Method for preparing sodium fluorophosphate vanadium for positive pole material of sodium-ion battery

A technology of sodium vanadium fluorophosphate and sodium ion battery, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor charge and discharge performance, long synthesis cycle, coarse product particles, etc., and achieves low synthesis temperature and short synthesis cycle. , the effect of a simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

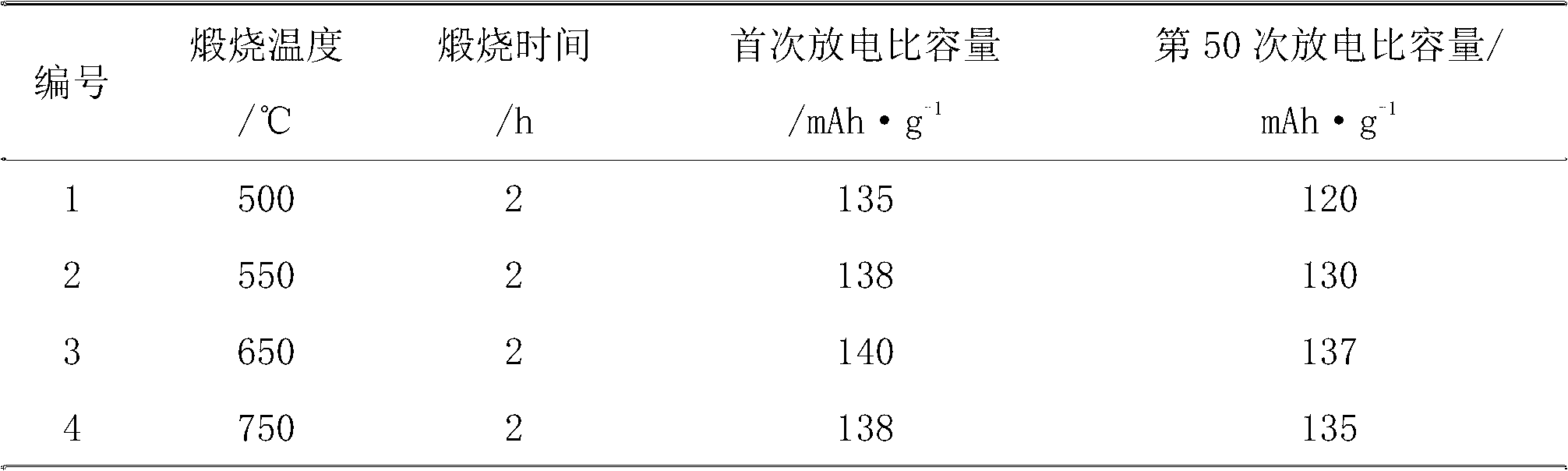

[0015] Using vanadium pentoxide, ammonium dihydrogen phosphate, sodium carbonate, hydrofluoric acid and lactic acid as raw materials, mix evenly according to the molar ratio of vanadium: phosphorus: sodium: fluorine element 1:1:1:1; then press lactic acid : The molar ratio of vanadium pentoxide is 1:1, adding reducing agent to mechanical activation (ball milling) for 0.5 hours, under normal temperature and pressure conditions, the reducing agent will reduce high-valent vanadium to form fine particles of amorphous sodium vanadium fluorophosphate; will The amorphous sodium vanadium fluorophosphate in step is loaded into a tube furnace, heated to 500°C, 550°C, 650°C and 750°C in an argon atmosphere, and calcined at a constant temperature for 2 hours to obtain crystalline powder. It was analyzed by X-ray diffraction as sodium vanadium fluorophosphate (NaVPO 4 F) Structure.

[0016] The resulting vanadium vanadium phosphate product was assembled into a button battery to measure ...

