Patents

Literature

31 results about "Triammonium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

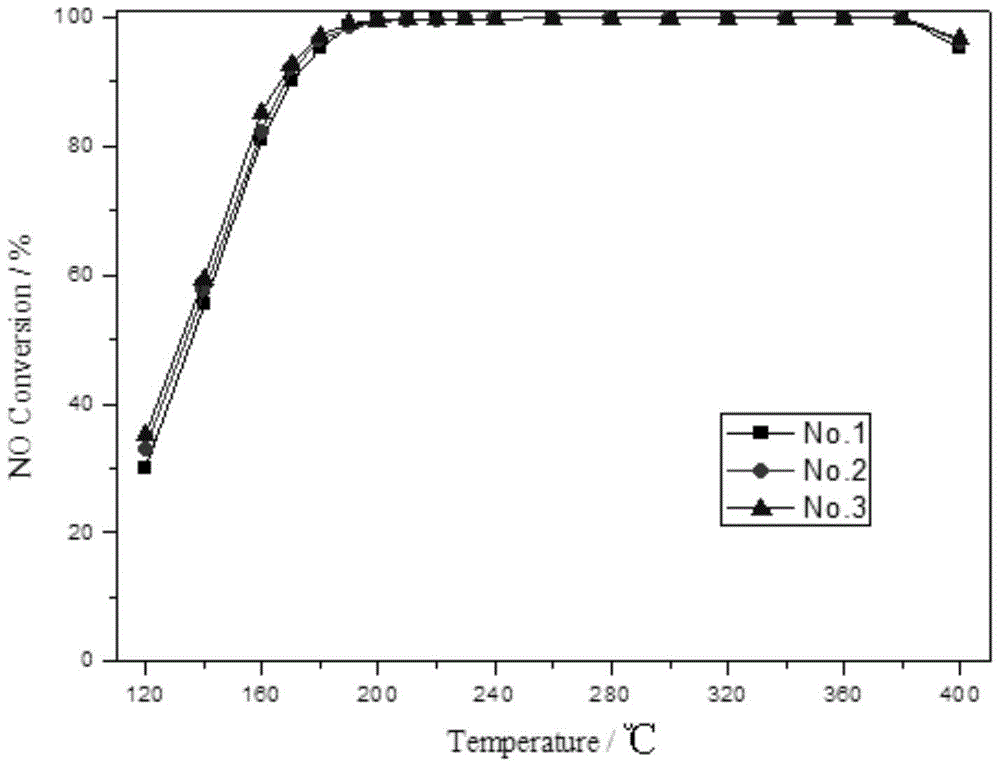

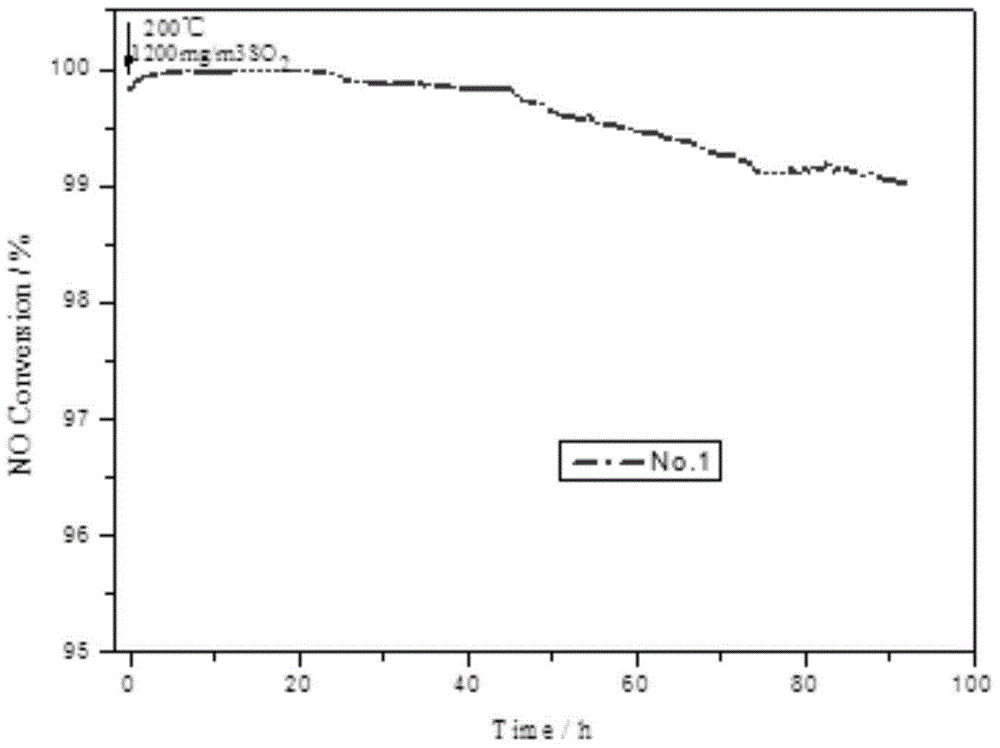

Preparation recipe and preparation method of low-temperature anti-sulfur SCR (Selective Catalytic Reduction) catalyst

ActiveCN104841464AGood catalytic activity at low temperatureHigh activity temperature rangePhysical/chemical process catalystsDispersed particle separationTungstateAmmonium metavanadate

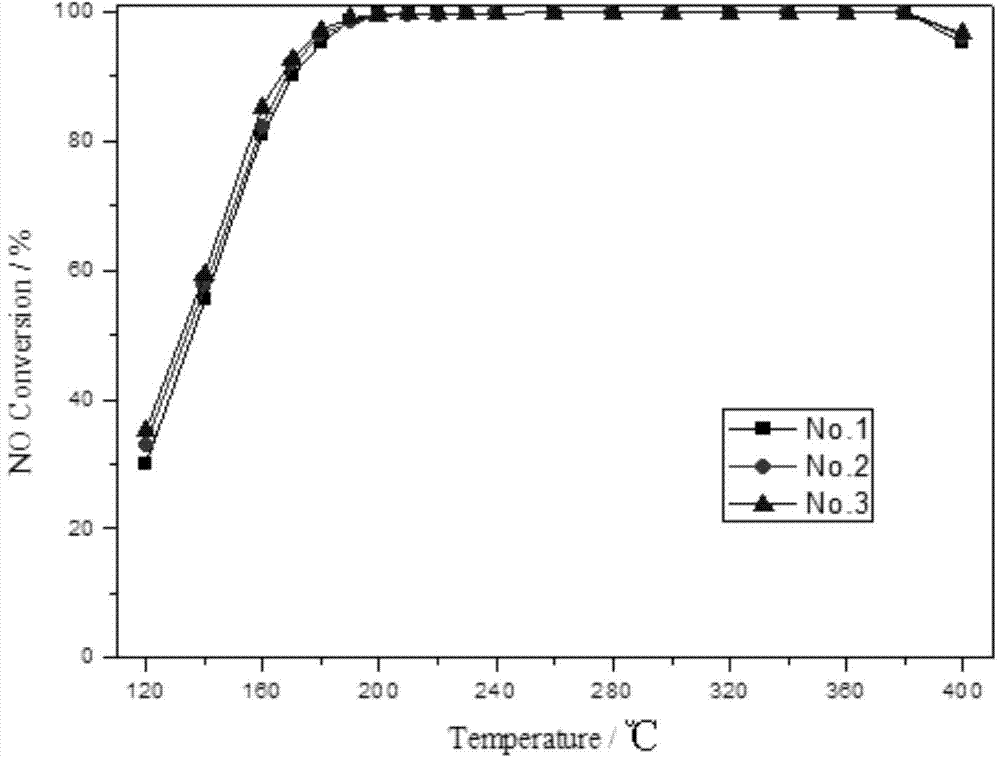

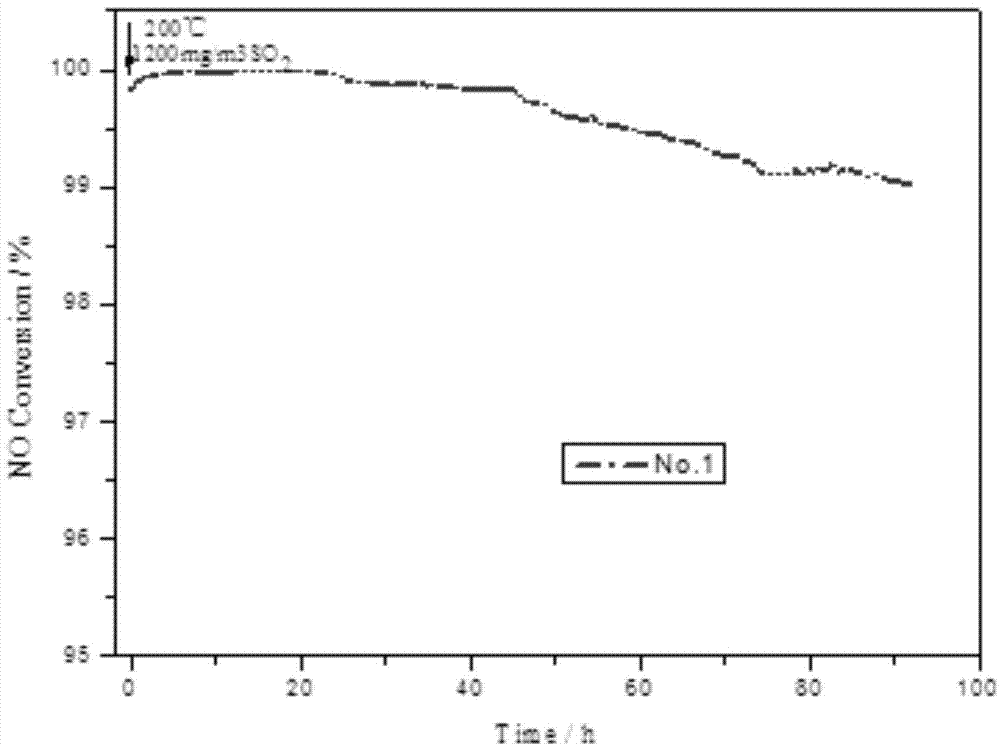

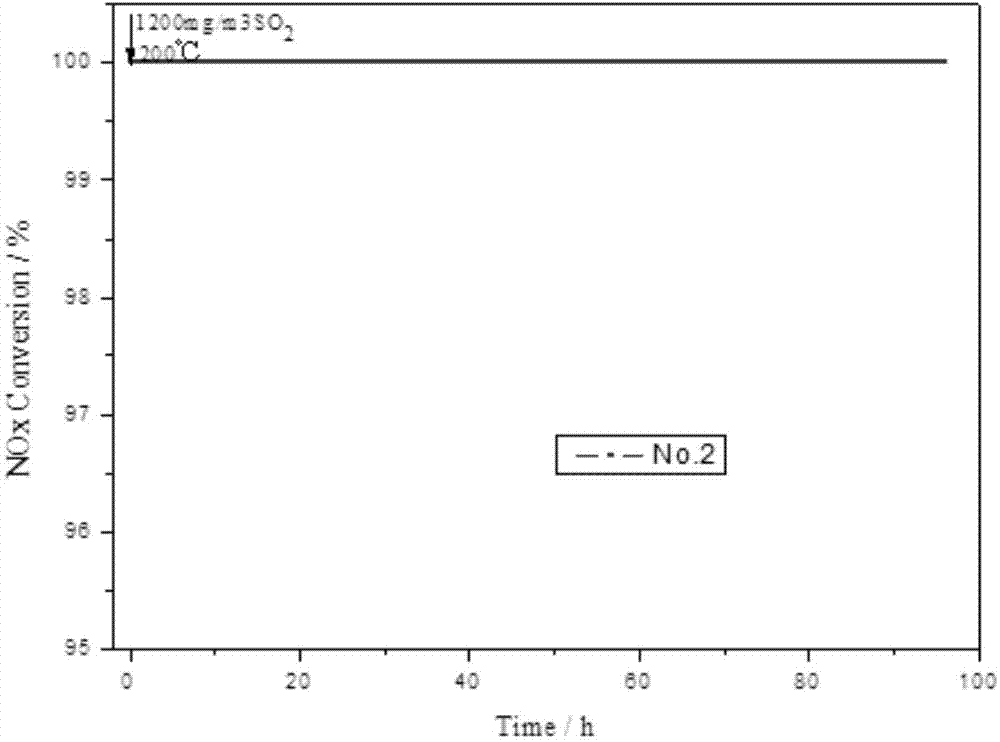

The invention provides a preparation recipe and a preparation method of a low-temperature anti-sulfur SCR (Selective Catalytic Reduction) catalyst for removing nitric oxides, belonging to the field of catalytic chemistry. A one-step dipping method is adopted to load V2O5, WO3, P2O5 and anion Br on the surface of anatase TiO2. The catalyst comprises the constituents with the following contents: 60 to 95 wt% of the TiO2, 0 to 10 wt% of the V2O5, 0 to 20 wt% of the WO3, 0 to 3 wt% of the P2O5 and 0.35 to 0.5 wt% of the Br. The precursors of the chemical constituents of the catalyst are respectively ammonium metavanadate as the precursor of the V2O5, ammonium tungstate as the precursor of the WO3, triammonium phosphate as the precursor of the P2O5 and ammonium bromide as the precursor of the Br. According to the preparation recipe, the trace non-metallic elements are loaded, sulfate generation in sulphur-containing flue gas by the catalyst is slowed down, the acid site of the catalyst is added, denitration efficiency and sulfur resistance of the catalyst are improved, and the service life of the catalyst under the low-temperature high-sulphur flue gas condition is prolonged; meanwhile, the preparation method of the catalyst is also improved, the one-step dipping method is adopted, a semifinished product drying process is reduced, the preparation time of the catalyst is shortened, and the industrialized production of the catalyst is facilitated.

