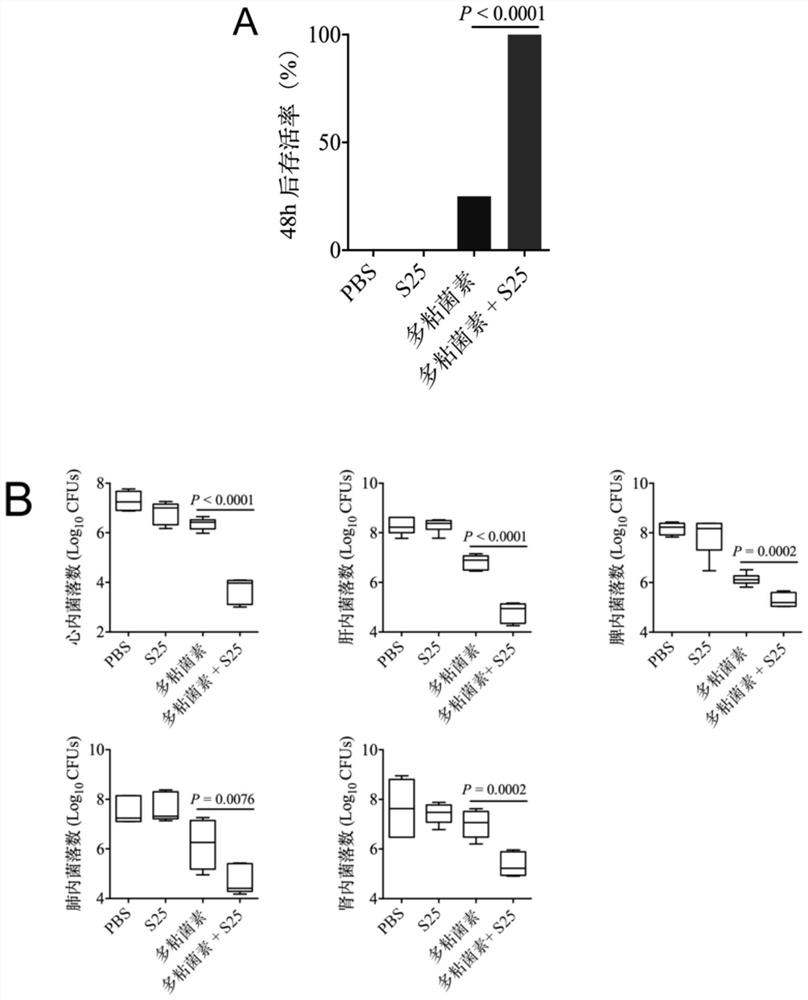

Linear antibacterial oligopeptide SLAP-S25 and application thereof

ActiveCN108467424AGood tissue compatibilitySmall molecular weightAntibacterial agentsPeptide/protein ingredientsChemistryK pneumoniae

The invention discloses a linear antibacterial oligopeptide SLAP-S25 and an application thereof. The linear antibacterial oligopeptide SLAP-S25 is an oligopeptide obtained by acetylation modificationof a nitrogen terminal and amidation modification of a carbon terminal of the oligopeptide as shown in a sequence 1 in a sequence table which is described in the specification. Experiment results showthat the linear antibacterial oligopeptide SLAP-S25 has a certain bacteriostatic effect on a variety of gram-positive and gram-negative bacteria, has good synergistic effects with antibacterial drugs(like tetracycline, vancomycin, ofloxacin and rifampicin), can restore the sensitivity of polymyxin-resistant gram-negative bacteria to polymyxin, reinforces the sensitivity of klebsiella pneumoniaeto a variety of antibacterial drugs, is free of hemolysis, has good tissue compatibility, can effectively inhibit polymyxin drug-resistance bacteria, and can treat bacteremia. The linear antibacterialoligopeptide SLAP-S25 provided by the invention has the advantages of small molecular weight, simple structure, convenient large-scale synthesis and important application values.

Owner:CHINA AGRI UNIV

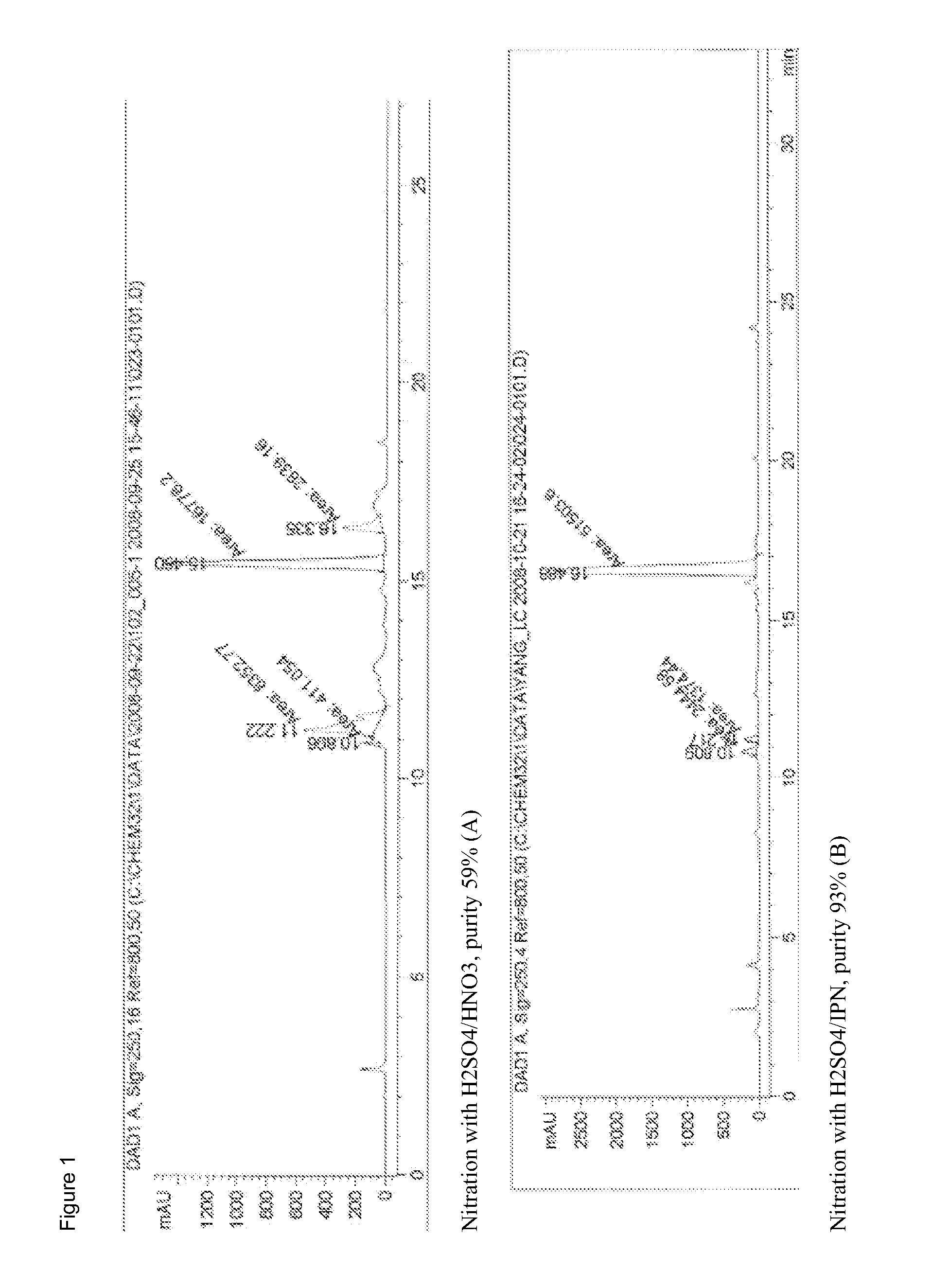

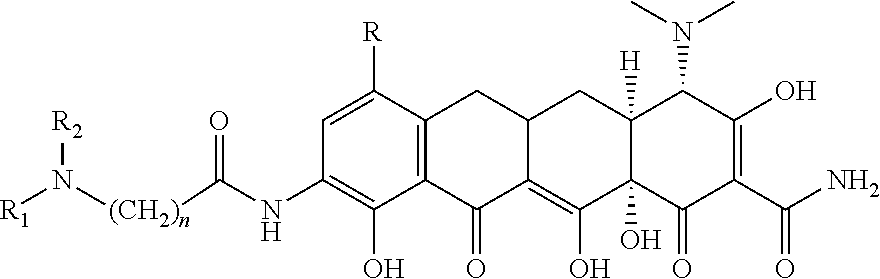

Novel nitration of tetracyclines

InactiveUS20120059190A1Reduce the amount requiredFacilitate large-scale synthesisOrganic compound preparationCarboxylic acid amides preparationHalogenSulfuric acid

The invention in one embodiment is directed to a method of preparing a compound of formula 1,or a pharmaceutically acceptable salt thereof, wherein R1 and R2 are each independently chosen from hydrogen, (C1-C6)alkyl, and cycloalkyl, R is —NR3R4, where R3 and R4 are each independently chosen from hydrogen, and (C1-C4)alkyl; and n ranges from 1-4, comprising:(a) reacting a C1-C12 alkyl nitrate with a compound of formula 2,or a salt thereof, in the presence of an acid at a concentration greater than 70% weight of acid / weight of solution, the acid being selected from the group consisting of sulfuric acid, and R5—SO3H wherein R5 is C1-C4 alkyl optionally substituted with one or more halogen, or R5 is C6-C10 aryl optionally substituted with one or more C1-C4 alkyl or halogen, to produce a reaction mixture containing a compound of formula 3 or a salt thereof;(b) reducing the compound of formula 3 or a salt thereof to form a compound of formula 4 or a salt thereof(c) acylating the compound of formula 4 to form a compound of formula 1; and(d) optionally forming a pharmaceutically acceptable salt of the compound of formula 1.

