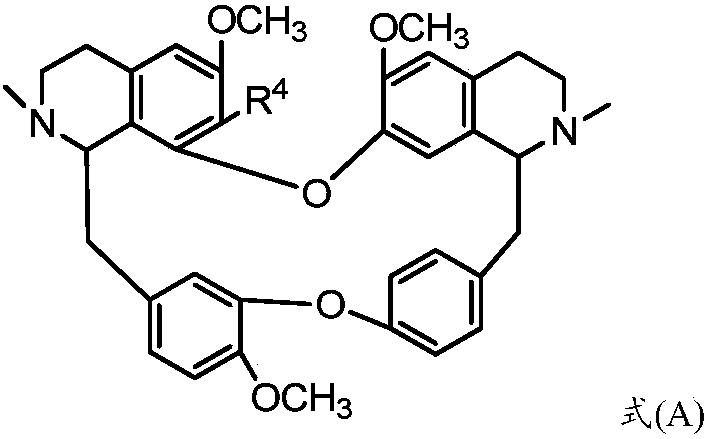

Method for preparing bisbenzylisoquinoline compounds

A technology of bisbenzylisoquinoline and compounds, applied in the field of medicine, can solve the problems of refractory treatment and many "three wastes"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

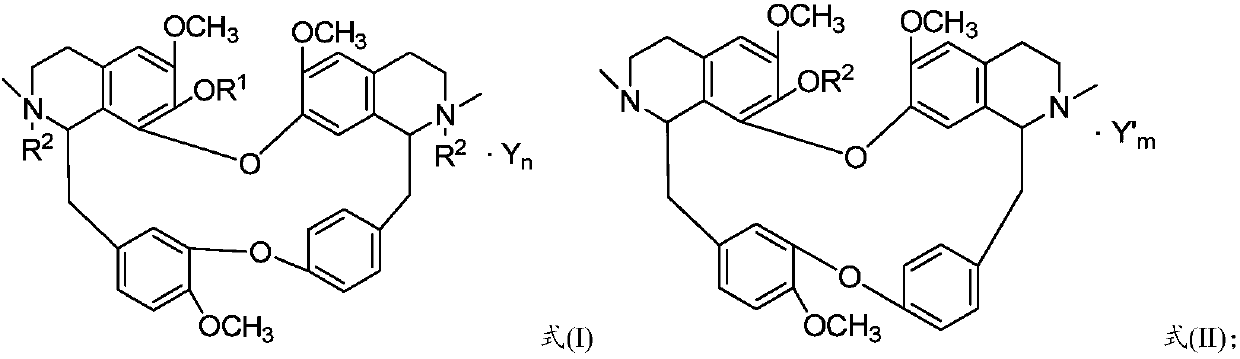

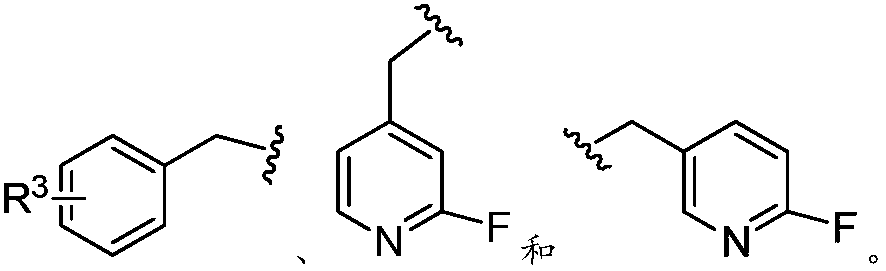

[0044] Example 1: R in formula (I') 2 is o-fluorobenzyl, Yn is Cl - 2 ,

[0045] Solvent method: Weigh 6.23g of tetrandrine and 0.20g of potassium hydride, dissolve it in 200mL of methanol in a 500mL three-necked flask, add 3.00g of o-fluorobenzyl chloride, stir and heat to boiling, and keep stirring for 8h, TLC detection of tetrandrine After the whole reaction, cool down to room temperature, add 80 mL of water after distilling off methanol, extract 3 times with dichloromethane (100 mL×3), trace the separation and purification process of the reaction and product by TLC, recover dichloromethane from the extract, and store the solid at 60°C After drying for 4 hours, 7.30 g of a light yellow powder was obtained, with a yield of 80%. The melting point of the target product: 207.7-209.5°C, 13 C NMR (CDCl 3 ,100MHz)δ160.77,157.87,152.75,150.35,148.34,147.80,147.38,146.09,142.95,137.64,137.51,137.33,133.77,131.71,131.41,129.71,129.65,129.54,128.26,128.06,127.66,127.54,126.90,1...

Embodiment 2

[0050] Example 2: R in formula (I') 2 is p-fluorobenzyl, Yn is Cl - 2 ,

[0051] Solvent method: Weigh 18.70g of tetrandrine and 0.20g of sodium ethoxide, dissolve it in 360mL of absolute ethanol in a 500mL three-neck flask, then add 9.00g of p-fluorobenzyl chloride, stir and heat to boiling, and keep stirring for 36h, TLC detection Tetrandrine was completely reacted, distilled off absolute ethanol, cooled to room temperature, added 100mL of water, extracted 3 times with chloroform (150mL×3), followed the separation and purification process of reaction and product by TLC, recovered chloroform from the extract, solid The product was dried at 60° C. for 4 hours to obtain 16.55 g of a light yellow powder product with a yield of 60.6%. The melting point of the target product: 208.5-209.9°C, 13 C NMR (CDCl 3 ,100MHz)δ163.55,161.11,153.75,151.39,149.43,148.78,148.52,147.13,143.95,137.41,137.29,136.98,135.12,133.61,133.54,132.65,132.55,132.43,130.09,130.01,128.65,128.43,128.26...

Embodiment 3

[0056] Example 3: R in formula (I') 2 is (2,5-difluoro)benzyl, Yn is Cl - 2 ,

[0057] Solvent method: Weigh 6.23g of tetrandrine and 0.50g of potassium carbonate, dissolve it in 100mL of propanol in a 500mL three-necked flask, then add 3.60g of 2,5-difluorobenzyl chloride, heat and stir until boiling, and keep stirring for 24h , TLC detects the entire reaction of tetrandrine, distills off the solvent under reduced pressure, cools down to room temperature, adds 100 mL of water, extracts with acetone for 3 times (150 mL×3), traces the separation and purification process of the reaction and the product by TLC, and uses anhydrous Na 2 SO 4 After drying for 8 hours, acetone was recovered, and the solid was dried at 60° C. for 4 hours to obtain 8.22 g of a light yellow powder product with a yield of 86%. The melting point of the target product: 209.2-210.7°C, TOF-HRMS: M / e (947.8780), molecular formula: C 52 h 52 o 6 N 2 f 4 Cl 2 .

[0058] Ionic liquid method: Weigh 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com