Owner:BEIJING UNIV OF TECH

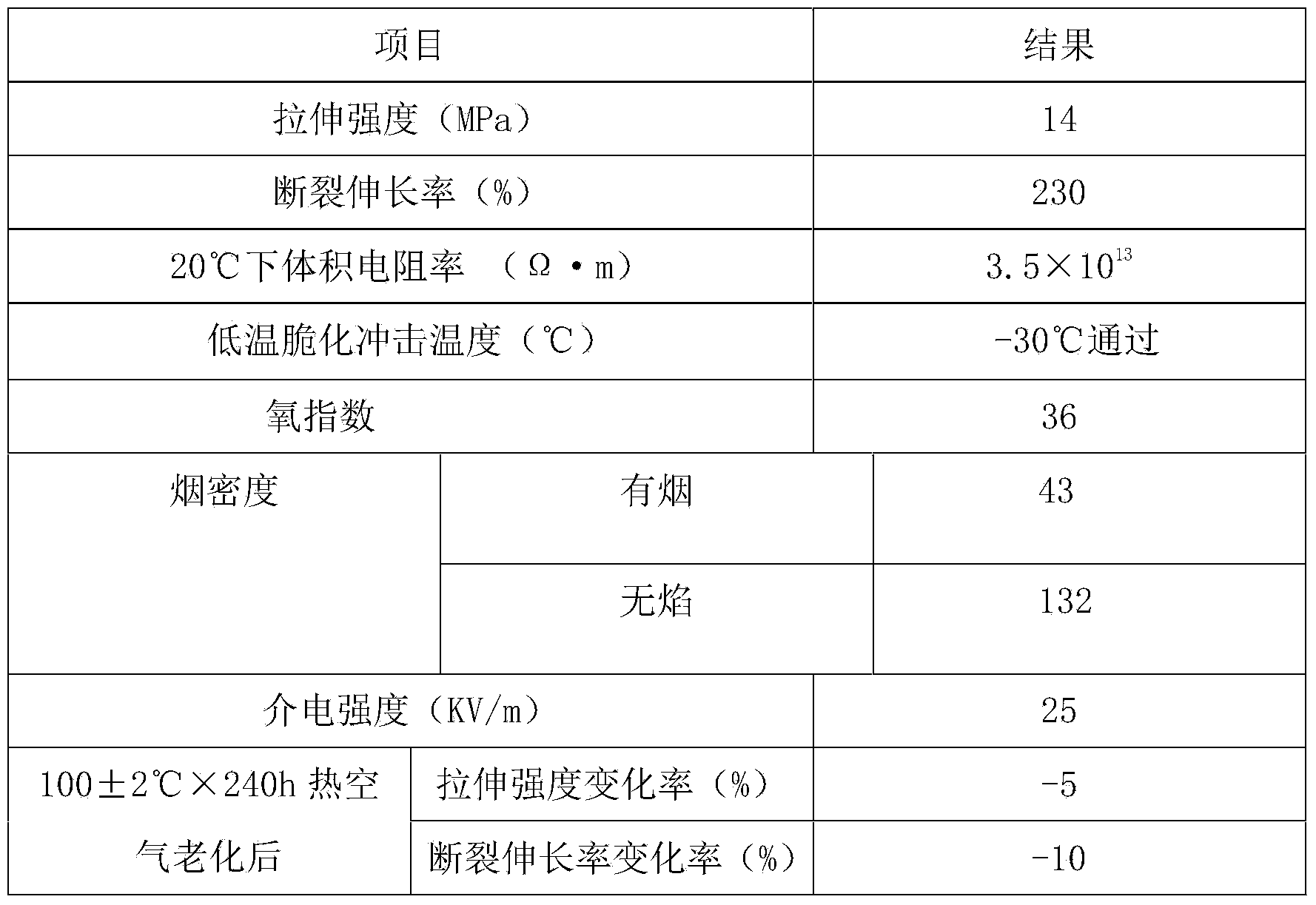

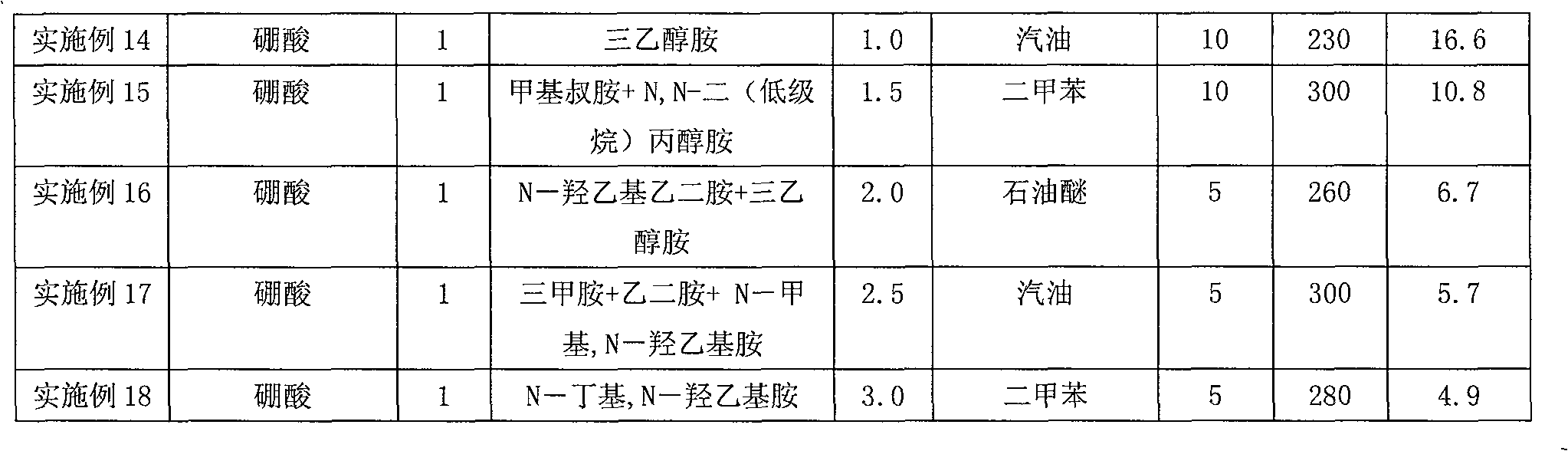

Flame-retardant polyethylene cable material capable of preventing mould

ActiveCN103509228AWith anti-mold functionWeather resistantInsulatorsZinc hydroxideLinear low-density polyethylene

The invention provides a flame-retardant polyethylene cable material capable of preventing mould. The flame-retardant polyethylene cable material is prepared with the following components and raw materials by weight: 50-60 parts of high-density polyethylene, 30-45 parts of linear low-density polyethylene, 10-15 parts of polyester resin, 8-10 parts of organic silicon resin, 2-3 parts of simethicone, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 1-2 parts of barium sulfate, 5-6 parts of dolomite, 6-8 parts of attapulgite, 4-6 parts of celestite, 10-12 parts of zinc hydroxide, 10-15 parts of triammonium phosphate, 10-12 parts of tricresyl phosphate (TCP), 6-8 parts of poly(1,2-propylene glycol adipate), 1-2 parts of sophora flavescens alcohol extract, 0.5-0.6 parts of zanthoxylum oil, 1-2 parts of OBPA (10,10'-oxybisphenoxarsine) mould inhibitor, 1-1.5 parts of PVC (polyvinyl chloride) processing agent ACR-401 (acrylate plastic modifier), and 10-15 parts of modified filler. The cable wire has good antibacterial property, and the characteristics of weather resistance, low smoke, ageing resistance, flame retardation and so on.

Owner:蚌埠尚维知识产权运营有限公司

Combustible pesticidal products

InactiveUS7344729B2Extension of timeBiocideOrganic active ingredientsAlkaline earth metalTriammonium phosphate

A combustible pesticidal product is disclosed which comprises a structural element formed from a cardboard having a thickness of at least 0.75 mm, a density of 450-850 kgm3 and consisting of 1 or more plies, the cardboard including: an alkali or alkaline earth metal nitrate or nitrite in an amount of from 0 to 1.83% w / w, or an alkali or alkaline earth carbonate or bicarbonate in an amount of from 0.02 to 7.0% w / w; one or more mineral silicates in an amount of from 0.01 to 8.0% w / w; a phosphate in an amount of from 0.01 to 0.40% w / w and selected from the group consisting of diammonium phosphate, monoammonium phosphate, triammonium phosphate and mixtures thereof; a boron compound in an amount of from 0.001 to 0.92% w / w (as boron) and selected from the group consisting of boric acid, sodium tetraborate hydrous, sodium borate, potassium borate, calcium borate, zinc perborate, boronatrocalcite and mixtures thereof; one or more pesticides; and optionally a perfume and / or a dye, which product on combustion emanates the pesticide into the atmosphere. Typically the combustible product will be a mosquito coil which has been impregnated with one or more insecticides effective against mosquitoes. On combustion of the coil, insecticide is emanated into the atmosphere for a period of at least 4 hours. However, the coils of the invention may be active against mosquitoes for 8 hours or more.

Owner:RB HYGIENE HOME AUSTRALIA PTY LTD

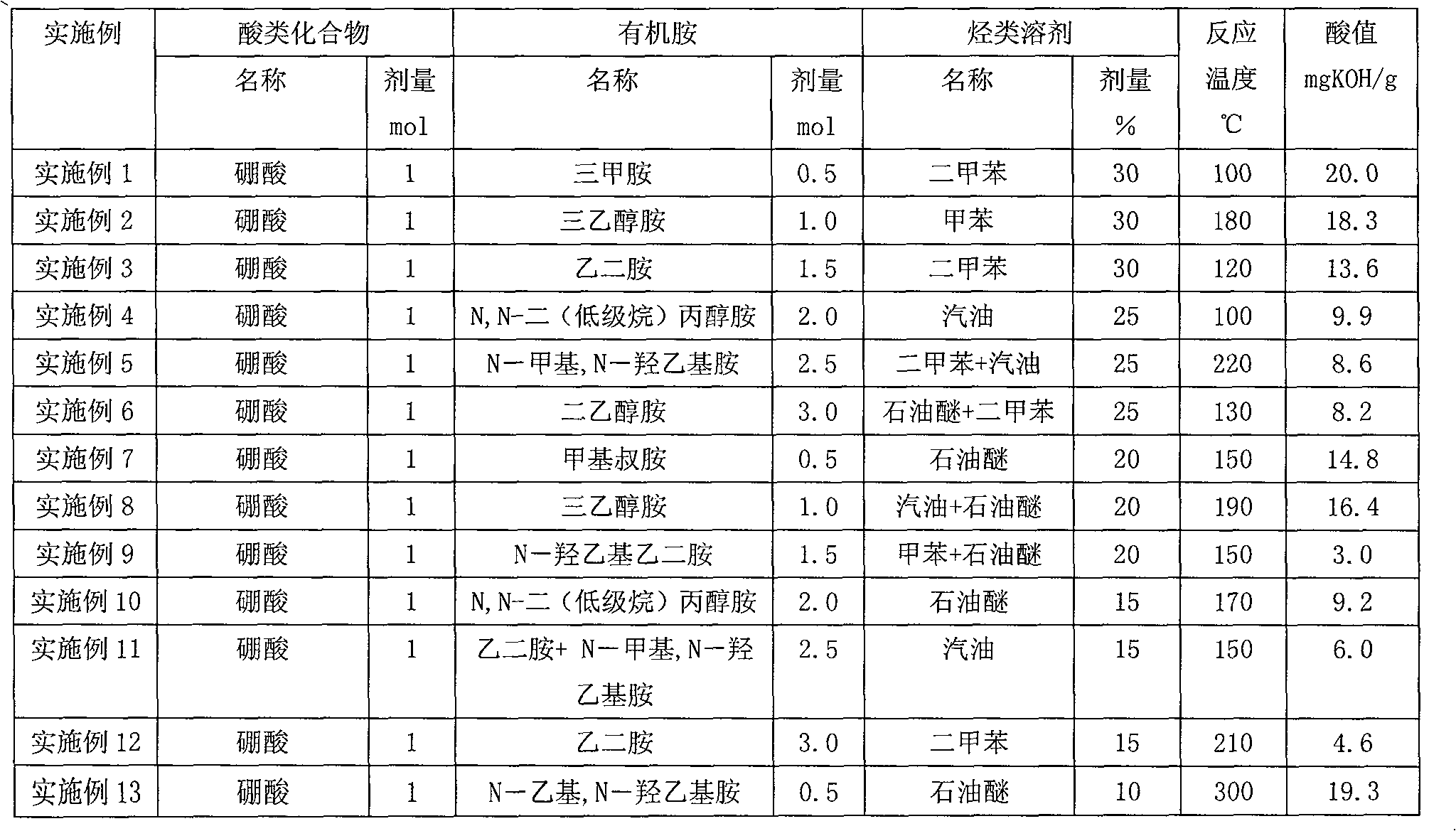

Water-soluble high-temperature organic acid inhibitor and preparing method and using method thereof