Owner:WYETH LLC

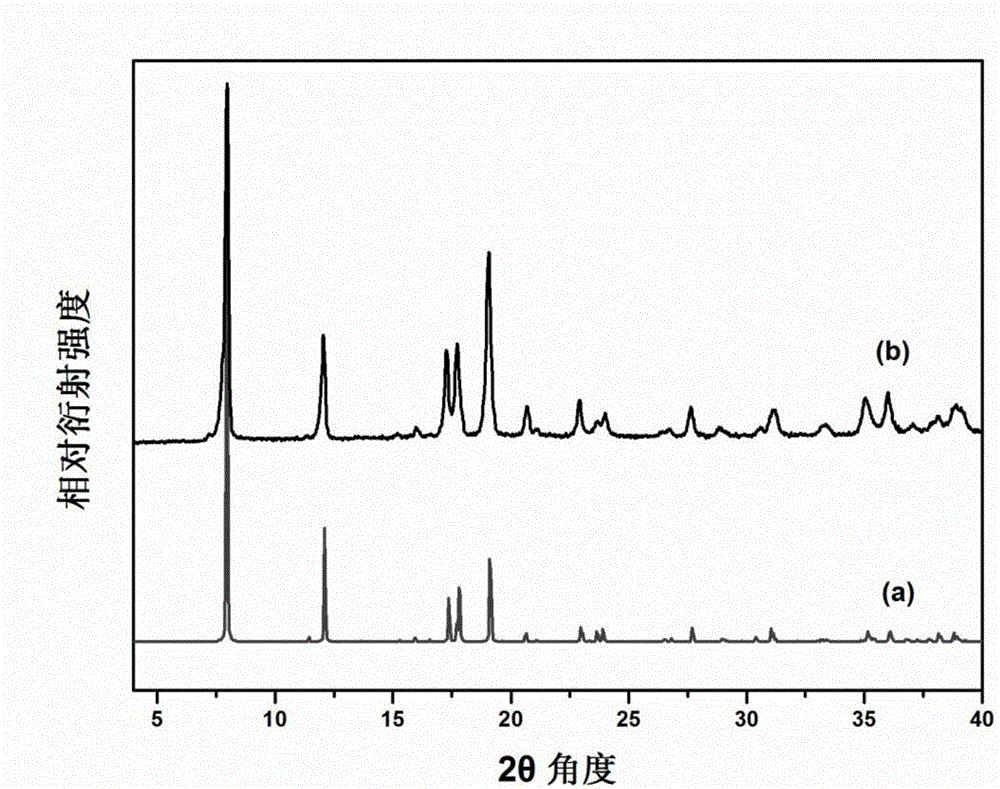

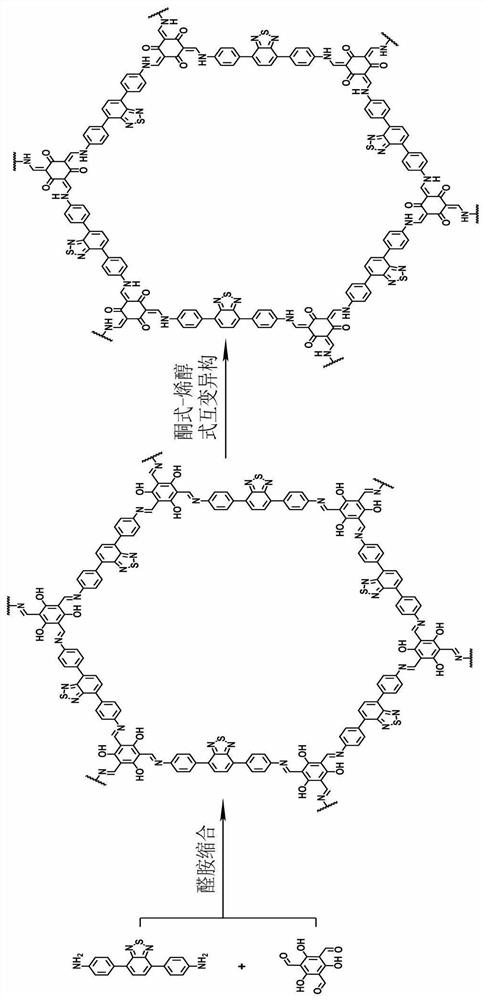

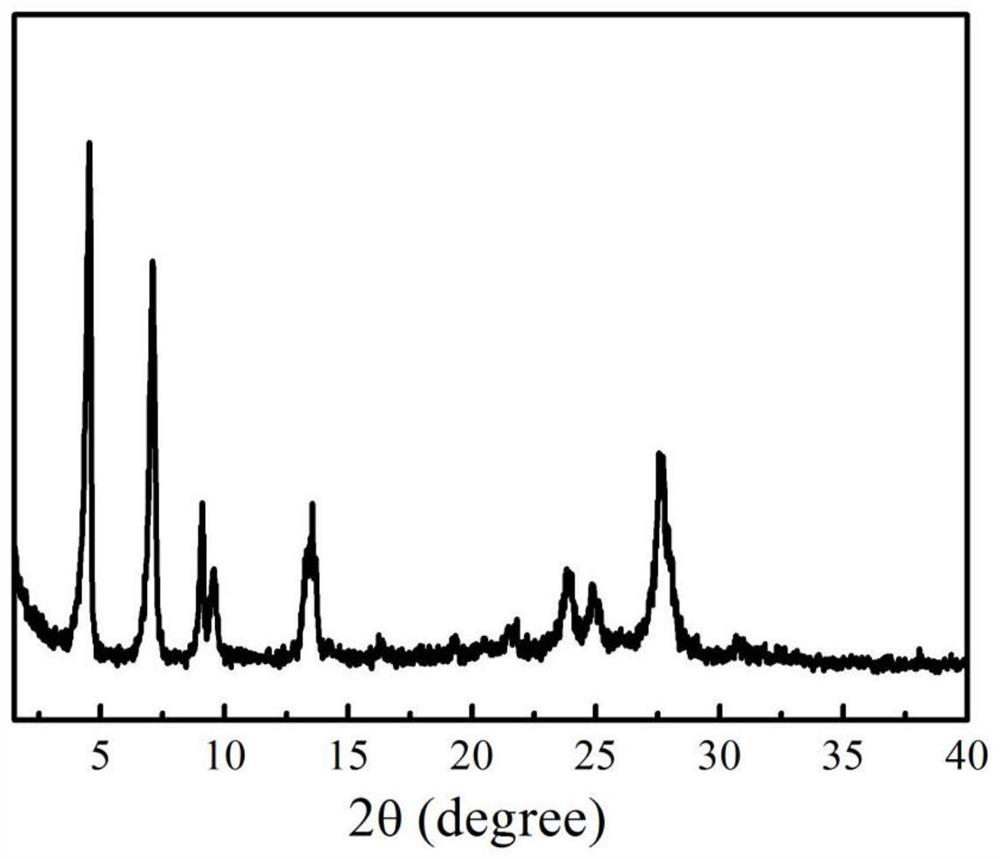

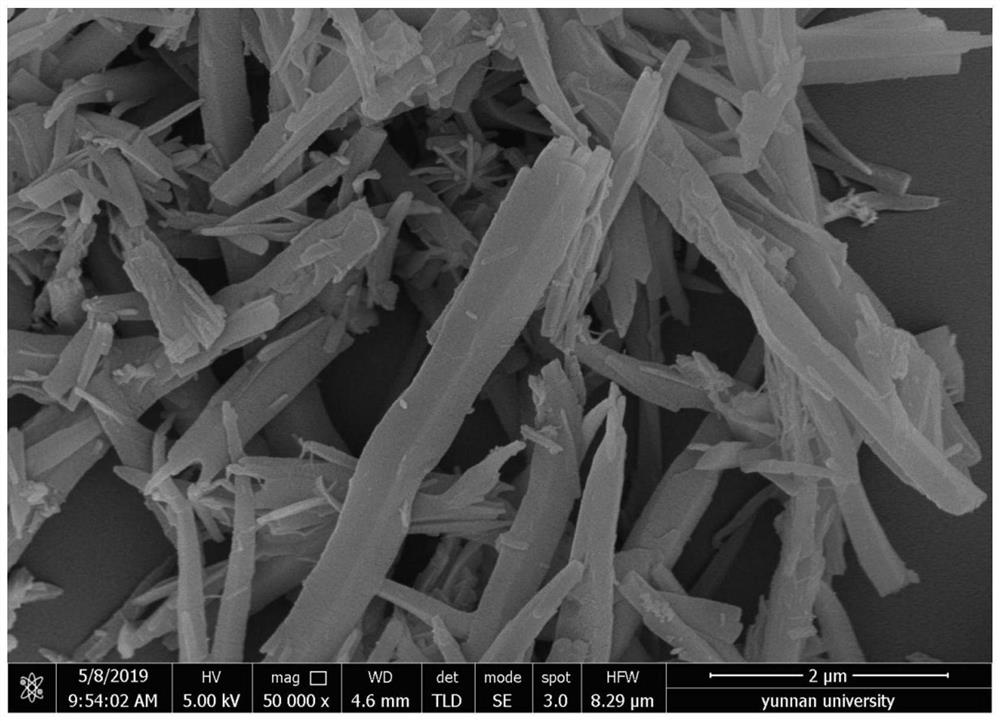

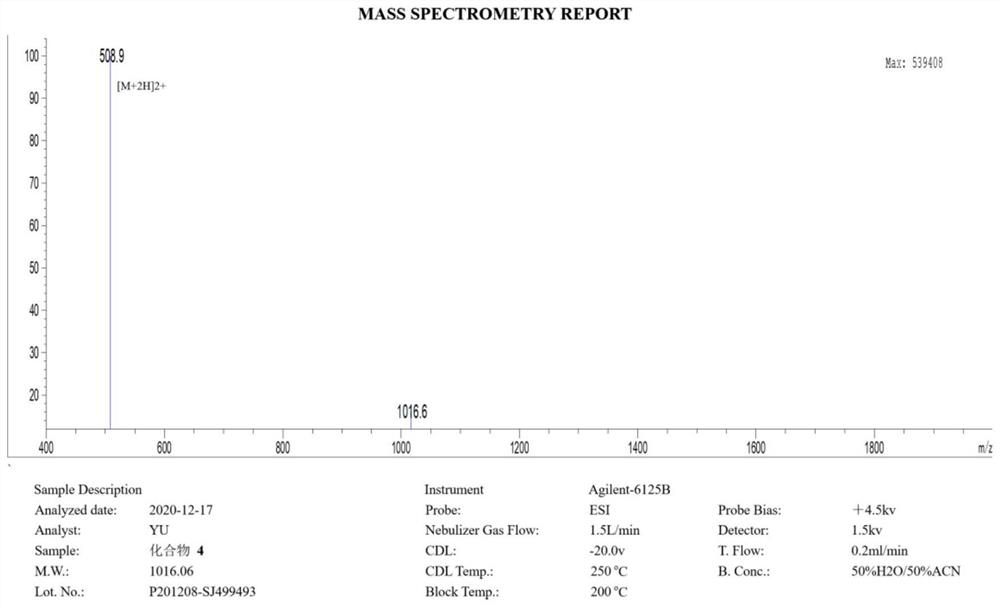

Photosensitive covalent organic framework material as well as preparation method and application thereof

The invention belongs to the technical field of preparation of covalent organic framework materials, and provides a photosensitive covalent organic framework material as well as a preparation method and application thereof. The organic monomers 4, 7-bis (4-aminophenyl)-2, 1, 3-benzothiadiazole and trialdehyde phloroglucinol are connected through a covalent bond at room temperature to form a photosensitive covalent organic framework material (COFs), and the photosensitive COFs material has an enol type structure and a ketone type structure at the same time, has excellent photosensitive property, and can generate I-type and II-type active oxygen at the same time under the irradiation of visible light. The preparation method only needs one-step simple reaction, the synthesis method is simple and convenient, the synthesis condition is mild, the consumed time is short, and large-scale synthesis is facilitated. Furthermore, the preparation method provided by the invention is easy to separate and purify, and the photosensitive COFs material can be obtained only by washing with an organic solvent.

