A Continuous Deacidification System Based on Dielectric Barrier Discharge

A dielectric barrier discharge and deacidification technology, which is applied in the field of deacidification system, can solve the problems of unsuitability for large-scale production, inability to realize continuous deacidification, and low deacidification efficiency, and achieve simple structure, avoid deformation, and high deacidification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

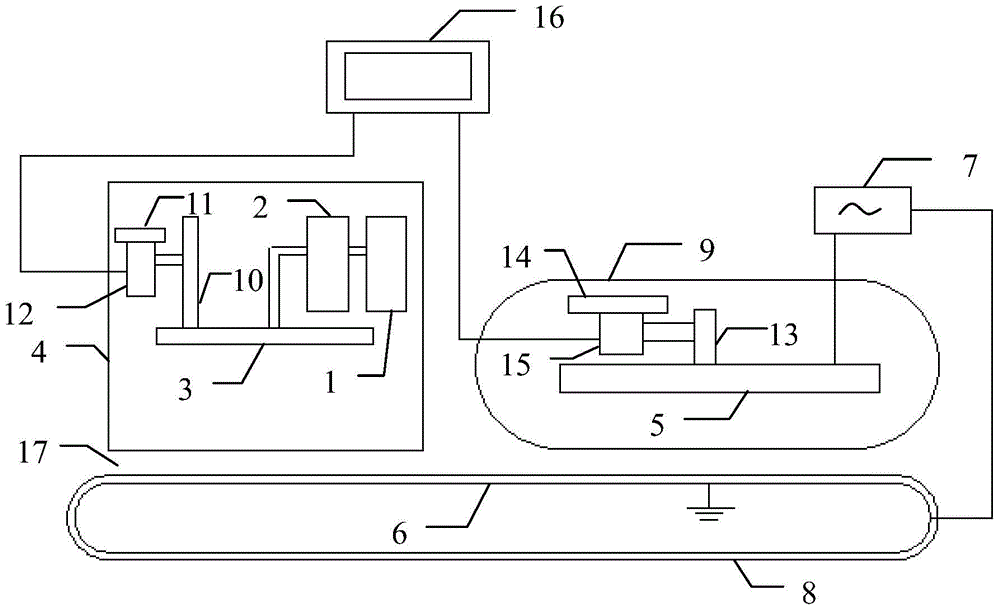

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0054] The continuous deacidification system based on dielectric barrier discharge in this embodiment includes a deacidification agent atomization device, a radio frequency discharge device and a driving device.

[0055] Wherein, the deacidification agent atomization device includes a deacidification agent tank 1 connected in sequence, an atomization generating mechanism 2 and a nozzle 3 for applying the deacidification agent to the sample to be deacidified;

[0056] The radio frequency discharge device comprises a discharge electrode 5, a ground electrode 6 and a matching circuit, the ground electrode 6 is made of copper and is wound around a conveyor belt for carrying samples to be deacidified;

[0057] The driving device includes a first lifting motor 15 for driving the first lifting platform 13 and a second lifting motor 12 for driving the second li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com