Embodiment 2

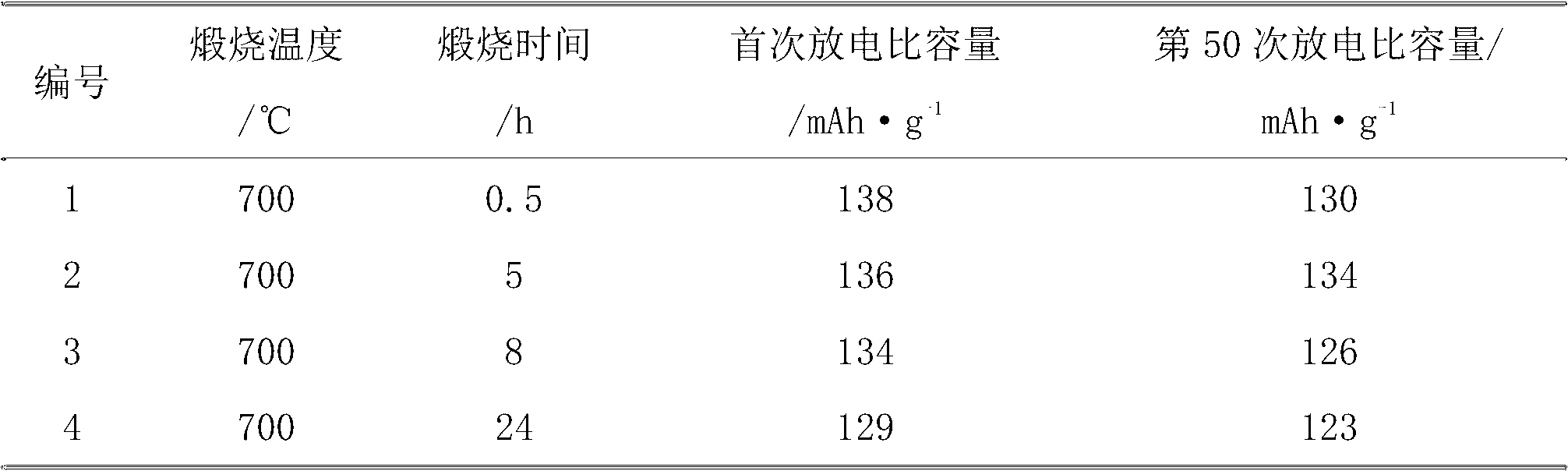

[0020] Using vanadium dioxide, triammonium phosphate, sodium fluoride and malic acid as raw materials, mix evenly according to the molar ratio of vanadium: phosphorus: sodium: fluorine element 1:1:1:1; The molar ratio of vanadium is 5:1, adding reducing agent to mechanical activation (ball milling) for 24 hours, under the condition of normal temperature and pressure, the reducing agent will reduce the high-valent vanadium to produce fine particles of amorphous sodium vanadium fluorophosphate;

[0021] Put the amorphous sodium vanadium fluorophosphate in step into a tube furnace, heat to 700°C in a hydrogen atmosphere, and calcine at a constant temperature for 0.5 hours, 5 hours, 8 hours and 24 hours respectively to obtain a crystalline state powder. It was analyzed by X-ray diffraction as sodium vanadium fluorophosphate (NaVPO 4 F) Structure.

[0022] The obtained sodium vanadium fluorophosphate product was assembled into a button battery to measure its charge-discharge sp...

Embodiment 3

[0026] Using ammonium metavanadate, diammonium hydrogen phosphate, sodium fluoride and acetaldehyde as raw materials, mix evenly according to the molar ratio of vanadium: phosphorus: sodium: fluorine element 1:1:1:1; then use acetaldehyde: The molar ratio of ammonium metavanadate is 10:1, adding a reducing agent for mechanical activation (ball milling) for 8 hours. Under normal temperature and pressure conditions, the reducing agent reduces the high-valent vanadium to form fine particles of amorphous sodium vanadium fluorophosphate;

[0027] Put the amorphous sodium vanadium fluorophosphate in the step into a tube furnace, heat to 560°C in a nitrogen atmosphere, and calcine at a constant temperature for 15 hours to obtain crystalline powder. It was analyzed by X-ray diffraction as sodium vanadium fluorophosphate (NaVPO 4 F) Structure.

[0028] Assemble the obtained sodium vanadium fluorophosphate product into a button battery to measure its charge-discharge specific capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com