Method for preparing CaCO3 nanotube/podophyllum composite material

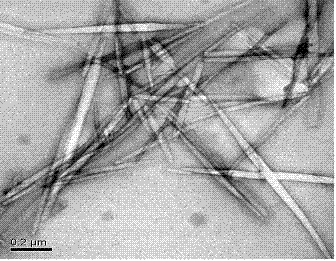

A composite material and nanotube technology, applied in the field of preparation of new CaCO3 nanotube/podophyllin composite materials, can solve problems such as toxic side effects and limited application, and achieve the effects of uniform distribution, easy product handling and mild reaction system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The structure of the self-made gas reaction generator is as Figure 4 As shown, it consists of a constant-speed stirring controller 1, an iron stand 2, a magnetic stirrer 3, an electric stirrer 4, a first glass container 5, an orderly molecular permeable membrane 6 and a constant temperature magnetic stirrer 7, wherein: the first glass The container 5 is placed above the constant temperature magnetic stirrer 7, one end of the second glass container is placed in the first glass container 5, and the bottom of the second glass container is open, and the opening is provided with an ordered molecular permeable membrane 6, and the second glass container There is a certain distance between the bottom and the bottom of the first glass container 5, the second glass container is fixed by the iron stand 2, the stirring rod of the electric mixer 4 is inserted in the second glass container, the electric mixer 4 is connected to the constant speed stirring controller 1, and the second ...

Embodiment 2

[0046] Step 1: Maximum absorption wavelength: Weigh 0.003g of podophyllotoxin, put it in a 10mL volumetric flask, dissolve it with double distilled water and make to volume. The UV-Vis spectrophotometer was used to scan in the range of 200-800 nm, and 285 nm was the maximum absorption wavelength of podophyllotoxin, so the experiment chose to test the concentration of podophyllotoxin in the solution at this wavelength.

[0047] Use the same method for UV detection of podophyllin / nano-CaCO 3 The full ultraviolet spectrum of nanomaterials, observe the absorption of its ultraviolet spectrum, and determine whether there is interference at the sensitive absorption wavelength of podophyllum.

[0048] Drawing of the working curve of podophyllum: prepare 1, 2, 3, 4, 5, 6, 8, 10μg / ml podophyllum standard solutions respectively, and measure the absorbance at 285nm. Fit the working curve.

[0049] Podophyllum / Nano CaCO 3 Determination of drug-loading capacity of composite nanomaterial...

Embodiment 3

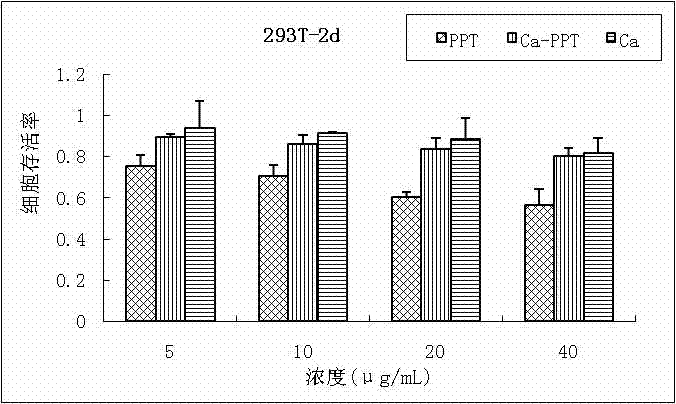

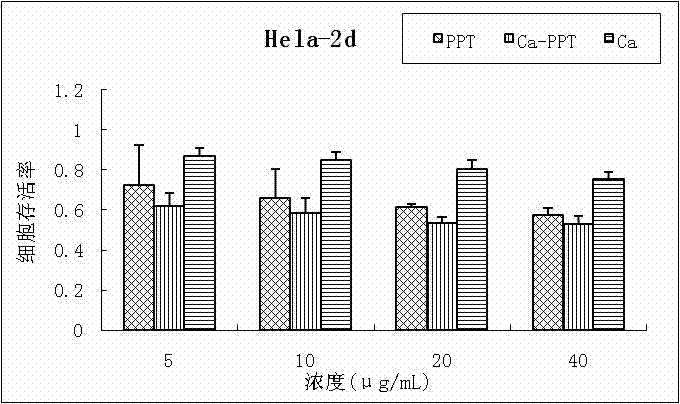

[0055] Step 1: Use the normal cell line HEK 293T to detect its cytotoxicity, and select Hela tumor cells for its inhibitory effect on tumor cells.

[0056] Step 2: After pre-cultured for 24 hours, the cells adhered to the wall, and the cell culture medium was used as the negative control group. Three wells in each group were added with different concentrations of PPT solution and CaCO 3 -PPT suspension and CaCO 3 Suspension (concentrations were 5, 10, 20, 40 μg / ml).

[0057] Step 3: After culturing for 24 h, add 20 μl of MTT solution to each well, discard the supernatant after incubation for 4 h, and add 150 μl of DMSO to each well to stop the reaction.

[0058] Step 4: Shake the culture plate horizontally for 30 min, measure the absorbance at 490 nm with an enzyme-linked detector, and calculate the cell survival rate according to the following formula:

[0059] Cell Viability % = A 490(样品) / A 490(对照) ×100%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com