Owner:YUNNAN UNIV

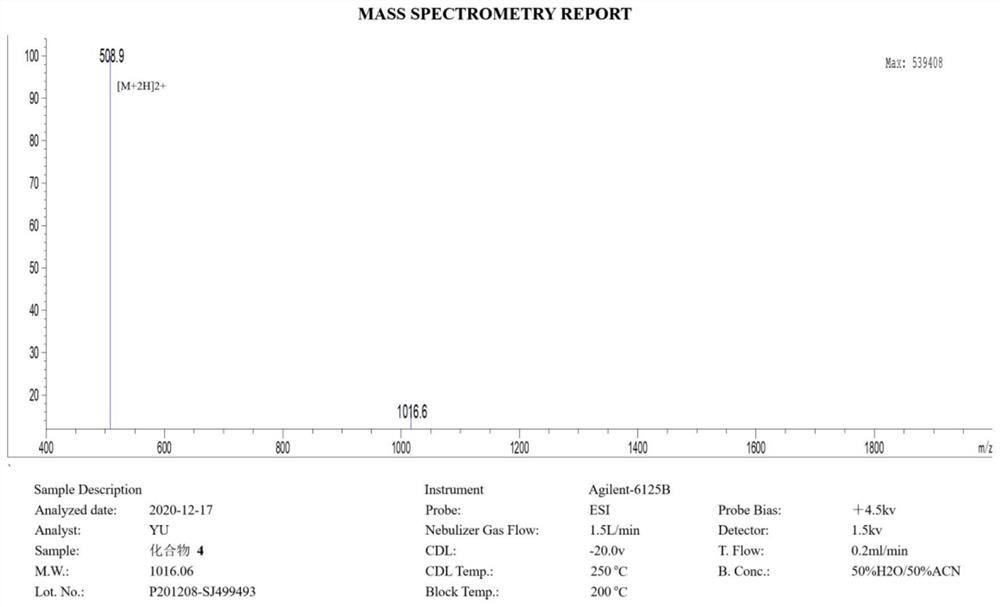

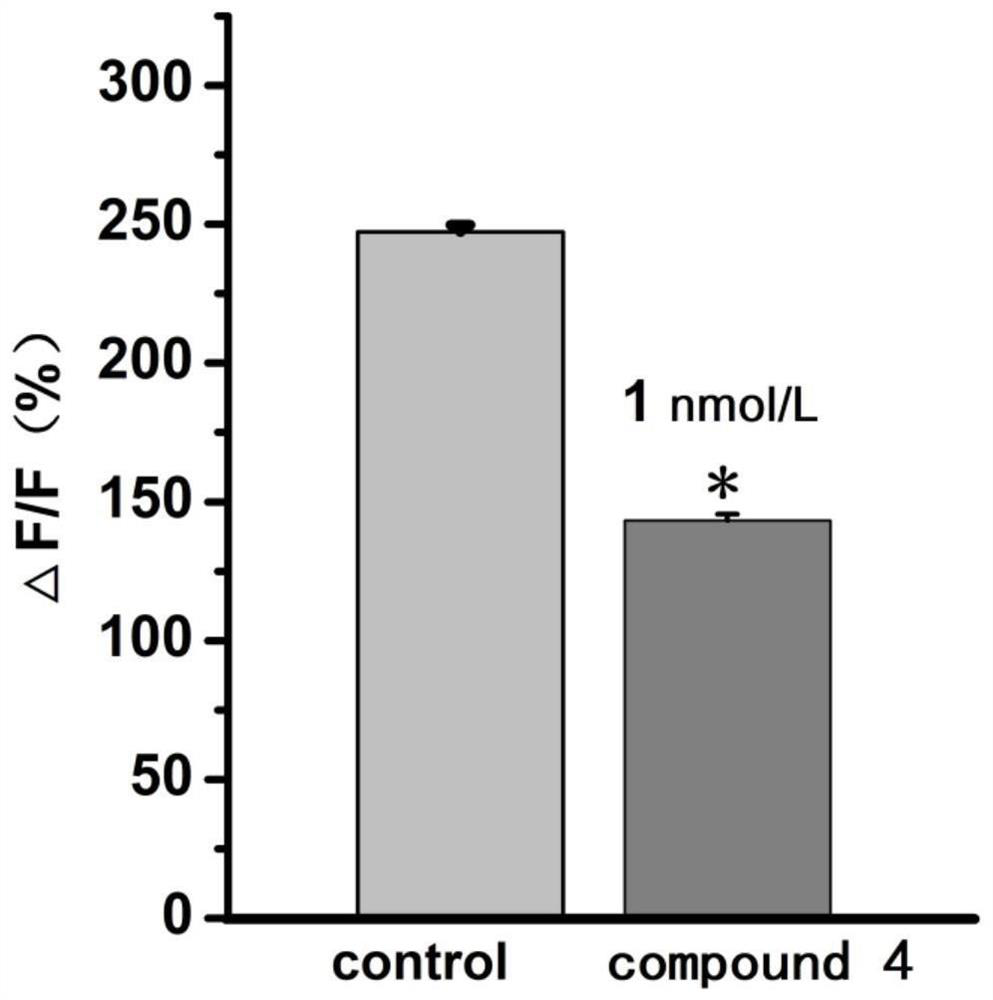

Polypeptide compound taking PD-1 receptor as target point as well as preparation method and application thereof

