Composite photocatalyst as well as preparation method and application thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problems of narrow spectral absorption range and low utilization rate of sunlight, and achieve the effects of simple steps, improved spectral absorption range, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a kind of preparation method of composite photocatalyst, comprises the following steps:

[0033] S101, adding a silicon dioxide source into the MXene solution for mixing and stirring to obtain a first reaction solution;

[0034] S102, adding the metal salt into the first reaction solution for mixing and stirring to obtain a second reaction solution;

[0035] S103, filtering, washing and drying the second reaction solution in sequence to obtain a composite photocatalyst.

[0036] The preparation method of this embodiment has the advantages of simple process, low cost, high yield, environmental friendliness and high sunlight utilization efficiency, and has great potential application value in organic sewage treatment.

[0037] In step S101, the two-dimensional material MXene is added to the solvent, and the MXene solution is prepared, and then the silica source is added to the prepared MXene solution, mixed and stirred, an...

Embodiment 1

[0046] This embodiment provides a method for preparing a composite photocatalyst, which is prepared through the following steps:

[0047]Step 1, 10 mL of MXene solution with a concentration of 10 mg / mL and 0.4 g of fumed silica were mixed and stirred for 1 hour to obtain a pure black solution, which was the first reaction solution;

[0048] Step 2, weigh 0.25g of metal salt Fe(NO 3 ) 2 ·6H 2 O was added to the first reaction solution and mixed and stirred for 1h to obtain the second reaction solution;

[0049] Step 3, the reacted product is filtered, washed and dried in turn to obtain the composite photocatalyst Fe-MXene / SiO 2 .

