A preparation method of SERS substrate based on 2D noble metal nanostructure

A nanostructure and noble metal technology, applied in metal material coating process, instrument, vacuum evaporation plating, etc., can solve the problems that it is difficult to prepare a plasma nanostructure array, and it is difficult to evenly distribute hot spots, so as to improve the detection sensitivity , excellent repeatability and stability, good periodic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for processing a SERS substrate based on a 2D noble metal nanostructure, which specifically includes the following steps:

[0035] S1, the surface is deposited with 300nm silicon oxide single crystal silicon (referred to as SiO 2 / Si) The substrate is successively placed in acetone, absolute ethanol and deionized water for ultrasonic cleaning for 10 minutes, taken out and dried with nitrogen, and treated with an ultraviolet ozone system for 30 minutes to make the surface of the substrate exhibit superhydrophilic properties;

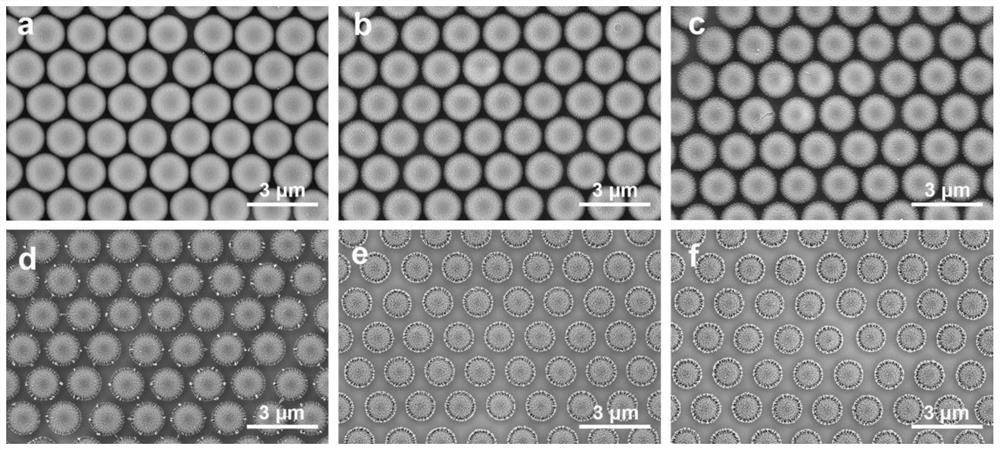

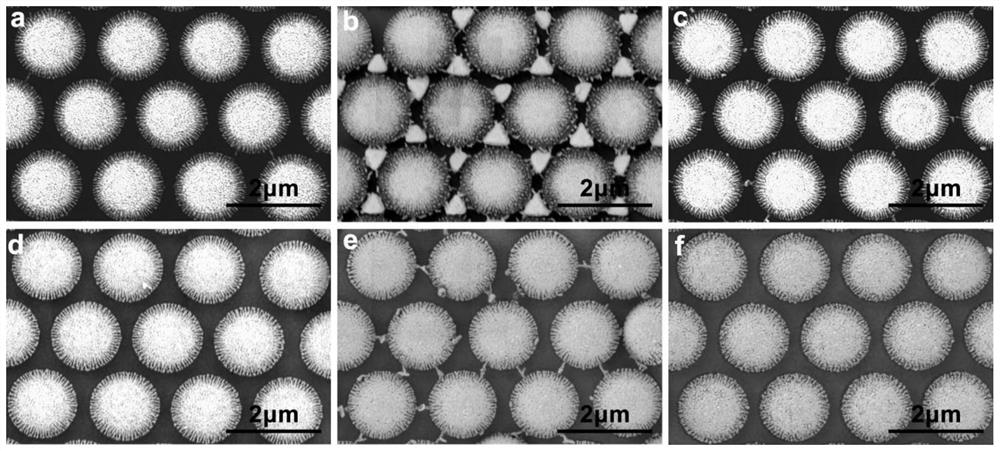

[0036]S2. Using the colloidal self-assembly method to self-assemble a layer of polystyrene (PS) microsphere arrays in a regular and orderly arrangement on the surface of the substrate after step S1, and then place the substrate in a drying oven at 60°C for drying treatment 90min, and then further increase the temperature to 80°C for 5min heat treatment to obtain substrate A;

[0037] In the step S2, the specific s...