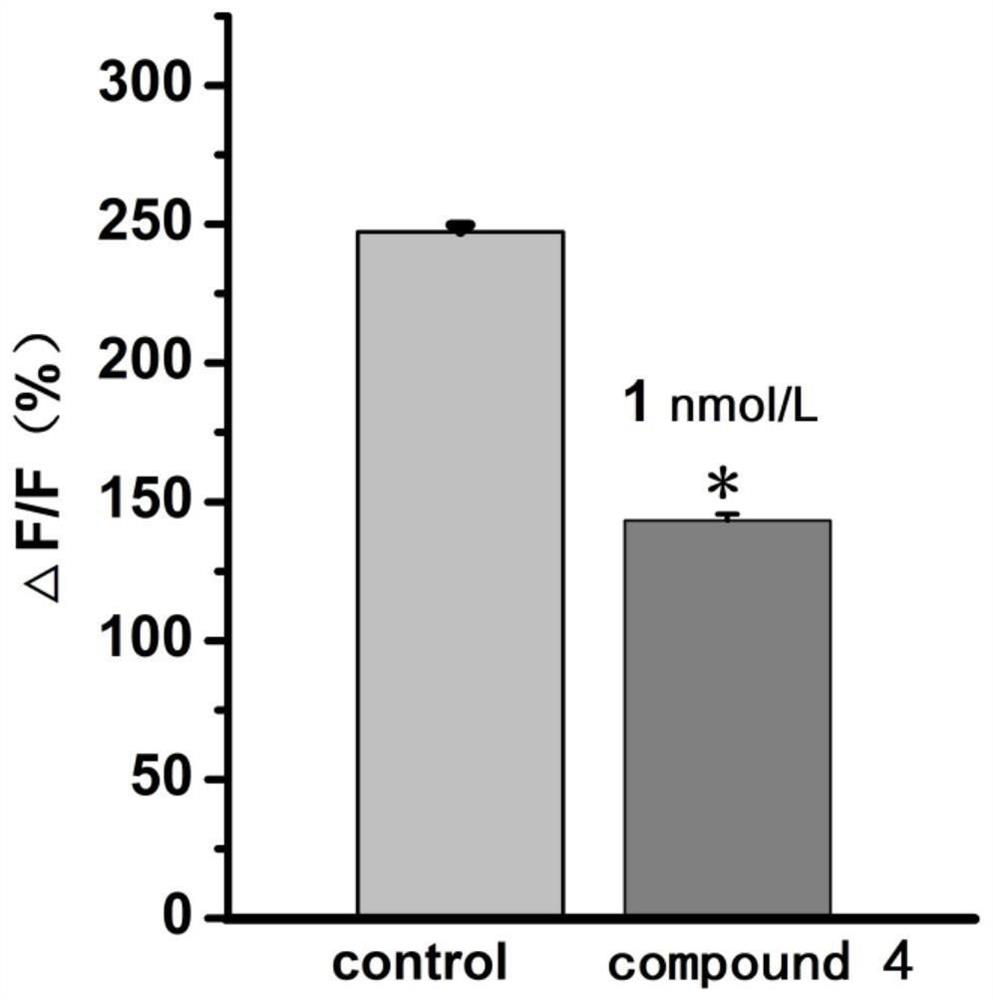

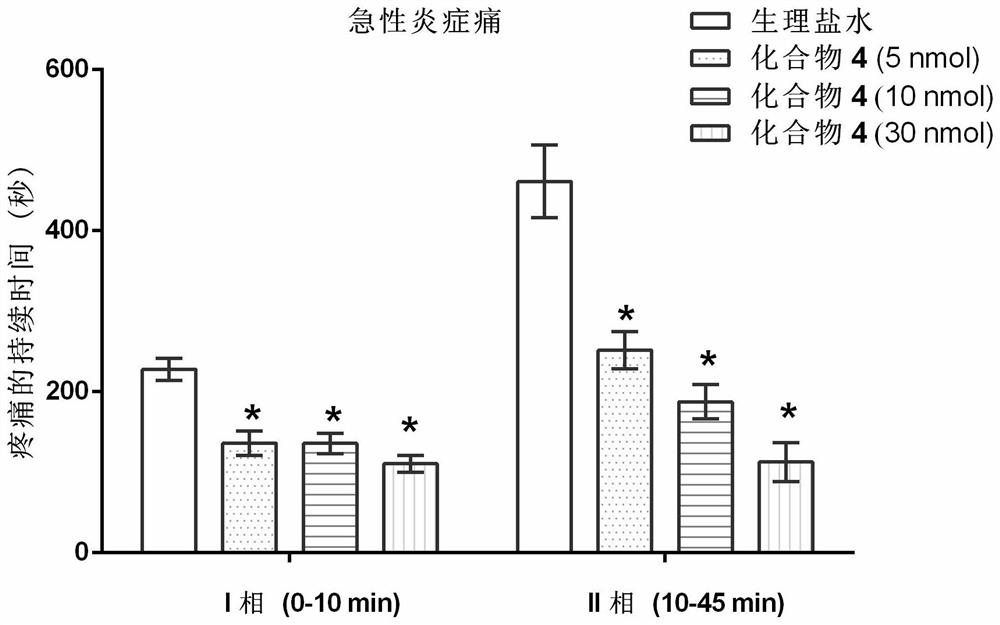

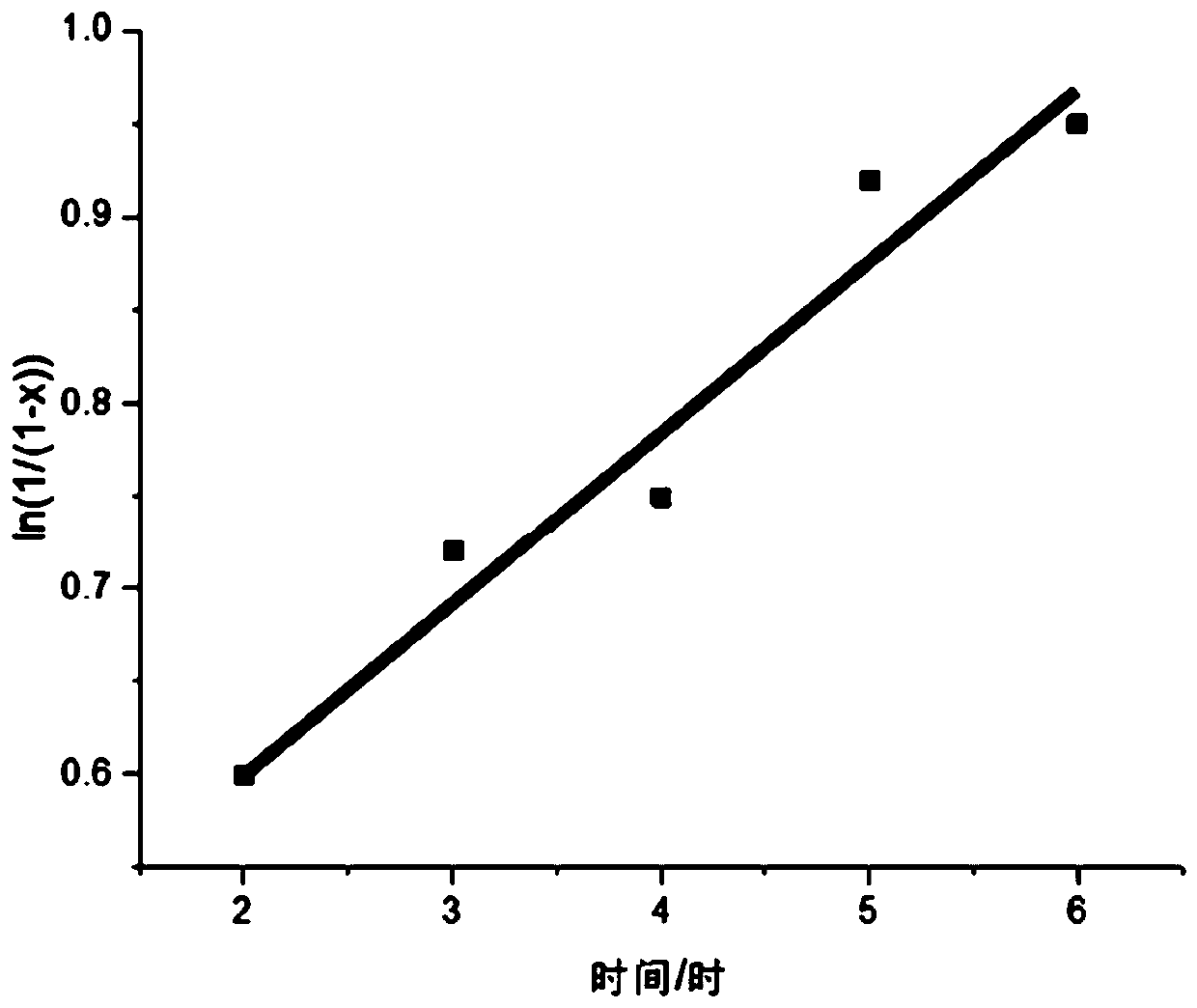

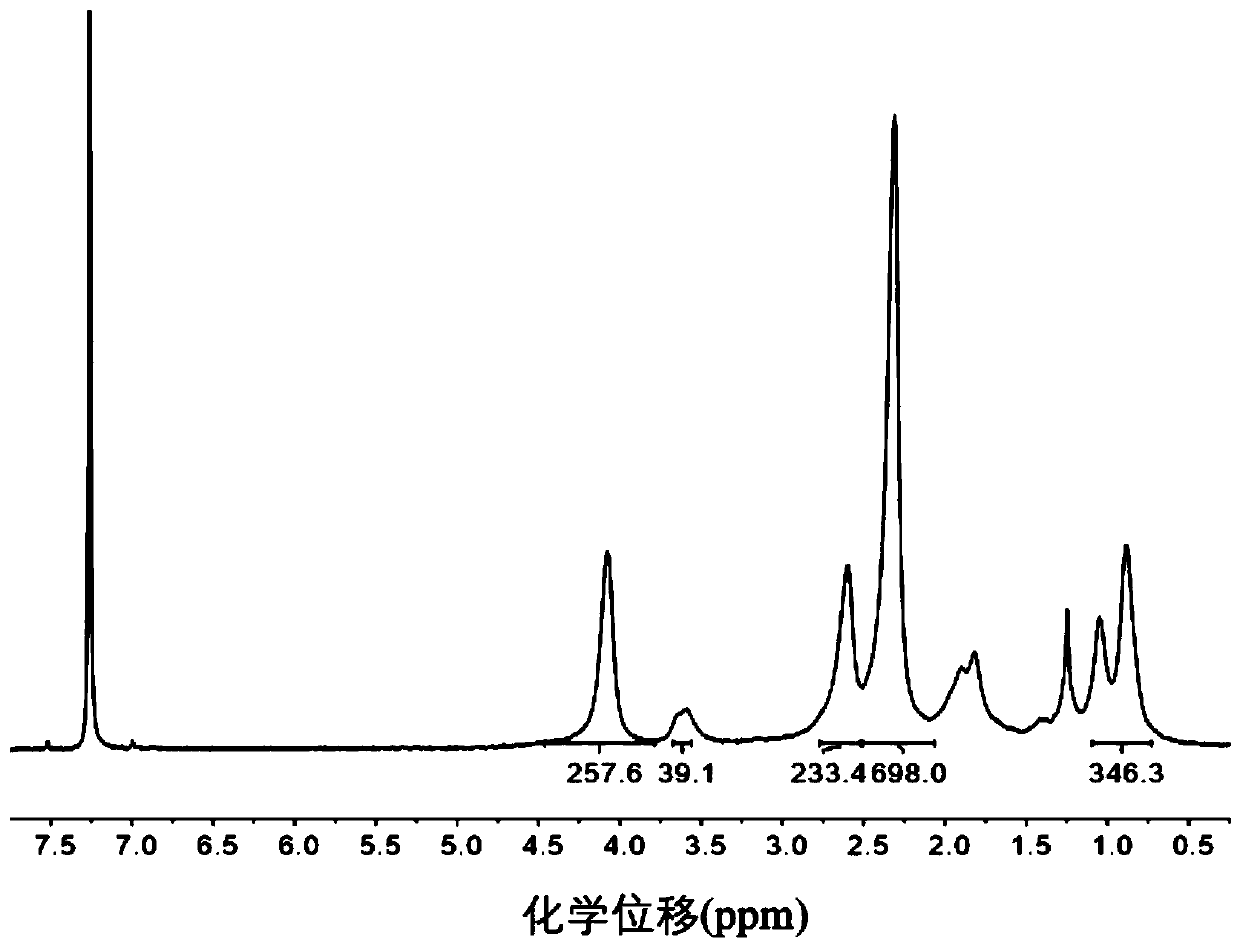

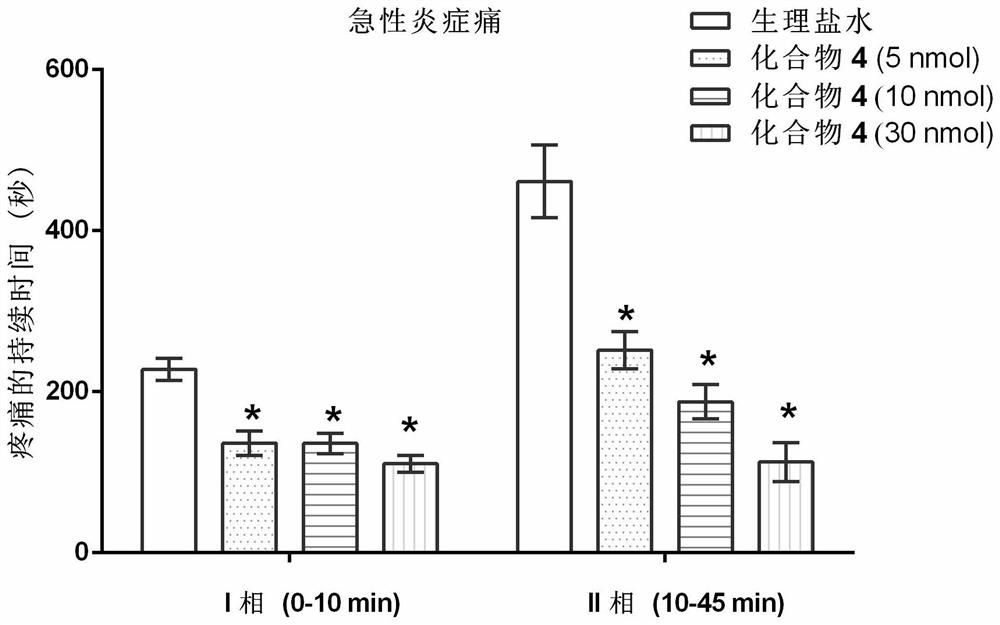

ActiveCN113416232AEnhanced inhibitory effectEasy to synthesizePeptide/protein ingredientsAntipyreticAnalgesics drugsReceptor

The invention discloses a polypeptide compound taking a PD-1 receptor as a target spot. The polypeptide compound comprises a compound 1, a compound 2, a compound 3, a compound 4 and a compound 5, wherein the amino acid sequences of the compounds 1-5 are as shown in SEQ ID NO: 1-5. The invention also discloses a preparation method of the polypeptide compound taking the PD-1 receptor as the target spot, and the preparation method comprises the following processes: coupling amino acids of compounds 1-5 to solid-phase resin in sequence according to a peptide sequence by utilizing a solid-phase synthesis mode, cracking by a cutting reagent, freeze-drying, preparing and purifying to obtain the target compound. The invention also discloses application of the polypeptide compound taking the PD-1 receptor as the target spot in preparation of analgesic drugs. According to the small molecule polypeptide, compounds 1-5 can be combined with PD-1, and the obvious inhibition effect on inflammatory pain and visceral pain is achieved under intrathecal administration; and synthesis is simple, purification is easy, and large-scale synthesis is facilitated.

