Patents

Literature

38results about How to "Reduce synthesis energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst

ActiveCN103191786ALess prone to elution and lossEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsWater basedPtru catalyst

The invention discloses a preparation method of an MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst. The preparation method comprises the steps of: adding raw materials for synthesizing phosphotungstic heteropolyacid into a certain amount of deionized water based on certain proportion; subsequently adding a certain amount of an iron source, mixing and stirring, further adding a certain amount of an organic ligand, mixing, stirring, adding a certain amount of an acid solution, and mixing and stirring; mixing, stirring and reacting for 5-20 hours under normal pressure at 80-95 DEG C; and filtering the obtained solid, washing for 10-20 hours at 60-80 DEG C by using absolute ethyl alcohol, subsequently treating for 10-15 hours at 60-80 DEG C by using a 30-60mmol / L ammonium fluoride solution, sufficiently washing by using deionized water, and finally drying for 5-10 hours at 100-200 DEG C so as to obtain the MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst. The method is temperate in synthesis condition, low in synthesis energy consumption and high in catalyst synthesis yield.

Owner:日照经济技术开发区客商服务有限公司

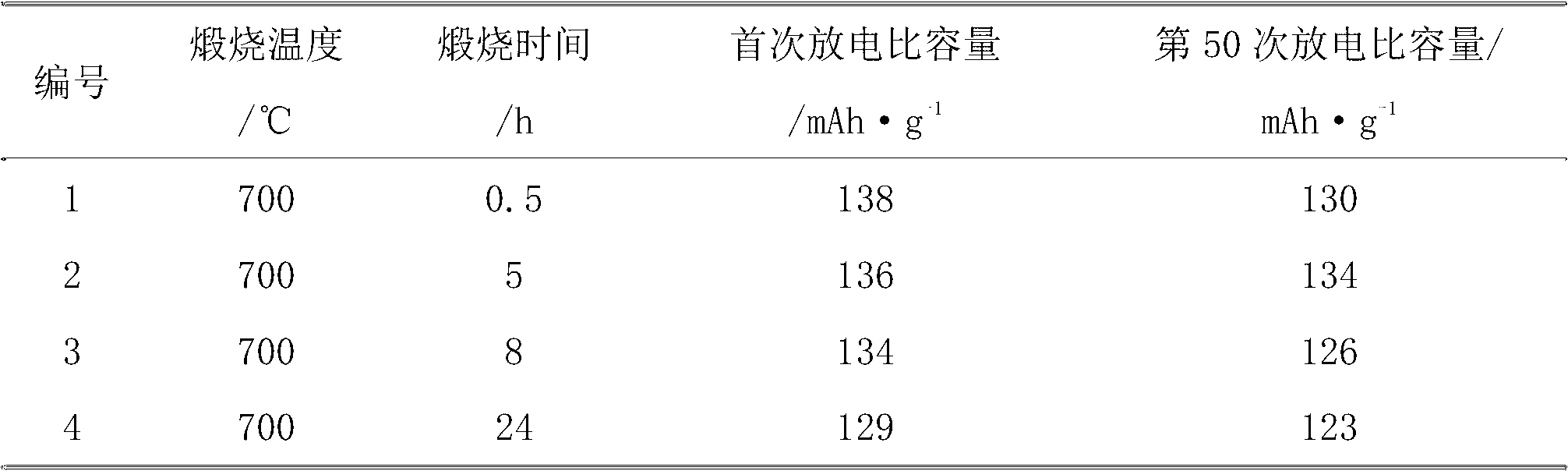

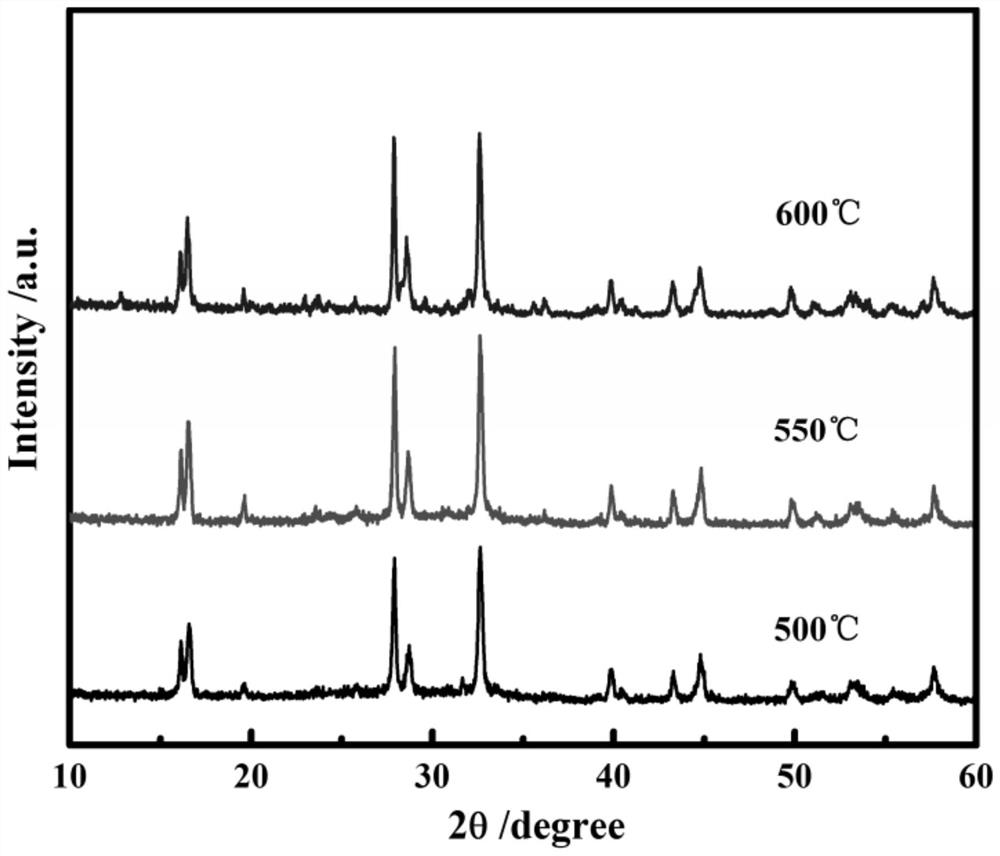

Method for preparing sodium fluorophosphate vanadium for positive pole material of sodium-ion battery

InactiveCN103022490AEasy to achieve large-scale industrial preparationLow costCell electrodesSynthesis methodsSodium-ion battery

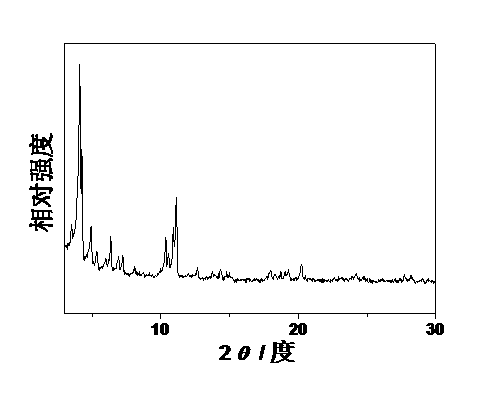

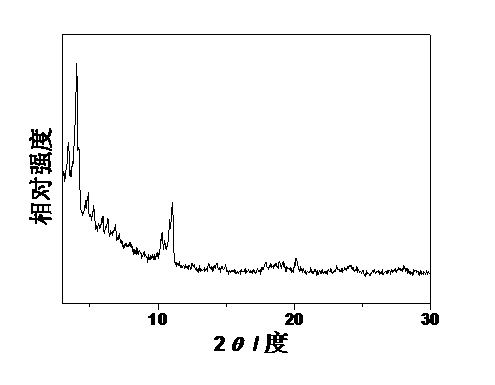

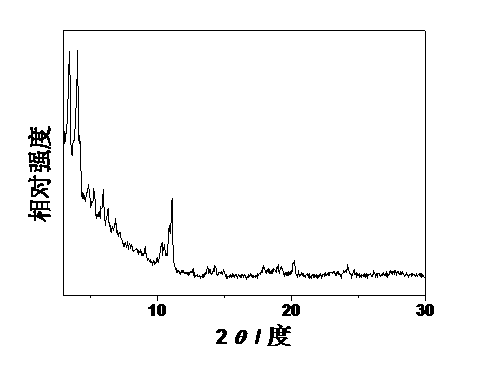

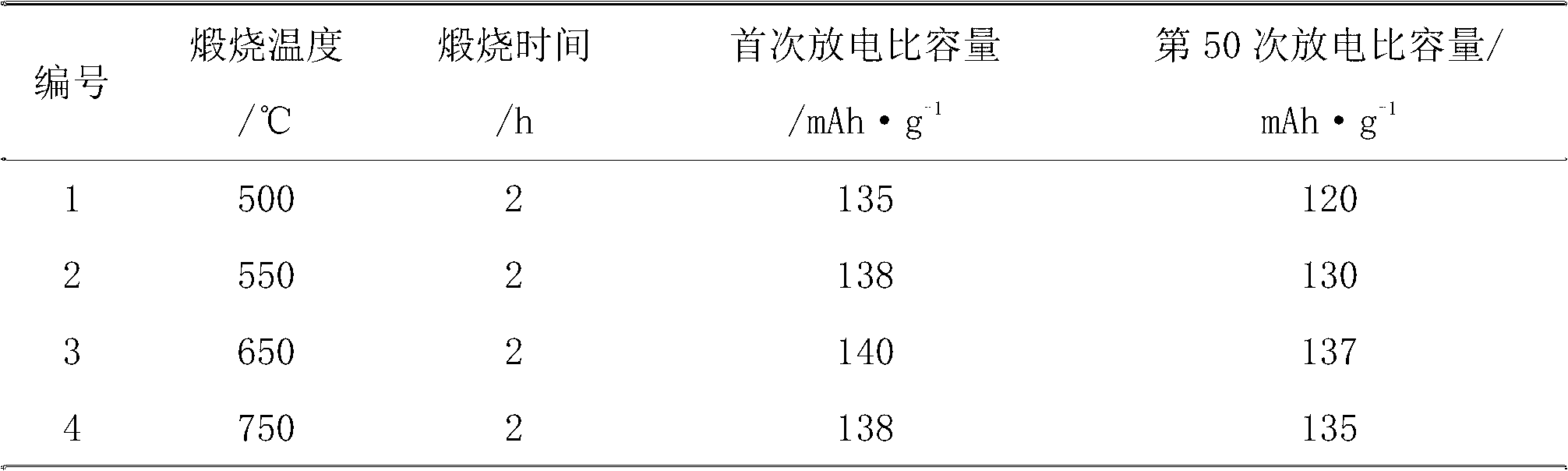

The invention discloses a method for preparing sodium fluorophosphate vanadium for a positive pole material of a sodium-ion battery. The method comprises the following steps of: taking a high-valence vanadium source compound, a phosphorus source compound, a sodium source compound, a fluorine source compound and a reductant as raw materials, and uniformly mixing the raw materials in a manner that the molar ratio of vanadium to phosphorus to sodium to fluorine is 1: 1: (1-1.05): 1; adding the reductant in a manner that the molar ratio of the reductant to the vanadium source compound is (1: 1) to (10: 1), carrying out mechanical activation for 0.5-24 hours, and producing small-particle amorphous sodium fluorophosphate vanadium under the conditions of normal temperature and normal pressure in a manner that high-valence vanadium is reduced by the reductant; and heating the amorphous sodium fluorophosphate vanadium to the temperature of 500-750 DEG C in a non-oxidizing atmosphere, and carrying out constant-temperature calcination for 0.5-24 hours, thereby obtaining crystalline-state sodium fluorophosphate vanadium powder. The method has the advantages that the synthesis temperature is low, the synthesis cycle is short, the synthesis method is simple, the quality of synthetic products is high, and the large-scale industrialized preparation of the sodium fluorophosphate vanadium for the positive pole material of the sodium-ion battery is easily realized.

