Method for synthesizing A type molecular sieve membrane at low temperature

A molecular sieve and low-temperature technology, applied in the field of membrane separation, can solve problems such as high temperature, achieve the effects of reducing film thickness, good synthesis repeatability, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Synthesis of type A molecular sieve membrane, hydrothermal crystallization at 25°C for 6 days

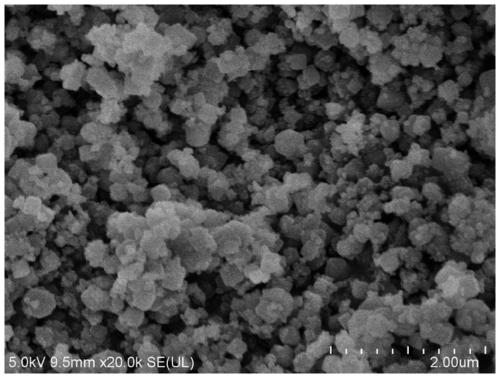

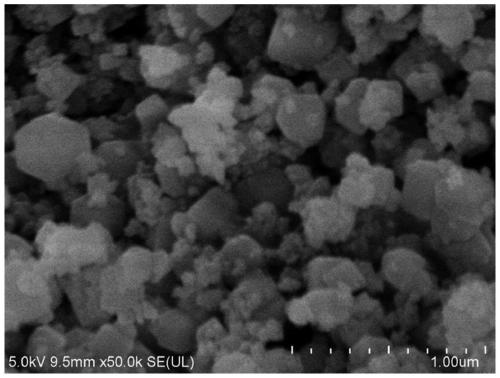

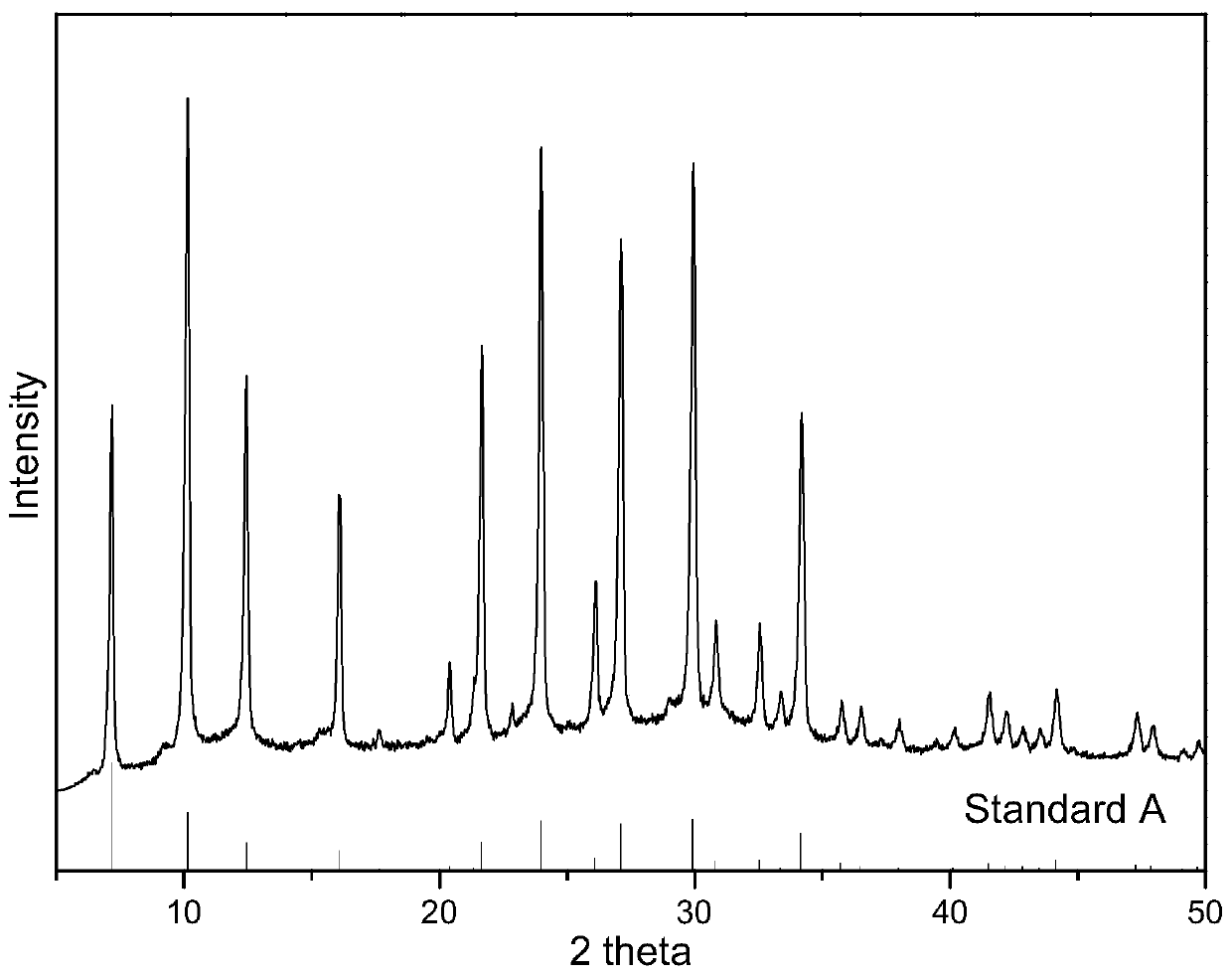

[0038] Step 1: Synthesis of A-type molecular sieve seed crystals: the mother liquor formula of A-type molecular sieve seed crystals is 6Na 2 O:0.55Al 2 o 3 :1.0SiO22 :150H 2 O (molar ratio), the silicon source is silica sol, and the aluminum source is sodium metaaluminate. Hydrothermal synthesis was carried out at room temperature for 7 days to obtain type A molecular sieve seed crystals. The seeds were centrifuged, washed with deionized water, and dried for later use. The SEM image of the seed crystal, such as Figure 1-2 As shown, the seed crystal is a cubic crystal of 50-300 nm. The XRD pattern of the seed crystal is as image 3 As shown, it is a pure type A molecular sieve without miscellaneous crystals.

[0039] Step 2: Select a porous ceramic tube (made of alumina) with a pore size of 100nm as the carrier, seal the two ends of the carrier with glaze, wash and dr...

Embodiment 2

[0049] Synthesis of type A molecular sieve membrane, hydrothermal crystallization at 25°C for 8 days

[0050] Example 2 is basically the same as Example 1, the only difference is that the crystallization time is 8 days.

[0051] The water / ethanol pervaporation separation test results of type A molecular sieve membrane tubes are shown in Table 2.

[0052] The water / ethanol pervaporation separation test result of table 2 embodiment 2

[0053]

[0054] Note: Separation temperature is 70°C, feed 5wt% water: 95wt% ethanol

Embodiment 3

[0056] Synthesis of type A molecular sieve membrane, hydrothermal crystallization at 25°C for 10 days

[0057] Example 3 is basically the same as Example 1, the only difference is that the crystallization time is 10 days.

[0058] The water / ethanol pervaporation separation test results of type A molecular sieve membrane tubes are shown in Table 3.

[0059] The water / ethanol pervaporation separation test result of table 3 embodiment 3

[0060]

[0061] Note: The separation temperature is 70°C, and the feed is 10wt% water: 90wt% ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com