Owner:NANTONG UNIVERSITY

Soluble linear conductive polymer and preparation method thereof

The invention provides a soluble linear conductive polymer and a preparation method thereof. The preparation method comprises the following steps: S1, taking S-dodecyl-S'-(R, R'-dimethyl-R''-(2-thienyl) ethyl acetate) trithiocarbonate as a chain transfer agent; carrying out a reversible addition-fragmentation chain transfer polymerization reaction on methyl acrylate, 2-(Dimethylamino)ethyl methacrylate and 1, 4-dioxane under the initiation of azodiisobutyronitrile to obtain polymethylacrylic acid N, N-dimethylaminoethyl ester-b-polymethyl acrylate; and S2, adding a 3, 4-ethylenedioxythiophenen-butyl alcohol solution into the polymethylacrylic acid N, N-dimethylaminoethyl ester-b-polymethyl acrylate hydrochloric acid solution, and carrying out interfacial polymerization reaction under theaction of a catalyst to obtain the soluble linear conductive polymer. The soluble linear conductive polymer is synthesized by adopting reversible addition-fragmentation chain transfer polymerization and interfacial polymerization methods, so that the length of a flexible chain segment of the soluble linear conductive polymer is controllable.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

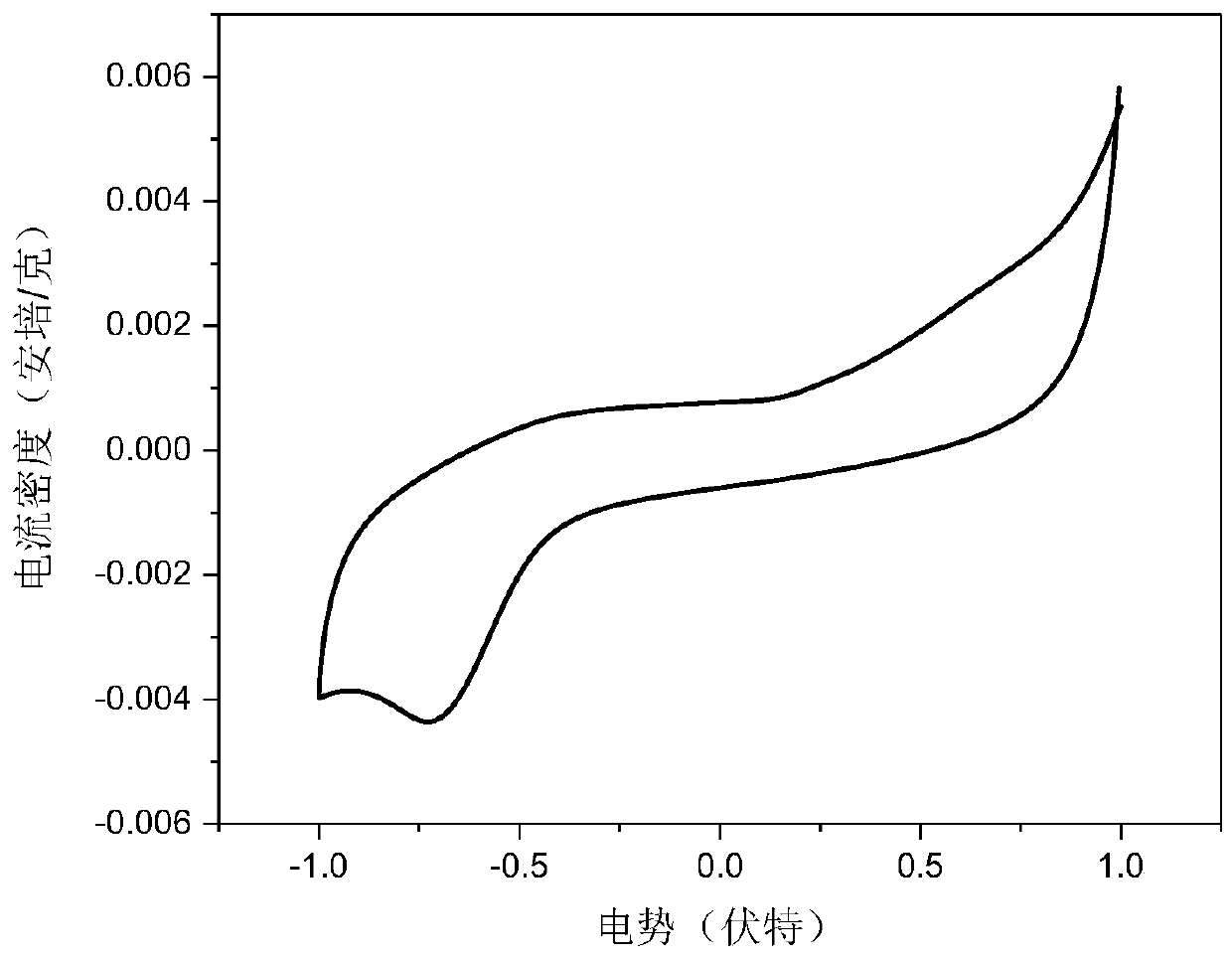

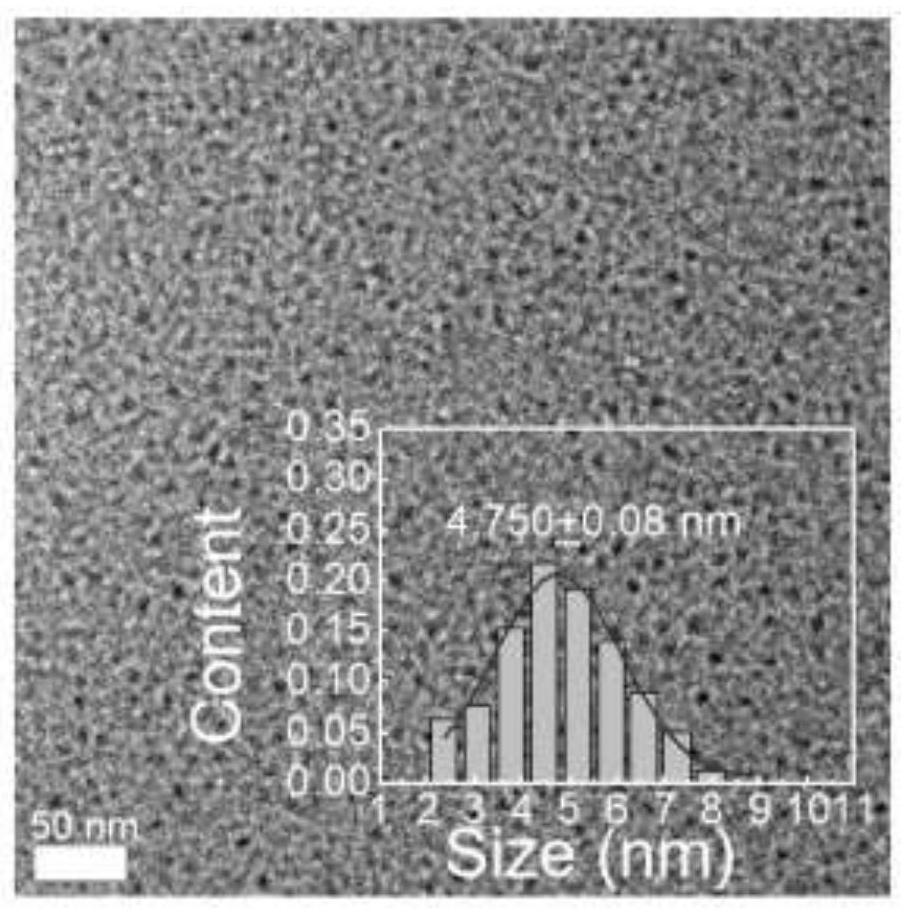

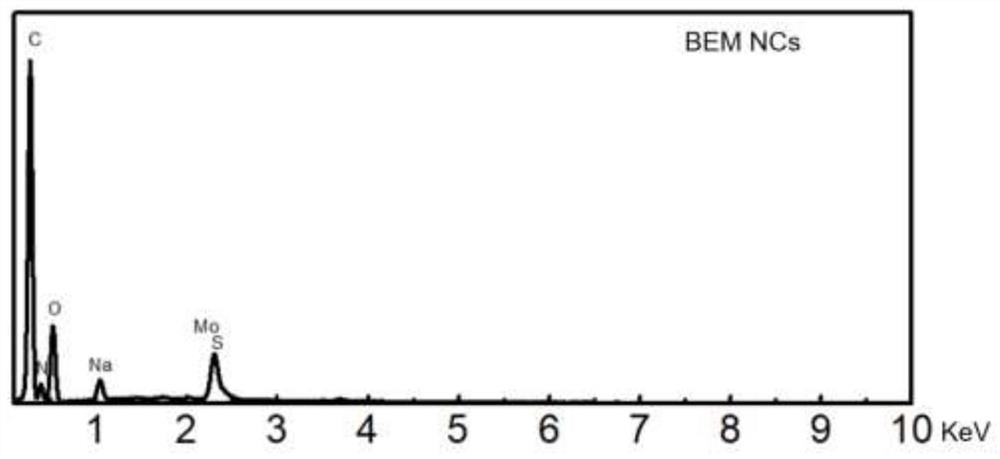

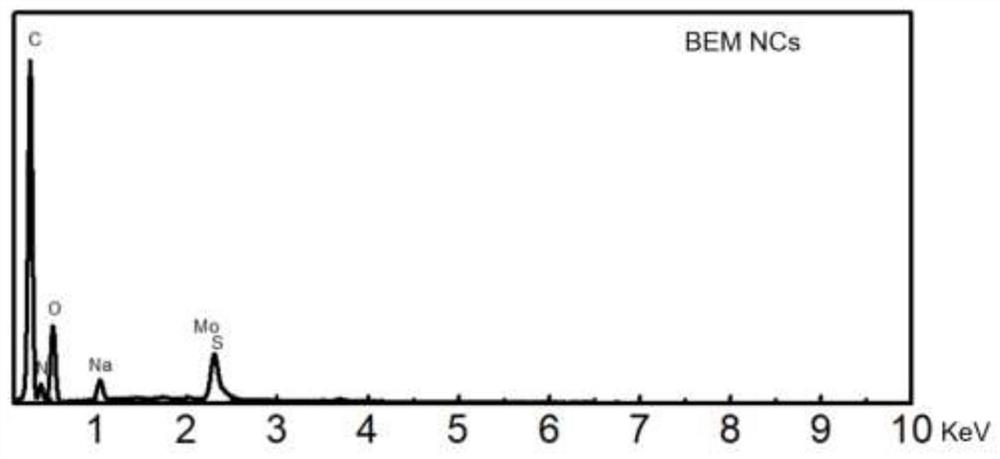

Bovine serum albumin-tea polyphenol-molybdenum nano-composite and application thereof