The present invention relates to a high-temperature organic acid corrosion inhibitor for inhibiting refinery vacuum tower high-temperature naphthenic acid corrosion environment with 200-400deg.C. Its composition includes (by wt%) 10-60% of corrosion inhibitor intermediate obtained by using boric acid and organic amine according to the mole ratio of 1:0.5-3 through a certain reaction process, 20-80% of monohydric alcohol or dihydric alcohol solvent formed from one kind and two kinds of methyl alcohol, ethyl alcohol, n-propyl alcohol, isopropyl alcohol, butyl alcohol, isobutyl alcohol, 1,2-propylene glycol, n-amyl alcohol, n-heptyl alcohol and n-caprylic alcohol or combination of more than two kinds of above-mentioned components and 0.1-20% of corrosion inhibition film-forming component formed from one kind or any two kinds of sulfourea, benzyl chloride, alkylene sulfide, propiolic alcohol, trisodium phosphate, ammonium phosphosulfate, diammonium phosphate, triammonium phosphate and benzotriazole or combination of more than two kind of above-mentioned all the components.

Owner:PETROCHINA CO LTD

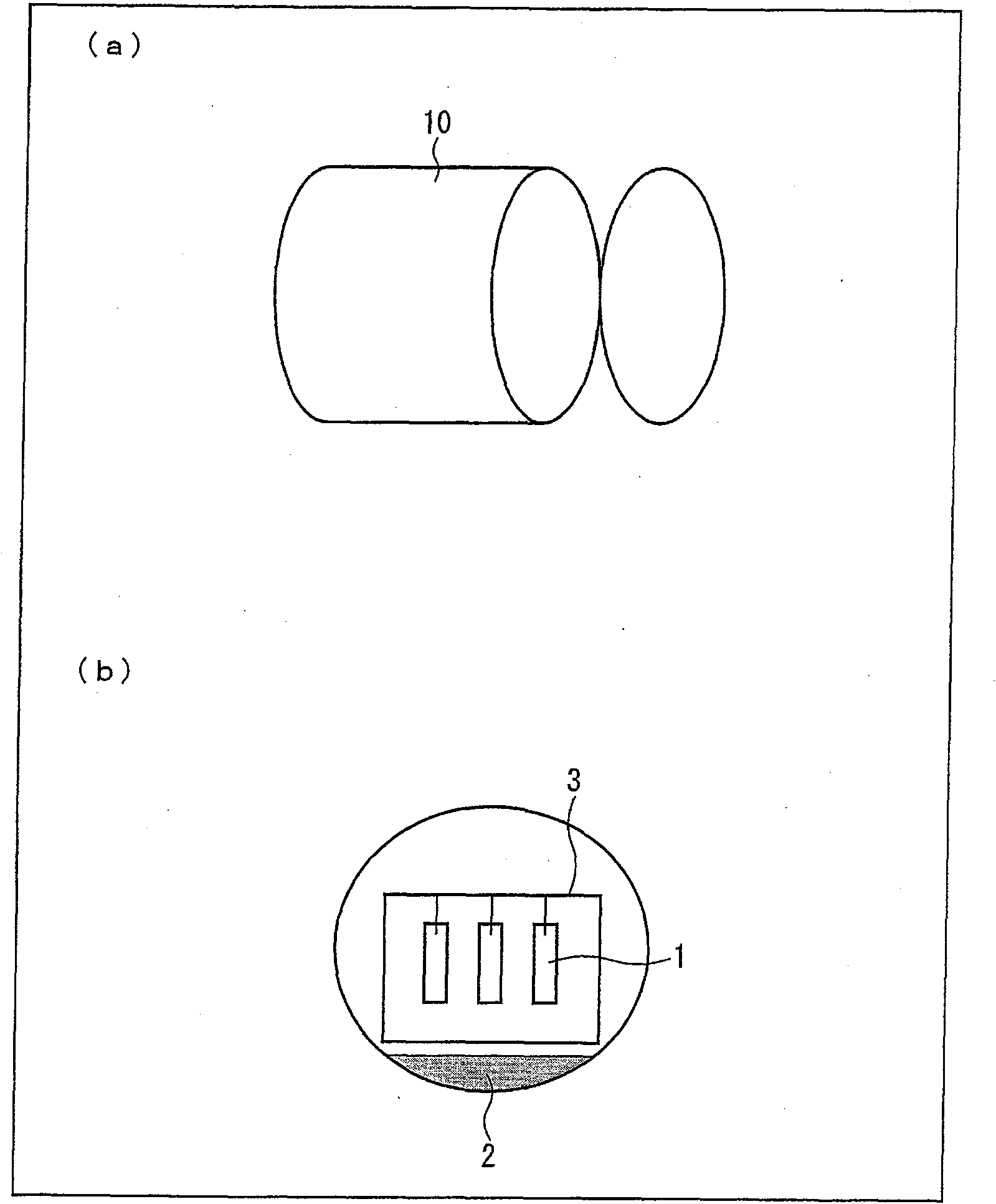

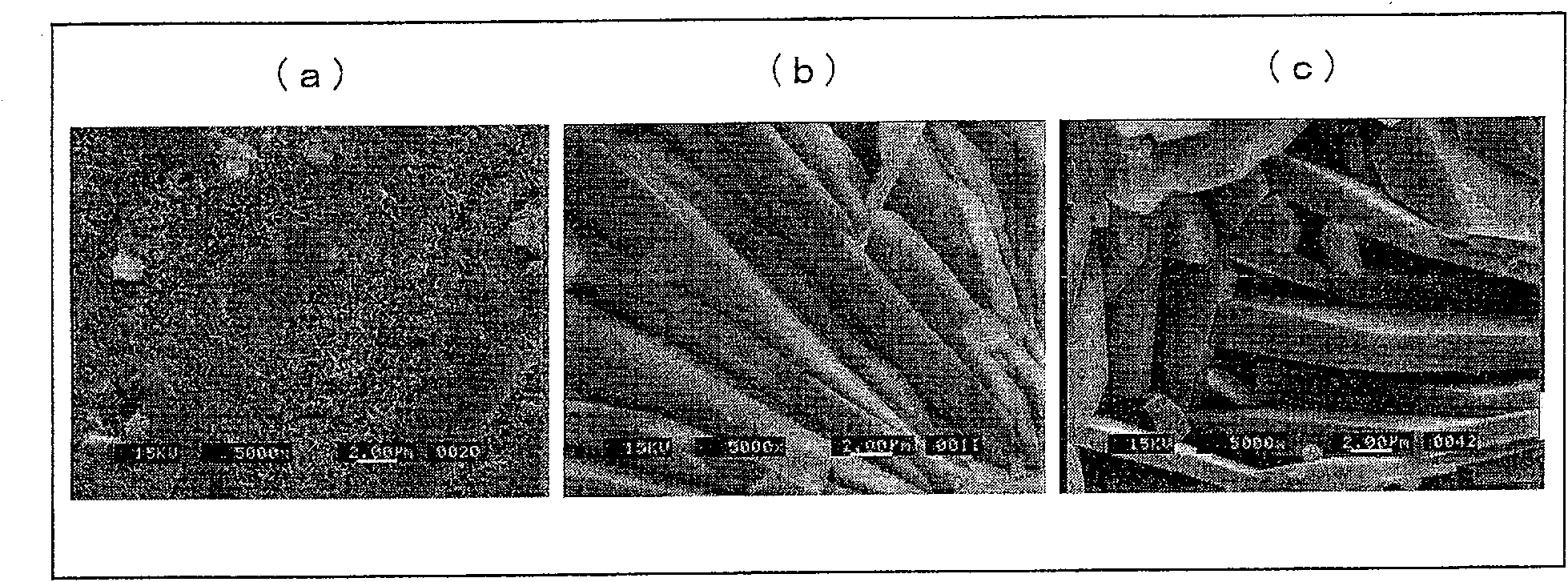

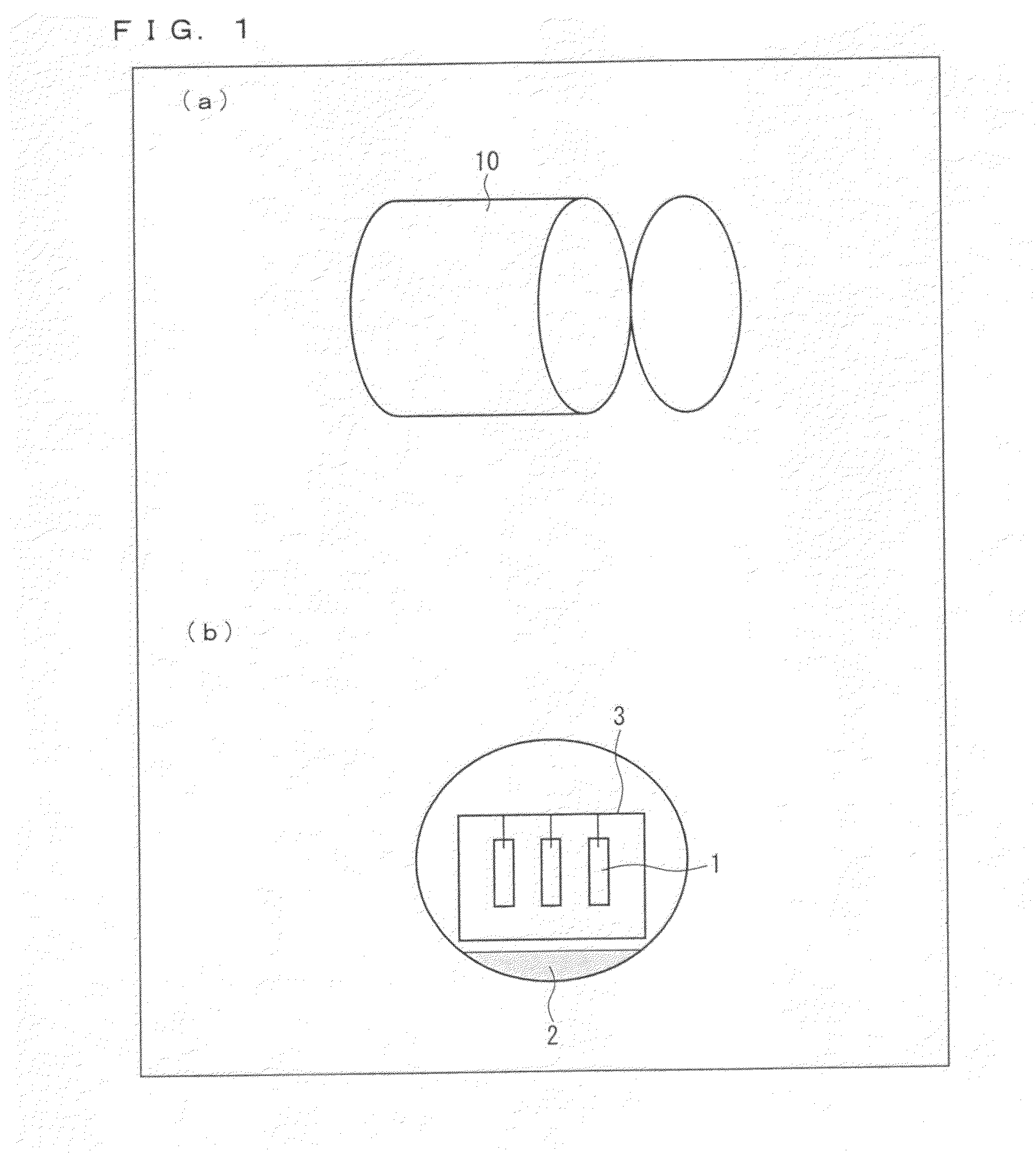

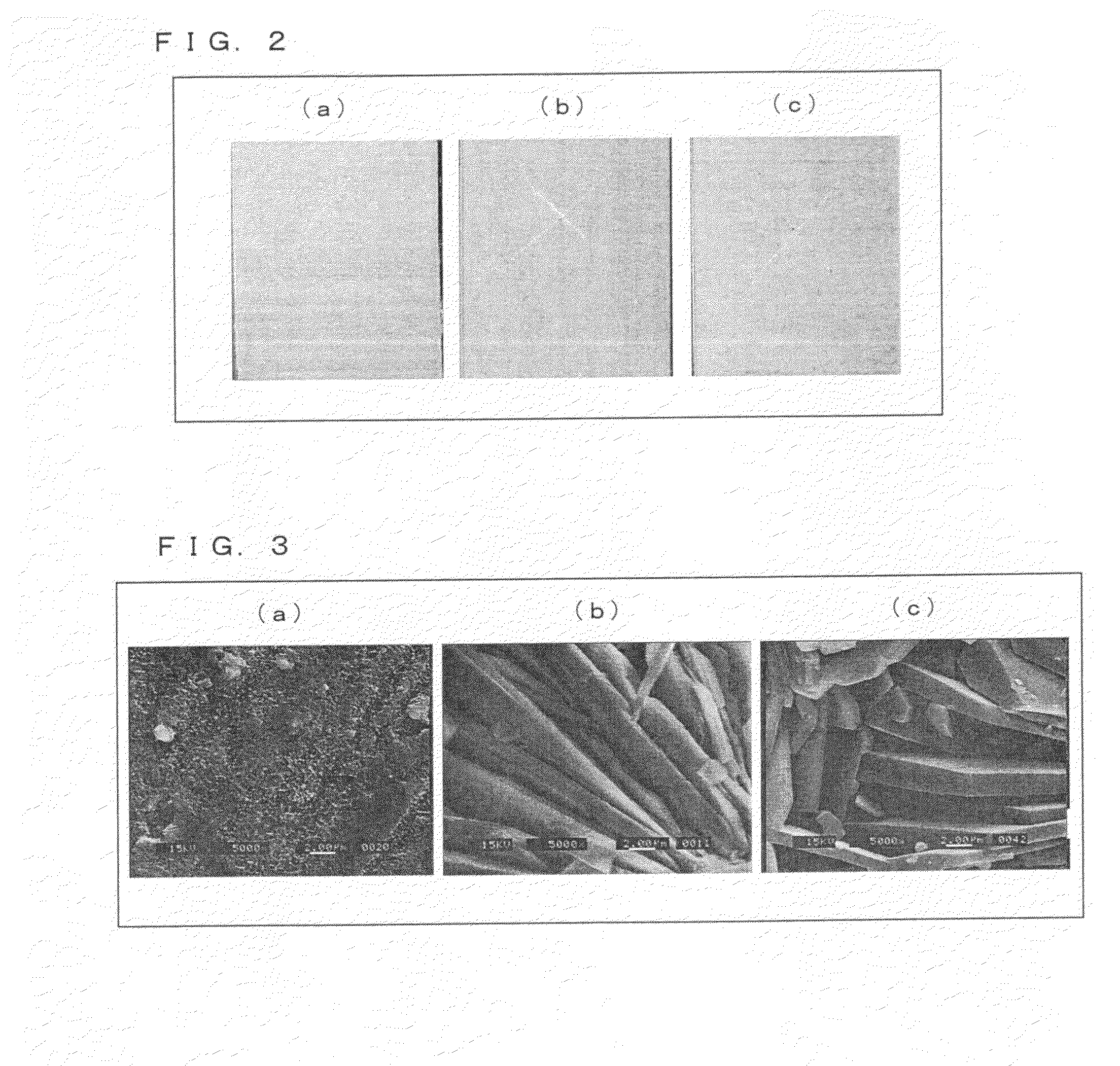

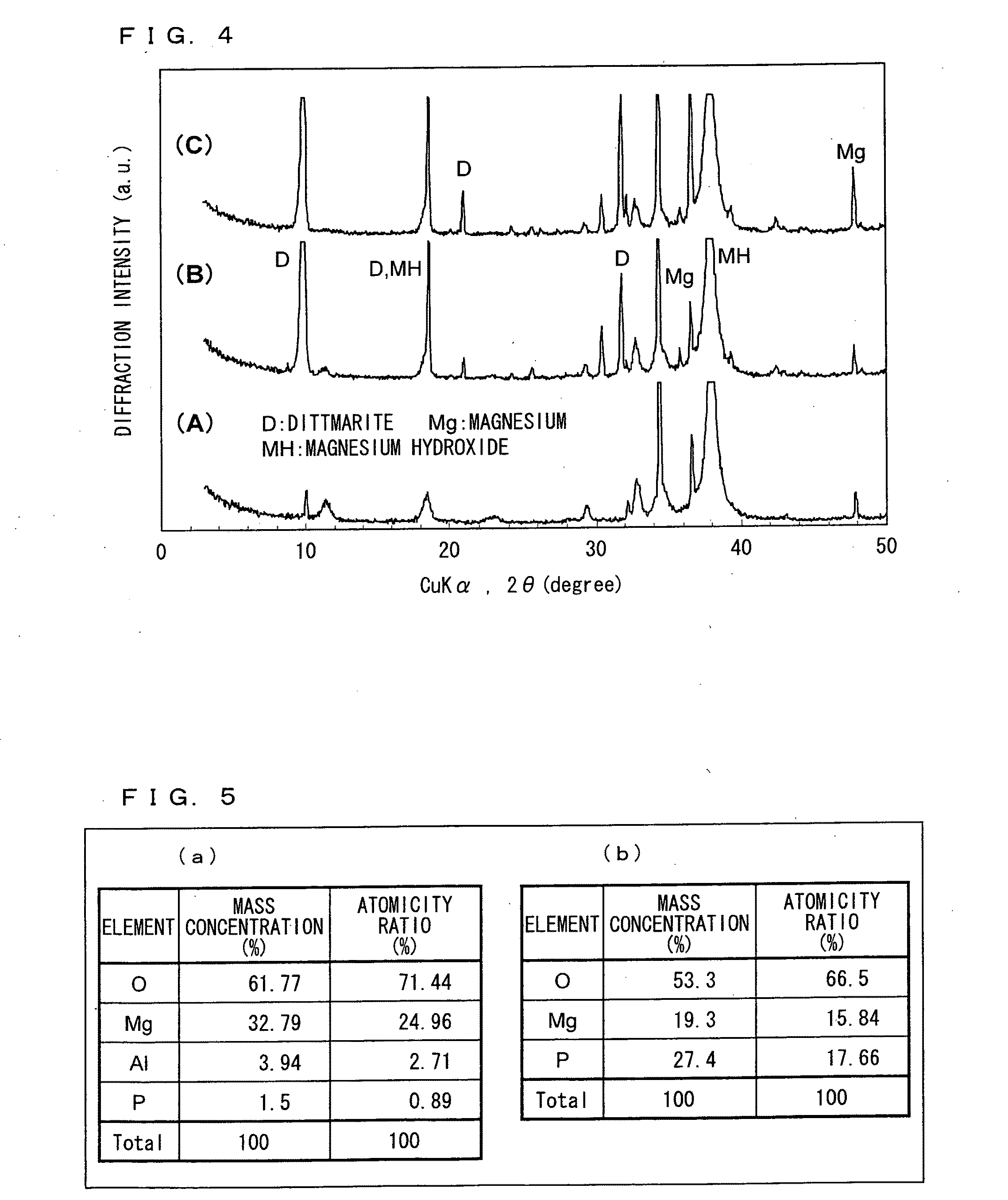

Magnesium alloy material, and method for treatment of surface of magnesium alloy material

InactiveCN101849031AAccelerated corrosionImprove impact resistanceAnodisationSolid state diffusion coatingDiammonium phosphateTriammonium phosphate

A magnesium alloy material is steam-cured with at least one compound selected from ammonium phosphate dibasic, ammonium dihydrogen phosphate and triammonium phosphate and water to form a complex of a phosphate-containing magnesium (e.g., Dittmarite) and magnesium hydroxide thereon. Thus, provided are: a magnesium alloy material having excellent corrosion resistance, impact resistance and the like; and a method for the treatment of the surface of a magnesium alloy material for producing a magnesium alloy material having excellent corrosion resistance, impact resistance and the like.

Owner:NAT INST OF ADVANCED IND SCI & TECH

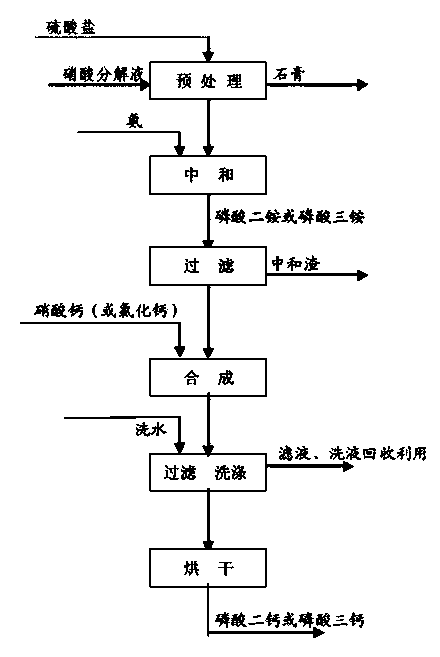

Method for preparing dicalcium phosphate and tricalcium phosphate