Owner:广西地博矿业集团股份有限公司

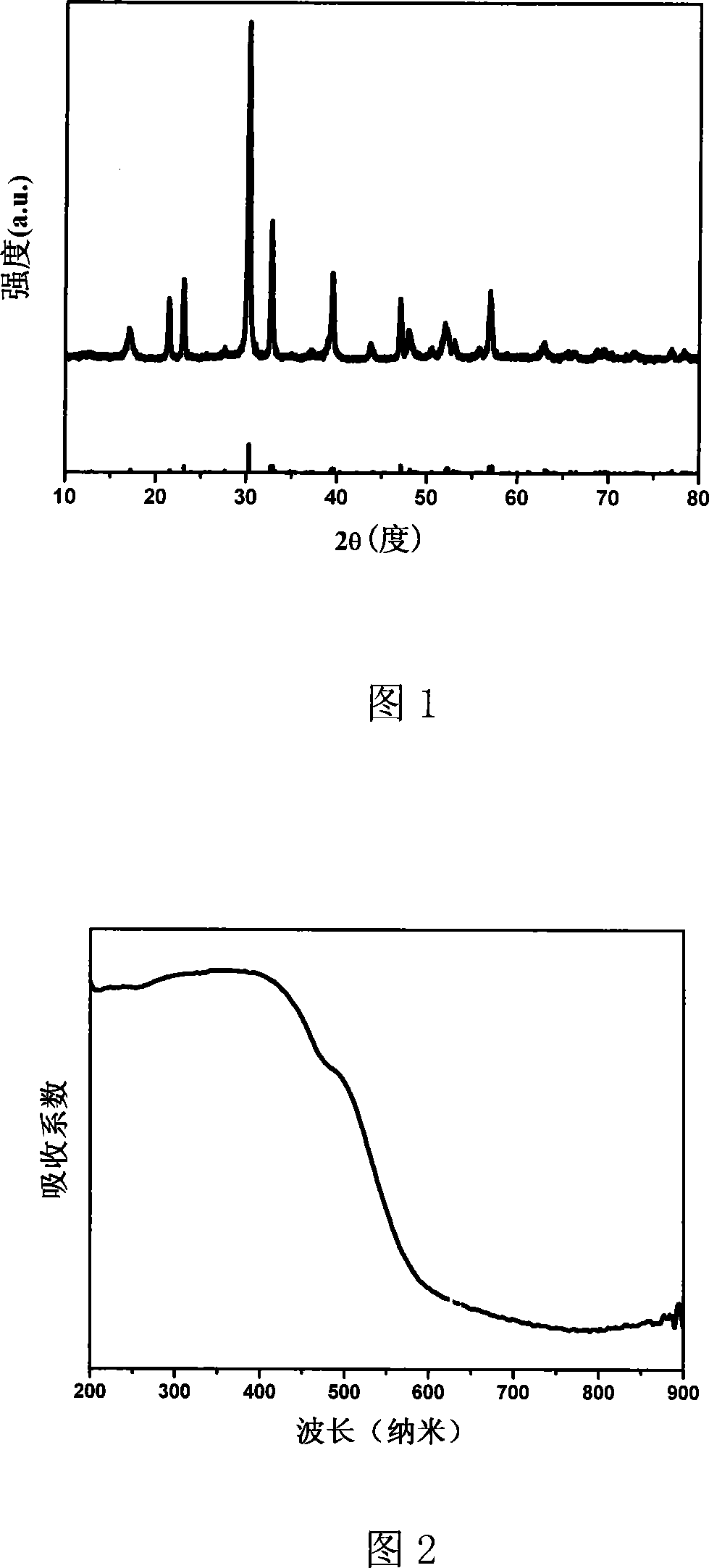

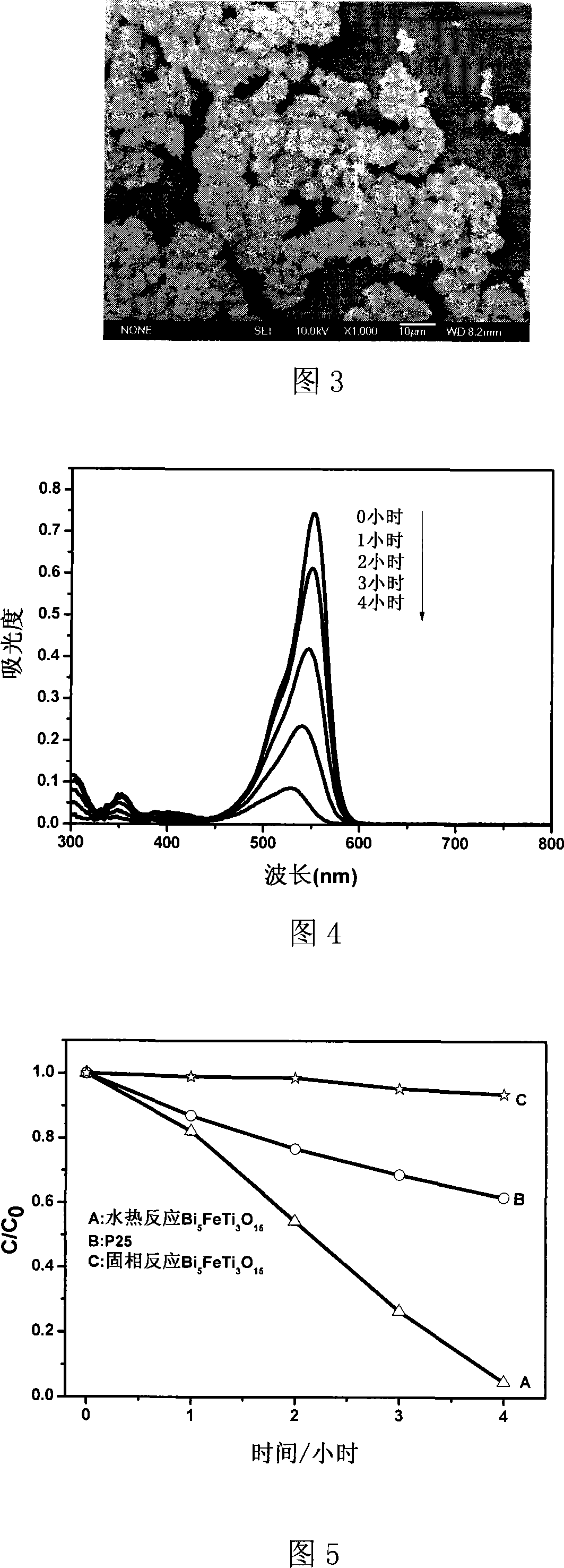

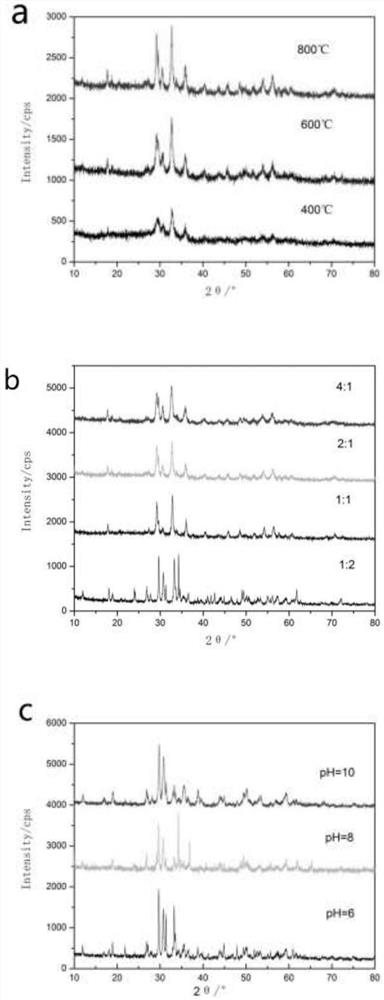

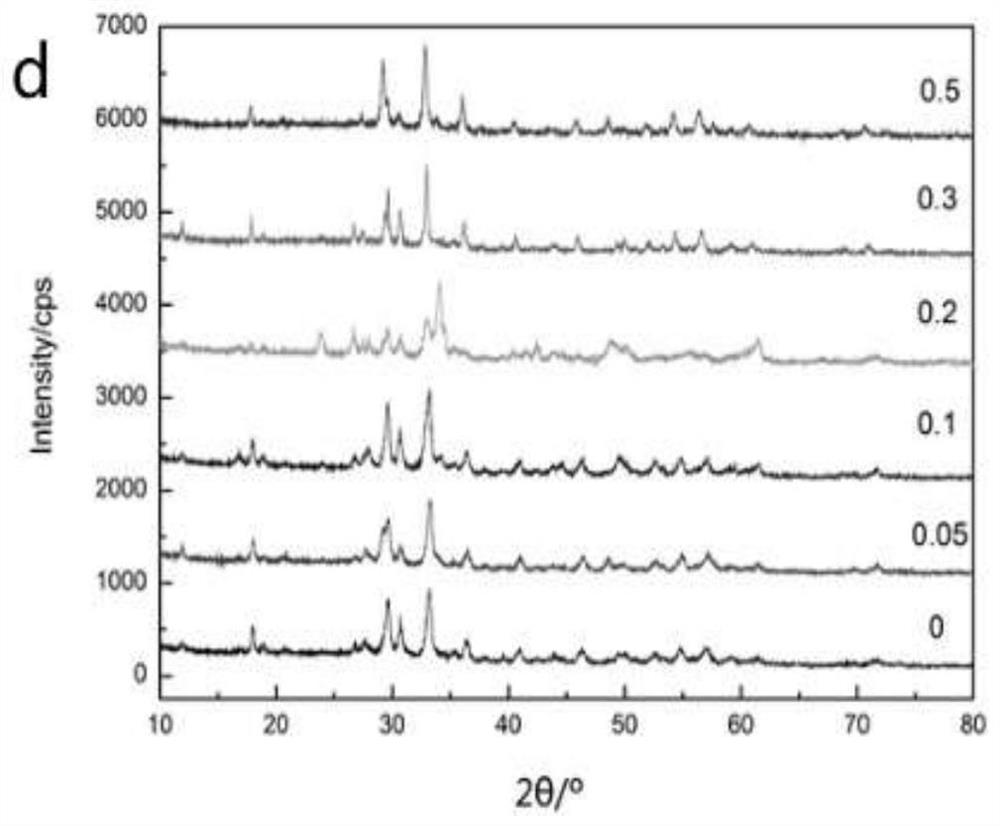

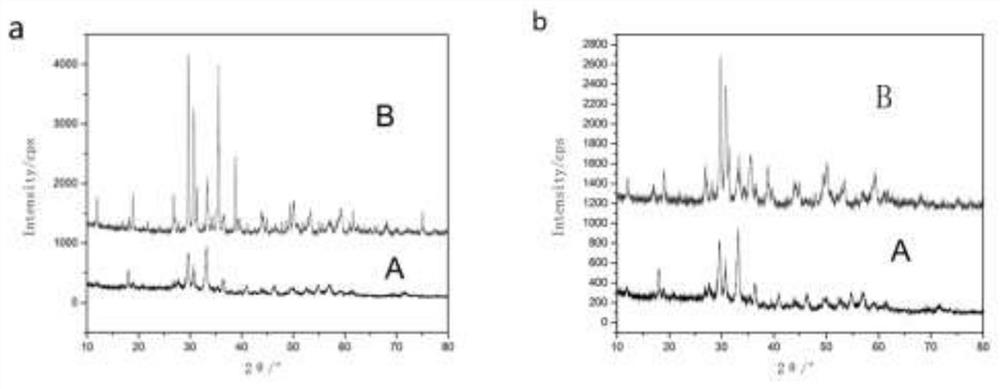

Preparation method of titanium barium ferrum series photocatalyst

InactiveCN101214441AAchieve the purpose of purificationVisible light catalytic activity is highMetal/metal-oxides/metal-hydroxide catalystsCentrifugationTitanium

The invention relates to a barium titanium iron series phhotocatalyst and a preparation method thereof, and belongs to the field of phhotocatalyst. In accordance with the chemical formula Bi5FeTi3O15, the invention adds titanium salt or titanate, malysite, bismuth salt into deionized water or acidic solution to dissolve and mix evenly, adds in aqueous alkali to produce settlings, and then adds the settlings into a water heat retort; after water heat reaction, the Bi5FeTi3O15 catalyst material is obtained after centrifugation, washing and drying. The invention reduces energy consumption of synthesization, and the product has even components, controllable grain size, quite high specific surface area, and good photocatalytic performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

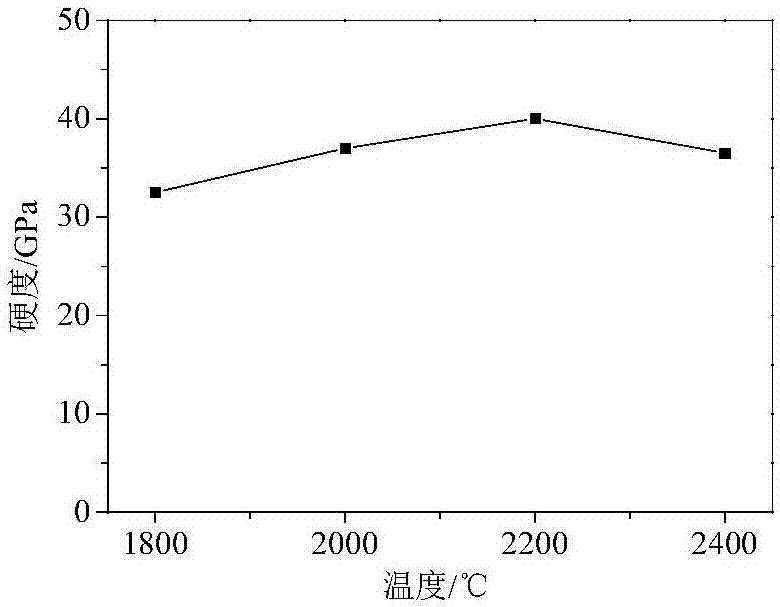

Polycrystalline cubic boron nitride, preparation method and application of polycrystalline cubic boron nitride and cutter which comprises polycrystalline cubic boron nitride

The invention relates to the field of superhard materials, and specifically provides a polycrystalline cubic boron nitride, a preparation method and application of the polycrystalline cubic boron nitride and a cutter which comprises the polycrystalline cubic boron nitride. The polycrystalline cubic boron nitride is mainly prepared from, in parts by volume, 55-65 parts of cubic boron nitride, 30-38parts of carbide of transition metal and 5-7 parts of metal powder, wherein the transition metal is at least one element of the subgroups of 4 or 5 or 6 in the periodic table, and the metal powder includes at least one of Al or Si or Ti. The polycrystalline cubic boron nitride is mainly prepared from the cubic boron nitride, carbide of the transition metal and metal powder according to specific volume fractions, and through scientific cooperation of the raw materials, the polycrystalline cubic boron nitride has the advantages of high hardness and good wear resistance.

Owner:FUNIK ULTRAHARD MATERIAL

Method for preparing titanium silicon molecular sieve TS-1 with high framework titanium content

ActiveCN107032366AImprove bindingSpeed up entryMolecular-sieve silicatesCrystalline aluminosilicate zeolitesMolecular sieveAlcohol

The invention provides a method for preparing a titanium silicon molecular sieve TS-1 with high framework titanium content. The method particularly comprises the following steps: mixing a silicon source and a titanium source according to the proportion, and adding an aqueous solution of quaternary ammonium base to obtain mixed liquid; hydrolyzing the mixed liquid to remove alcohol, adding a starch solution and performing crystallization to obtain a crystallization product; and drying and roasting the crystallization product to obtain the titanium silicon molecular sieve TS-1 with high framework titanium content. According to the method, the starch solution is added in the synthesis process, the silicon source is in bridge connection with the titanium source by utilizing a large amount of hydroxyl groups in the starch, and the silicon source and the titanium source are easy to combine, so that more titanium can enter the TS-1 framework. The titanium silicon molecular sieve prepared with the method has high titanium content and hardly contains extra-framework titanium, and mother liquid can be recycled.

Owner:DALIAN UNIV OF TECH

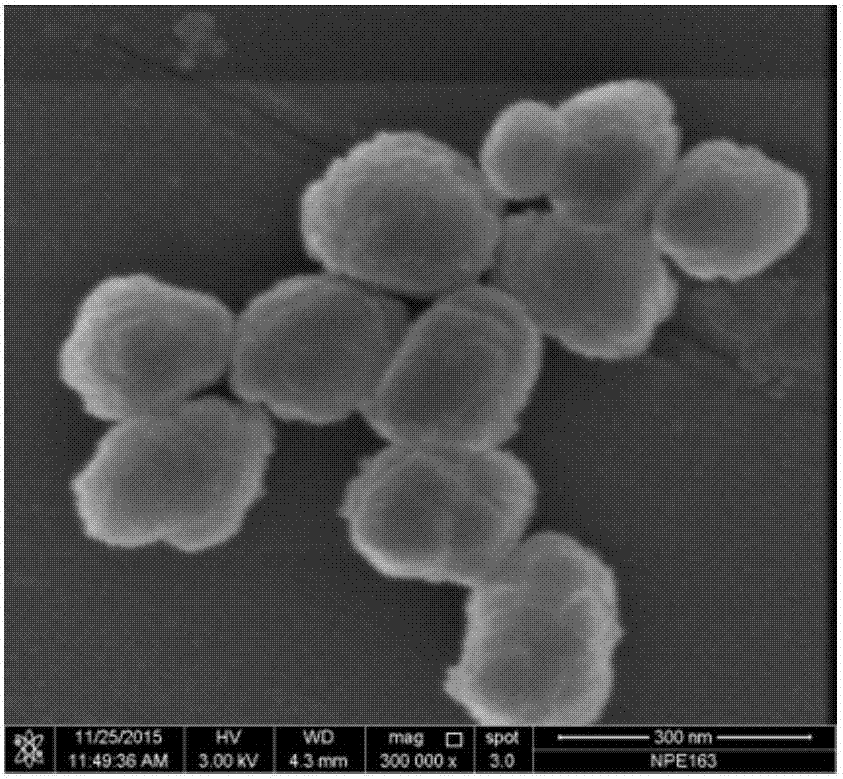

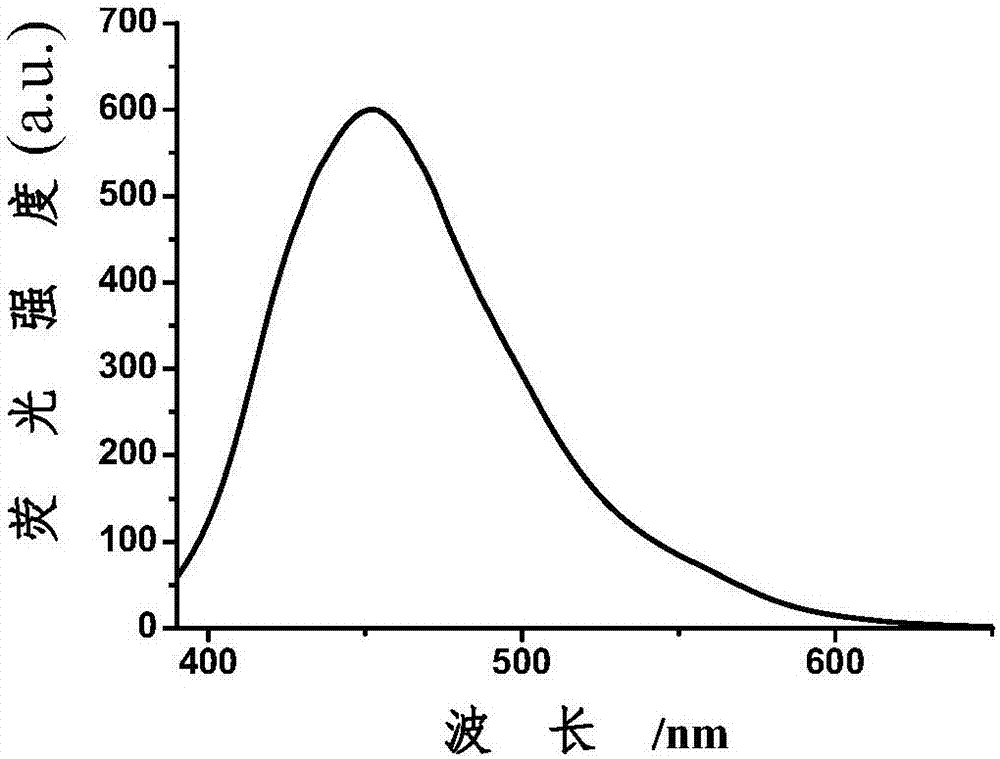

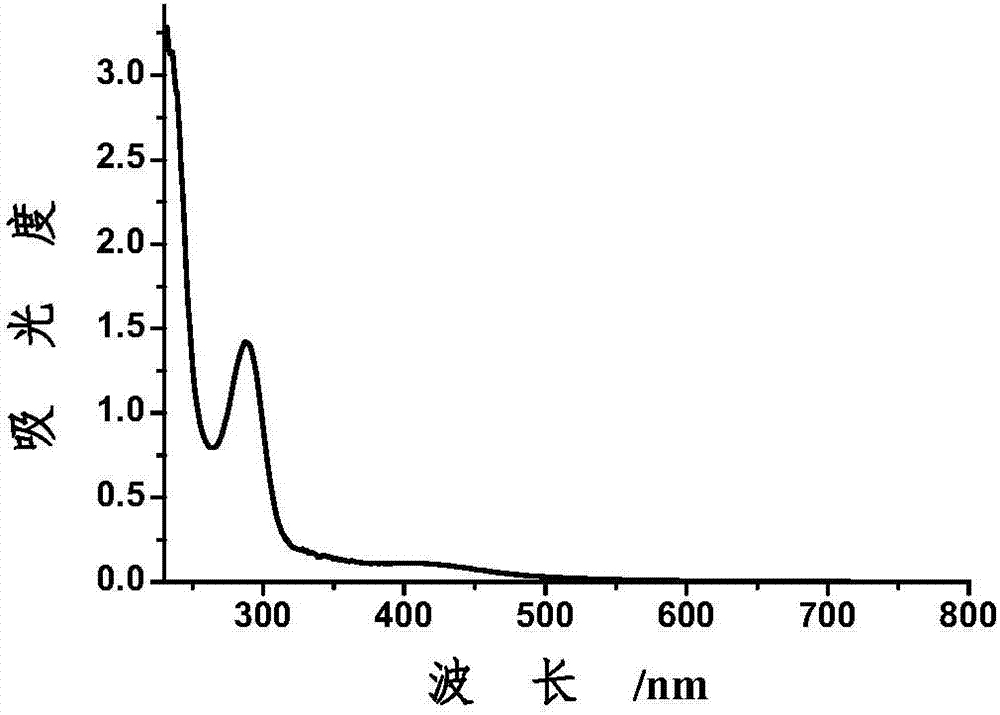

Pulse potential preparation method for nitrogen-doped fluorescent carbon dots

ActiveCN106894038ASimple purificationReduce manufacturing costElectrolysis componentsLuminescent compositionsSolubilityEvaporation

The invention discloses a pulse potential preparation method for nitrogen-doped fluorescent carbon dots. The pulse potential preparation method is characterized in that a combination of organic matter 1 and organic matter 2 is used as a carbon source, mixed liquid formed by ultrasonically configurating water and the combination is used as electrolyte, the organic matter 1 is one of ethanol, citric acid and ascorbic acid, the organic matter 2 is one of o-phenylenediamine, m-phenylenediamine and p-phenylenediamine, and the ratio of the amount of matter of the organic matter 1, the organic matter 2 and water is 200-50:1:120-20; a two-electrode system is adopted, a working electrode and a counter electrode both are platinum electrodes, the pulse potential method parameters are set, the electrolyte is carbonized for 1-4 hours, and a reaction solution is obtained; after the reaction solution stands still for a period of time, supernatant is taken, the pH of the supernatant is adjusted to be neutral, centrifugal treatment is conducted, rotation, evaporation and concentration are conducted, and a concentrated solution is obtained; and the concentrated solution is subjected to dialysis treatment in deionized water, and then an aqueous solution of the nitrogen-doped fluorescent carbon dots is obtained. The method is simple, the fluorescence yield of the obtained fluorescent carbon dots is high, the water solubility is good, and the stability is good.