ActiveCN112641852AUniform particle sizeGood dispersionHeavy metal active ingredientsOrganic active ingredientsPhenolic content in teaBovine serum albumin

The invention provides a bovine serum albumin-tea polyphenol molybdenum nano-composite, and belongs to the field of nano-medicine. The bovine serum albumin-tea polyphenol-molybdenum nano-composite is prepared by dissolving bovine serum albumin in water, dropwise adding a tea polyphenol aqueous solution and a molybdenum source aqueous solution, dropwise adding a sodium hydroxide aqueous solution, and reacting by adopting a biomineralization method to obtain the bovine serum albumin-tea polyphenol-molybdenum nano-composite. The invention also provides application of the bovine serum albumin-tea polyphenol molybdenum nano-composite in preparation of drugs for treating cancer cell immunogenic cell death and tumor immunotherapy. The composite provided by the invention has good biocompatibility, good dispersibility in water and good capability of triggering mouse cancer cell immunogenic cell death, and can be effectively applied to immunotherapy of tumors.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

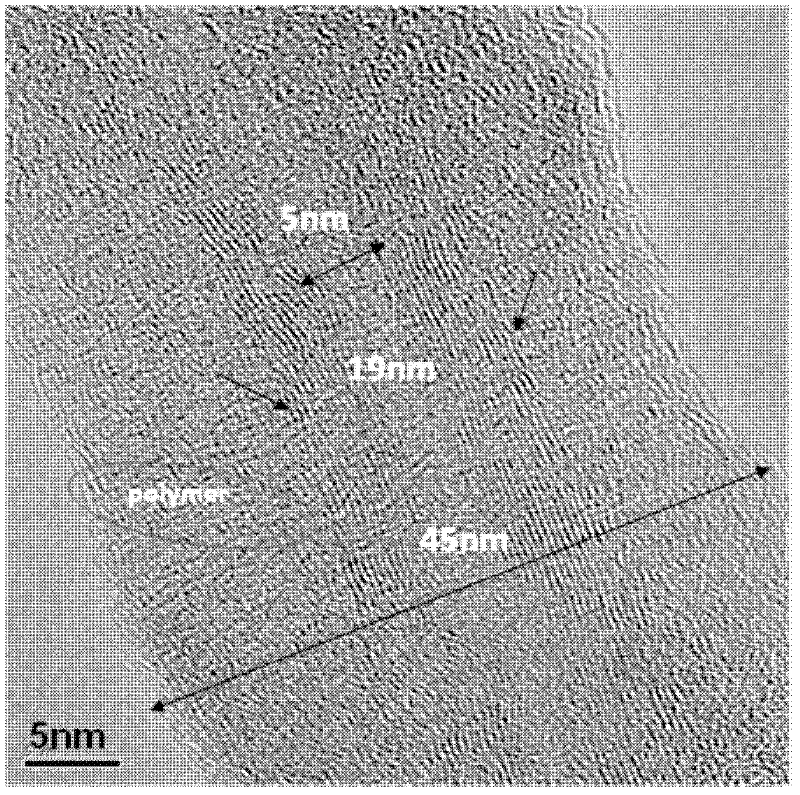

Preparation method of poly(3,4-ethylenedioxythiophene) (PEDOT)-coated carbon nanotube composite material

The invention belongs to the fields of carbon materials and electroconductive polymer composite materials, and relates to a preparation method of a poly(3,4-ethylenedioxythiophene) (PEDOT)-coated carbon nanotube composite material. The preparation method comprises: adding an oxidant solution, a carbon nanotube dispersion and a 3,4-ethylenedioxythiophene (EDOT) monomer to a three-phase system of an organic solvent, a surfactant and water, and carrying out an in-situ chemical polymerization reaction. The preparation method provided by the invention is simple, feasible and controllable, and is beneficial to large-scale synthesis. The composite material obtained in the invention has high electrical conductivity and higher specific surface area, so that the composite material is expected to have good application prospects in the fields of energy storage devices (including super capacitors, lithium ion cells and the like), sensors and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of polypeptide compound targeting PD-1 receptor, its preparation method and application

ActiveCN113416232BEnhanced inhibitory effectEasy to synthesizePeptide/protein ingredientsAntipyreticAnalgesics drugsVisceral pain

The present invention discloses a class of polypeptide compounds targeting PD-1 receptors. The polypeptide compounds include compound 1, compound 2, compound 3, compound 4 and compound 5; wherein, the amino acid sequence of compound 1-5 is as shown in SEQ ID NO : as shown in 1‑5. The invention also discloses a preparation method of a polypeptide compound targeting the PD-1 receptor, including the following process: using solid-phase synthesis, sequentially coupling the amino acids of compound 1-5 to a solid-phase resin according to the peptide sequence Above, the target compound is obtained through cleavage reagent cleavage, freeze-drying, preparation and purification. The invention also discloses the application of a class of polypeptide compounds targeting PD‑1 receptors in the preparation of analgesic drugs. The small molecule polypeptide of the present invention: compounds 1-5 can bind to PD-1, and have significant inhibitory effects on inflammatory pain and visceral pain under intrathecal administration; and the synthesis is simple, easy to purify, and facilitates large-scale synthesis.

Owner:NANTONG UNIVERSITY

Method for preparing amide compounds through ionic liquid catalysis in high-pressure environment

ActiveCN112209847ALow costLow raw material costOrganic compound preparationCarboxylic acid amides preparationPtru catalystAlcohol

The invention relates to a method for preparing amide compounds through ionic liquid catalysis in a high-pressure environment. According to the method, ionic liquid 1-ethyl-3-methylimidazolium acetateis used as a catalyst and a solvent, oxygen is used as an oxidizing agent, and aromatic methanol or alkyl alcohol is converted into an amide compound under the conditions of high pressure and heating. The synthesis method provided by the invention has the advantages that the raw material and technical cost is low; compared with other traditional methods, the method is safe, low in toxicity, economical and environmentally friendly; and the method has few steps, is simple and convenient to operate, is beneficial to large-scale synthesis, and has important significance for synthesis of amide compounds and large-scale industrialization of preparation.

Owner:YANTAI UNIV

A rapid method for preparing silver nanoclusters with strong fluorescence emission

The invention relates to a method for quickly preparing a silver nanocluster with strong fluorescence emission. The method is characterized in that by volume, 14.75 parts of redistilled water is put into a container, 2.0 parts of AgNO3 solution, 0.25 parts of NaBH4 solution and 3.0 parts of amino black 10B are added into a thermostat water bath in sequence in a mixing condition, so as to be mixed for 3 to 90 min at 30-80 DEG C, and then the silver nanocluster with strong fluorescence emission can be obtained. According to the method, a biological dye of amino black is used as a stabilizing agent, and the silver nanocluster with strong fluorescence emission can be prepared after 10 min. The method has the advantages of easiness in obtaining raw materials, simple system, short synthetic time, strong fluorescence and smaller size.

Owner:HUNAN UNIV OF SCI & TECH

A bovine serum albumin-tea polyphenol-molybdenum nanocomposite and its application

ActiveCN112641852BUniform particle sizeGood dispersionOrganic active ingredientsHeavy metal active ingredientsPhenolic content in teaEngineering

The invention provides a bovine serum albumin-tea polyphenol-molybdenum nanocomposite, which belongs to the field of nanomedicine. The complex is to dissolve bovine serum albumin in water, then add tea polyphenol aqueous solution and molybdenum source aqueous solution drop by drop, and then add sodium hydroxide aqueous solution drop by drop, adopt biomineralization method to react, and obtain bovine serum albumin-tea Polyphenol‑Molybdenum Nanocomposite. The invention also provides the application of the bovine serum albumin-tea polyphenol-molybdenum nanocomposite in the preparation of immunogenic cell death and tumor immunotherapy drugs induced by the treatment of cancer cells. The complex of the invention has good biocompatibility, good dispersibility in water, good ability of inducing immunogenic cell death of mouse cancer cells, and can be effectively applied in tumor immunotherapy.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