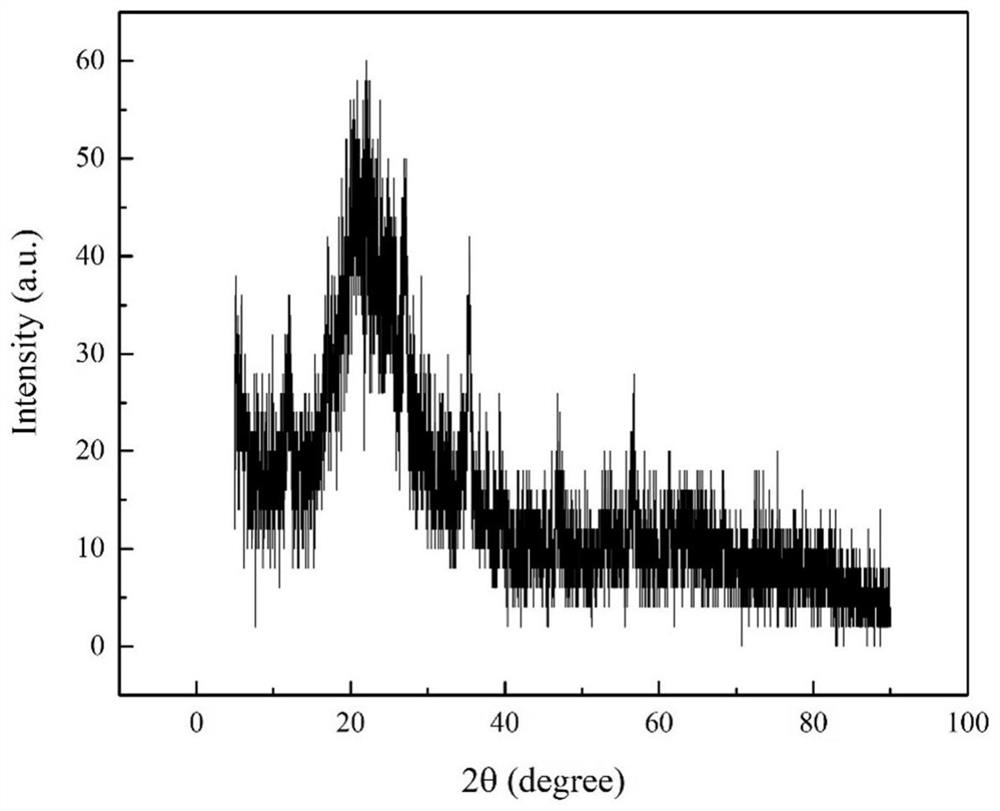

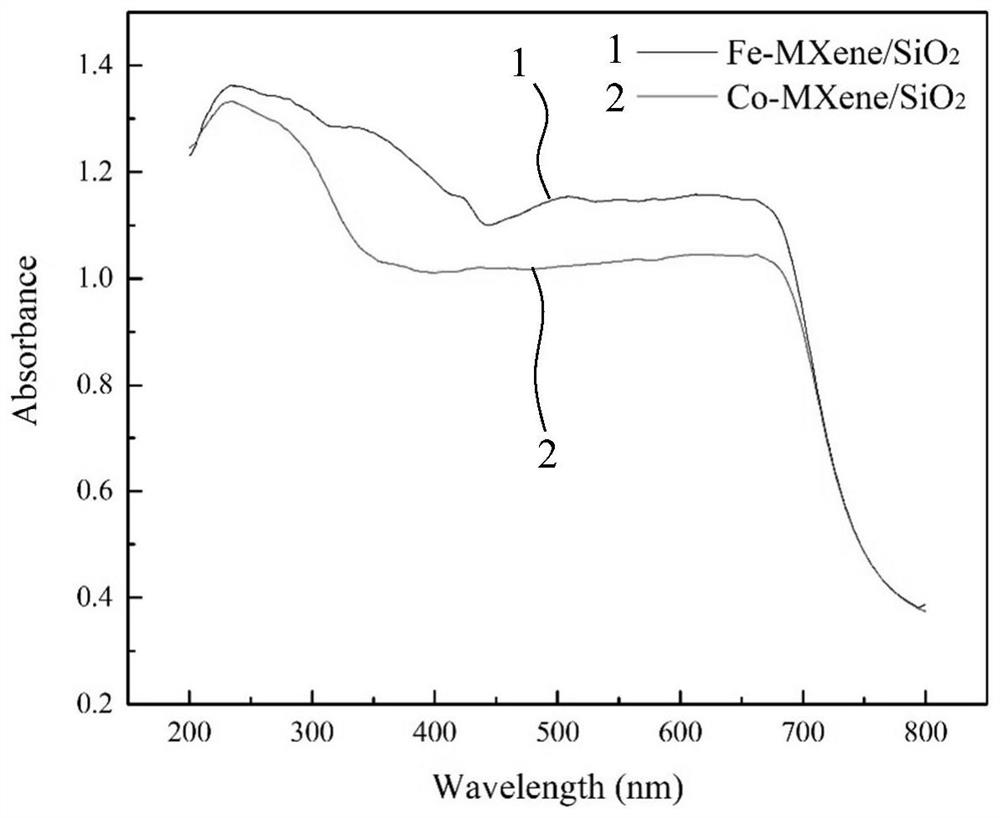

[0050] Composite photocatalyst Fe-MXene / SiO obtained in step 3 of this embodiment 2 The X-ray diffraction (XRD) results see figure 1 Shown; Present embodiment step 3 gained composite photocatalyst Fe-MXene / SiO 2 The UV-vis DRS results see image 3 shown.

Embodiment 2

[0052] This embodiment provides a method for preparing a composite photocatalyst, which is prepared through the following steps:

[0053] Step 1, 10 mL of MXene solution with a concentration of 10 mg / mL and 0.4 g of fumed silica were mixed and stirred for 1 hour to obtain a pure black solution, which was the first reaction solution;

[0054] Step 2, weigh 0.25g of metal salt Co(NO 3 ) 2 ·6H 2 O was added to the first reaction solution and mixed and stirred for 1h to obtain the second reaction solution;

[0055] Step 3, the reacted product is filtered, washed and dried in sequence to obtain the composite photocatalyst Co-MXene / SiO 2 .

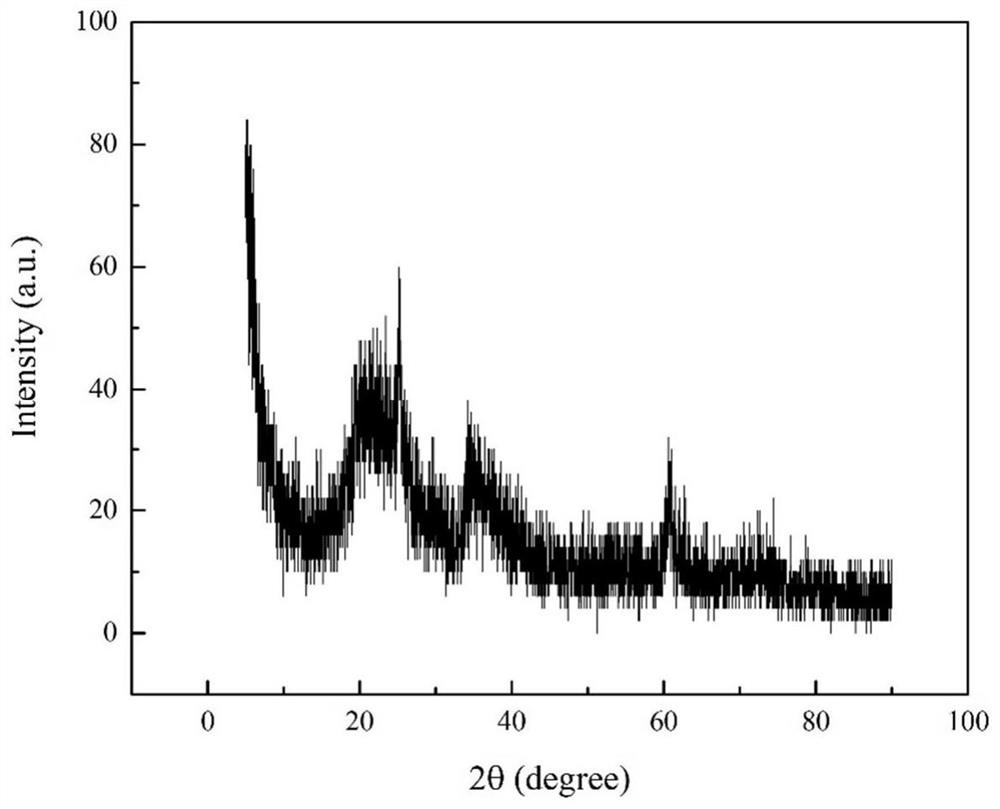

[0056] Composite photocatalyst Co-MXene / SiO obtained in step 3 of this embodiment 2 The X-ray diffraction (XRD) results see figure 2 Shown; The composite photocatalyst Co-MXene / SiO of present embodiment step 3 gained 2 The UV-vis DRS results see image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com