The invention discloses a method for preparing dicalcium phosphate and tricalcium phosphate. The method comprises: preparing diammonium phosphate and triammonium phosphate through phosphoric acid extracted from industrial phosphoric acid or sulfuric acid or a nitric acid decomposition solution obtained by nitric acid decomposition phosphorite and freezing crystallization and separation of calcium nitrate, and then, carrying out a double decomposition reaction on the diammonium phosphate and the triammonium phosphate with calcium nitrate or calcium chloride to prepare the dicalcium phosphate and the tricalcium phosphate. The specific production process comprises: step 1. neutralization and impurity removal; step 2. double decomposition; step 3. filtration and drying. The method provided by the invention can be used for preparing dicalcium phosphate or tricalcium phosphate products and further producing feed grade or food grade dicalcium phosphate or tricalcium phosphate products; and the method is simple in process, little in waste emission, environment-friendly and is applied in traditional phosphorus chemical industry to realize structure adjustment and product upgrade and update so as to generate good economic benefit and environmental protection benefit. The method is suitable for production enterprises of ammonia, nitric acid or ammonium phosphate.

Owner:顾春光

Combustible pesticidal products

A combustible pesticidal product is disclosed which comprises a structural element formed from a cardboard having a thickness of at least 0.75 mm, a density of 450-850 kgm<3> and consisting of 1 or more plies, the cardboard including: an alkali or alkaline earth metal nitrate or nitrite in an amount of from 0 to 1.83 % w / w, or an alkali or alkaline earth carbonate or bicarbonate in an amount of from 0.02 to 7.0 % w / w; one or more mineral silicates in an amount of from 0.01 to 8.0 % w / w; a phosphate in an amount of from 0.01 to 0.40 % w / w and selected from the group consisting of diammonium phosphate, monoammonium phosphate, triammonium phosphate and mixtures thereof; a boron compound in an amount of from 0.001 to 0.92 % w / w (as boron) and selected from the group consisting of boric acid, sodium tetraborate hydrous, sodium borate, potassium borate, calcium borate, zinc perborate, boronatrocalcite and mixtures thereof; one or more pesticides; and optionally a perfume and / or a dye, which product on combustion emanates the pesticide into the atmosphere. Typically the combustible product will be a mosquito coil which has been impregnated with one or more insecticides effective against mosquitoes. On combustion of the coil, insecticide is emanated into the atmosphere for a period of at least 4 hours. However, the coils of the invention may be active against mosquitoes for 8 hours or more.

