Soluble linear conductive polymer and preparation method thereof

A conductive polymer and soluble technology, applied in the field of soluble linear conductive polymers and their preparation, can solve problems such as difficulty in controlling the growth of conjugated segments, and achieve the effects of being conducive to large-scale synthesis, mild reaction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a kind of soluble linear conductive polymer, and its preparation method comprises the following steps:

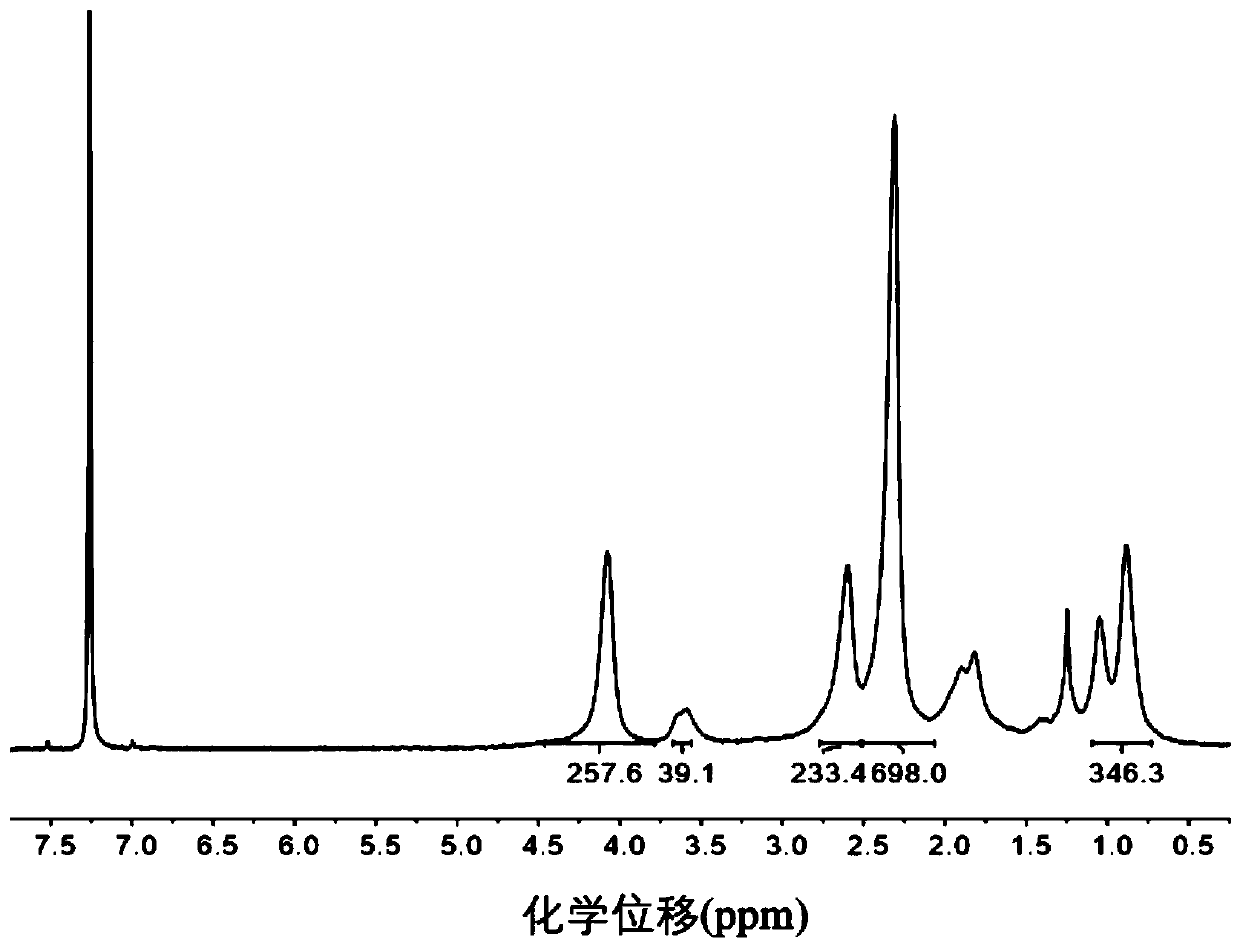

[0035]S1: Use S-dodecyl-S'-(R,R-dimethyl-R"-(2-thienyl) ethyl acetate) trithiocarbonate (DTTC-Th) as chain transfer agent , the reversible addition of methyl acrylate (MA), N,N-dimethylaminoethyl methacrylate (DMAEMA) and 1,4-dioxane initiated by azobisisobutyronitrile (AIBN) - fragmentation chain transfer polymerization to obtain polymethacrylic acid N,N-dimethylaminoethyl ester-b-polymethyl acrylate (PDMAEMA-b-PMA-Th);

