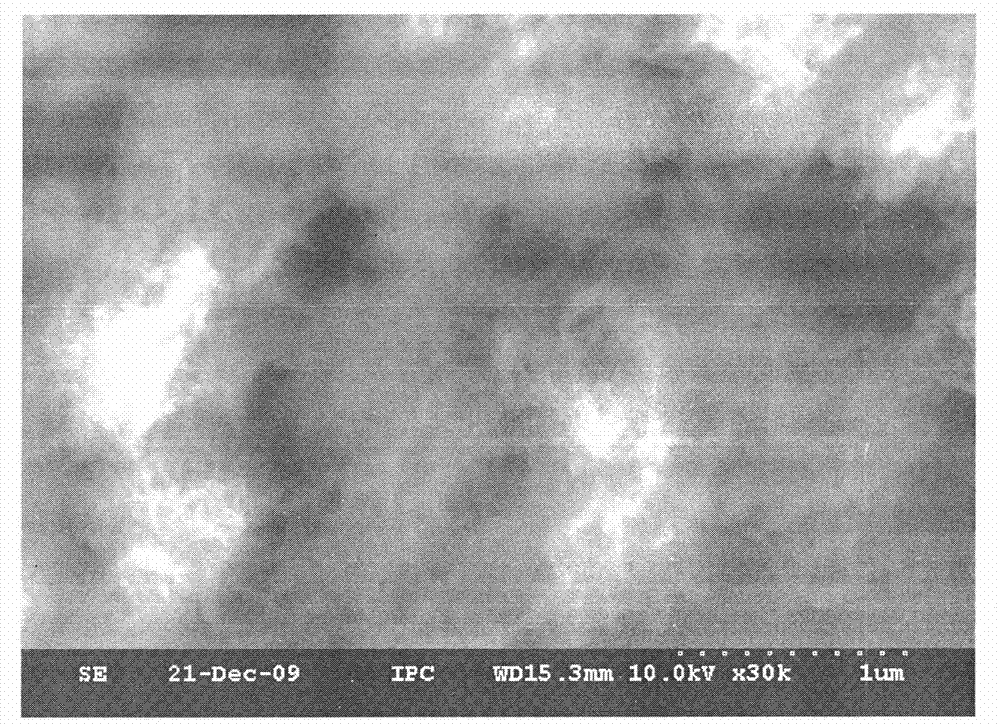

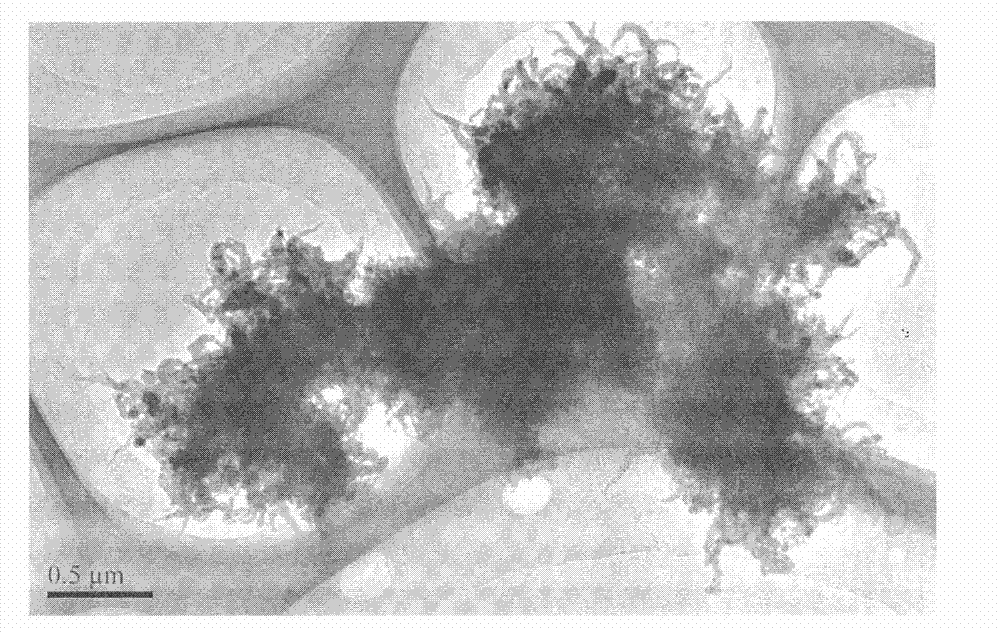

Preparation method of three-dimensional chrysanthemum-shaped poly (3, 4-ethylenedioxythiophene) nanostructural material

A dioxyethyl, nanostructured technology, applied in the field of nanostructured materials of polythiophene, can solve the problems of no literature and patent reports, and achieve the effects of controllable scale synthesis, high specific surface area, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a) Sodium succinate sulfonate is placed in a p-xylene solvent, ultrasonically and continuously stirred to dissolve the sodium succinate sulfonate, and the concentration of sodium succinate sulfonate in the resulting solution is 1.3mol / L;

[0020] b) Iron trichloride (FeCl 3 ) is placed in deionized water, and stirred to dissolve ferric chloride to obtain an orange-yellow aqueous solution that contains a concentration of 5mol / L ferric chloride;

[0021] c) under stirring conditions, the aqueous solution containing ferric chloride obtained in step b) is added to the solution obtained in step a), fully stirred so that the two solutions are mixed evenly, wherein: the added step b) contains ferric chloride The molar weight of the water in the aqueous solution is step a) 3 times of the molar weight of sodium succinate sulfonate;

[0022] d) Add monomer 3,4-dioxyethylthiophene (EDOT) to the orange-yellow mixed solution obtained in step c) under stirring conditions, wherein: t...

Embodiment 2

[0025] The preparation method and conditions are basically the same as in Example 1, except that the added step b) the molar weight of water in the aqueous solution containing iron trichloride is 6 times that of step a) sodium succinate sulfonate molar weight, and the single added The molar weight of 3,4-dioxyethylthiophene is 0.15 times of the molar weight of sodium succinate sulfonate in step a), and the poly(3,4-dioxyethyl)thiophene of three-dimensional "chrysanthemum shape" is still obtained For nanostructure materials, the particle size of the material remains unchanged, which is still about 700-800nm, and the electrical conductivity increases to 45.0S / cm.

Embodiment 3

[0027] The preparation method and conditions are basically the same as in Example 1, except that the concentration of sodium succinate sulfonate in the solution obtained by changing step a) is 1.6mol / L; and the step b) added by changing the water in the aqueous solution containing iron trichloride The molar amount is step a) 20 times of the sodium succinate sulfonate molar amount, still obtains the nanostructure material of the poly(3,4-dioxyethyl)thiophene of three-dimensional " chrysanthemum shape ", and the particle size of this material is different Change, still about 700 ~ 800nm, the conductivity further increased to 71.2S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com