Owner:RECKITT BENCKISER AUSTRALIA

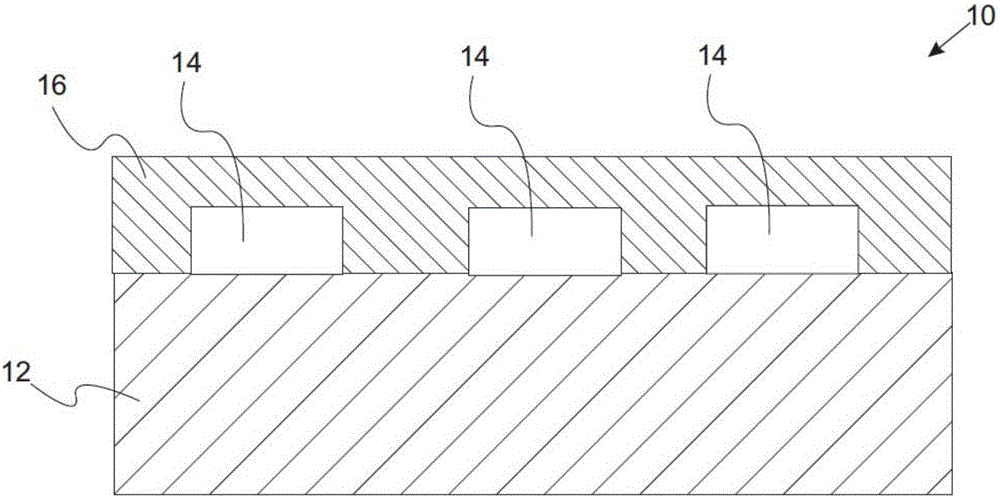

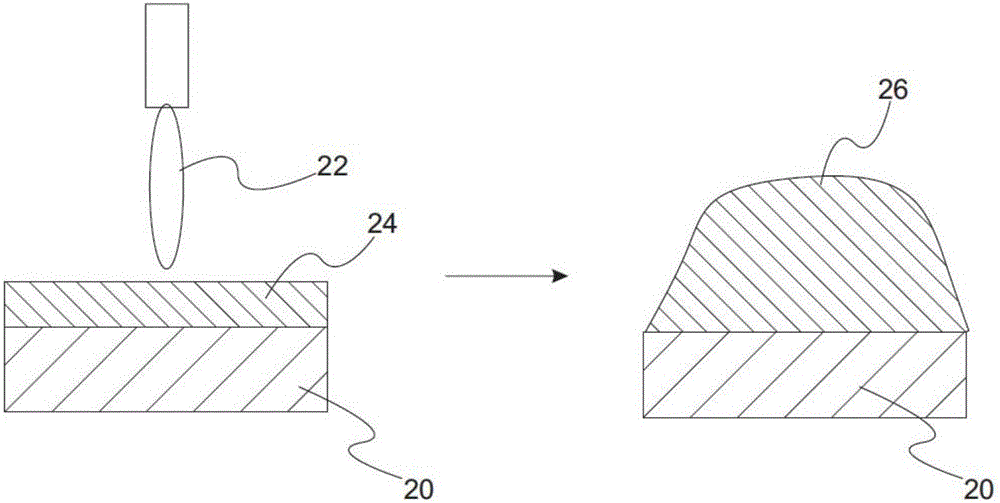

Novel Thermal Protection System for Powered Circuit Boards Including Fuses

A coated electronic device that is fire resistant includes an electronic component and an intumescent layer disposed over the electronic component. The intumescent layer includes sodium silicate having formula Na2SiO3, pentaerythitol, a resin that is cross-linked by melamine, boron nitride particles, and triammonium phosphate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Low-temperature flue gas denitration catalyst powder and preparation method of low-temperature flue gas denitration catalyst powder

InactiveCN105749943AIncreased loading areaIncrease contact areaPhysical/chemical process catalystsAmmonium paratungstateCopper nitrate

The invention discloses low-temperature flue gas denitration catalyst powder and a preparation method of the low-temperature flue gas denitration catalyst powder. The low-temperature flue gas denitration catalyst powder takes vanadium oxide, molybdenum oxide and tungstic oxide as main active components, takes phosphorus oxide, boron oxide and copper oxide as auxiliary active components and takes titanium dioxide as a carrier. The preparation method comprises the following steps: dissolving ammonium metavanadate, ammonium heptamolybdate and ammonium paratungstate into de-ionized water, and adding copper nitrate, boric acid and triammonium phosphate; heating and adjusting the pH value of the solution to be 2.0 to 3.0; slowly adding nano anatase titanium dioxide into an active component solution and dispersing the mixed active component solution by utilizing ultrasonic waves; drying and calcining to obtain the catalyst. According to the low-temperature flue gas denitration catalyst powder, the activity and the catalytic capability of the low-temperature denitration catalyst are remarkably improved; the low-temperature flue gas denitration catalyst powder has higher mechanical strength and anti-corrosion property, has stronger industrial application value and can be widely applied to NH3 selective catalytic reduction of nitrogen oxide in flue gas.

Owner:东营信拓汽车消声器有限公司

Preparation method of lithium manganese phosphate/carbon composite material

InactiveCN104916839AImprove electronic conductivityImprove electrochemical performanceCell electrodesCarbon coatingCarbon composites

The invention relates to a preparation method of a lithium manganese phosphate / carbon composite material so as to solve the problem that charge-discharge property is poor when a lithium manganese phosphate material prepared by an existing method has high magnification. The preparation method provided by the invention comprises the following steps: mixing a manganese source compound, doped compound and an ammonium phosphate compound (including ammonium biphosphate, diammonium phosphate and triammonium phosphate) by an ultrafine sand milling method to prepare a precursor with the molecular formula being NH4Mn1-xMxPO4, wherein x is less than or equal to 0.2 and greater than or equal to 0, M is any one or more elements selected from Co, Fe, Mg and Ni, and a dispersant is an organic solvent; then, uniformly mixing the NH4Mn1-xMxPO4 precursor and a lithium compound, transferring the mixture into a hydrothermal kettle, reacting at a certain temperature for an appropriate period of time, and drying to obtain a lithium manganese phosphate material; and finally, preparing the lithium manganese phosphate / carbon composite material by a thermal-treatment in-situ carbon-coating method. According to the invention, the preparation process is simple and cost is low. The prepared lithium manganese phosphate / carbon composite material has good charge-discharge property and cycle performance.