Embodiment 2

[0046] This embodiment provides a method for processing a SERS substrate based on a 2D noble metal nanostructure, which specifically includes the following steps:

[0047] S1, put 2 pieces of SiO 2 The / Si substrate was placed in acetone, absolute ethanol, and deionized water for 8 minutes to be ultrasonically cleaned, taken out and dried with nitrogen, and then treated with an ultraviolet ozone system for 25 minutes to make the surface of the substrate appear super-hydrophilic;

[0048] S2. Using the colloidal self-assembly method to self-assemble a layer of polystyrene (PS) microsphere arrays in a regular and orderly arrangement on the surface of the substrate after step S1, and then place the substrate in a drying oven at 60°C for drying treatment After 60 minutes, the temperature was further raised to 80°C for 5 minutes of heat treatment to obtain substrate A;

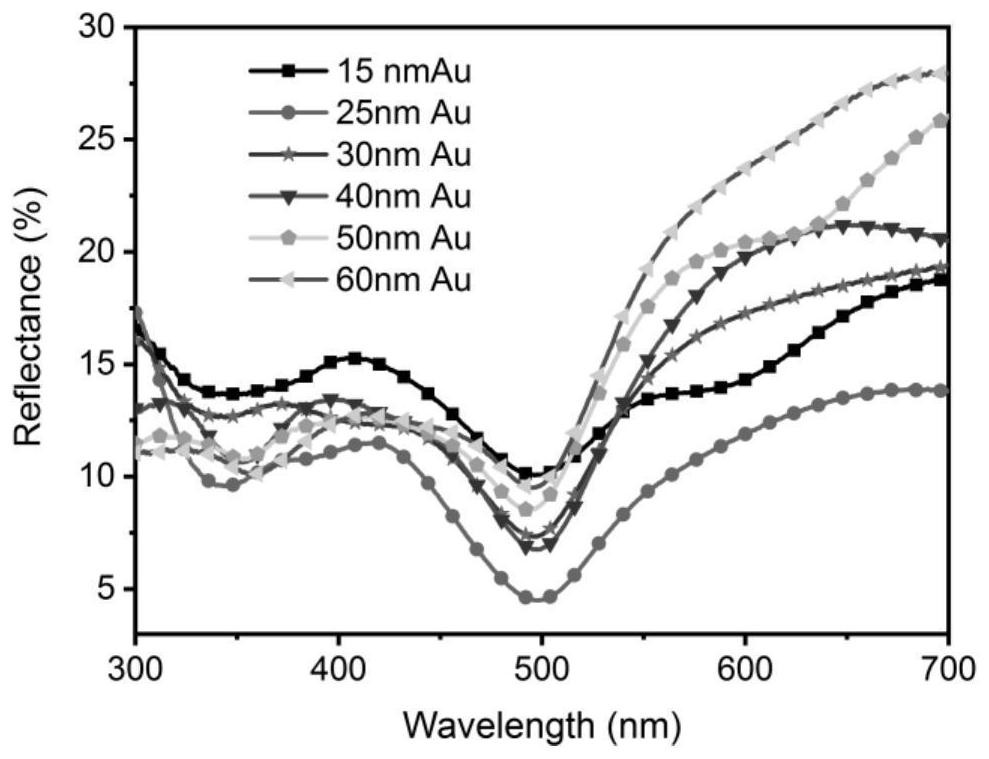

[0049] S3, using a plasma etching machine to carry out oxygen plasma etching on the substrate A prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com