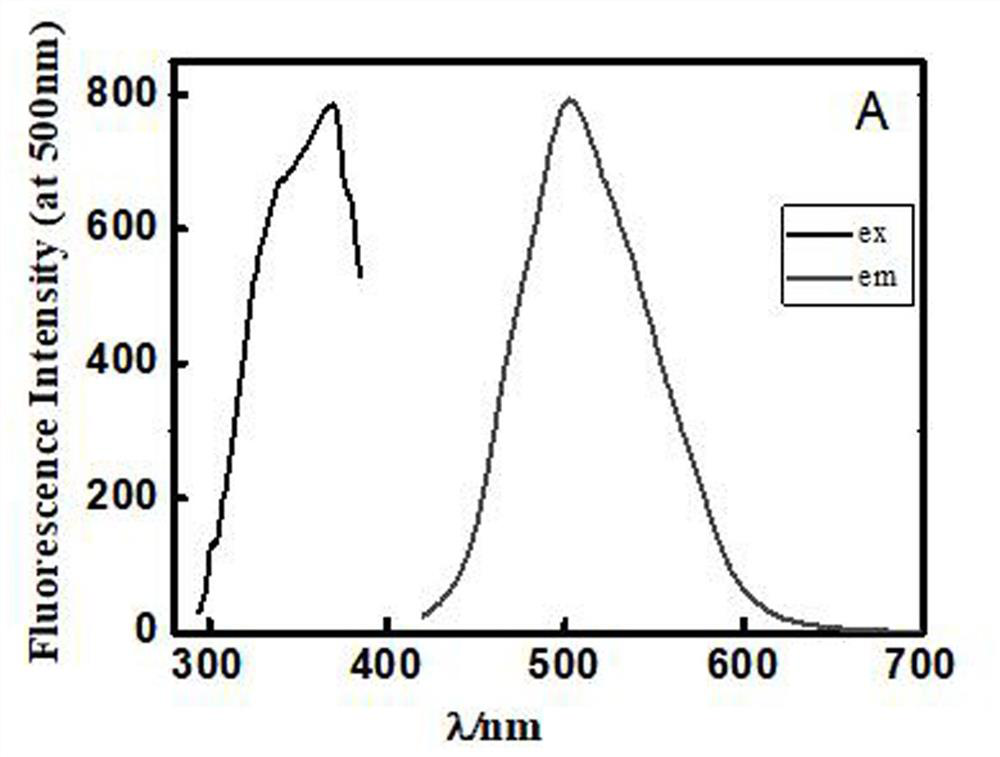

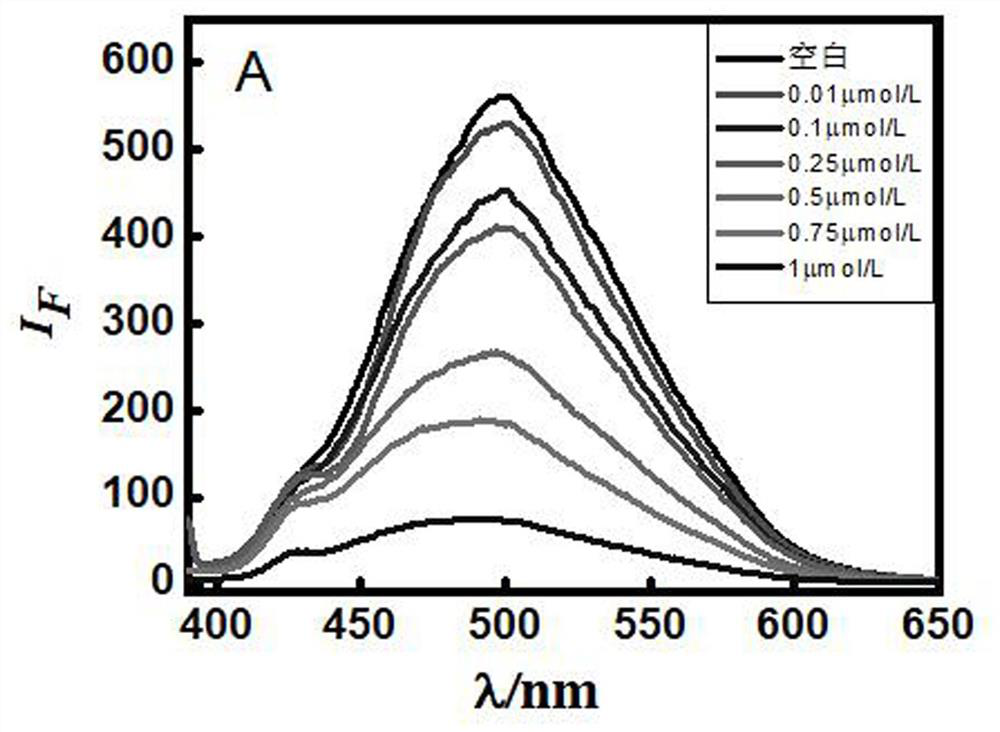

A Simple and Fast Method for Detecting CTAB

ActiveCN113533285BSimple reaction systemEasy to operateNanosensorsFluorescence/phosphorescenceAmmonium bromideMethyl palmoxirate

The invention provides a simple and fast method for detecting CTAB, using nuclear fast red as a stabilizer, AgNO 3 and NaBH 4 As the reaction reagent, AgNCs were prepared by chemical reduction method. AgNCs exhibit strong fluorescence emission at 500 nm when excited at 370 nm. The study found that when cetyltrimethylammonium bromide (CTAB) was added to the AgNCs solution, the fluorescence intensity of AgNCs was effectively quenched. When the CTAB concentration was in the range of 0.01‑1.0 mmol / L, the silver nanoclusters The reduction degree of fluorescence intensity has a good linear relationship with it, and the detection limit is 6.1´10 ‑9 mol / L.

Owner:HUNAN UNIV OF SCI & TECH

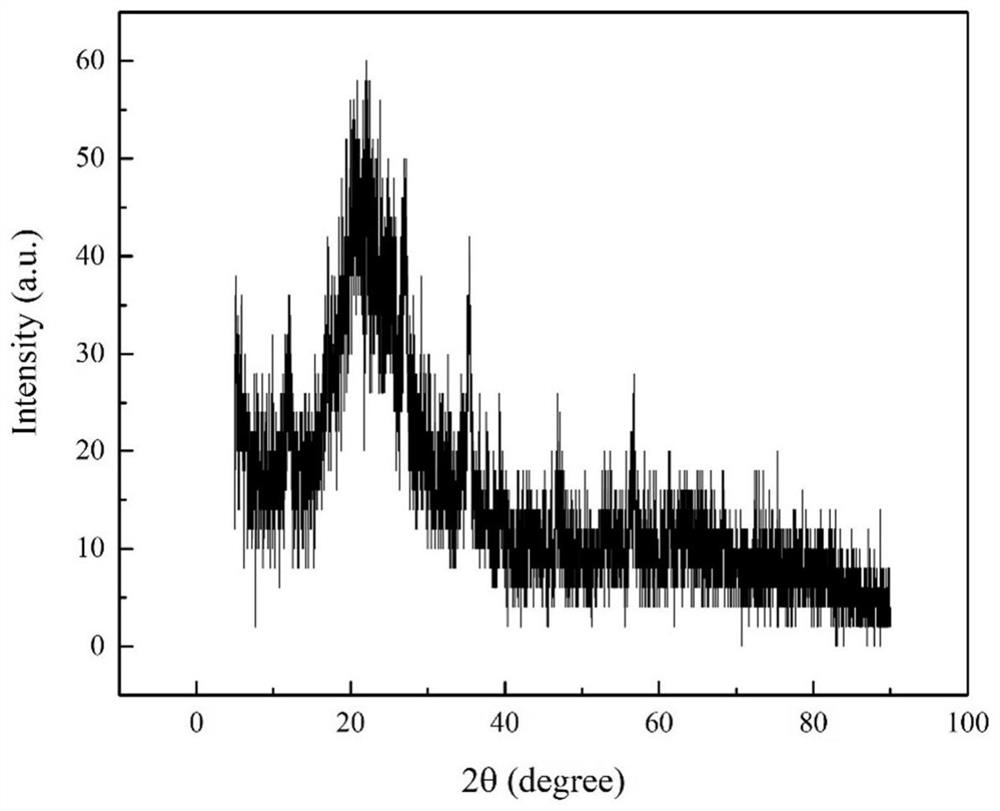

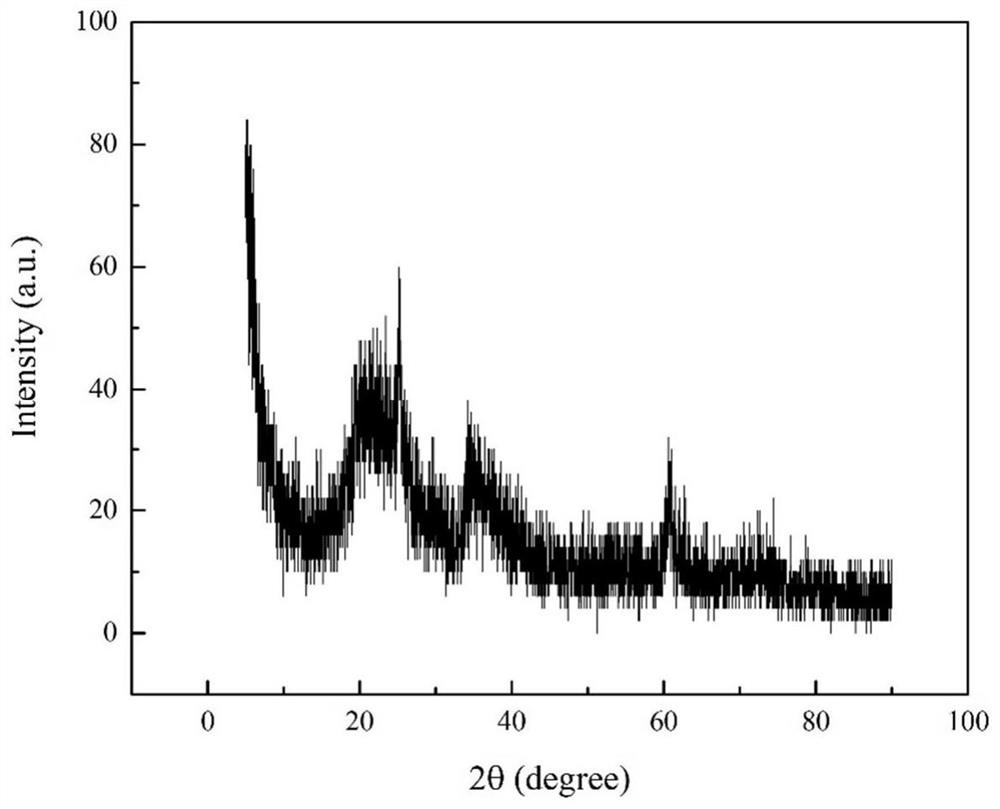

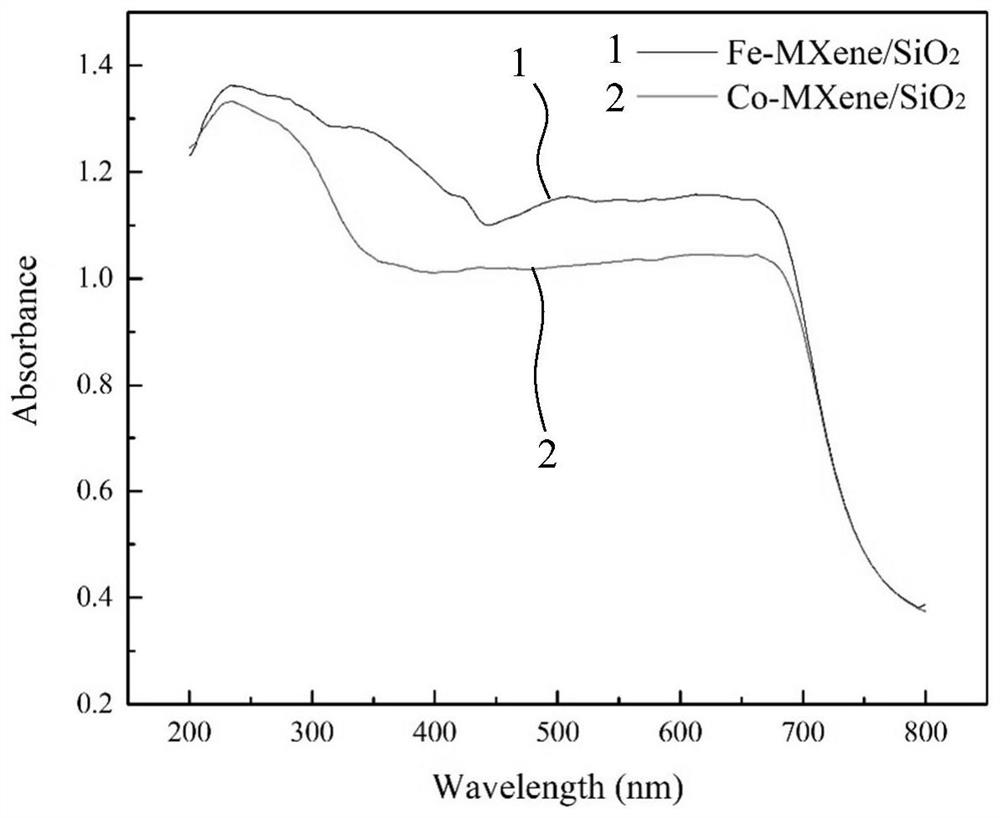

Composite photocatalyst as well as preparation method and application thereof

ActiveCN113083342AStrong light absorption efficiencyFacilitate large-scale synthesisPhysical/chemical process catalystsWater/sewage treatment by irradiationUltraviolet lightsOrganic chemistry