Owner:TIANJIN POLYTECHNIC UNIV

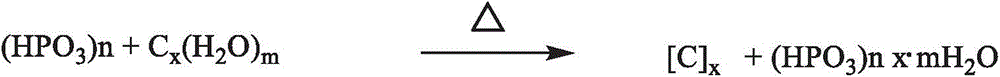

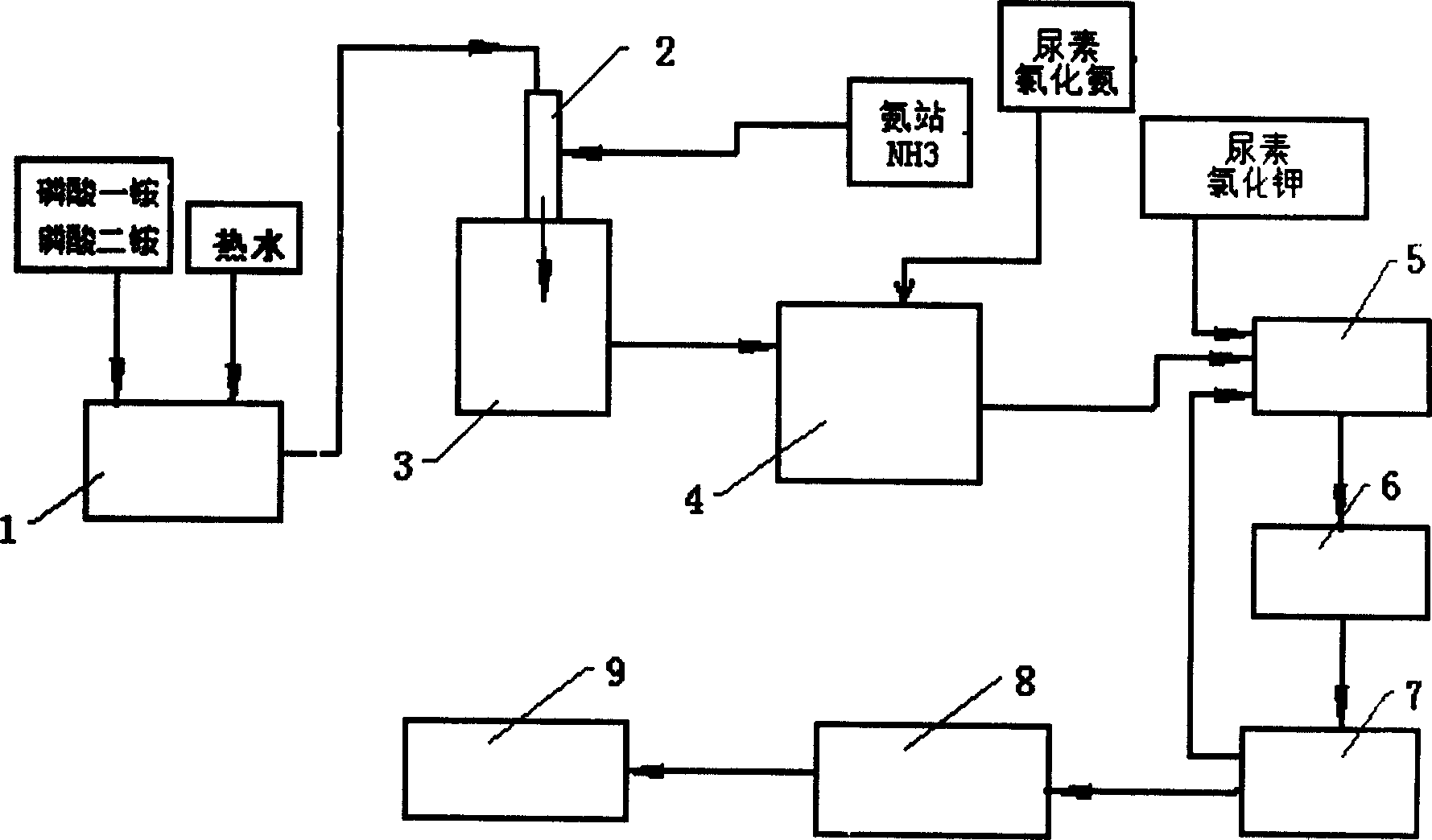

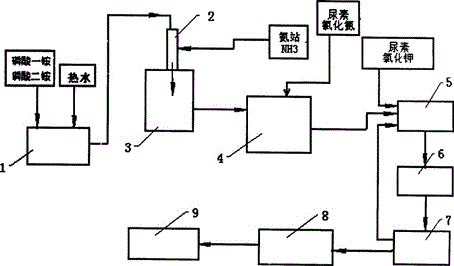

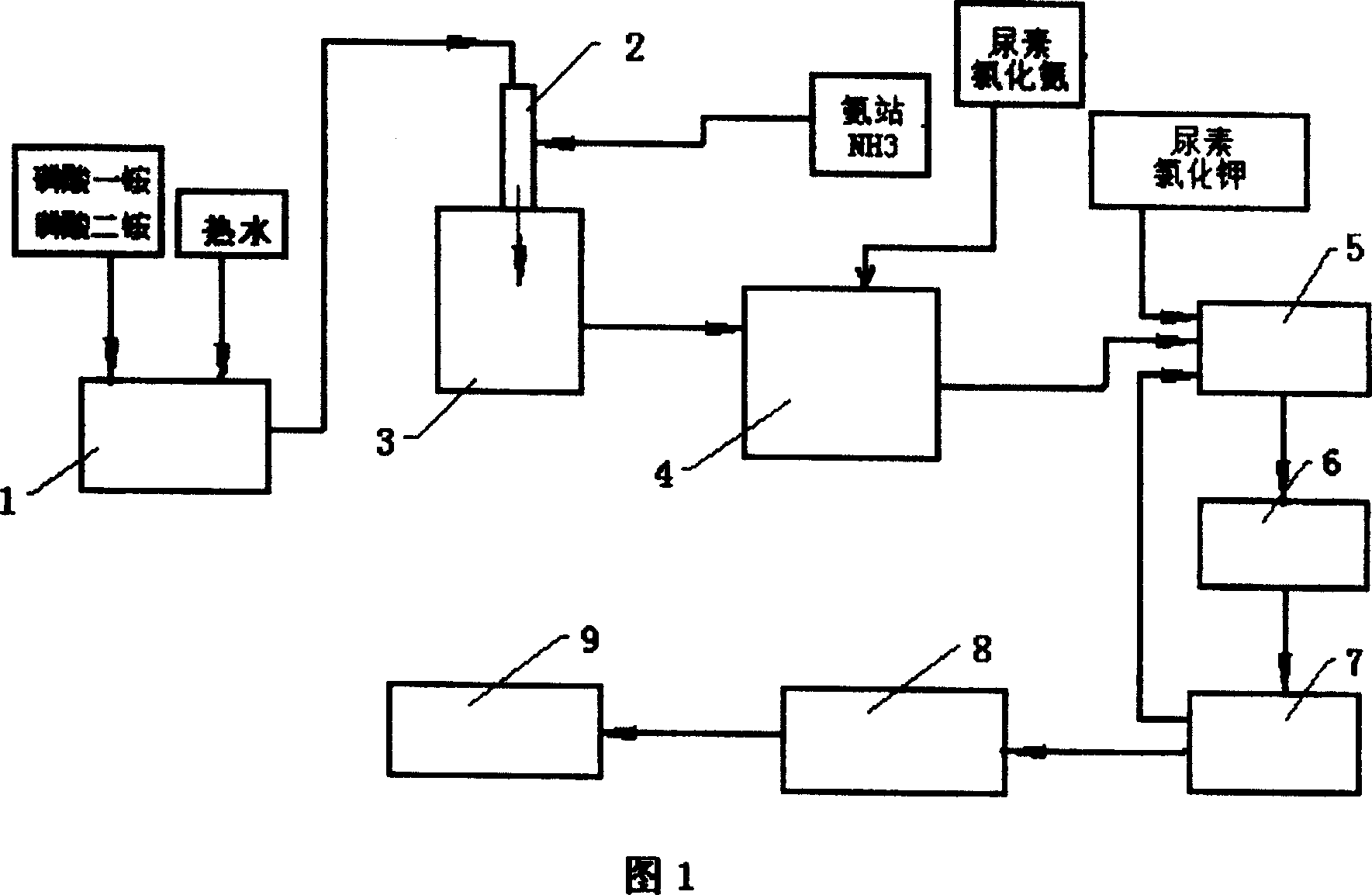

Triammonium phosphate composite fertilizer and its making process

ActiveCN1569763AEfficient productionOmit phosphoric acidAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidTriammonium phosphate

The invention provides a triammonium phosphate composite fertilizer and its making process, wherein the composite fertilizer comprises (by weight portion) urea 30-40 parts, potassium chloride 28-35 parts, phosphoric ammonium 28-35 parts, ammonium chloride 3-5 parts.

Owner:STANLEY AGRI GRP CO LTD

Combustible pesticidal products

InactiveUS20040037779A1Easily separate each helixEasy to replaceBiocideOrganic active ingredientsCardboardAlkaline earth metal

A combustible pesticidal product is disclosed which comprises a structural element formed from a cardboard having a thickness of at least 0.75 mm, a density of 450-850 kgm<3 >and consisting of 1 or more plies, the cardboard including: an alkali or alkaline earth metal nitrate or nitrite in an amount of from 0 to 1.83% w / w, or an alkali or alkaline earth carbonate or bicarbonate in an amount of from 0.02 to 7.0% w / w; one or more mineral silicates in an amount of from 0.01 to 8.0% w / w; a phosphate in an amount of from 0.01 to 0.40% w / w and selected from the group consisting of diammonium phosphate, monoammonium phosphate, triammonium phosphate and mixtures thereof; a boron compound in an amount of from 0.001 to 0.92% w / w (as boron) and selected from the group consisting of boric acid, sodium tetraborate hydrous, sodium borate, potassium borate, calcium borate, zinc perborate, boronatrocalcite and mixtures thereof; one or more pesticides; and optionally a perfume and / or a dye, which product on combustion emanates the pesticide into the atmosphere. Typically the combustible product will be a mosquito coil which has been impregnated with one or more insecticides effective against mosquitoes. On combustion of the coil, insecticide is emanated into the atmosphere for a period of at least 4 hours. However, the coils of the invention may be active against mosquitoes for 8 hours or more.

Owner:RB HYGIENE HOME AUSTRALIA PTY LTD

Preparation method of silicon-based lithium nickel phosphate composite material

InactiveCN105720245AImprove electronic conductivityImprove conductivityMaterial nanotechnologyCell electrodesCarbon coatingNickel phosphate

The invention relates to a preparation method of a silicon-based lithium nickel phosphate composite material and aims at solving the problem of poor charge and discharge performance of a lithium nickel phosphate material prepared by an existing method at a high rate. A manganese source compound, a doped compound and an ammonium phosphate compound (comprising monoammonium phosphate, diammonium hydrogen phosphate and triammonium phosphate) are mixed to prepare a precursor of which the molecular formula is SiNi<1-x>M<x>PO<4> in a superfine grinding manner; x is smaller than or equal to 0.2 and greater than or equal to 0; M is selected from one or more of Co, Fe, Mg and Ni; a dispersant is an organic solvent; the SiNi<1-x>M<x>PO<4> precursor and a lithium salt compound are mixed evenly and then transferred into a hydrothermal kettle, and are dried to obtain the lithium nickel phosphate material after reacting at a certain temperature for appropriate time; and finally the silicon-based lithium nickel phosphate composite material is prepared in a thermal treatment in-situ carbon-coating manner. The preparation method has the advantages of being simple in procedure and relatively low in cost; and the prepared silicon-based lithium nickel phosphate composite material has the advantages of relatively good charge and discharge performance and relatively good cycle performance.

Owner:TIANJIN POLYTECHNIC UNIV

Organic-inorganic compound fertilizer for increasing yield of crop

InactiveCN107118013AStrong disease resistanceImprove Nutrient Utilization EfficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCross-linkTriammonium phosphate

The invention relates to an organic-inorganic compound fertilizer for increasing yield of crops. The organic-inorganic compound fertilizer comprises the following components: 27-31 parts of rice straw, 23-26 parts of artemisia selengensis stalk, 25-29 parts of soybean straw, 28-33 parts of kieselguhr, 13-17 parts of mushroom dregs, 11-14 parts of tofu dregs, 17-21 parts of furfural residues, 43-48 parts of urea, 32-36 parts of potassium chloride, 13-16 parts of potassium sulfate, 16-19 parts of triammonium phosphate, 10-13 parts of magnesium sulfate, 8-11 parts of calcium ammonium nitrate, copper sulfate, 5-7 parts of ferrous sulfate, 3-6 parts of manganese sulfate, 2-4 parts of zinc sulfate, 43-50 parts of rice washing water, 2-4 parts of thiophanate methyl, 1-3 parts of trichloroisocyanuric acid, 3-5 parts of fenaminosulf and 17-20 parts of an acrylamide-acrylate copolymerization cross-linking agent. By adopting the organic-inorganic compound fertilizer for increasing yield of crops, the production cost of raw materials is effectively lowered, and the cost can be reduced by 52-57%.