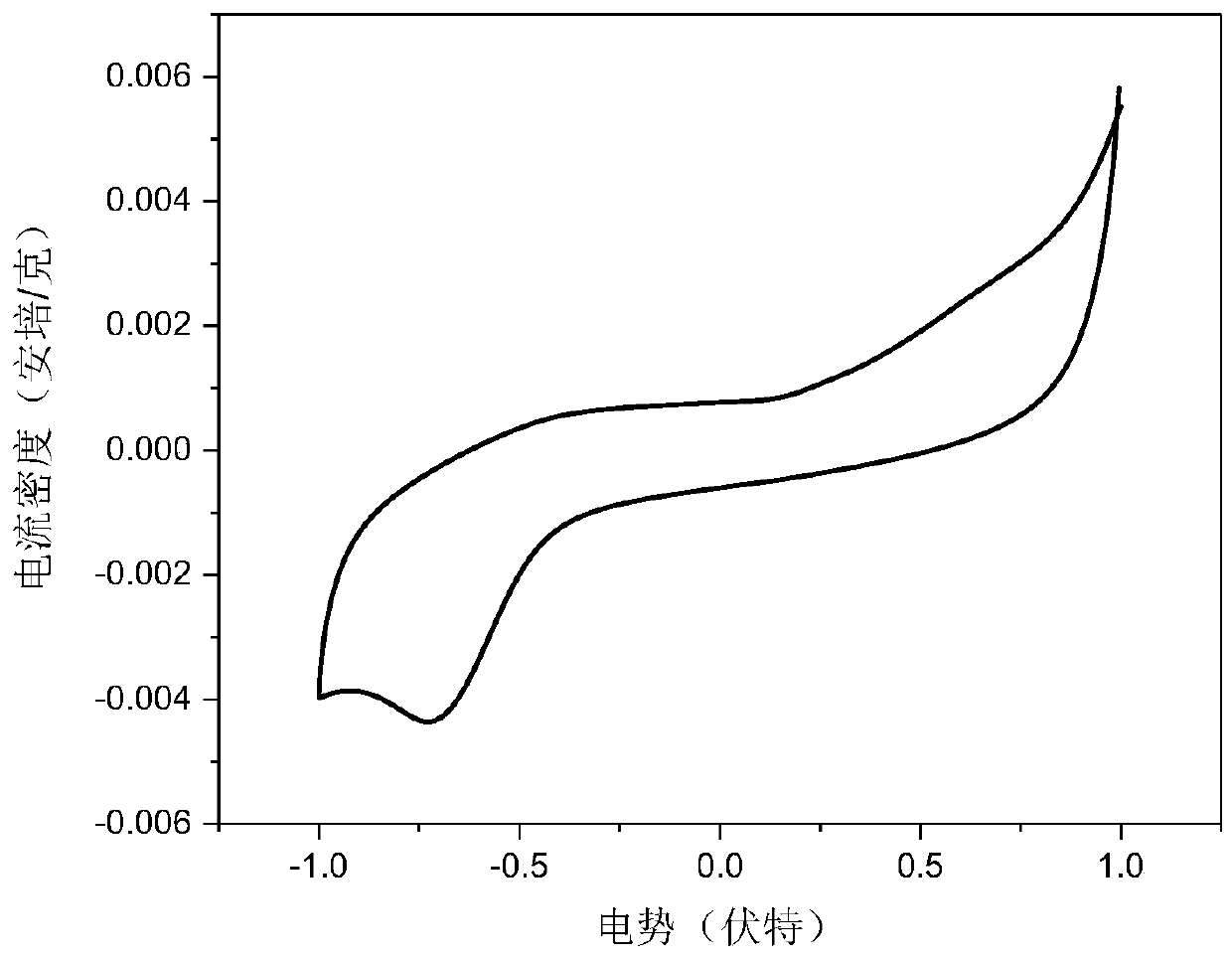

[0036] S2: Under the action of a catalyst, add 3,4-ethylenedioxy The n-butanol solution of thiophene (EDOT) is subjected to interfacial polymerization to obtain poly-N,N-dimethylaminoethyl methacrylate-b-polymethyl acrylate-b-poly 3,4-ethylenedioxythiophene (PDMAEMA -b-PMA-b-PEDOT), a soluble linear conductive polymer.

[0037] Specifically, step S1 includes the following steps:

[0038] (1) Synthesis of DTTC-Th

[003...

Embodiment 2

[0054] This embodiment provides a kind of soluble linear conductive polymer, and its preparation method comprises the following steps:

[0055] (1) Synthesis of DTTC-Th

[0056] Add 2.5g of DTTC, 1.1g of 2-thiophenethanol, 2.5g of dicyclohexylcarbodiimide, 0.08g of 4-dimethylaminopyridine and 5mL of tetrahydrofuran into a 25mL flask, dissolve it under stirring at 400r / min, and then quickly shake the flask Refrigerated and degassed three times, and then placed in an oil bath at 30°C for 30 h. After the reaction, the mixed solution was filtered and concentrated, and the product was separated by gel chromatography to obtain DTTC-Th.

