Method for compounding hexagon silver nanosheet

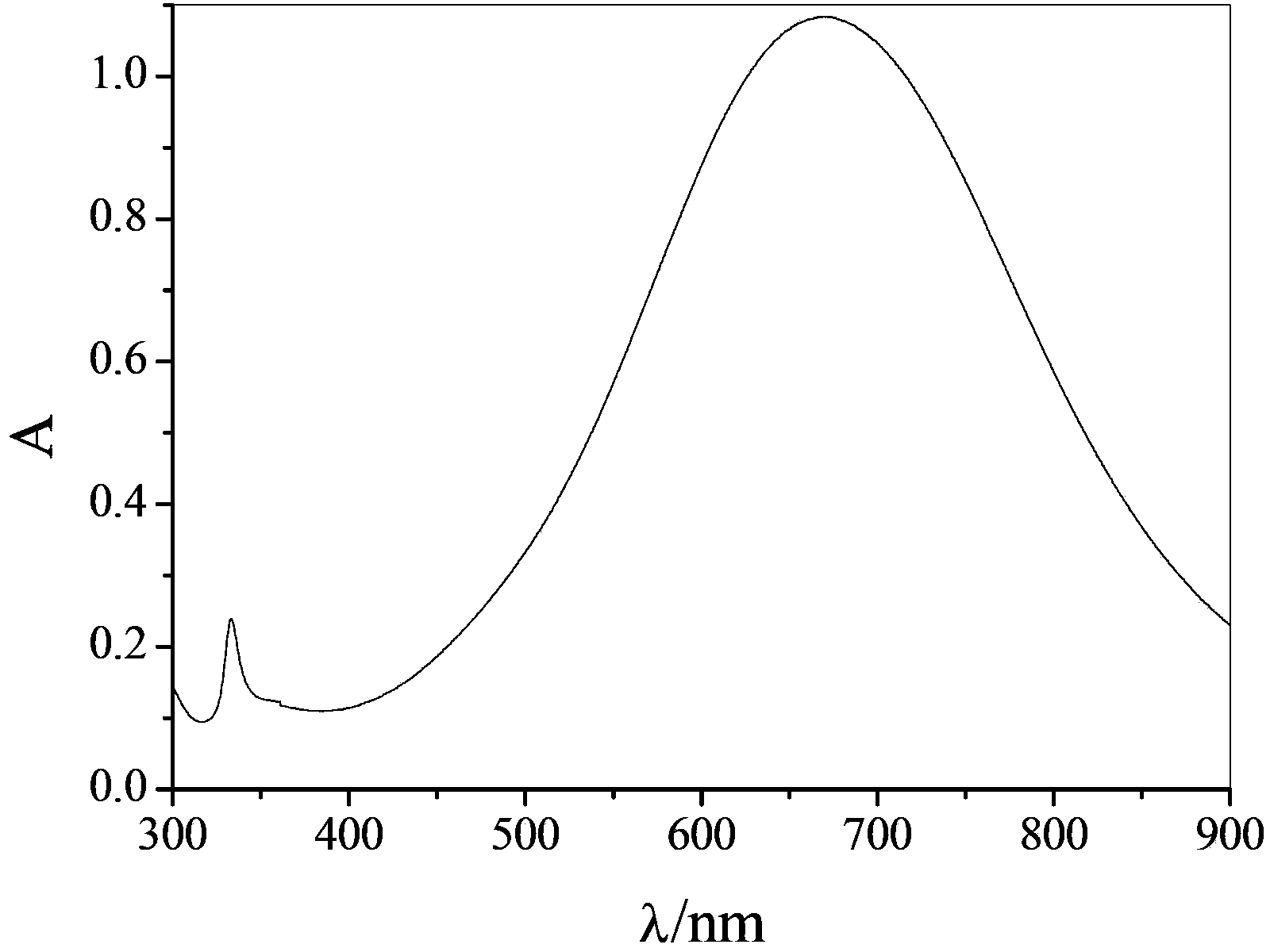

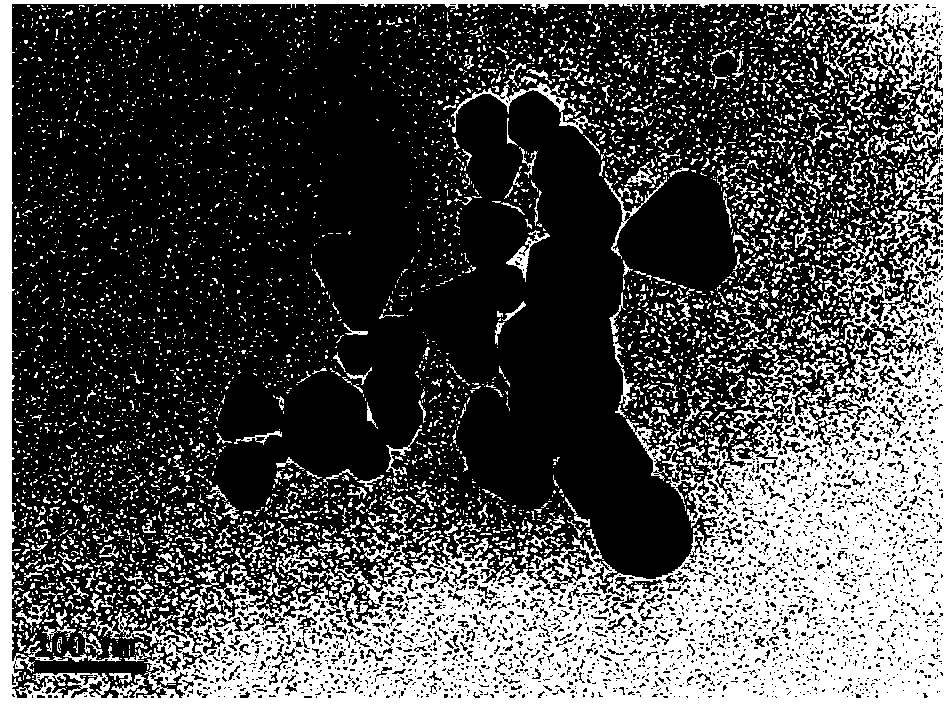

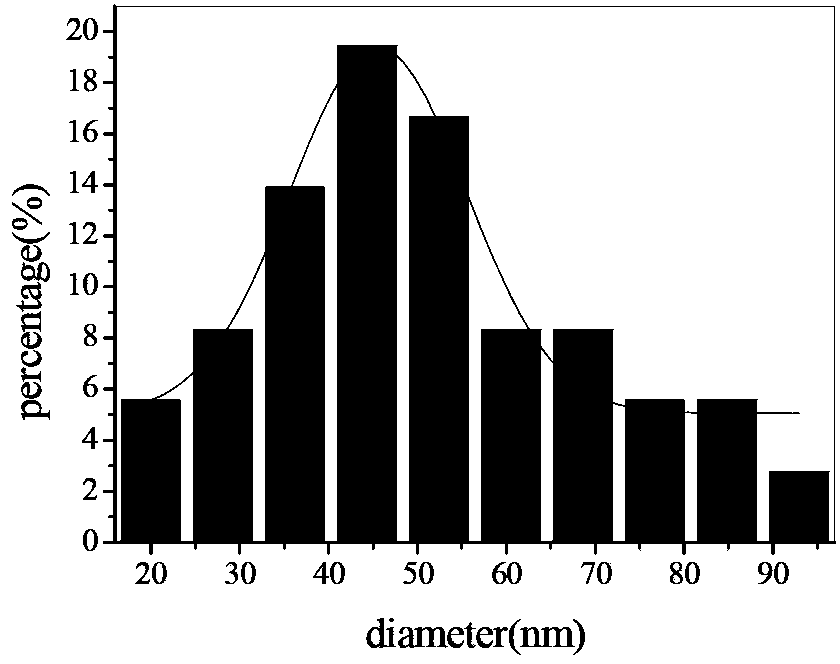

A technology of silver nanosheets and hexagons, which is applied in the field of synthesizing hexagonal silver nanosheets with silver ammonia solution, can solve the problems of unsatisfactory synthesis uniformity and slow synthesis speed, and achieve the convenience of large-scale synthesis and short synthesis cycle , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific experimental examples.

[0017] (1) Preparation of the solution used:

[0018] Weigh 0.8494g AgNO 3 Prepare AgNO at a concentration of 0.1M with 50mL of water 3 Stock solution; 3.0 mL of prepared AgNO 3 Add the solution (0.1M) into a 50mL beaker, slowly add 250μL NaOH solution (0.2M) and shake it, a precipitate is formed, add NH drop by drop under shaking 3 ·H 2 O (5%) 720 μL until the precipitate is completely dissolved, and finally diluted with twice distilled water to prepare a concentration of 0.05MAg (NH 3 ) 2 OH stock solution; take 1.1029g trisodium citrate and dissolve it in 50mL water to prepare a trisodium citrate stock solution with a concentration of 0.075M; weigh 0.1892g NaBH 4 Dissolve in 50mL water to prepare NaBH with a concentration of 0.1M 4 Stock solution; carboxymethyl dextran concentration is 0.01M; commercially available 30% HO 2 o 2 .

[0019] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com