Owner:HUNAN AGRICULTURAL UNIV

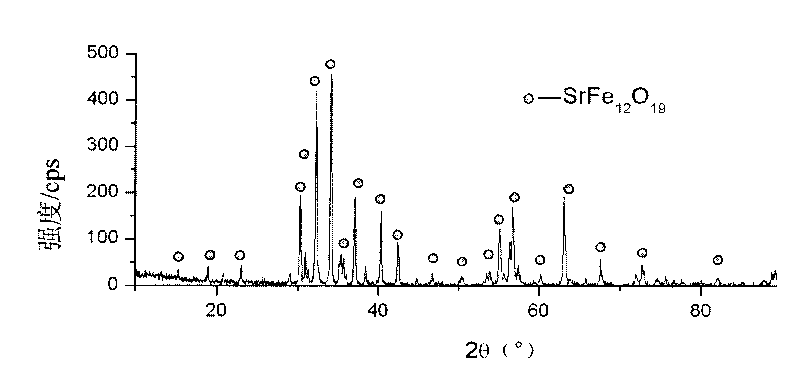

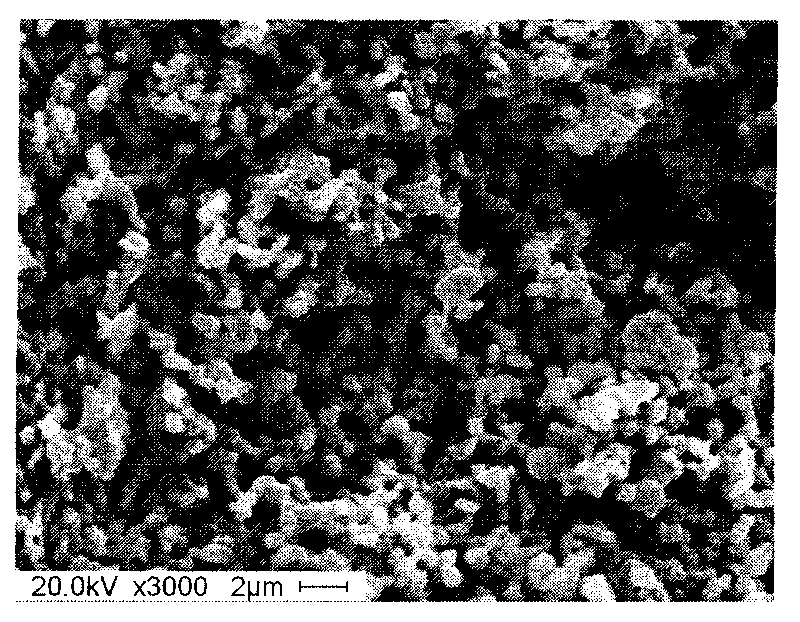

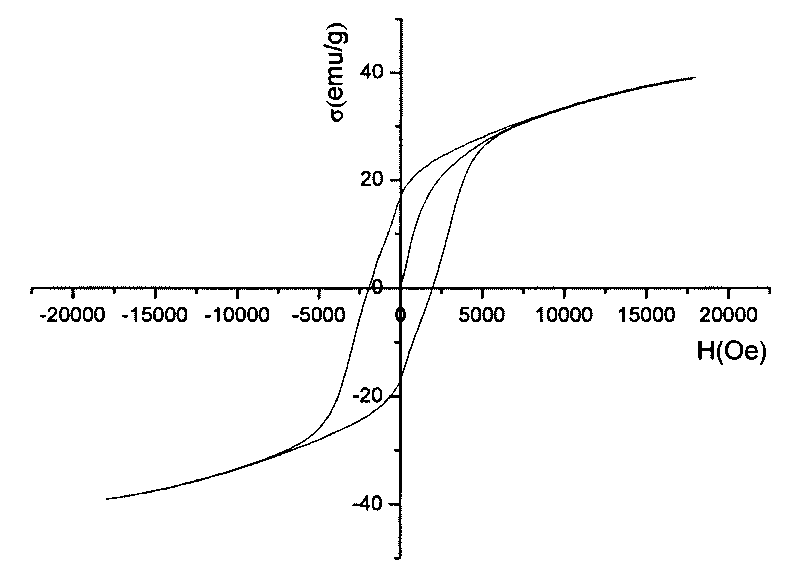

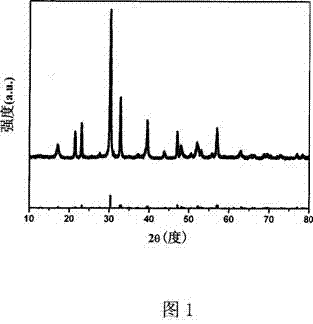

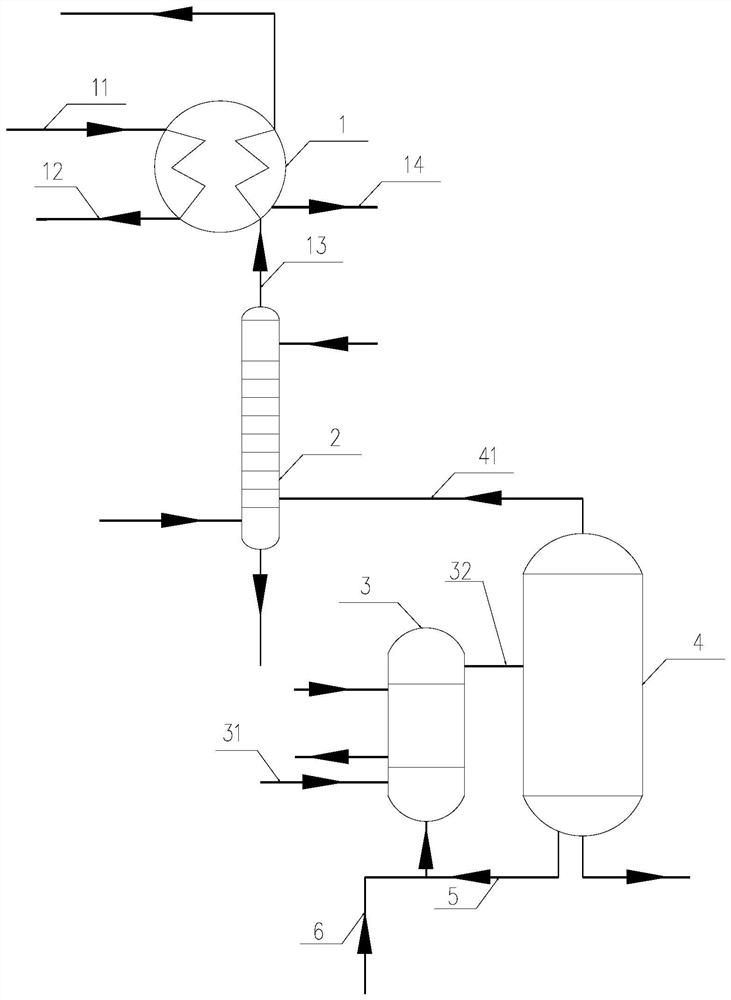

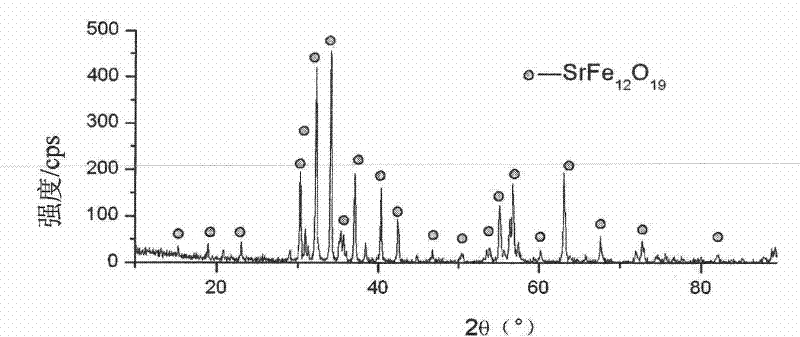

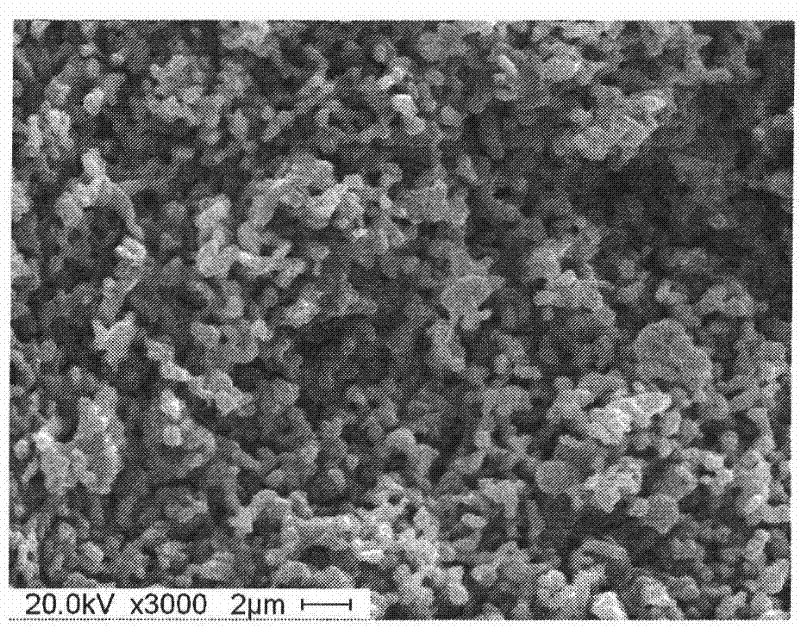

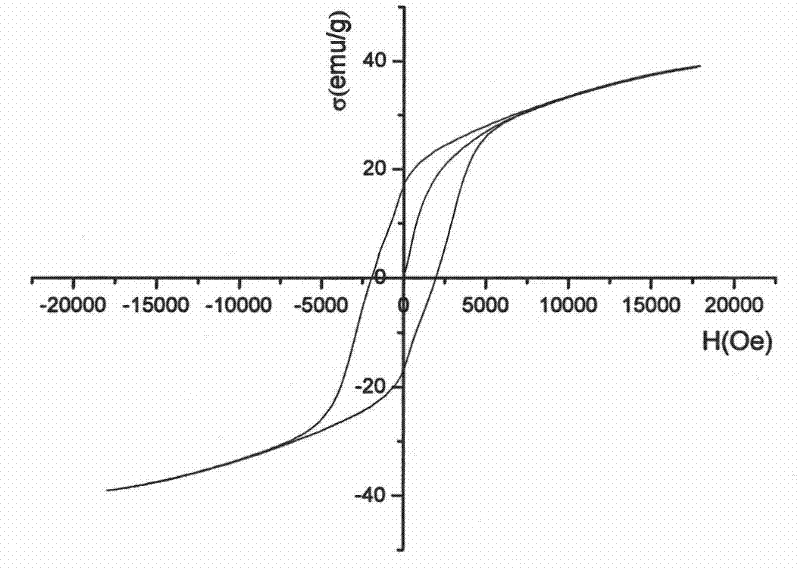

Method for synthesizing presintering hard ferrite material

InactiveCN101712556AUniform grain distributionGood molding effectInorganic material magnetismMicrowavePhysical field

The invention discloses a method for synthesizing a presintering hard ferrite material, which takes one or more of oxide or carbonate of ferrite cations and other additives such as CaO, Al2O3 and the like as raw materials, and comprises the following steps: ball milling and tempering, drying, heating by a microwave physical field with the frequency of 300-3,000MHz, raising the temperature to 1,150-1,350 DEG C at the heating-warming speed of 20-80 DEG C / min, and preserving the temperature for 30-180min to obtain the single-phase presintering hard ferrite material with the grain size being about 0.2-2 mu m. Compared with the traditional method for synthesizing presintering materials, the method in the invention has the advantages of short presintering time, low energy consumption, fine and uniform grains of the presintering materials, good moldability and stable magnetic performance, and can be used for preparing sintering bodies by wet compression moulding and dry compression moulding.

Owner:SHANGHAI INST OF TECH

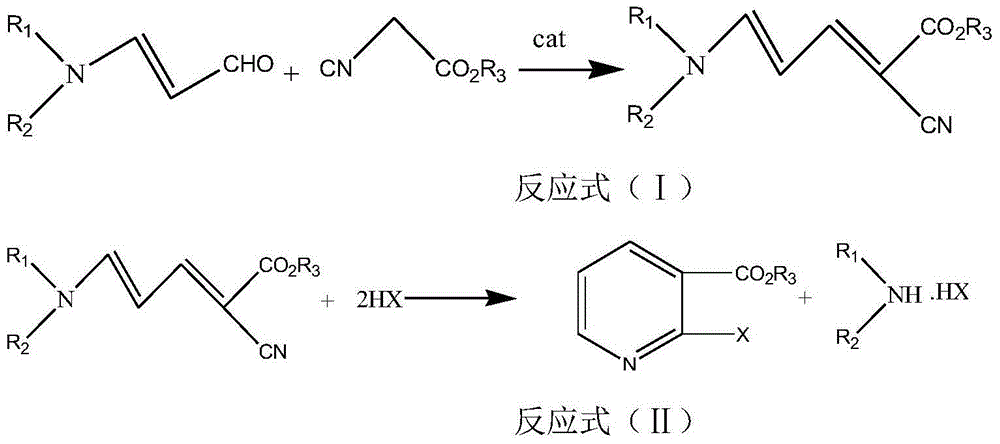

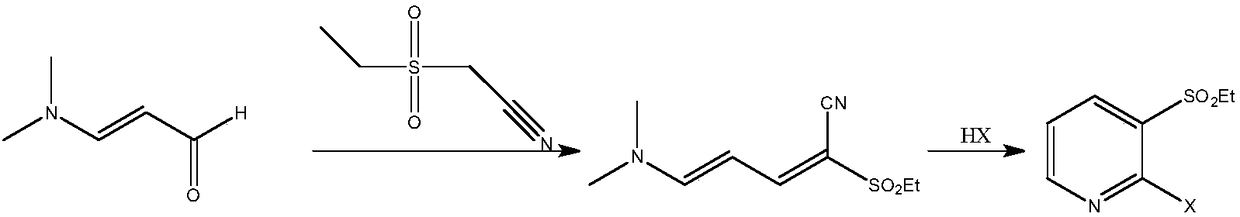

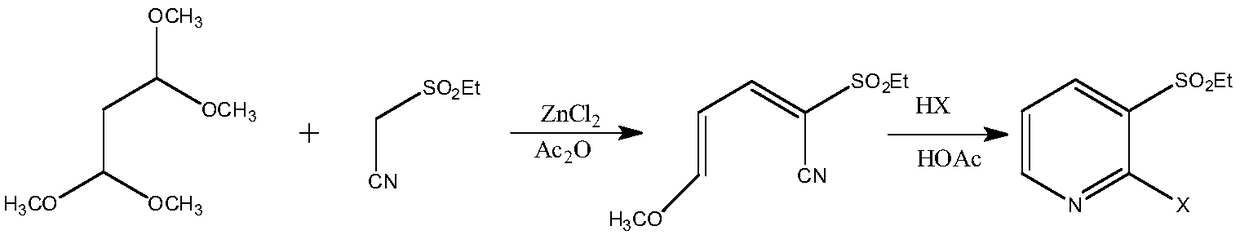

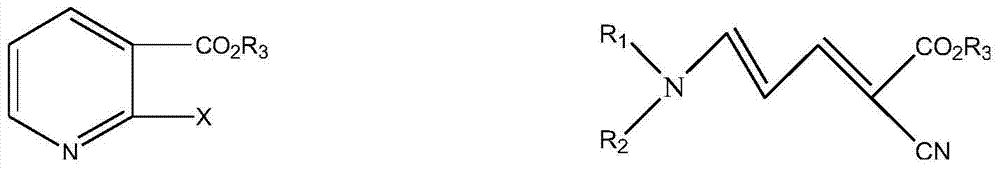

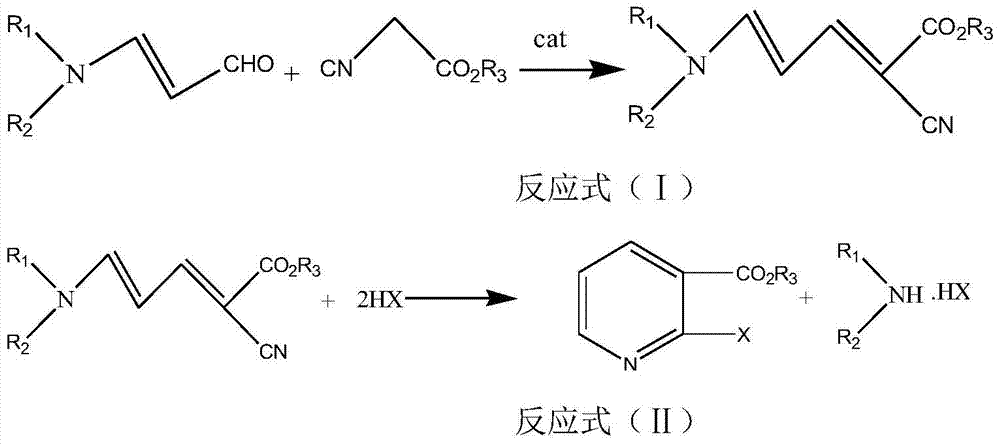

Method for synthesizing 2-halogenated nicotinic acid ester and intermediates thereof through microwave method

ActiveCN104945316AAvoid flammableAvoid explosionCarboxylic acid nitrile preparationOrganic compound preparationHydrogen halideOrganic solvent

The invention discloses a method for synthesizing 2-halogenated nicotinic acid ester and intermediates thereof through microwave method. The method comprises the following steps: adding substitute amino acrolein, a catalyst and cyan-acetic ester into a reactor, carrying out reaction under microwave radiation, and tracking the reaction till substitute amino acrolein disappears to prepare and obtain reaction liquid of the intermediates of 2-halogenated nicotinic acid ester; adding hydrogen halide into the reaction liquid, continuously carrying out reaction, and tracking and monitoring the reaction till the reaction is complete; adding alkali liquor into the reaction liquid to adjust the pH value to 5-6; carrying out standing delamination to obtain an aqueous layer and an organic layer; extracting the aqueous layer with an organic solvent, combining the extracted aqueous layer with the organic layer, and carrying out refinement to prepare and obtain 2-halogenated nicotinic acid ester. The synthesis method of 2-halogenated nicotinic acid ester related to the invention has the advantages of beingenvironment-friendly, short in reaction time, simple to operate, high in product yield and good in quality.