Owner:NANJING MINGZHU FERTILIZER

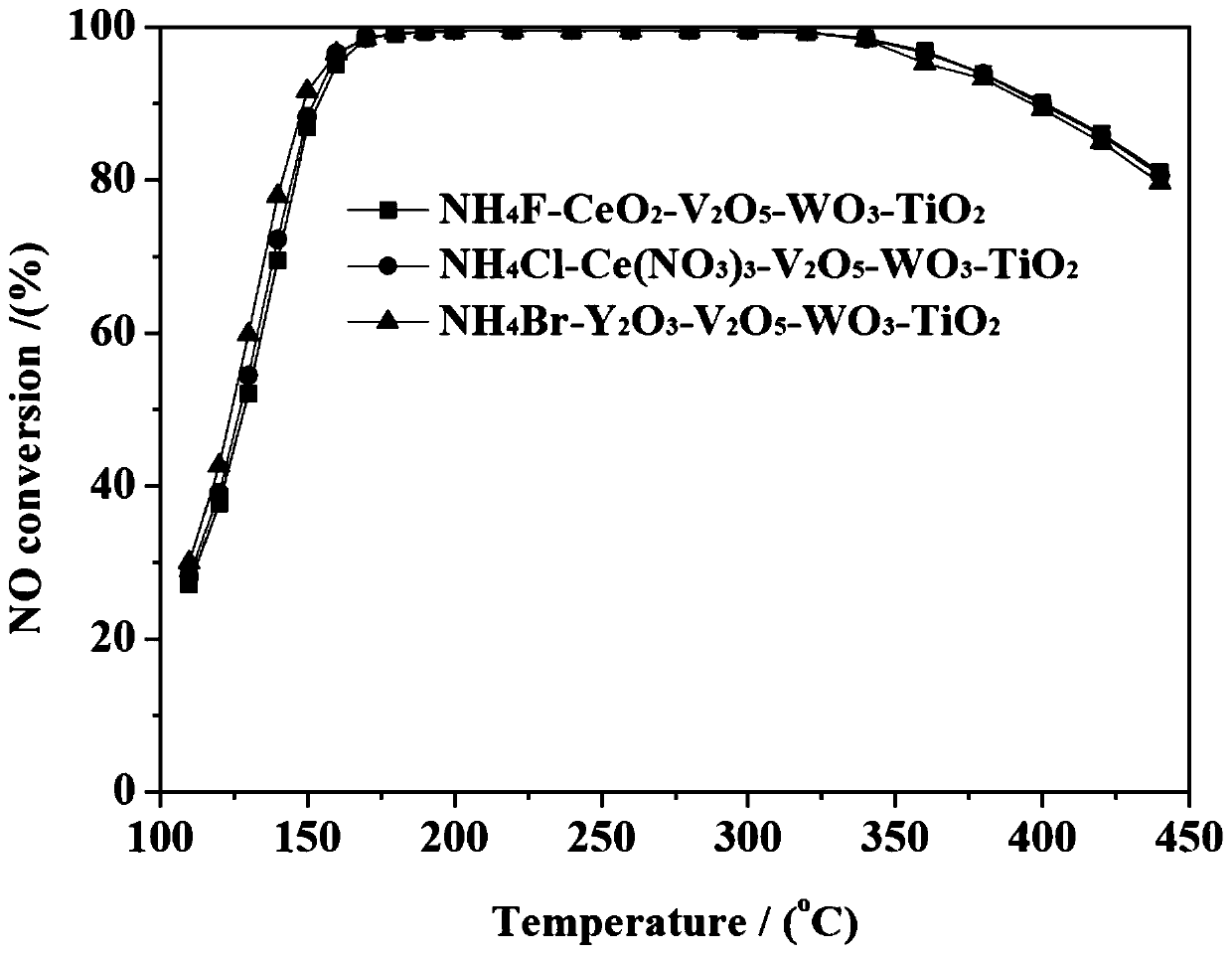

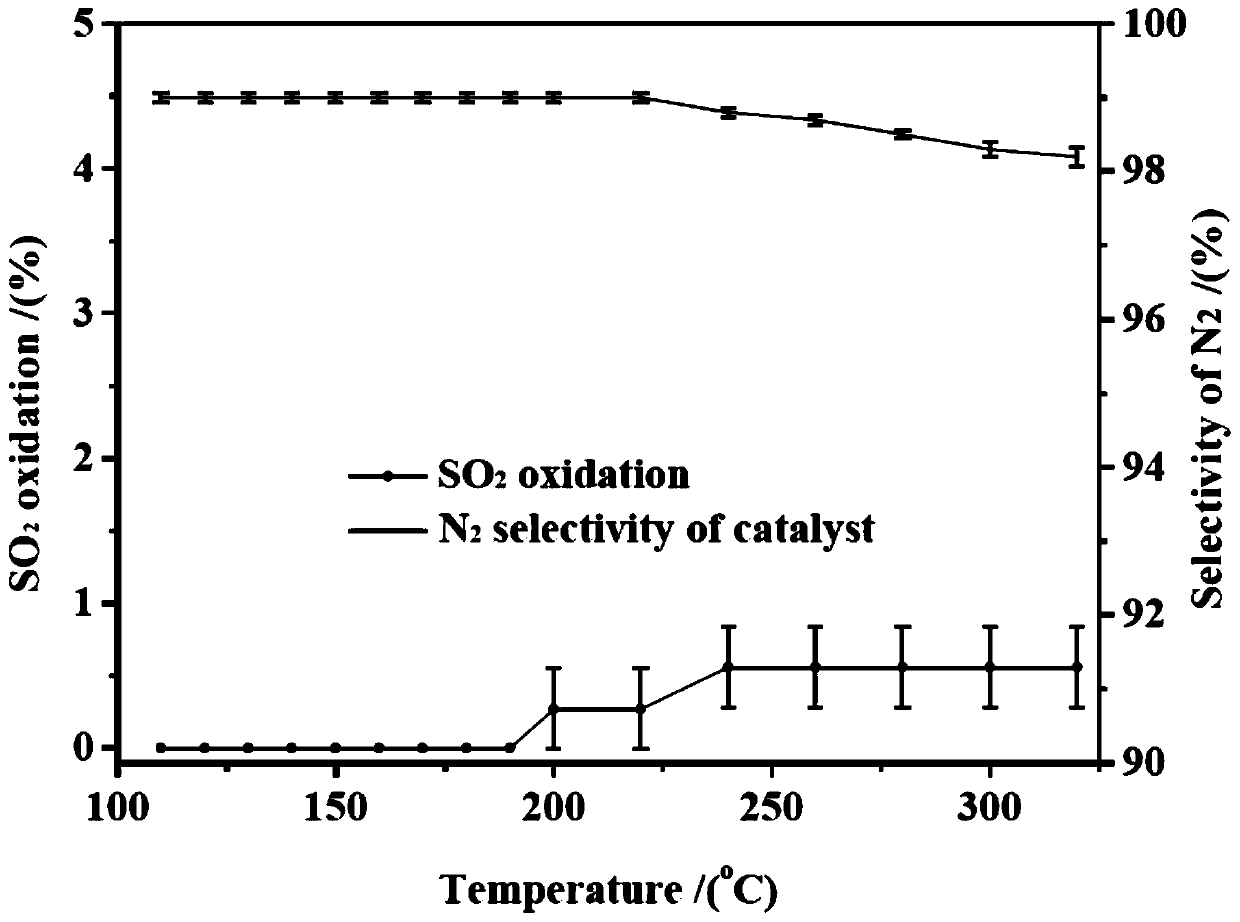

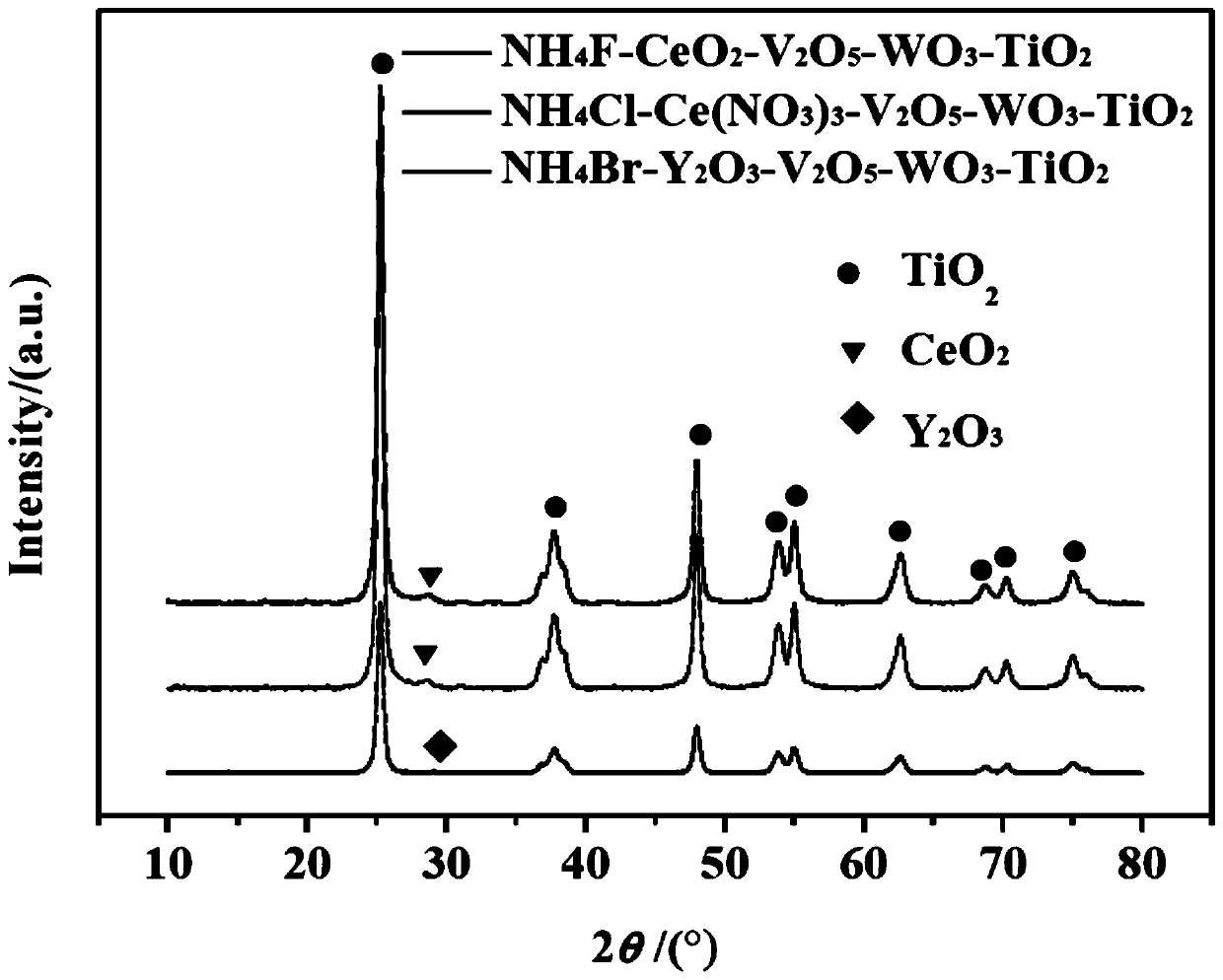

Denitration catalyst using rare earth and anion synergistically-modified titanium dioxide as carrier and preparation of catalyst

InactiveCN110142054ARaise the pHImprove denitrification performanceDispersed particle separationCatalyst activation/preparationTungstateRare earth

The invention provides a denitration catalyst using rare earth and anion synergistically-modified titanium dioxide as a carrier and preparation of the catalyst, and belongs to the field of catalytic chemistry. The preparation method comprises the steps of performing synergistic modification on a titanium dioxide carrier by adopting a rare earth compound and anions, and supporting P2O5, V2O5 and WO3, wherein a precursor of the V2O5 is ammonium metavanadate, a precursor of the WO3 is ammonium tungstate, and a precursor of the P2O5 is triammonium phosphate. The catalyst provided by the inventionhas excellent medium and low temperature catalytic activity, and a large high-activity range; and under the temperature condition of 160-320 DEG C, the NOx removal rate is maintained at 95% or more, the N2 selectivity is higher than 98%, and the SO2 oxidation rate is lower than 1%.

Owner:BEIJING UNIV OF TECH +1

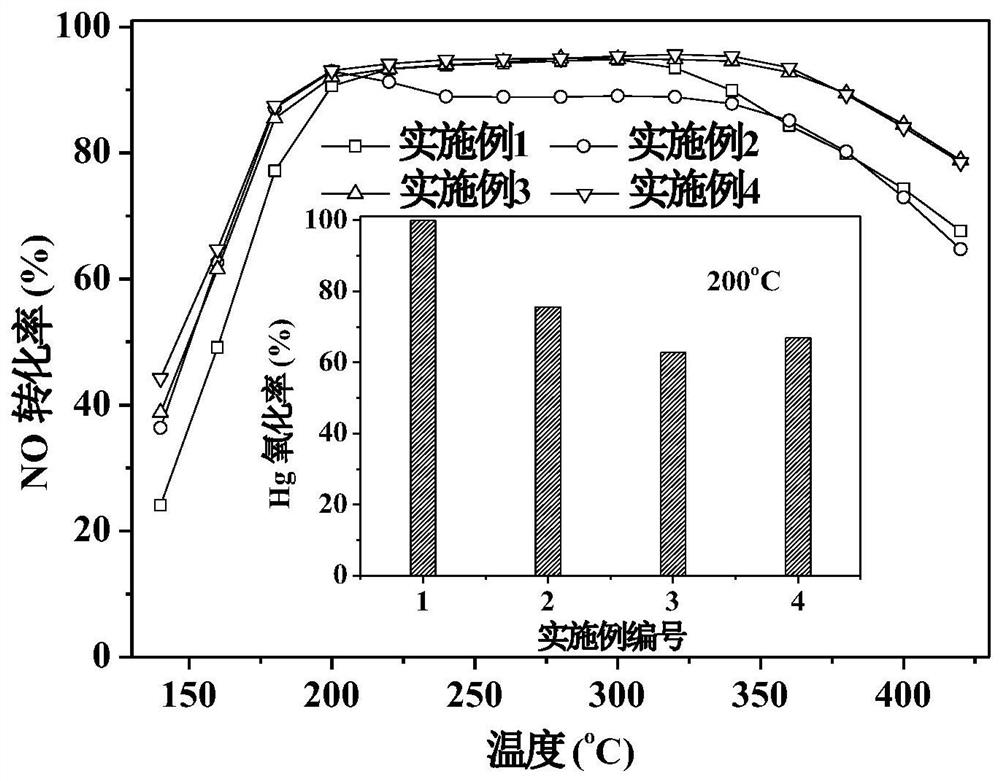

Catalyst for synergistically purifying multiple pollutants and preparation method thereof

PendingCN113750981ALow costImprove air qualityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhosphoric acid