The invention relates to the technical field of photocatalysis, in particular to a composite photocatalyst as well as a preparation method and application thereof. The composite photocatalyst comprises a matrix and a photocatalytic material layer loaded on the surface of the matrix, wherein the matrix comprises silicon dioxide, and the photocatalytic material layer comprises MXene and metal ions connected to the surface of the MXene; through the mode, compounding of photoelectrons and holes can be effectively prevented by utilizing compounding of metal and MXene, and meanwhile, hydrogel is effectively prevented from being formed when the metal and MXene are compounded by utilizing the substrate containing silicon dioxide as a carrier. The composite photocatalyst disclosed by the invention has relatively high light absorption efficiency in both an ultraviolet light region and a visible light region, so that the spectral absorption range is widened, and the utilization rate of sunlight can be effectively improved; the preparation method of the composite photocatalyst is simple in step and beneficial to large-scale synthesis of materials.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

A method for preparing water-soluble silver nanoclusters by reducing silver-ammonia solution with ultraviolet light

ActiveCN104174868BSimple reaction systemEasy to operateMaterial nanotechnologyFluorescenceUltraviolet lights

The invention provides a method for preparing water-soluble silver nanoclusters by reducing silver ammonia solution with ultraviolet light, comprising: taking AgNO 3 Add the solution into the reaction vessel, slowly add NaOH solution while shaking, and add NH dropwise under shaking after precipitation is formed. 3 ·H 2 O until the precipitate is completely dissolved, add twice distilled water to make the concentration 5.0×10 - 3 Silver ammonia stock solution of M; add carboxymethyl dextran dropwise into a weighing bottle, add silver ammonia stock solution under stirring, add secondary water until the volume of the solution is 5-10 times the volume of carboxymethyl dextran times, stir with a magnetic stirrer for 5-10min, and place it under a UV lamp at room temperature for 2-4 hours while stirring. The method of the present invention adopts carboxymethyl dextran as a stabilizer and a reducing agent, and irradiates silver ammonia solution with UVC ultraviolet light to synthesize water-soluble silver nanoclusters; the system is simple, the fluorescence is strong, the particle size is relatively uniform, and the stability is very high it is good.

Owner:HUNAN UNIV OF SCI & TECH

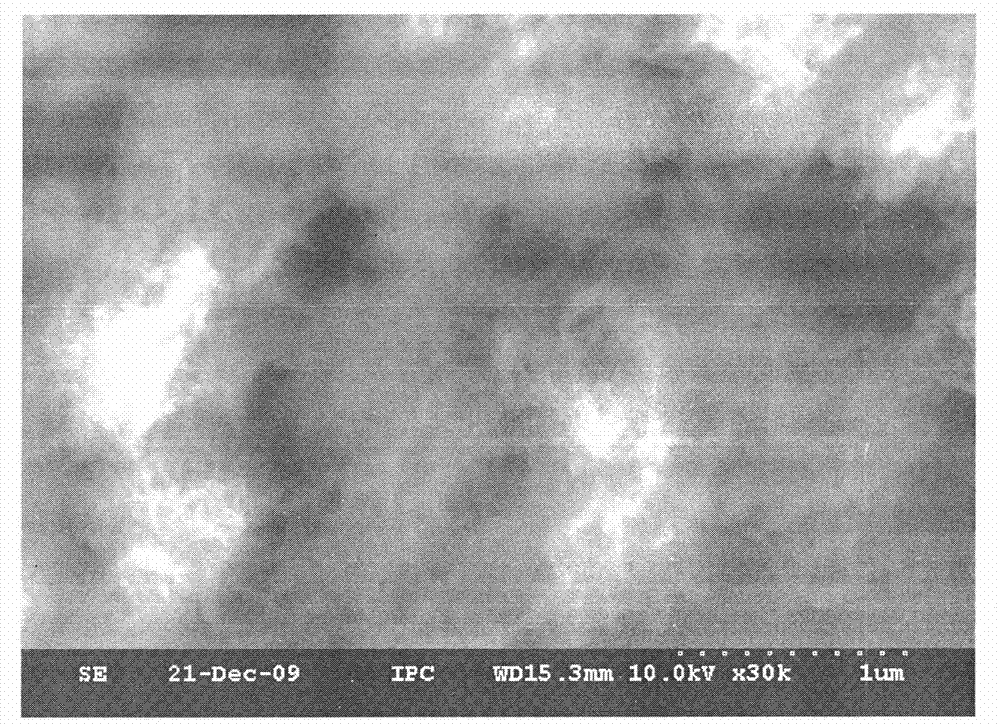

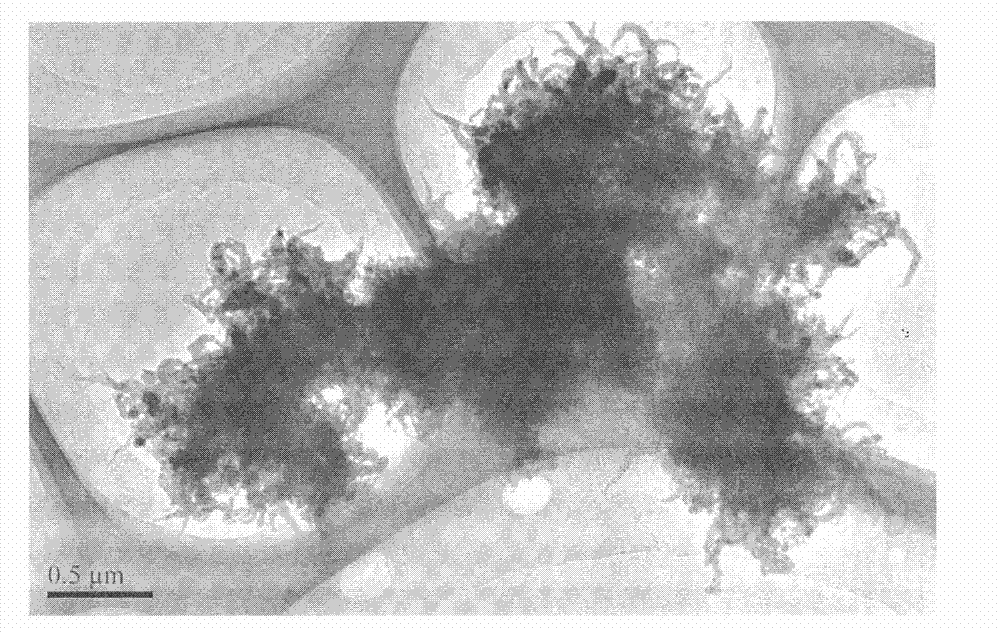

Preparation method of three-dimensional chrysanthemum-shaped poly (3, 4-ethylenedioxythiophene) nanostructural material

Belonging to the field of conducting polymer materials, the invention relates to a preparation method of polythiophene three-dimensional (3D) nanostructural materials with high conductivity, especially to a one-step method for preparing a 3D chrysanthemum-shaped poly (3, 4-ethylenedioxythiophene) nanostructural material with high conductivity on the basis of a three-phase system of an organic solvent, a surfactant and water. The 3D chrysanthemum-shaped poly (3, 4-ethylenedioxythiophene) nanostructural material of the invention has conductivity of 30-140S / cm. The method in the invention is easy, practical, controllable and conducive to scale synthesis. According to the invention, mainly through controlling the mole ratio of deionized water to the surfactant as well as the concentration of an oxidant solution, the 3D chrysanthemum-shaped poly (3, 4-ethylenedioxythiophene) (PEDOT) nanostructural material can be obtained.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for synthesizing fluorogold nanometer quantum dots by taking micromolecules as stabilizer

InactiveCN102861922BSmall particle sizeFacilitate large-scale synthesisNanotechnologyLuminescent compositionsFluorescenceQuantum dot

Owner:HUNAN UNIV OF SCI & TECH

Linear antimicrobial oligopeptide slap-s25 and its application

ActiveCN108467424BGood tissue compatibilitySmall molecular weightAntibacterial agentsPeptide/protein ingredientsHemolysisAntimicrobial drug

The invention discloses a linear antibacterial oligopeptide SLAP-S25 and an application thereof. The linear antibacterial oligopeptide SLAP-S25 is an oligopeptide obtained by acetylation modificationof a nitrogen terminal and amidation modification of a carbon terminal of the oligopeptide as shown in a sequence 1 in a sequence table which is described in the specification. Experiment results showthat the linear antibacterial oligopeptide SLAP-S25 has a certain bacteriostatic effect on a variety of gram-positive and gram-negative bacteria, has good synergistic effects with antibacterial drugs(like tetracycline, vancomycin, ofloxacin and rifampicin), can restore the sensitivity of polymyxin-resistant gram-negative bacteria to polymyxin, reinforces the sensitivity of klebsiella pneumoniaeto a variety of antibacterial drugs, is free of hemolysis, has good tissue compatibility, can effectively inhibit polymyxin drug-resistance bacteria, and can treat bacteremia. The linear antibacterialoligopeptide SLAP-S25 provided by the invention has the advantages of small molecular weight, simple structure, convenient large-scale synthesis and important application values.

Owner:CHINA AGRI UNIV

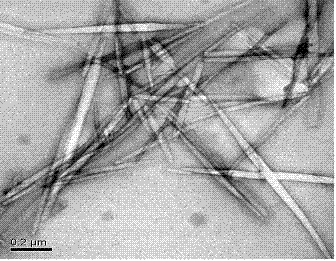

Method for preparing CaCO3 nanotube/podophyllum composite material

InactiveCN102240403BEvenly distributedLarge amount of productCalcium/strontium/barium carbonatesOrganic active ingredientsPhenanthrolineEngineering

The invention relates to a preparation method of a CaCO3 nanotube / podophyllum composite material, specifically: first dissolving 4.0 g of o-phenanthroline carrier in 100 ml of chloroform, vigorously stirring, and then cleaning and drying TFOM and putting it into a solution system for soaking After a certain period of time, take it out, clean it with filter paper, put it in the middle of the GRC container, and form a TFOM in the middle, and a solution phase separation system on the left and right. Prepare 0.53%-0.57% sodium carbonate solution and 2.13%-2.17% calcium chloride The solution was placed on the left and right sides of the above-mentioned TFOM respectively, and the crystal growth modifier M was added according to different situations, and the pH value was adjusted to 8. After stirring at a low speed, the solution on one side of the sodium carbonate solution was taken out, and the precipitated product was obtained by centrifugation. Water, acetone, Wash each with absolute ethanol twice, and finally store the product in absolute ethanol. The present invention has stable reaction, simple operation and easy control, low cost and no pollution, easy control of appearance and structure, uniform product distribution, not easy to agglomerate, and high purity. Easy to industrialize.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com