Owner:SHANDONG NORMAL UNIV

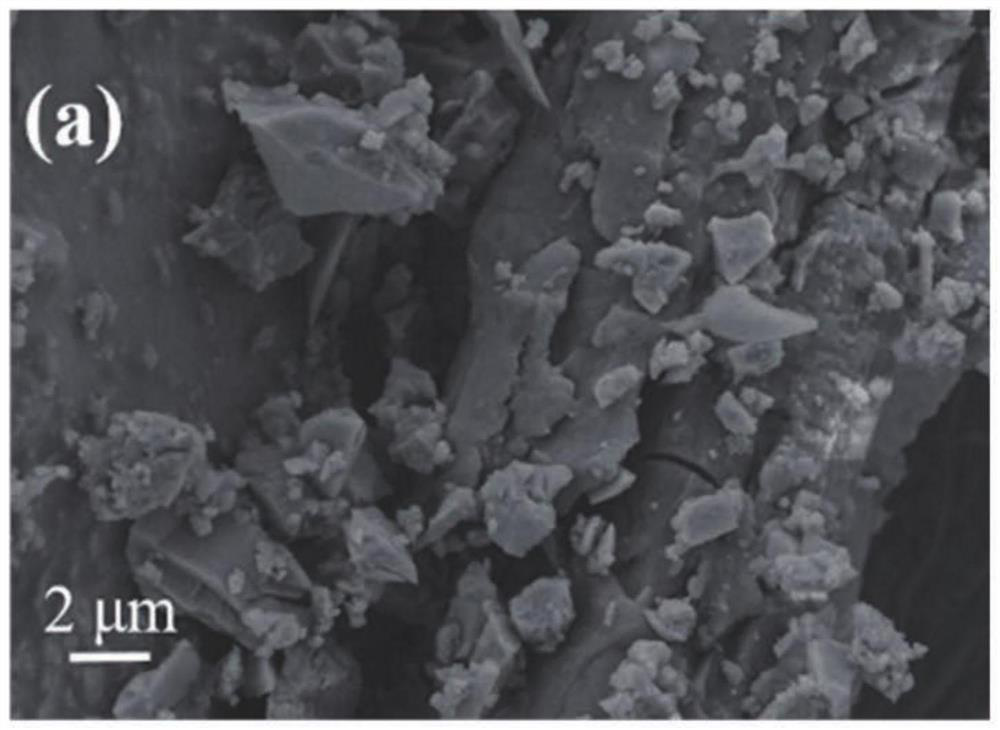

Method for synthesizing A type molecular sieve membrane at low temperature

ActiveCN109970075AReduce crosslinkingReduce film thicknessAluminosilicate zeolite type-ACross-linkMolecular sieve

The invention relates to a method for synthesizing an A type molecular sieve membrane at a low temperature. The method comprises the following steps: crystallizing a silicon source, an aluminum source, an alkali and water to prepare an A type molecular sieve nano-seed crystal; preparing a synthetic mother liquor from the silicon source, the aluminum source, the alkali and water; and coating a carrier with the A type molecular sieve nano-seed crystal, placing the carrier in the synthetic mother liquor, and carrying out hydrothermal crystallization at 20-45 DEG C for 2-10 d to obtain the ultrathin A type molecular sieve membrane. The size of the molecular sieve crystal synthesized in the present invention is reduced from 1 [mu]m to about 300-500 nm, so the thickness of the membrane is reduced to about 1 [mu]m, and the permeation flux is high. In addition, the reduction of the crystallization temperature can slow down the formation process of the molecular sieve membrane and facilitate the cross-linking between the molecular sieve crystals, so generated defects are reduced, and the separation selectivity is high. The synthesis of the A type molecular sieve membrane at room temperaturemakes the synthesis process consume no energy, so energy saving and environmental protection are benefited. The synthesized A type molecular sieve membrane has a high flux and a high separation coefficient in solvent dehydration.