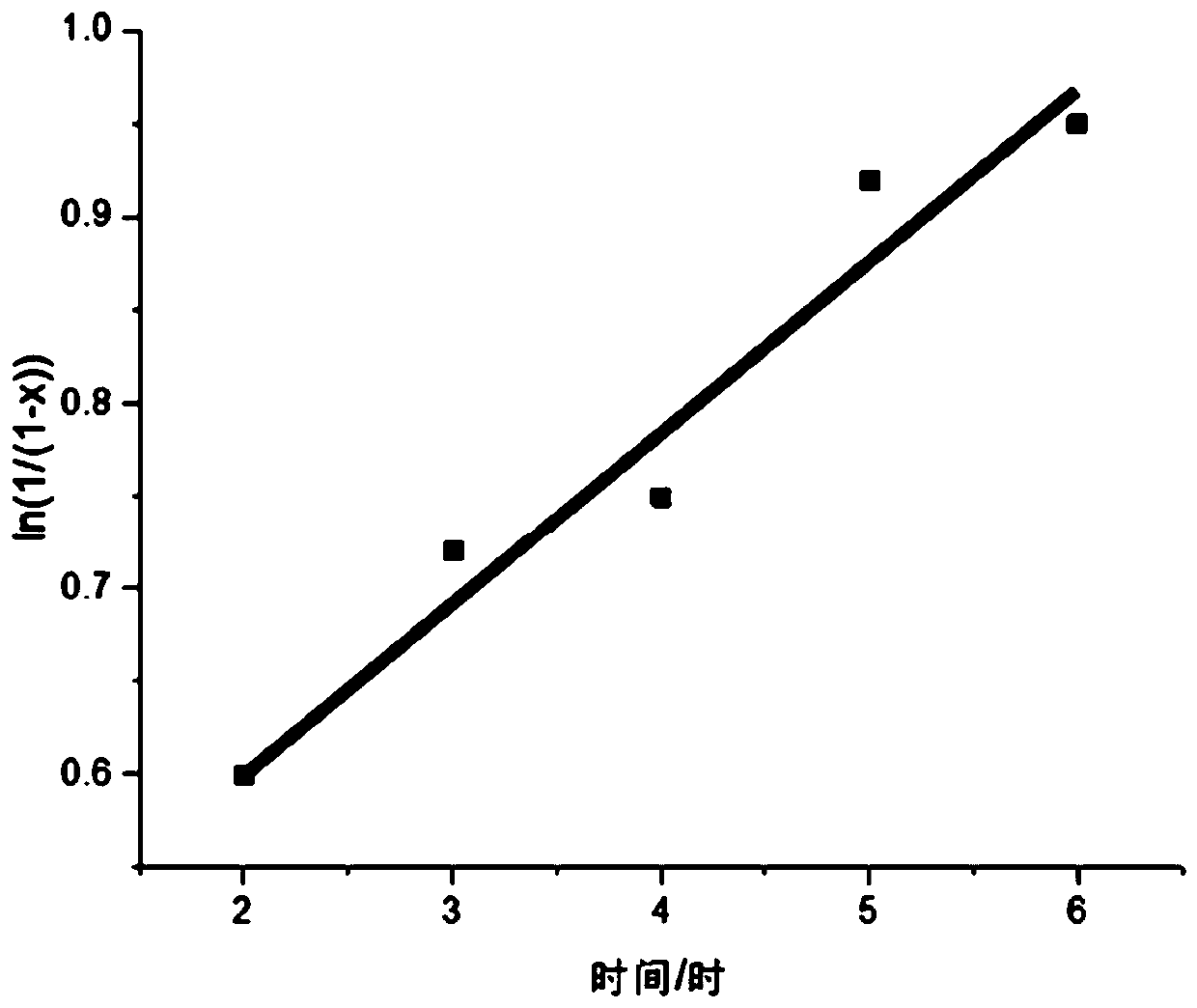

[0057] (2) Synthesis of PDMAEMA-Th

[0058] Add 16.7g DMAEMA, 0.4g DTTC-Th, 0.02g AIBN and 10mL 1,4-dioxane into a 25mL flask, dissolve under stirring at 400r / min, freeze and degas the flask 3 times quickly, and then place Reaction in an oil bath at 75°C for 5h. After the reaction, cool at room temperature, add the reaction solution dropwise int...

Embodiment 3

[0064] (1) Synthesis of DTTC-Th

[0065] Add 2.2g of DTTC, 1g of 2-thiophenethanol, 1.5g of dicyclohexylcarbodiimide, 0.07g of 4-dimethylaminopyridine and 5mL of tetrahydrofuran into a 25mL flask, and dissolve it under stirring at 500r / min. Refrigerated and degassed 3 times, and then placed in an oil bath at 35°C for 30 h. After the reaction, the mixed solution was filtered and concentrated, and the product was separated by gel chromatography to obtain DTTC-Th.

[0066] (2) Synthesis of PDMAEMA-Th

[0067]Add 15.7g DMAEMA, 0.36g DTTC-Th, 0.016g AIBN and 10mL 1,4-dioxane into a 25mL flask, dissolve under stirring at 500r / min, freeze and degas the flask 3 times quickly, and then place Reaction in an oil bath at 65°C for 5h. After the reaction, cool at room temperature, add the reaction solution dropwise into 200 mL of petroleum ether for precipitation, obtain the precipitate, and dry it in vacuum at 25° C. for 24 hours to obtain PDMAEMA-Th.

[0068] (3) Synthesis of PDMAEMA-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com