Owner:SHANGHAI UNIV OF ENG SCI

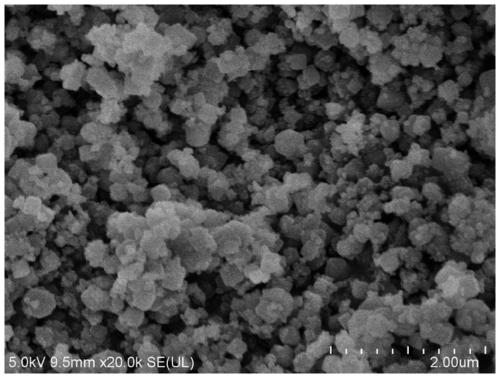

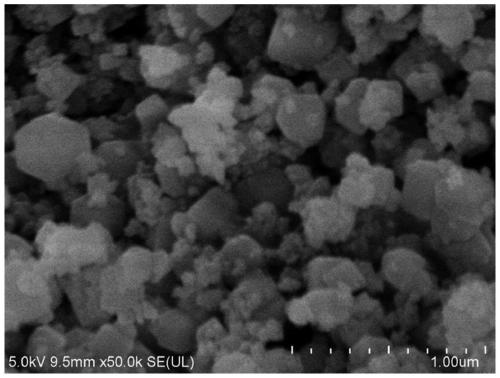

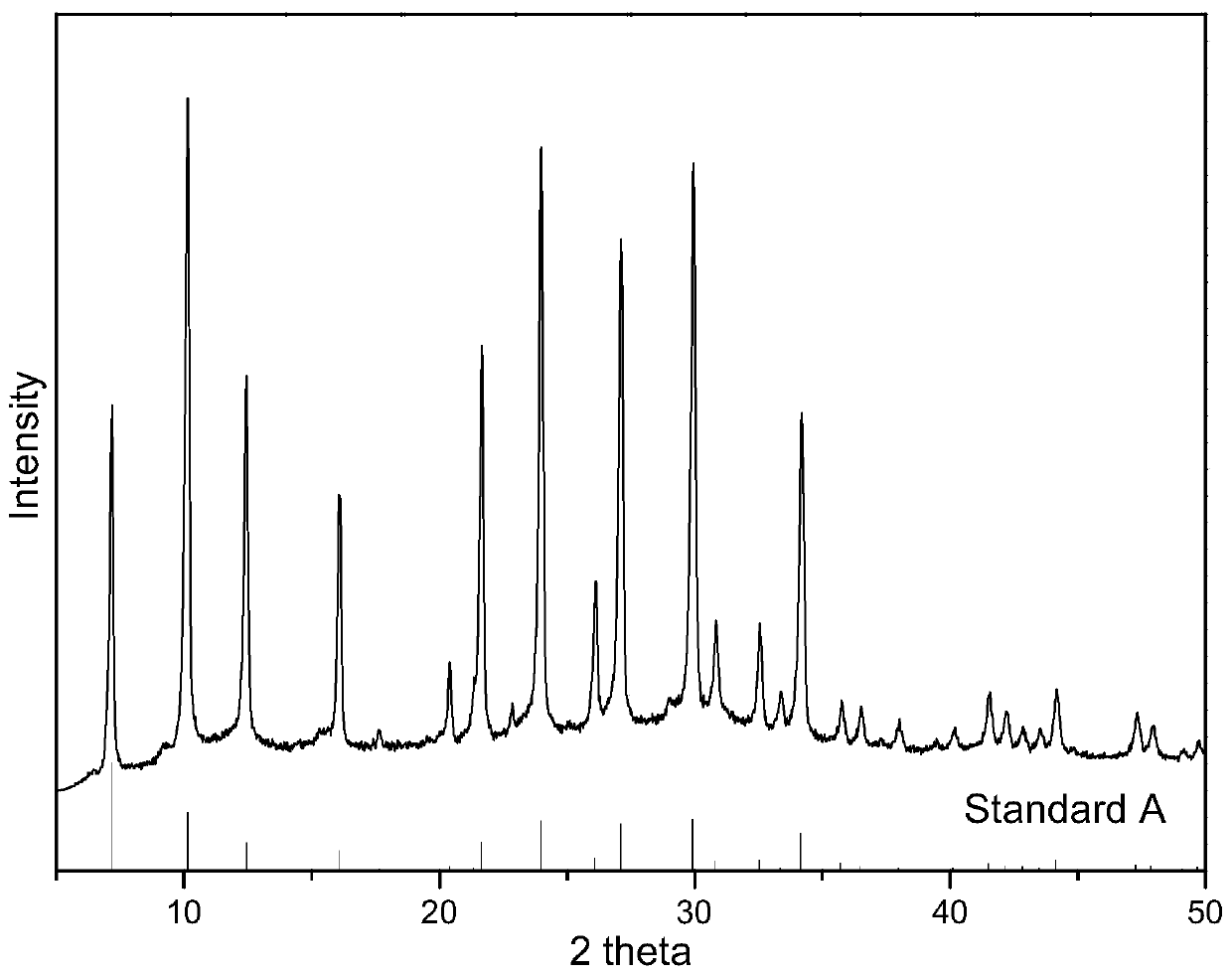

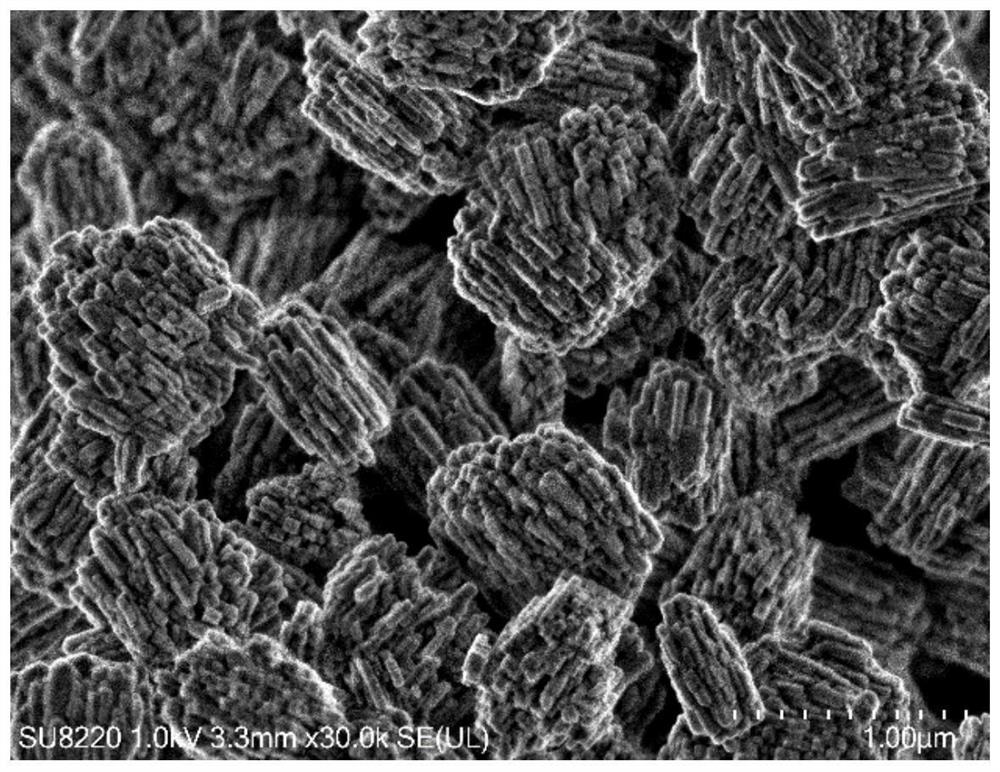

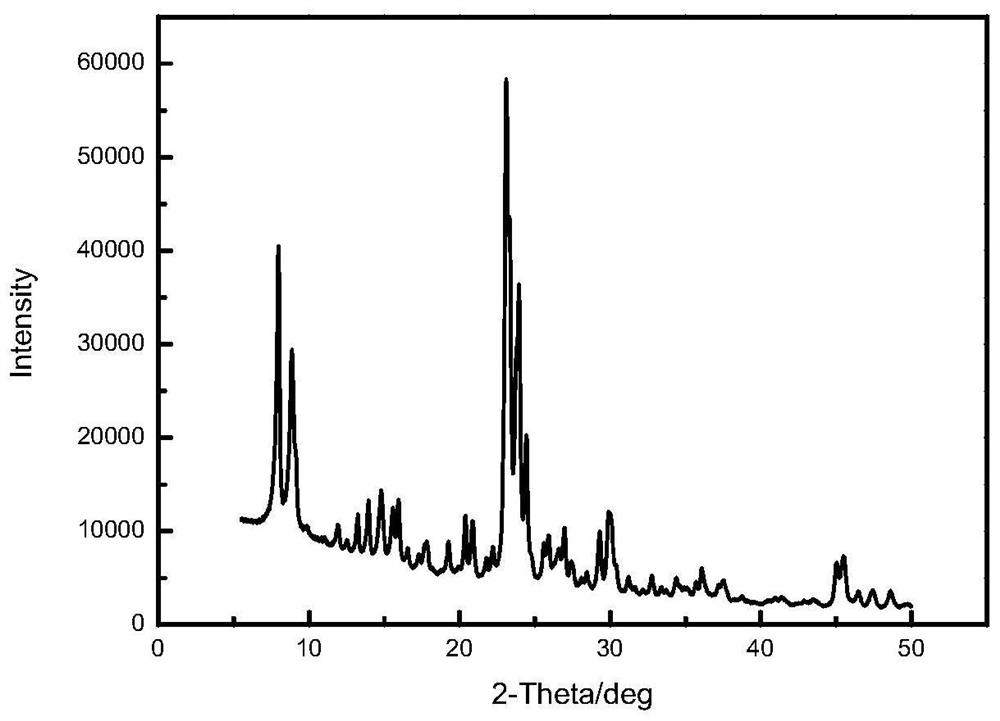

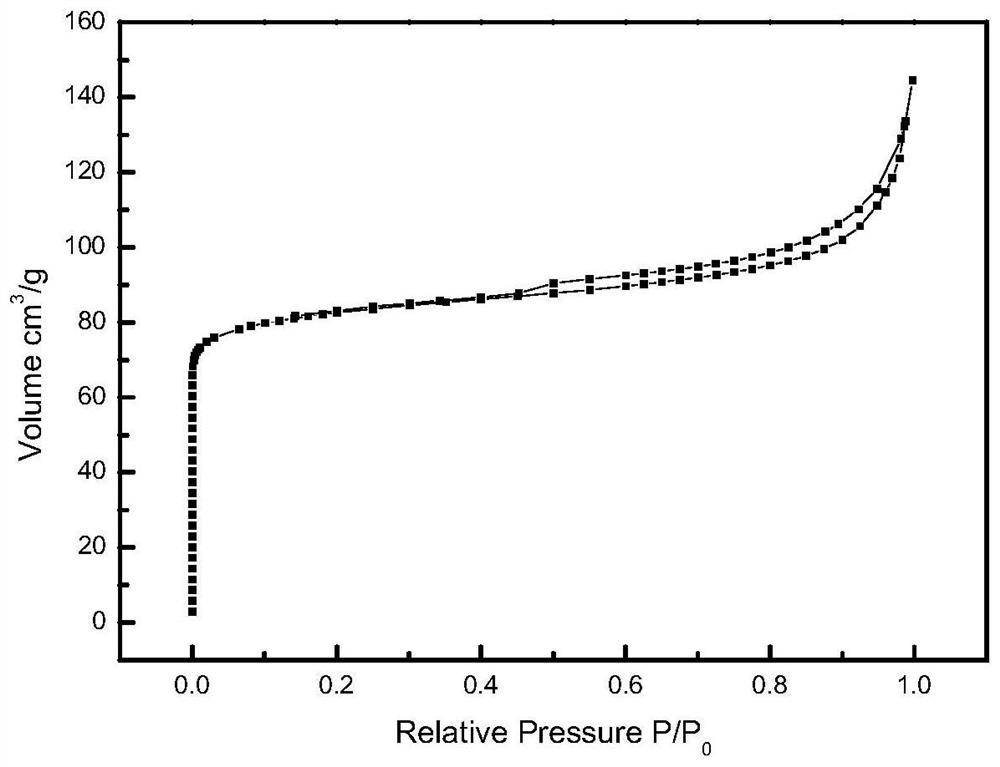

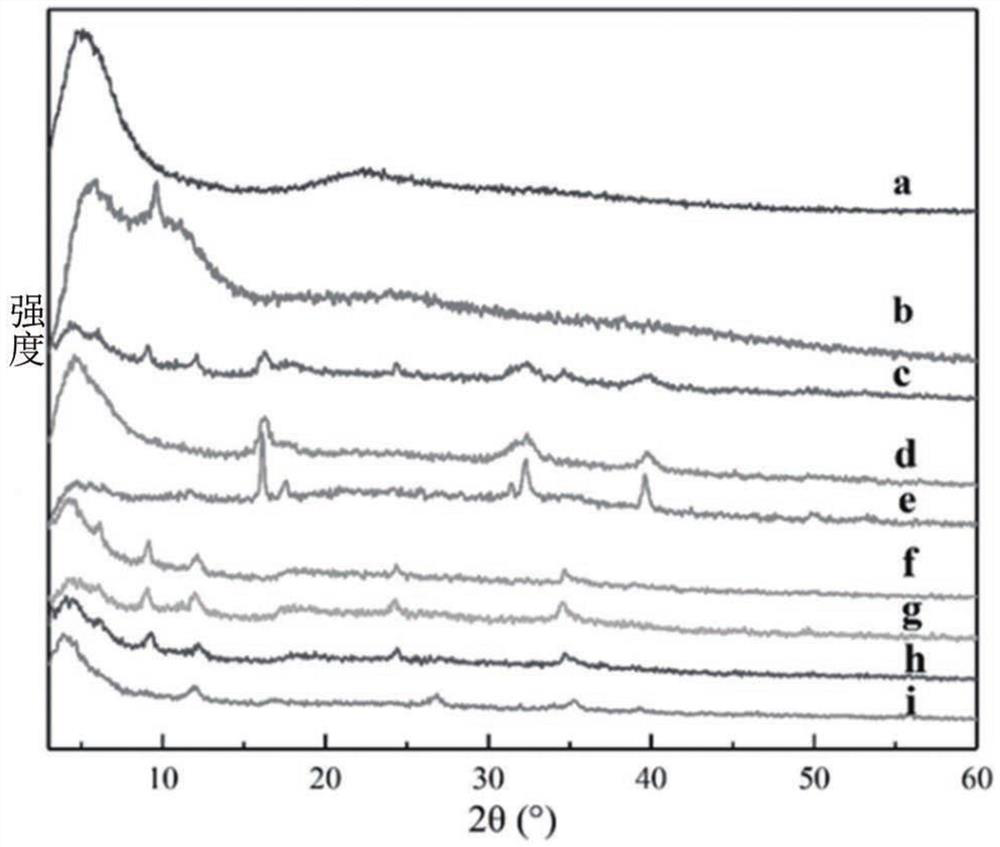

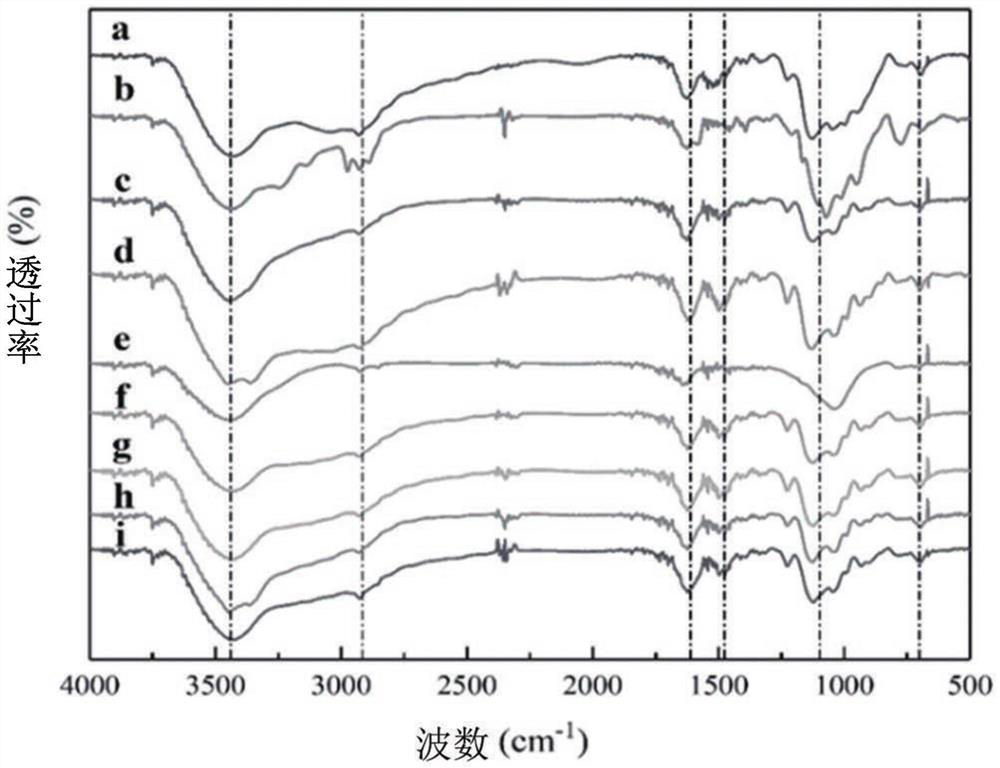

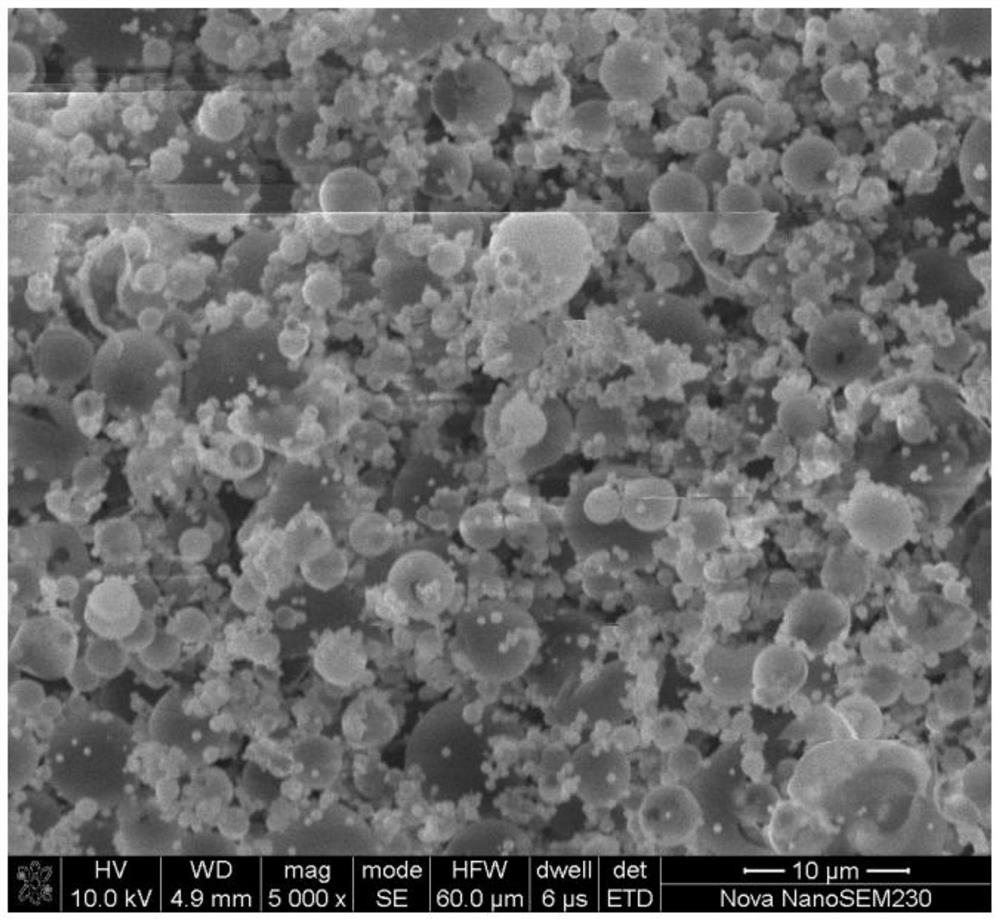

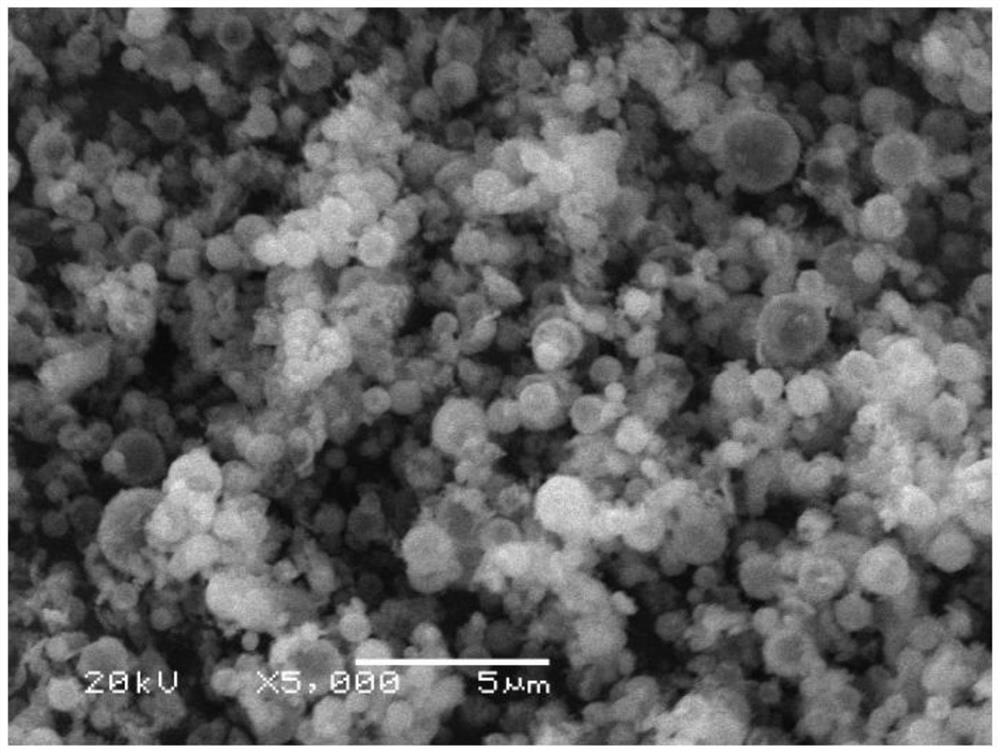

Preparation method of ZSM-5 nanosheet aggregate grown through directional piling

ActiveCN112110457AReduce synthesis energy consumptionShorten crystallization timeMaterial nanotechnologyMolecular sieve catalystsEmulsionMixed solution

The invention provides a preparation method of a ZSM-5 nanosheet aggregate grown through directional piling. The method comprises the following steps: mixing a silicon source, a template agent, organic amine and water, and crystallizing the obtained mixed solution to obtain a nano-microcrystalline emulsion; mixing and dissolving inorganic alkali and an aluminum source in water, and dropwise addingsilica sol to obtain silicon-aluminum mixed gel; and dropwise adding the nano-microcrystalline emulsion into the silicon-aluminum mixed gel, sequentially carrying out pre-crystallization and high-temperature crystallization, carrying out solid-liquid separation, and performing calcining to obtain the ZSM-5 nano-sheet aggregate. The ZSM-5 nanosheet aggregate prepared by the preparation method is uniform in particle size, and ZSM-5 crystals that form particles are stacked in order; and the preparation method is simple to operate and low in cost, and has wide industrial application prospects.

Owner:CHINA NAT OFFSHORE OIL CORP +3

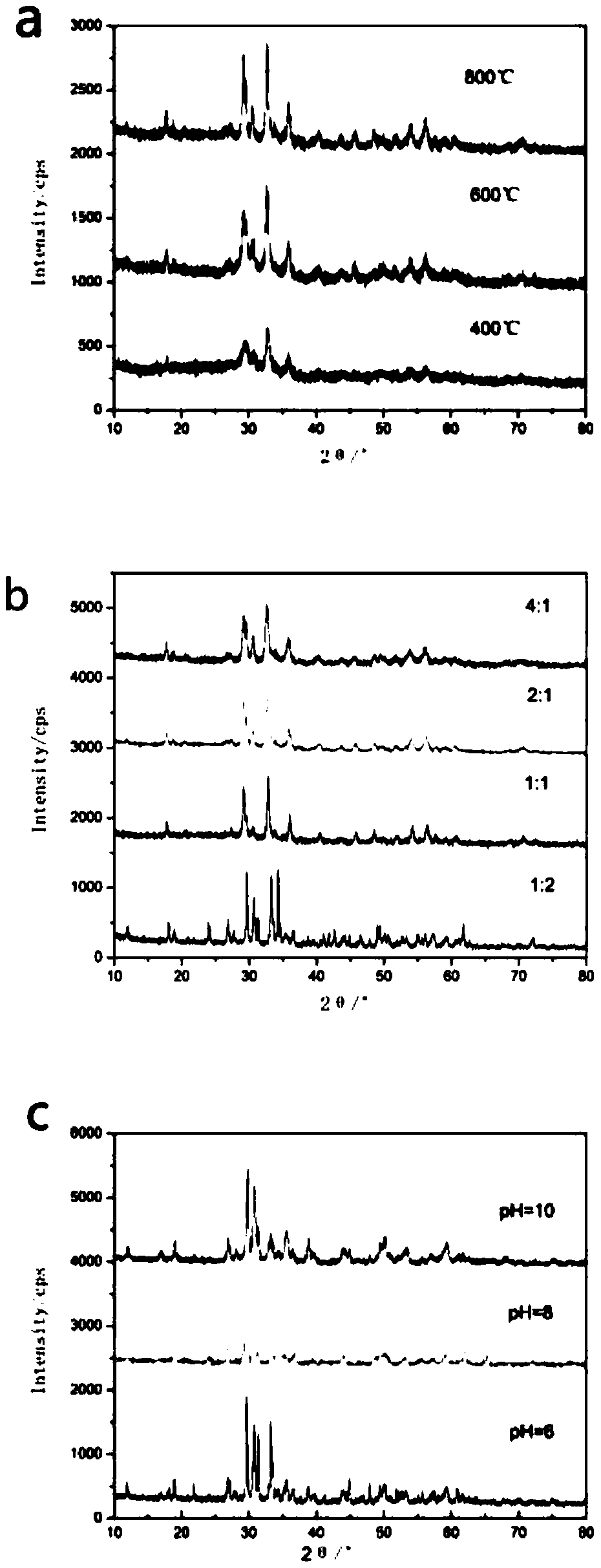

Lithium manganate composite material and preparation method thereof

ActiveCN105932232AReduce energy consumptionUniform particle sizeCell electrodesSecondary cellsIon exchangeManganese

The invention discloses a lithium manganate composite material and a preparation method thereof. The preparation method has the following advantages: 1) a natural lithium-bearing brine resource is comprehensively utilized as a lithium source, the usage amount of a refined lithium salt is reduced, and the material synthesis cost is substantially reduced; 2) the lithium source and a manganate source are uniformly distributed on an atomic level by an ion exchange method, a lattice matrix is easy to rearrange through short-range diffusion, the energy consumption is low during the synthesis process, a relatively low synthesis temperature and relatively short synthesis time are obtained, the grain distribution is uniform, and the polarization is reduced; 3) the constituent contents of lithium and magnesium are reasonably controlled by adjusting a pH value, lithium magnesium-doped type lithium manganate is prepared, the average valence state of manganate during the charge-discharge process is improved, a Jahn-Teller effect is effectively inhibited, and the cycle stability is improved; and 4) from the aspect of economic and environmental protection, the preparation method has more advantages than other schemes, and particularly, the preparation method has practical significance to extract lithium from a liquid-state lithium-bearing brine resource with a high magnesium-lithium ratio to synthesize a composite battery material.

Owner:SHENZHEN LIWEI LI ENERGY TECH CO LTD

Lithium titanate negative electrode material and preparation method therefor

ActiveCN105895895AReduce energy consumptionUniform particle sizeAlkali titanatesCell electrodesCarbon layerElectricity

The invention discloses a lithium titanate negative electrode material and a preparation method therefor. Metatitanic acid is adopted to absorb lithium from brine through ion exchange; then a lithium salt is added; the molar ratio of lithium to titanium is adjusted to be 4 to 5; and the lithium titanate negative electrode material is obtained by sintering through a solid-phase method. The lithium titanate negative electrode material and the preparation method therefor have the following technological advantages that: 1) the natural lithium-bearing brine is taken as the lithium source comprehensively, so that the usage amount of the refined lithium salt is lowered, and the material synthesis cost is greatly lowered; 2) due to the ion exchange method, the lithium source and the titanium source are uniformly distributed on the atomic level; the rearrangement of lattice matrix can be realized through short-range diffusion easily, so that the synthesis process is low in cost, and relatively low synthesis temperature and relatively short synthesis time can be realized; 3) due to the low synthesis temperature, the grain fineness distribution is uniform, and an more excellent electrochemical performance is presented after the carbon layer is coated in an in-situ manner; and 4) a higher advantage is realized compared with other schemes in the aspects of economic efficiency and environmental protection, and particularly, the practical meaning of extracting lithium from liquid lithium resource to synthesize the battery material is achieved.

Owner:SHENZHEN LIWEI LI ENERGY TECH CO LTD

Preparation method of YAl1-xMxO3 (M equals Fe, Co and Cu) nano-pigment

The invention discloses a preparation method of a YAl1-xMxO3 (M equals Fe, Co and Cu) nano-pigment. The preparation method comprises the following steps: firstly, at normal temperature, taking deionized water, stirring on a magnetic stirrer, sequentially and completely dissolving moderate ferric nitrate, aluminum nitrate and yttrium nitrate into the deionized water according to the molar ratio ofY to Al to Fe, and adding succinic acid as a stabilizer to obtain a solution A after the raw materials are completely dissolved; secondly, after a substance in the mixed solution A is completely dissolved, dropwise adding ammonium hydroxide and adjusting a pH value of the solution A to obtain a solution B, and then adding 1,2-propylene glycol into the solution B to obtain a mixed solution; and thirdly, stirring the mixed solution in the second step on a 60 DEG C thermostatic magnetic stirrer for 2 hours until the solution forms gel, and then drying, grinding and calcining to obtain solid powder. The preparation method disclosed by the invention is green and pollution-free; an obtained product has the advantages of high dispersity, low energy consumption, uniform particles, excellent environment friendliness, low synthetic temperature, simple and controllable process, suitability for large-scale production and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

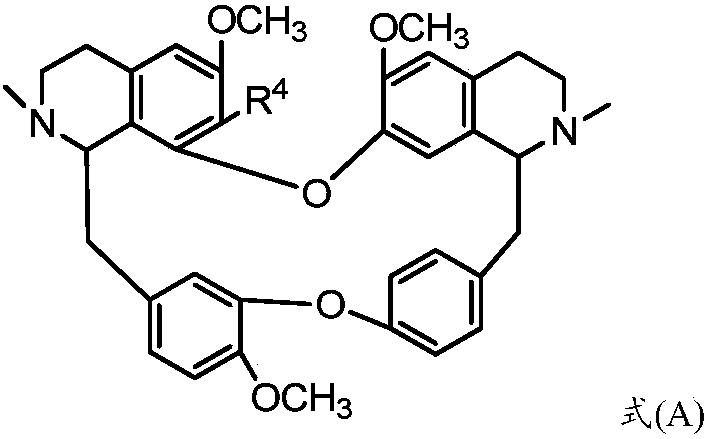

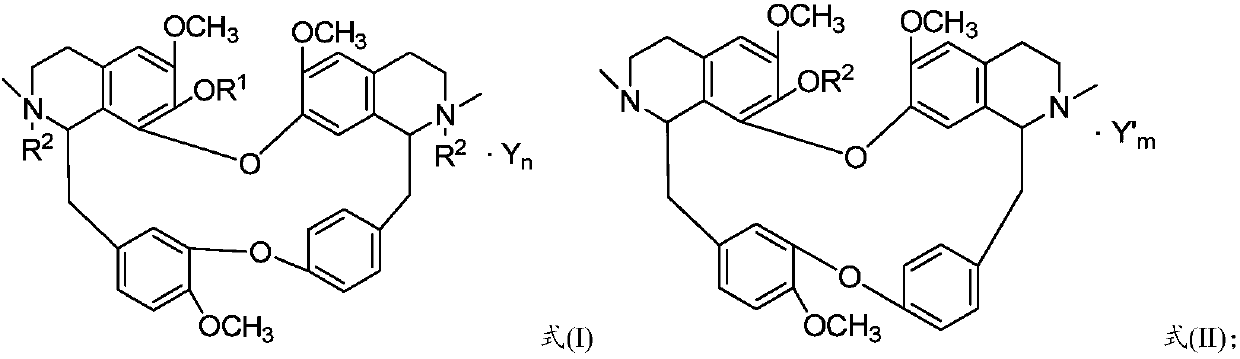

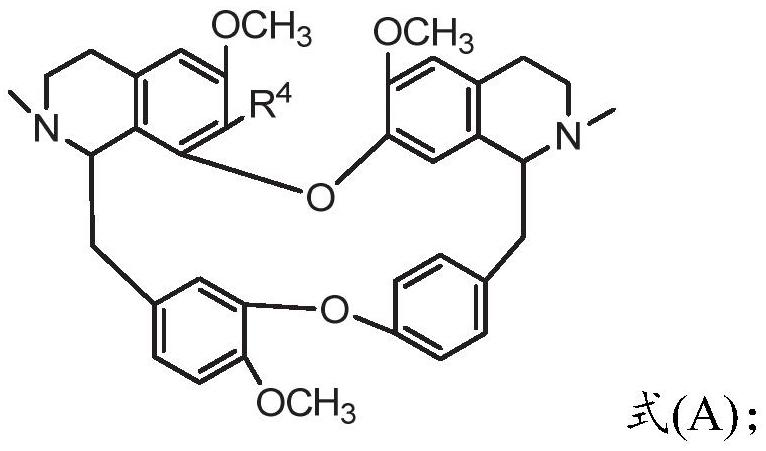

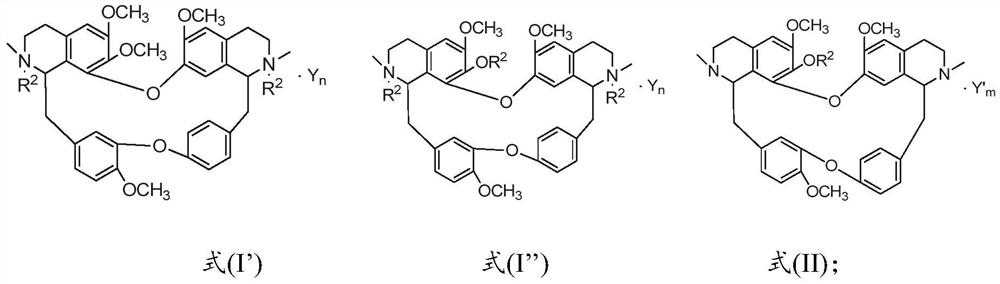

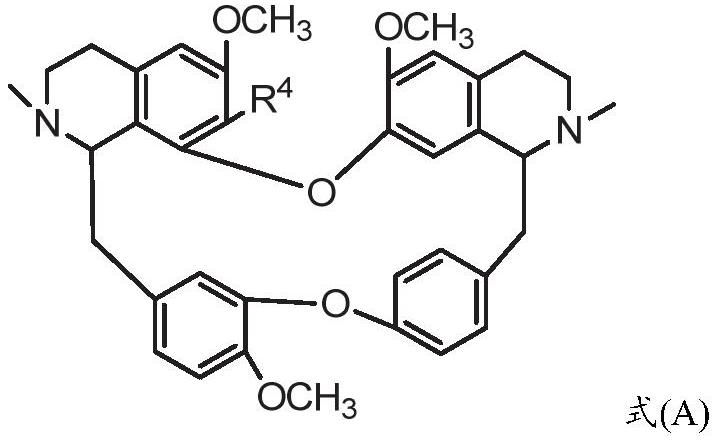

Method for preparing bisbenzylisoquinoline compounds

ActiveCN109678871AModerately alkalineImprove catalytic performanceOrganic chemistryChemical compoundSolvent

The invention provides a preparation method of bisbenzylisoquinoline compounds. The method comprises the following steps: taking a formula (A) and RX as reactants and carrying out a reaction in a reactor in the presence of ionic liquid or assistants; detecting the reaction progress by chromatography; after the reaction ends, separating and purifying or further adding acid and neutralizing to neutral; then separating and purifying to obtain the bisbenzylisoquinoline compound (The formula is shown in the specification). The method has the advantages of simplicity, environmental protection, highefficiency, as well as high yield which is 90 percent or above, is up to 98 percent or above and is far higher than the yield of a traditional solvent method (20 to 80 percent).

Owner:SHANDONG NORMAL UNIV

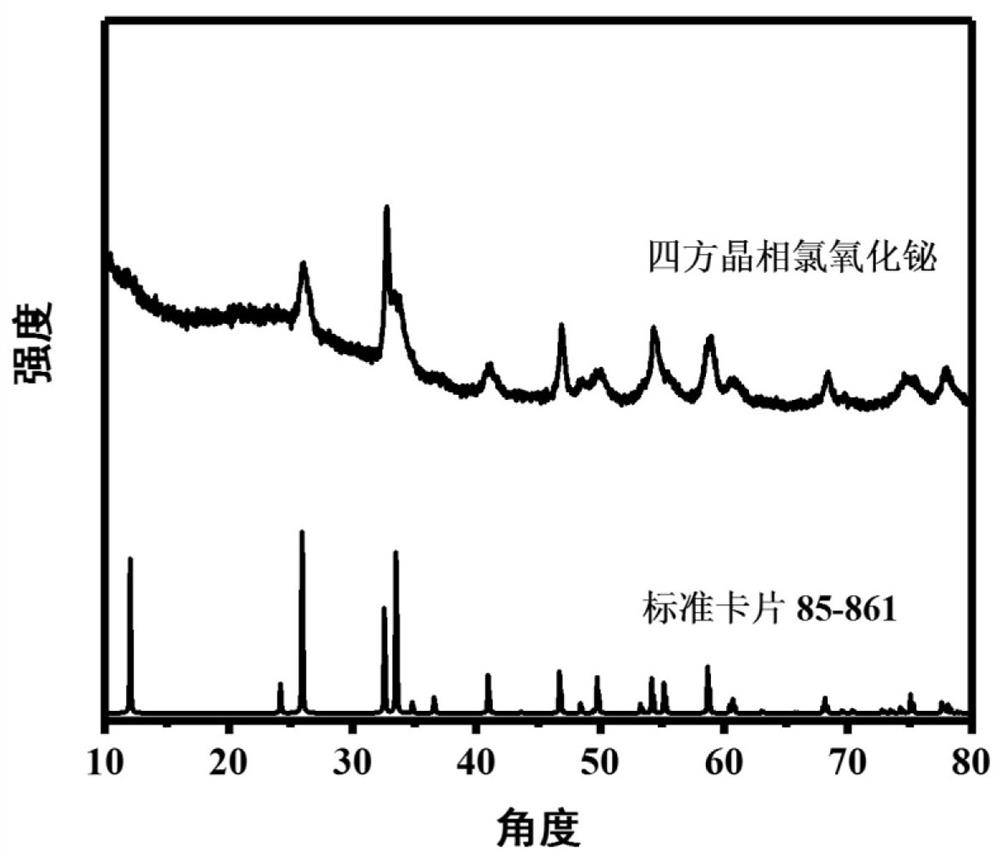

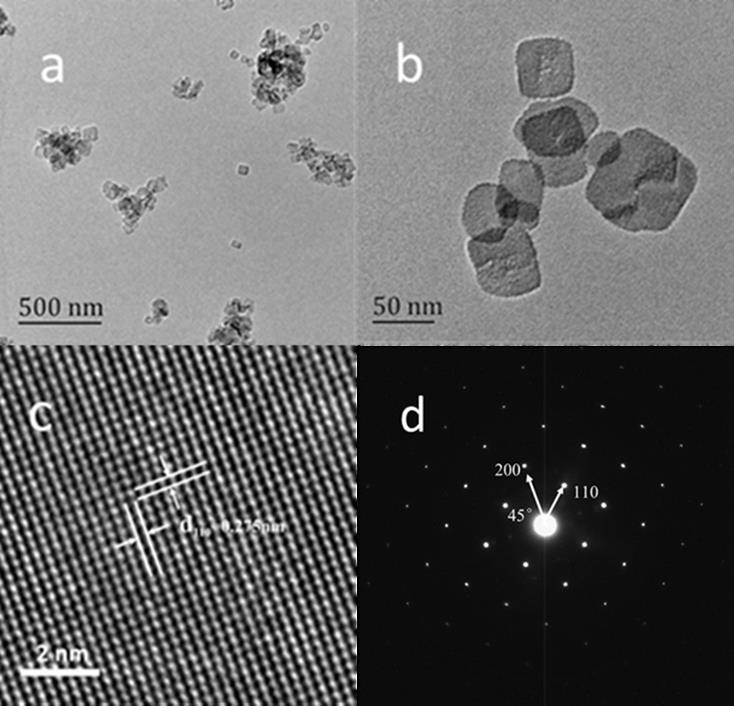

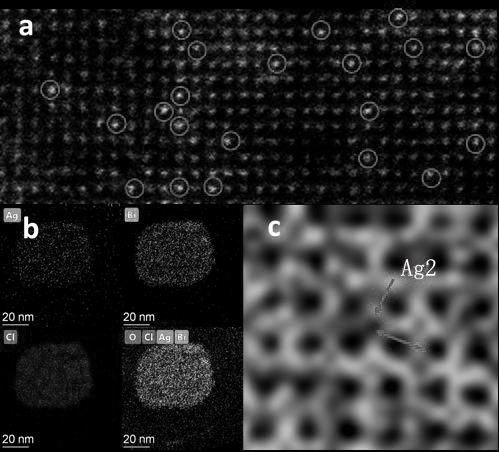

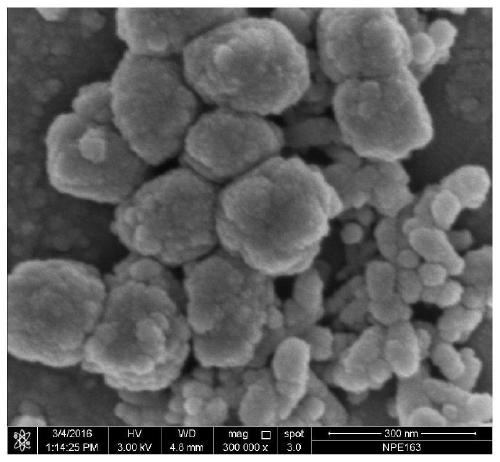

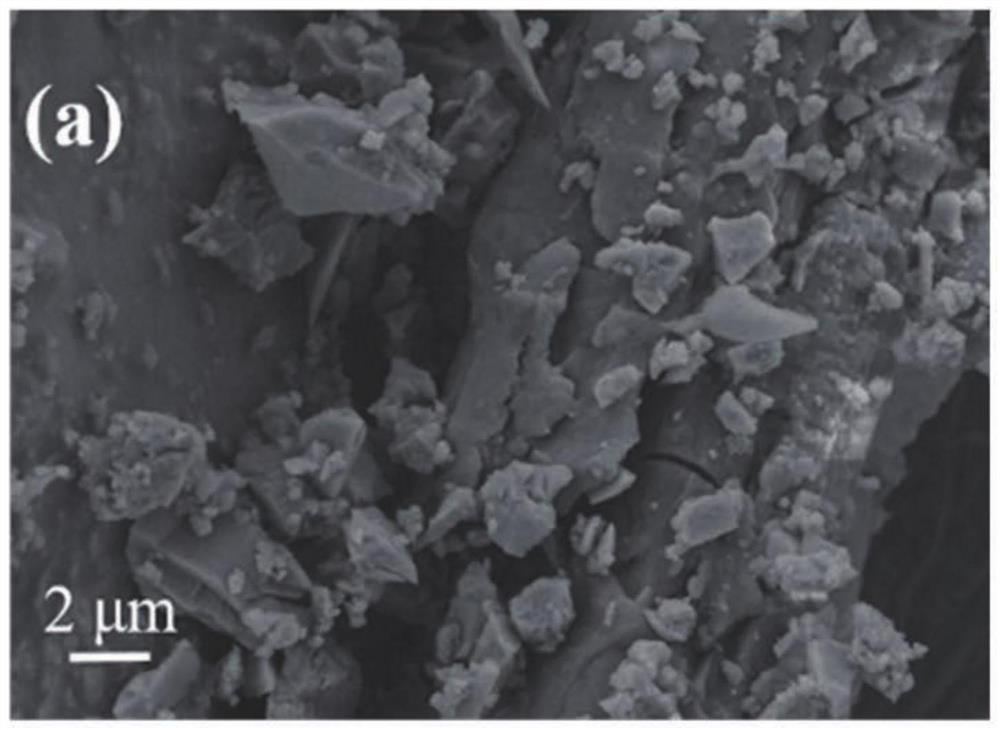

A kind of silver-supported bismuth oxychloride nanomaterial and its preparation method and application

ActiveCN112958120BLow costRegular and uniform shapeGas treatmentDispersed particle separationWaferingPhysical chemistry

The invention discloses a silver-loaded bismuth oxychloride nanometer material and a preparation method and application thereof. The material is formed by chemical bonds between silver atoms and chlorine atoms on the exposed crystal plane of a bismuth oxychloride nanometer wafer with exposed crystal planes. The preparation method includes: (1) providing a bismuth oxychloride nano wafer with exposed crystal planes, and the exposed crystal plane of the bismuth oxychloride nano wafer has chlorine atoms; (2) chemically bonding silver ions of a silver source to the Exposed crystal faces of a bismuth oxychloride nanowafer. The silver-supported bismuth oxychloride nanomaterial prepared by the strategy provided by the invention has regular and uniform morphology, simple process, low synthesis energy consumption, and the nanomaterial has high photocatalytic activity and can effectively degrade NOx and other gaseous pollutants. It can play a very good role in treating or repairing the atmospheric environment.

Owner:HUAZHONG NORMAL UNIV

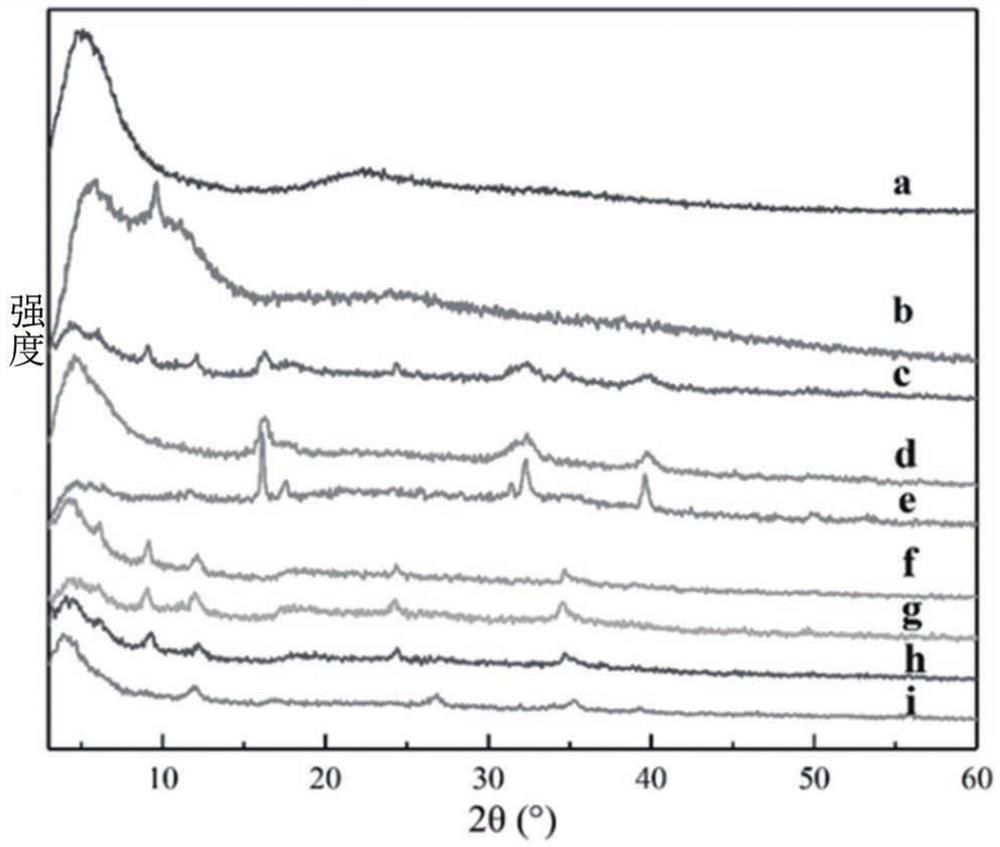

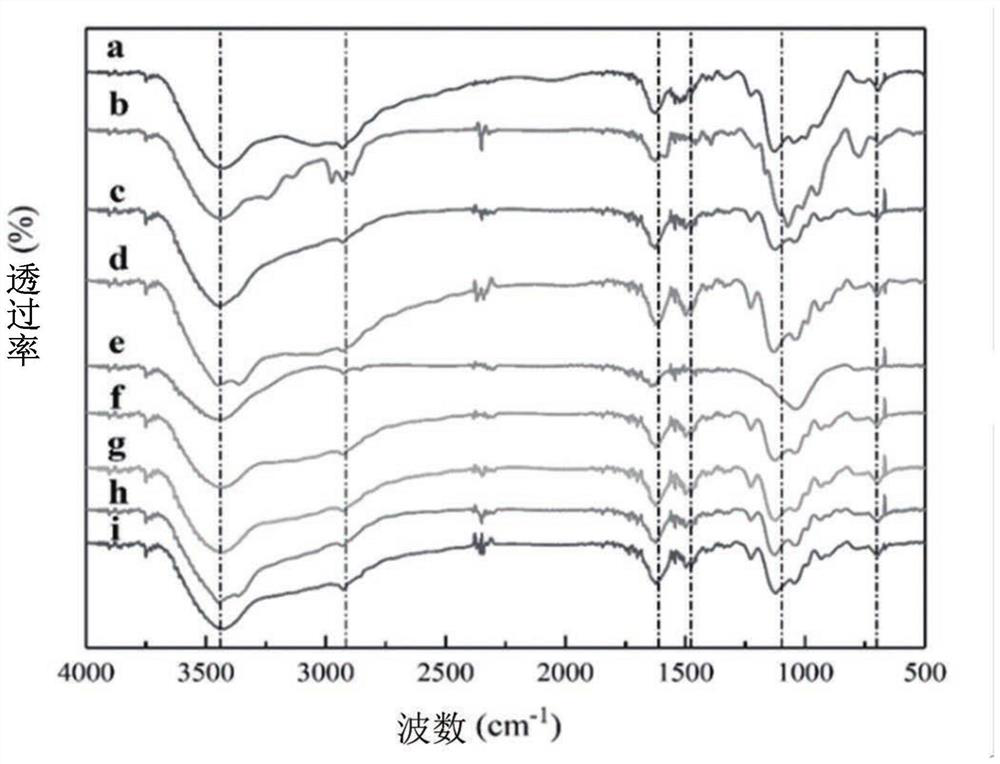

Application and evaluation method of catalytic product and organic layered bimetallic silicate

PendingCN114849771AImprove enzyme catalytic activityLow costOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystLiquid state

The invention provides an application and evaluation method of a catalytic product and organic layered double-metal silicate, the catalytic product is in a liquid state or a solid state, and under the condition that the product is in the liquid state, the catalytic product comprises a solvent and the organic layered double-metal silicate dissolved in the solvent; under the condition that the product is in a solid state, the catalytic product comprises a carrier and organic layered bimetallic silicate attached to the carrier; the chemical formula of the organic layered bimetallic silicate is [H2N (CH2) 3] 4 [Siz (MxQy) 6O8 (OH) 2]. The application of the organic layered double-metal silicate in preparation of a catalyst and an evaluation method of the enzymatic activity of the organic layered double-metal silicate adopt the organic layered double-metal silicate. The organic layered bimetallic silicate can be used for catalysis; the organic layered bimetallic silicate has improved enzyme catalytic activity, and is low in cost and low in synthesis energy consumption.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A method for preparing titanium-silicon molecular sieve ts-1 with high skeleton titanium content

ActiveCN107032366BImprove bindingSpeed up entryMolecular-sieve silicatesCrystalline aluminosilicate zeolitesMolecular sieveTitanium

The invention provides a method for preparing a titanium silicon molecular sieve TS-1 with high framework titanium content. The method particularly comprises the following steps: mixing a silicon source and a titanium source according to the proportion, and adding an aqueous solution of quaternary ammonium base to obtain mixed liquid; hydrolyzing the mixed liquid to remove alcohol, adding a starch solution and performing crystallization to obtain a crystallization product; and drying and roasting the crystallization product to obtain the titanium silicon molecular sieve TS-1 with high framework titanium content. According to the method, the starch solution is added in the synthesis process, the silicon source is in bridge connection with the titanium source by utilizing a large amount of hydroxyl groups in the starch, and the silicon source and the titanium source are easy to combine, so that more titanium can enter the TS-1 framework. The titanium silicon molecular sieve prepared with the method has high titanium content and hardly contains extra-framework titanium, and mother liquid can be recycled.

Owner:DALIAN UNIV OF TECH

Hydantoin precursor solution and method for preparing glycine by using hydantoin precursor solution

PendingCN114507150ACerium oxide content is not lowReduce synthesis energy consumptionOrganic compound preparationAmino-carboxyl compound preparationPtru catalystHydrolysate

The invention relates to the technical field of organic chemical industry, in particular to a hydantoin precursor solution and a method for preparing glycine by using the hydantoin precursor solution, the hydantoin precursor solution is an aqueous solution containing hydantoin amide and hydantoin components, and the molar ratio of the hydantoin amide to the hydantoin in the components is not lower than 2: 1; the method comprises the following steps: reacting a hydroxyacetonitrile material with a carbon dioxide source, an ammonia source and water in a synthesis device at 80-100 DEG C to prepare a hydantoin precursor solution, enabling the obtained hydantoin precursor solution to enter a hydrolysis device to contact with a solid catalyst containing a metal oxide, and hydrolyzing at 70-120 DEG C to obtain glycine hydrolysate; after the solid catalyst is separated from the glycine hydrolysate through the solid-liquid separation device, the glycine hydrolysate is concentrated and deaminated and then fed into the spraying device to be subjected to spray drying to obtain a glycine product, and the separated solid catalyst is returned to the hydrolysate device to be recycled. According to the method, the problem that hydantoin completely depends on self-hydrolysis and is difficult to be fully converted into a glycine product in an existing direct hydantoin method is solved.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

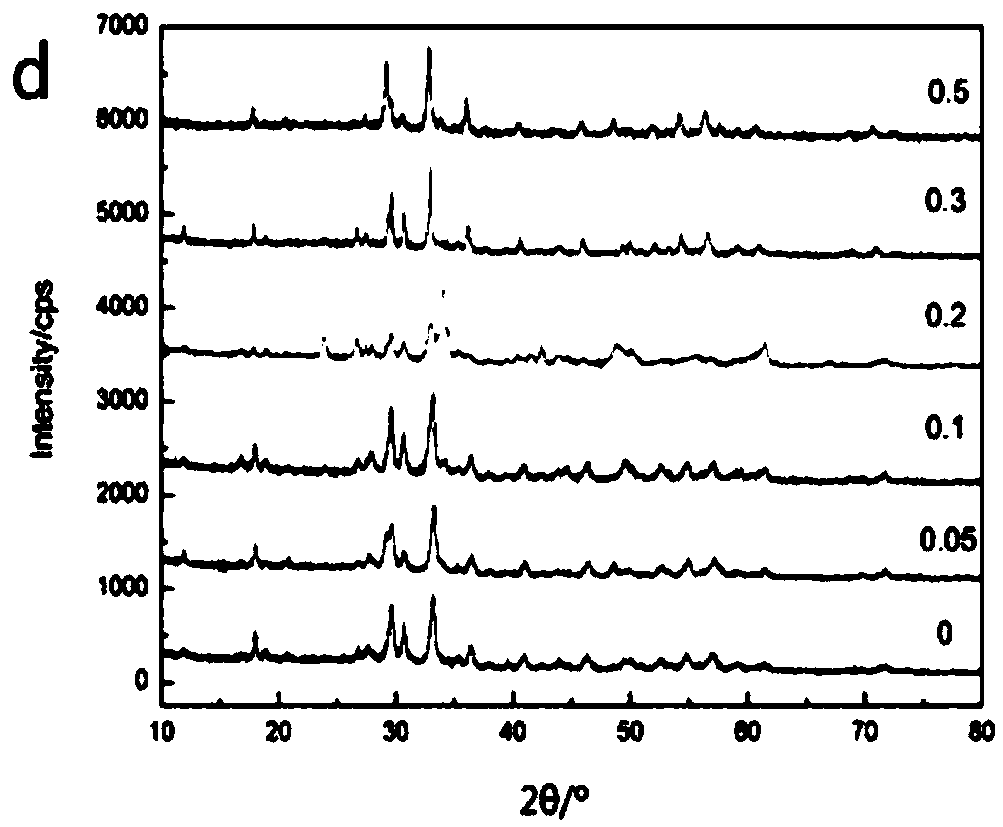

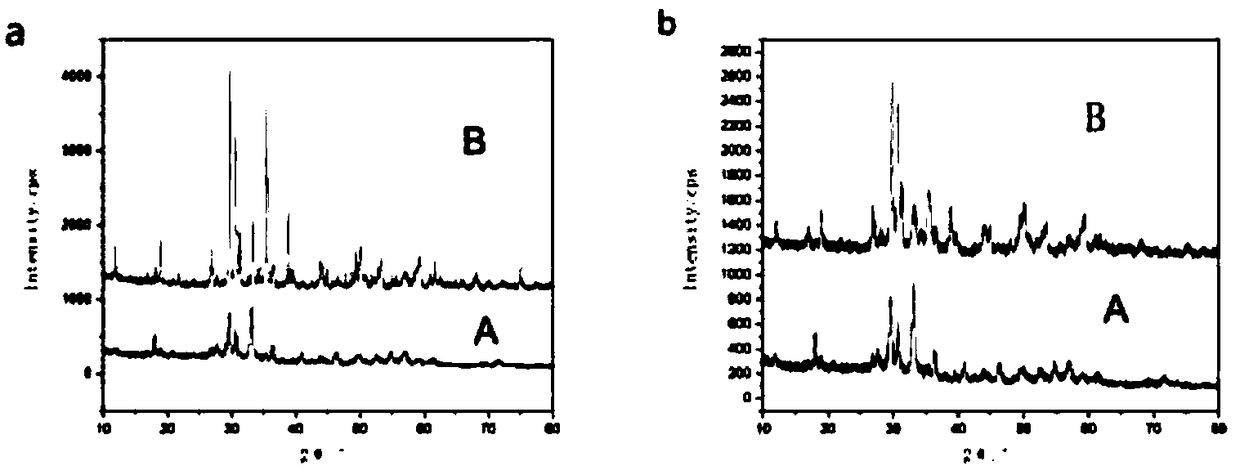

The preparation method of sodium vanadium fluorophosphate

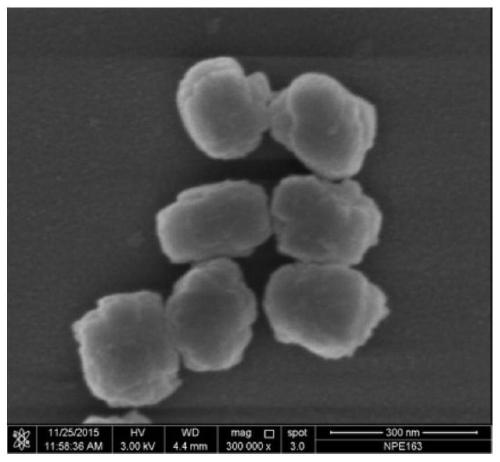

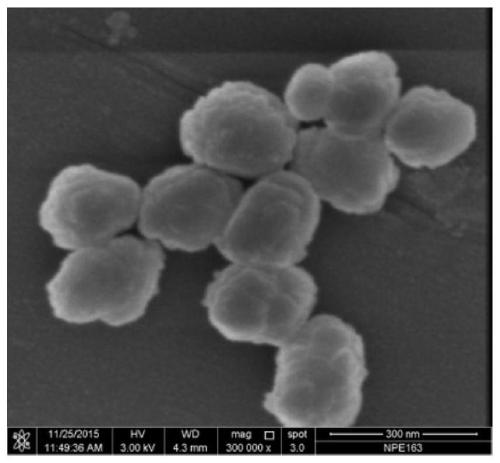

ActiveCN108878875BHigh crystallinitySmall particle sizeCell electrodesSecondary cellsSpray pyrolysisPhosphoric acid

The invention provides a preparation method of sodium vanadium fluorophosphate. The preparation method comprises the steps that a low-cost pentavalent inorganic vanadium source is adopted, the vanadium source, a phosphate radical source and an organic reducing agent are mixed under normal temperature and pressure, and then a spray pyrolysis method is adopted to prepare and obtain a vanadium phosphate intermediate at a low temperature and within a short period of time; and the vanadium phosphate intermediate is further mixed with a sodium source and a fluorine source in a solid phase mode, andthe sodium vanadium fluorophosphate with good crystallinity is synthesized through calcining at a low temperature and in a short period of time. The obtained sodium vanadium fluorophosphate has a spherical shape and part of the sodium vanadium fluorophosphate is in the hollow sphere form, and the particle size is small. The vanadium phosphate intermediate is prepared by the spray pyrolysis methodin the preparation process, the process flow is short, the process is simple, the productivity is large, and the production efficiency is high.

Owner:CENT SOUTH UNIV

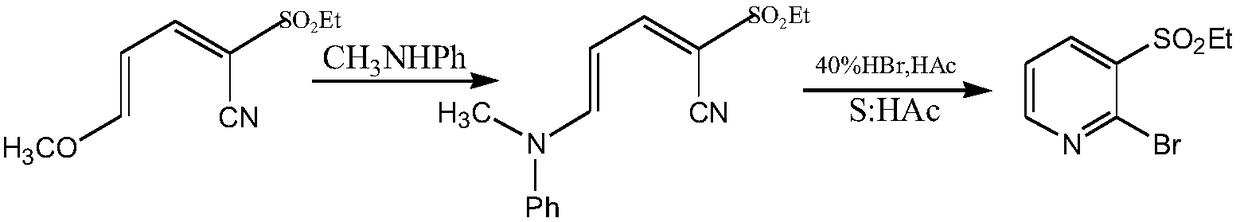

A method for synthesizing 2-halo-3-substituted hydrocarbylsulfonylpyridine and its intermediates by microwave method

InactiveCN106518757BImprove responseHigh bactericidal activityBiocideOrganic chemistryMicrowave methodOrganic layer

The invention discloses a method for synthesizing 2-halo-3-substited alkylsulfonyl pyridine and an intermediate compound thereof through a microwave method. The method comprises the following steps: adding substituted amino acraldehyde, a catalyst and substituent cyanoethyl sulfone into a reactor, reacting under microwave radiation, and tracking the reaction until the substituted amino acraldehyde or the substituent cyanoethyl sulfone reacts completely, thereby preparing the intermediate compound; adding halogen hydride into the reaction solution, further reacting, and tracking detection until the reaction is complete; and adding an alkaline solution into the reaction solution to regulate the pH value to 7-8, standing for stratification to obtain a water layer and an organic layer, extracting the water layer with organic solvent, then merging the organic layers, and refining to prepare the 2-halo-3-substited alkylsulfonyl pyridine. According to the invention, the method for synthesizing 2-halo-3-substited alkylsulfonyl pyridine has the advantages of greenness, environment friendliness, short reaction time, simple operation process and high product yield; and the product has favorable bactericidal activity.

Owner:SHANDONG NORMAL UNIV

A kind of method for preparing bisbenzylisoquinoline compound

ActiveCN109678871BModerately alkalineImprove catalytic performanceOrganic chemistryIsoquinolineBiochemical engineering

The invention provides a preparation method of bisbenzylisoquinoline compounds. The method comprises the following steps: taking a formula (A) and RX as reactants and carrying out a reaction in a reactor in the presence of ionic liquid or assistants; detecting the reaction progress by chromatography; after the reaction ends, separating and purifying or further adding acid and neutralizing to neutral; then separating and purifying to obtain the bisbenzylisoquinoline compound (The formula is shown in the specification). The method has the advantages of simplicity, environmental protection, highefficiency, as well as high yield which is 90 percent or above, is up to 98 percent or above and is far higher than the yield of a traditional solvent method (20 to 80 percent).

Owner:SHANDONG NORMAL UNIV

Preparation method of titanium barium ferrum series photocatalyst

InactiveCN101214441BAchieve the purpose of purificationVisible light catalytic activity is highMetal/metal-oxides/metal-hydroxide catalystsCentrifugationTitanium

The present invention relates to a preparation method of a barium titanium iron series photocatalyst, belonging to the field of photocatalyst. In accordance with the chemical formula Bi5FeTi3O15, the invention adds titanium salt or titanate, malysite, bismuth salt into deionized water or acidic solution to dissolve and mix evenly, adds in aqueous alkali to produce settlings, and then adds the settlings into a water heat retort; after water heat reaction, the Bi5FeTi3O15 catalyst material is obtained after centrifugation, washing and drying. The preparation method of a barium titanium iron series photocatalyst provided by the present invention reduces energy consumption of synthesization, and the product has even components, controllable grain size, quite high specific surface area, and good photocatalytic performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of lithium manganate composite material and preparation method thereof

ActiveCN105932232BReduce usageLower synthesis costCell electrodesSecondary cellsIon exchangeManganese

Owner:SHENZHEN LIWEI LI ENERGY TECH CO LTD

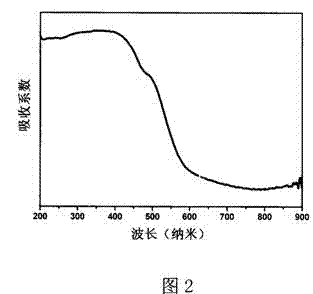

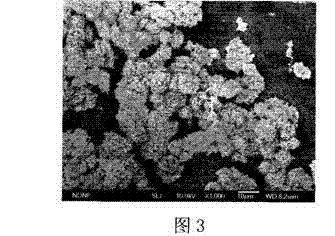

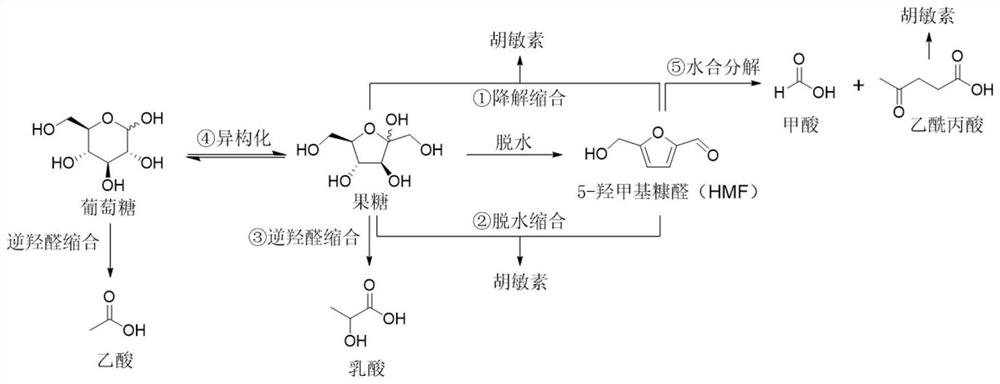

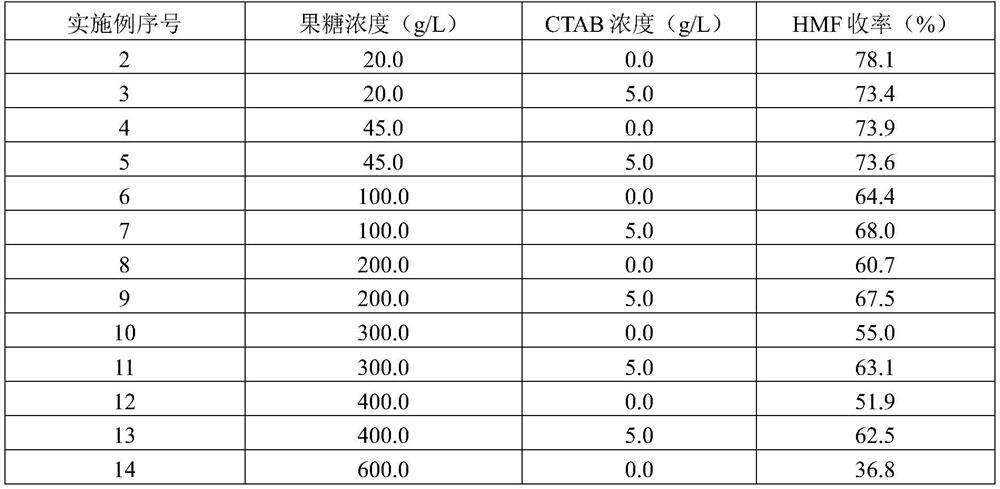

Synthetic method of 5-hydroxymethylfurfural promoted by surfactant

The invention relates to a synthetic method of 5-hydroxymethylfurfural promoted by a surfactant. According to the method, fructose is used as a raw material, 1, 4-dioxane and water are used as a mixed solvent, dodecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide, hexadecyl dimethyl ethyl ammonium bromide, octadecyl trimethyl ammonium bromide or hexadecyl trimethyl ammonium chloride are used as surfactants, sulfuric acid is used as a catalyst, and the fructose is synthesized through a one-pot method. And synthesizing the 5-hydroxymethylfurfural in a closed reactor in which air is removed. According to the method, the surfactant is utilized to create a solvent microenvironment beneficial to fructose dehydration and timely removal of HMF, generation of by-products such as micromolecular organic acid and humin is reduced, and the utilization rate of raw material carbon is high; the method is suitable for the dehydration reaction of high-concentration fructose, and the synthesis efficiency of HMF is high; the method has the advantages of high HMF yield, few byproducts, easiness in separation and purification, low synthesis energy consumption and favorable industrial application prospect.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

A kind of preparation method of yal1-x Fe xO3 nanometer pigment

ActiveCN109096796BSmall particle sizeGood dispersionPigmenting treatmentButanedioic acidSuccinic acid

The invention discloses a doped nano pigment YAl 1‑ x m x o 3 The preparation method of (M=Fe, Co, Cu) comprises the following steps: 1) at normal temperature, get deionized water and stir on a magnetic stirrer, according to the molar ratio of Y, Al, and Fe, appropriate ferric nitrate, nitric acid Aluminum and yttrium nitrate are completely dissolved in deionized water successively, and after the above raw materials are completely dissolved, succinic acid is added as a stabilizer to obtain solution A; pH value, to obtain solution B, and then add 1,2-propylene glycol to solution B to obtain a mixed solution; 3) Stir the mixed solution obtained in step 2) on a 60°C constant temperature magnetic stirrer for 2h until the solution becomes condensed glue, then dried, ground, and calcined to obtain solid powder. The preparation method of the invention is green and pollution-free, and the obtained product has the advantages of good dispersibility, low energy consumption, uniform particles, environmental friendliness, low synthesis temperature, simple and controllable process, and is suitable for large-scale production.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

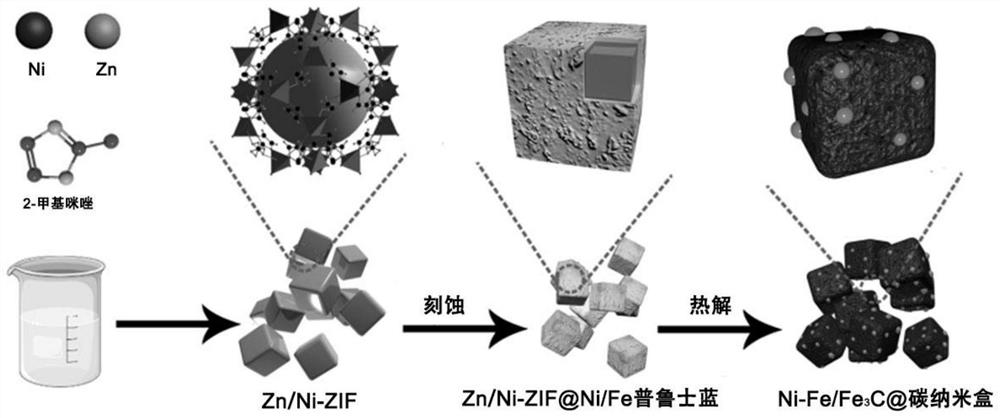

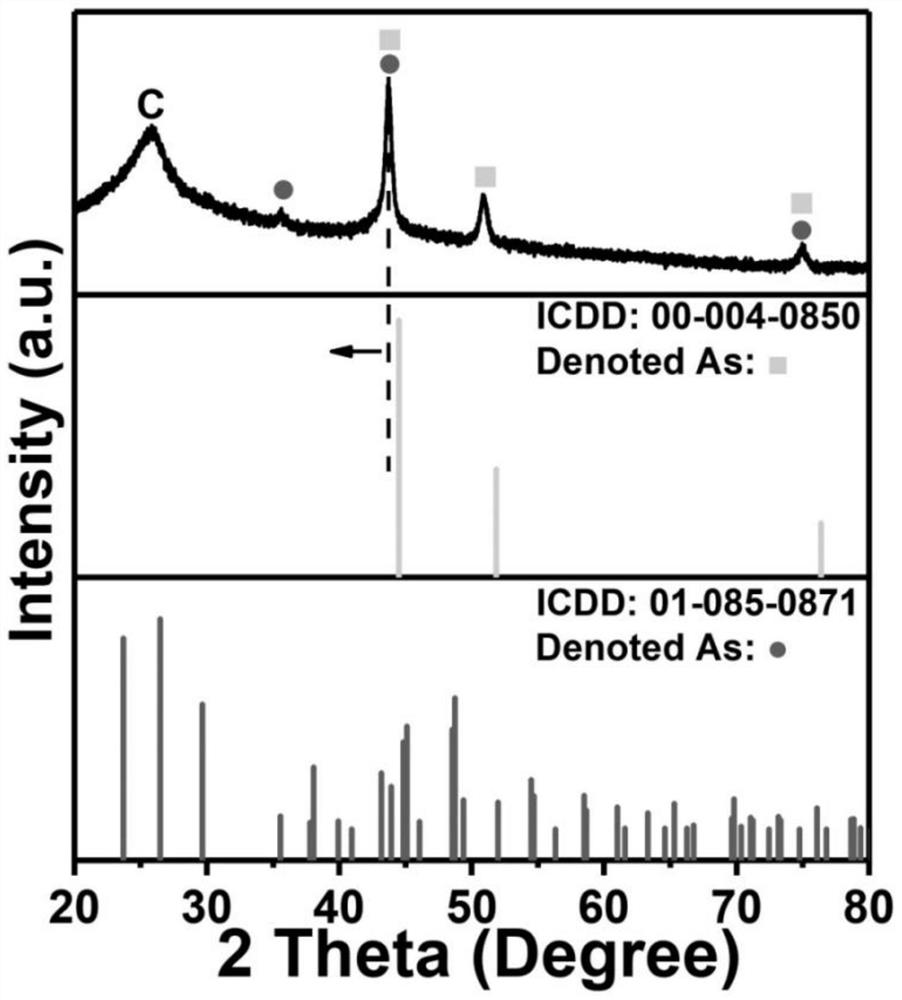

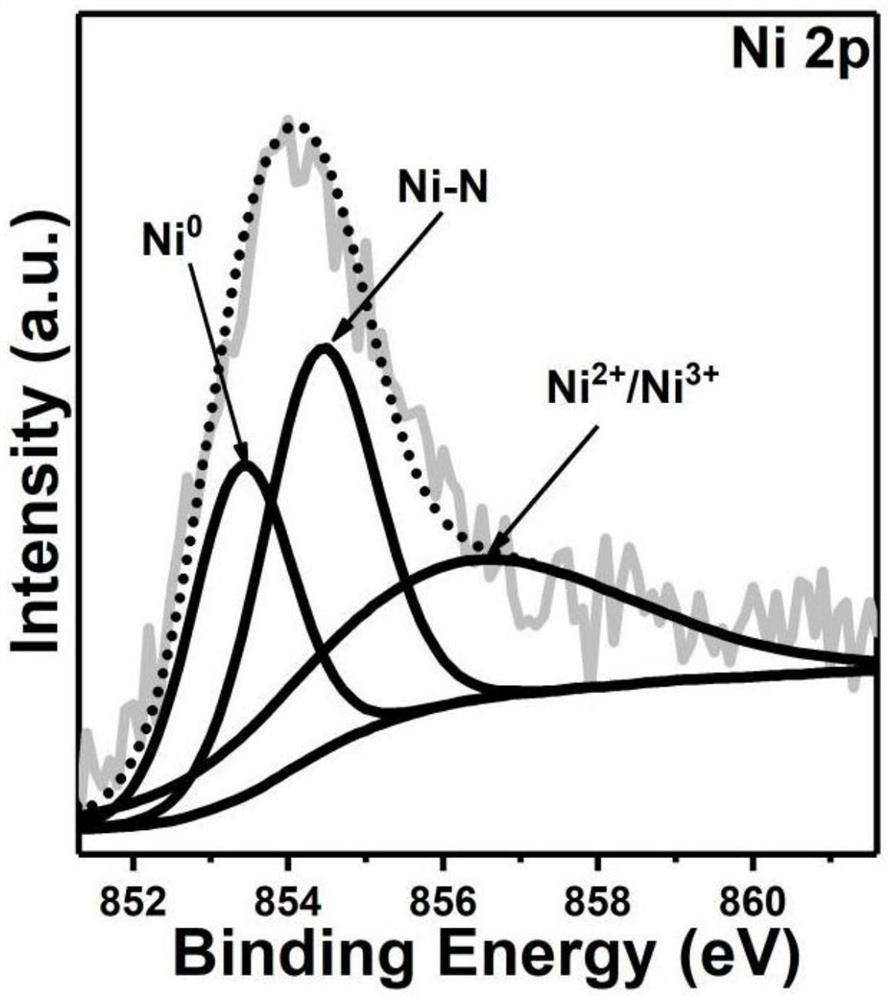

Iron-nickel-based or iron-cobalt-based Mott-Schottky electrocatalyst as well as preparation method and application thereof

PendingCN114784300ALow costHigh purityFuel and primary cellsCell electrodesPtru catalystPotassium ferricyanide

The invention relates to the technical field of catalyst preparation, in particular to an iron-nickel-based or iron-cobalt-based Mott-Schottky electrocatalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly synthesizing a metal organic framework material (Zn-Ni-ZIF or Zn-Co-ZIF) nano cube containing zinc and nickel (or cobalt), and then etching the metal organic framework material (Zn-Ni-ZIF or Zn-Co-ZIF) nano cube by using potassium ferricyanide to form a hollow structure so as to form a Zn-Ni (Co)-ZIF nano cube-Prussian blue analogue core-shell structure; and finally, performing pyrolysis under the atmosphere of nitrogen to form the NiFe-Fe3C (or CoFe-Fe3C) Mott-Schottky electrocatalyst. The catalyst has a typical hollow nanometer box structure, the specific surface area is higher, more active sites exist, nitrogen-doped carbon serving as a main framework of the catalyst has good conductivity, and mass transfer and charge transfer processes of electro-catalytic reaction can be accelerated. The catalyst belongs to a bifunctional catalyst, not only can catalyze an oxygen reduction reaction, but also can drive an oxygen evolution reaction, meets the requirements of a rechargeable zinc-air battery, and shows a potential application prospect to replace a commercial noble metal catalyst.

Owner:ANHUI UNIV OF SCI & TECH

A method for synthesizing 2-halogenated nicotinic acid esters and intermediates thereof by microwave method

ActiveCN104945316BShort reaction timeShorten the timeCarboxylic acid nitrile preparationOrganic compound preparationHydrogen halideMicrowave method

Owner:SHANDONG NORMAL UNIV

A kind of continuous reaction method of polyamide

ActiveCN111647154BReduce reaction energy consumptionEfficient use ofChemical/physical/physico-chemical processesPolymer sciencePolyamide

The invention relates to a continuous reaction process of polyamide. The continuous reaction by using a reaction device comprises the following steps: 1) introducing a heating medium into a shell passof a heating system; 2) enabling the polymerization raw material to pass through a preheating system and a light component removal system, discharging the polymerization raw material into a tube passof a heating system, heating the raw material to 200-250 DEG C until the water content in the polymerization raw material is reduced to be less than or equal to 20%, and carrying out a pre-polymerization reaction; 3) discharging a material obtained by prepolymerization into a reaction system, and carrying out a reaction after prepolymerization to generate process steam; 4) feeding the process steam into a light component removal system, heating the polymerization raw material passing through the light component removal system to 180-240 DEG C and feeding the raw material into a shell pass ofa preheating system, and heating the polymerization raw material passing through the preheating system to 180-230 DEG C; 5) condensing the process steam in the shell pass of the preheating system to serve as reflux liquid, and 6) continuously discharging when the viscosity is 150-300 cp to obtain a polyamide prepolymerization product. The reaction process is simple in process and low in synthesiscost, can effectively guarantee the quality stability of polyamide, and is a guarantee for producing high-end polyamide.

Owner:华峰集团上海工程有限公司

Method for synthesizing presintering hard ferrite material

InactiveCN101712556BUniform grain distributionGood molding effectInorganic material magnetismMicrowavePhysical field

The invention discloses a method for synthesizing a presintering hard ferrite material, which takes one or more of oxide or carbonate of ferrite cations and other additives such as CaO, Al2O3 and the like as raw materials, and comprises the following steps: ball milling and tempering, drying, heating by a microwave physical field with the frequency of 300-3,000MHz, raising the temperature to 1,150-1,350 DEG C at the heating-warming speed of 20-80 DEG C / min, and preserving the temperature for 30-180min to obtain the single-phase presintering hard ferrite material with the grain size being about 0.2-2 mu m. Compared with the traditional method for synthesizing presintering materials, the method in the invention has the advantages of short presintering time, low energy consumption, fine and uniform grains of the presintering materials, good moldability and stable magnetic performance, and can be used for preparing sintering bodies by wet compression moulding and dry compression moulding.

Owner:SHANGHAI INST OF TECH

Preparation method of organic layered bimetallic silicate

PendingCN114733567ALow costReduce synthesis energy consumptionSilicon organic compoundsMaterial nanotechnologyNitrateTriethoxysilane

The invention provides a preparation method of organic layered bimetallic silicate. The method comprises the following steps that chloride or nitrate of a first transition metal element and chloride or nitrate of a second transition metal element are added into a solvent and dissolved, a mixed solution is obtained, and the molar ratio of the first transition metal element to the second transition metal element is 1: (1 / 10-10); 3-aminopropyltriethoxysilane is slowly added into the mixed solution, precipitate slurry is formed, and the adding amount of the 3-aminopropyltriethoxysilane enables the ratio of the total molar weight of the first transition metal element and the second transition metal element in the mixed solution to the molar weight of the silicon element in the 3-aminopropyltriethoxysilane to meet the requirement that the ratio of the total molar weight of the first transition metal element and the second transition metal element in the mixed solution to the molar weight of the silicon element in the 3-aminopropyltriethoxysilane is (1-4): 4; stirring until the reaction is finished, separating, cleaning and drying. The preparation method of the organic layered bimetallic silicate is low in cost and low in synthesis energy consumption.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com