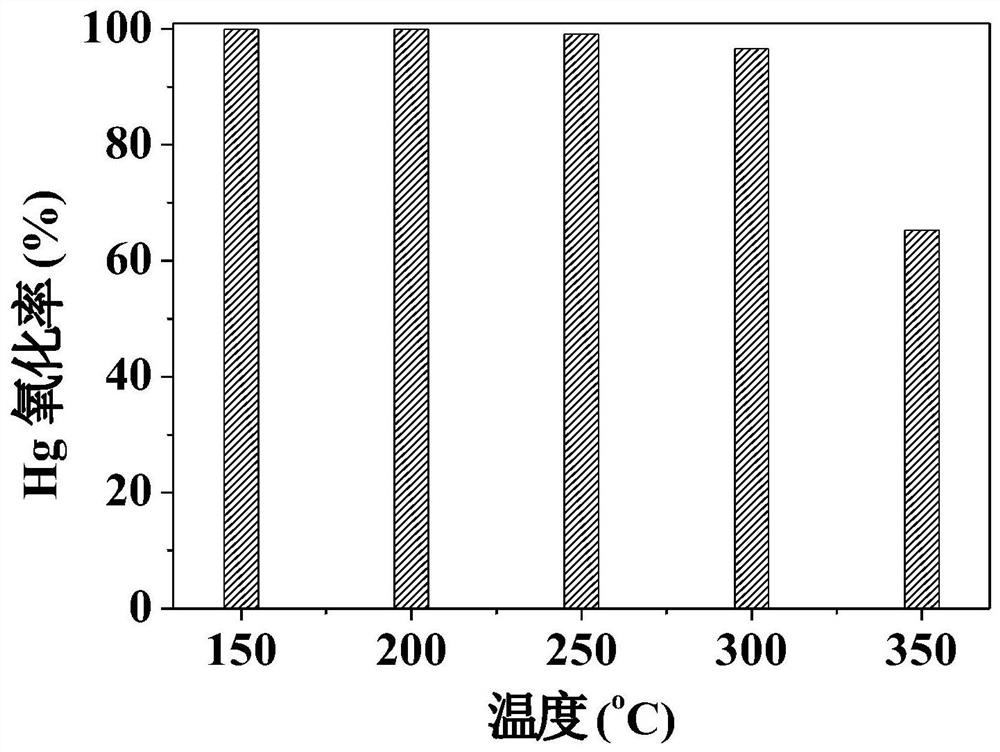

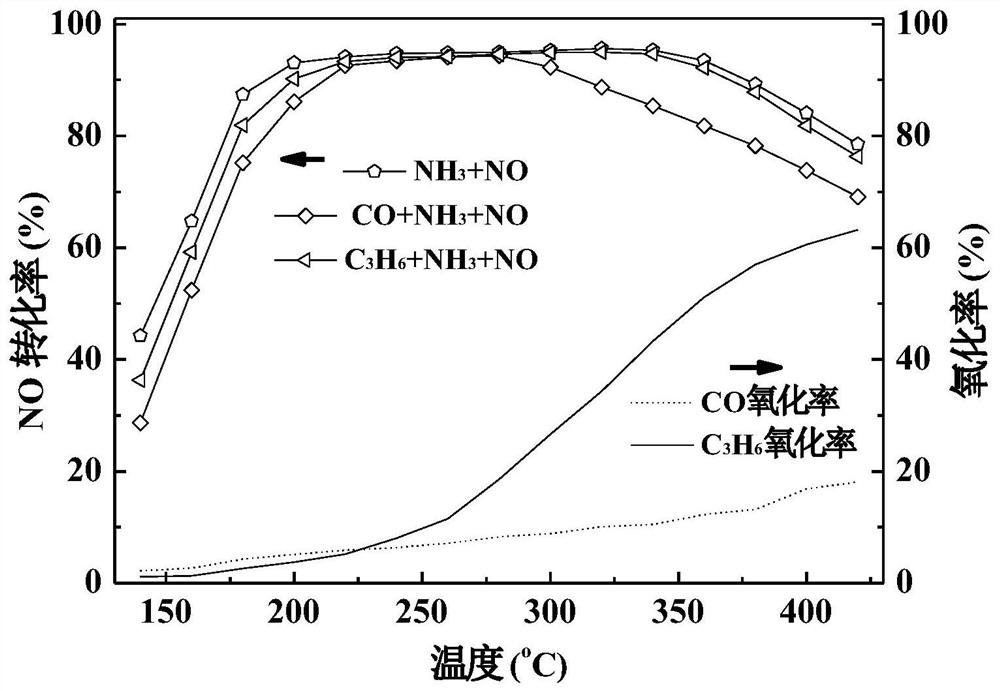

The invention relates to the field of environmental catalysis and air pollution treatment, in particular to a catalyst for synergistically purifying multiple pollutants and a preparation method thereof. The catalyst comprises the following raw materials: an active component, an auxiliary agent and a composite carrier, wherein the active component is selected from one or more metal compounds of V, Mo, W, Cu, La, Sn and Nb; the auxiliary agent is ammonium fluoride and / or triammonium phosphate; the composite carrier is a mixture of anatase titanium dioxide and gamma-aluminum oxide; and the pH value of the catalyst is 3 to 10. The catalyst disclosed by the invention can be used for synergistically purifying various pollutants, and especially for synergistically controlling NOx, CO, Hg and VOCs; wherein at the temperature of 200-360 DEG C, the NOx conversion rate reaches 90% or above; the Hg oxidation rate is greater than 95% at the temperature of 150-300 DEG C; the oxidation rate of C3H6 is greater than 50% at 360-420 DEG C; and the CO oxidation rate is greater than 10% at the temperature of 340-420 DEG C.

Owner:INST OF URBAN SAFETY & ENVIRONMENTAL SCI BEIJING ACAD OF SCI & TECH

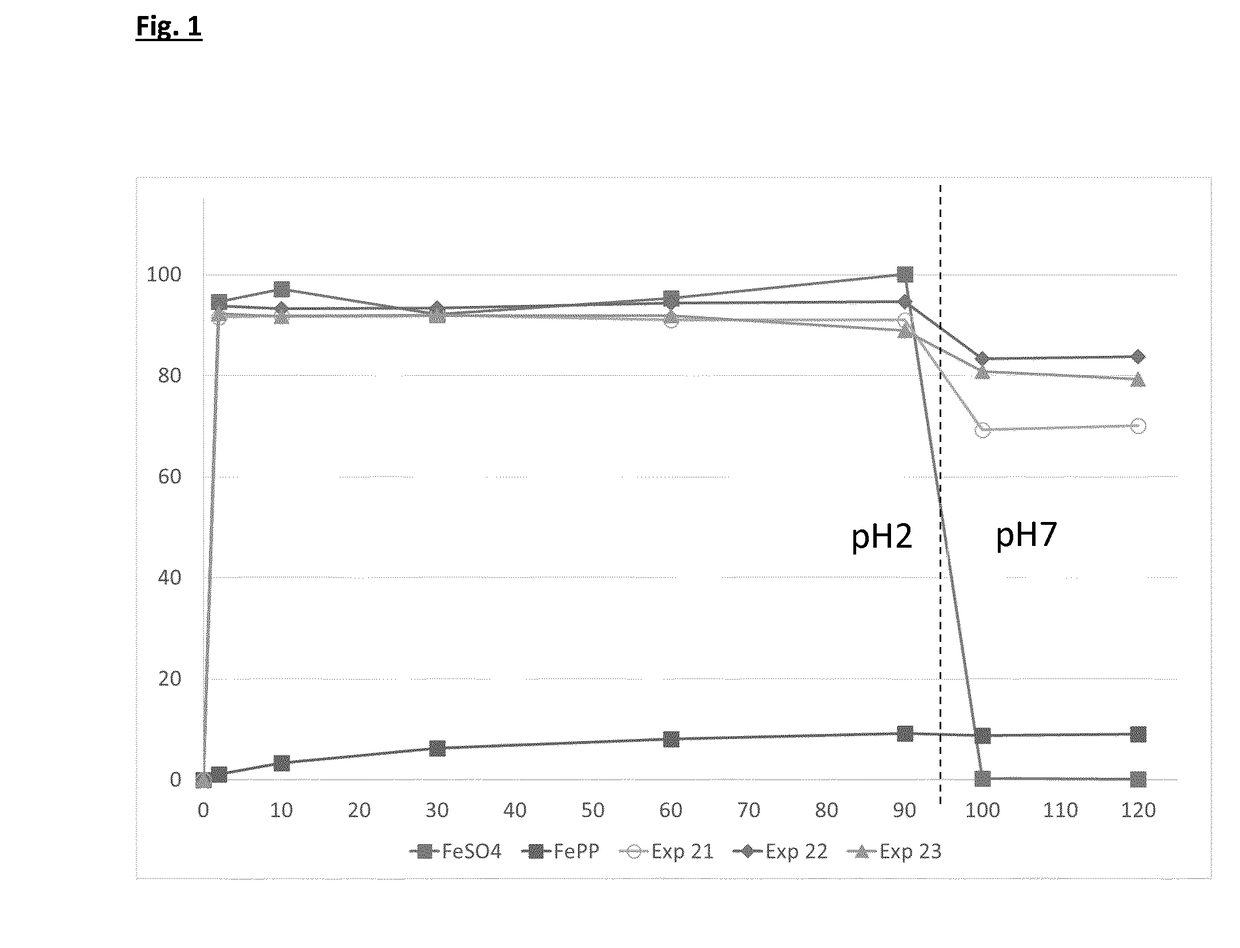

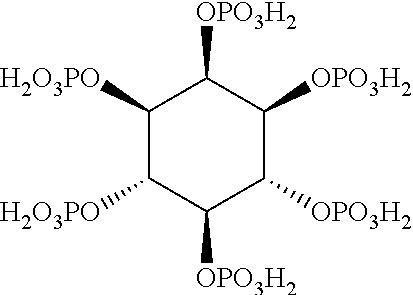

Iron-fortified food composition

ActiveUS20180249752A1Increases bioavailability of ironImprove stabilityMilk preparationHeavy metal active ingredientsAdditive ingredientSodium phosphates

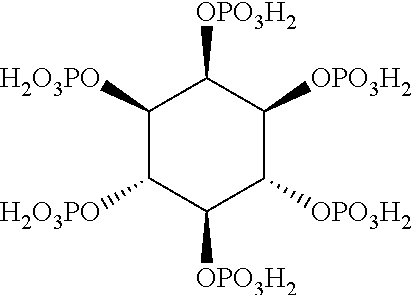

A composition for fortifying food and / or beverages comprising a complex of Fe(III), phytic acid and an amino compound selected from the group consisting of ammonium hydroxide; ammonium carbonate; ammonium phosphate dibasic; ammonium sodium phosphate dibasic and triammonium phosphate.

Owner:SOC DES PROD NESTLE SA

Method for preparing lithium iron phosphate material suitable for power battery

InactiveCN101867044AImprove electrochemical performanceRich sourcesCell electrodesPhosphorus compoundsIron saltsElectrical battery

The invention discloses a method for preparing a lithium iron phosphate material suitable for a power battery. In the method, lithium iron phosphate is taken as a substrate and the lithium iron phosphate material is prepared by mixing and sintering by a hydrothermal method, wherein the lithium iron phosphate consists of lithium salt, iron salt and phosphate; the mole ratio of lithium to iron to phosphorus is 1:1:1; the lithium salt is lithium carbonate, lithium hydroxide or lithium fluoride; the iron salt is iron acetate, ferrous chloride or iron hydroxide; and the phosphate is lithium dihydrogen phosphate, ammonium dihydrogen phosphate or triammonium phosphate. The lithium iron phosphate prepared by the method of the invention has high purity and specific capacity. Moreover, a synthesizing process of the invention has the advantages of simpleness, practicability, safety, reliability, low production cost, high yield and environmental friendliness.

Owner:IRICO

Iron-fortified food composition

ActiveUS10617140B2Improve stabilityLittle effect on their organoleptic propertiesMilk preparationOrganic active ingredientsBiotechnologySodium phosphates

A composition for fortifying food and / or beverages comprising a complex of Fe(III), phytic acid and an amino compound selected from the group consisting of ammonium hydroxide; ammonium carbonate; ammonium phosphate dibasic; ammonium sodium phosphate dibasic and triammonium phosphate.

Owner:SOC DES PROD NESTLE SA

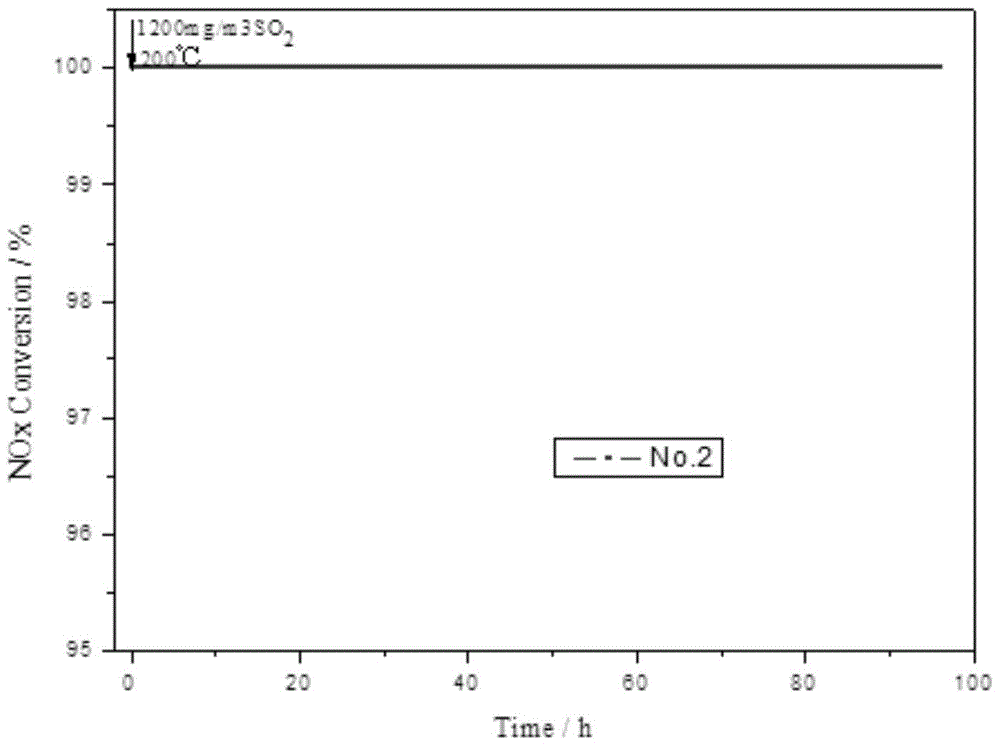

Preparation formula and preparation method of a low-temperature sulfur-resistant SCR catalyst

ActiveCN104841464BGood catalytic activity at low temperatureHigh activity temperature rangePhysical/chemical process catalystsDispersed particle separationPtru catalystTungstate

The invention provides a preparation recipe and a preparation method of a low-temperature anti-sulfur SCR (Selective Catalytic Reduction) catalyst for removing nitric oxides, belonging to the field of catalytic chemistry. A one-step dipping method is adopted to load V2O5, WO3, P2O5 and anion Br on the surface of anatase TiO2. The catalyst comprises the constituents with the following contents: 60 to 95 wt% of the TiO2, 0 to 10 wt% of the V2O5, 0 to 20 wt% of the WO3, 0 to 3 wt% of the P2O5 and 0.35 to 0.5 wt% of the Br. The precursors of the chemical constituents of the catalyst are respectively ammonium metavanadate as the precursor of the V2O5, ammonium tungstate as the precursor of the WO3, triammonium phosphate as the precursor of the P2O5 and ammonium bromide as the precursor of the Br. According to the preparation recipe, the trace non-metallic elements are loaded, sulfate generation in sulphur-containing flue gas by the catalyst is slowed down, the acid site of the catalyst is added, denitration efficiency and sulfur resistance of the catalyst are improved, and the service life of the catalyst under the low-temperature high-sulphur flue gas condition is prolonged; meanwhile, the preparation method of the catalyst is also improved, the one-step dipping method is adopted, a semifinished product drying process is reduced, the preparation time of the catalyst is shortened, and the industrialized production of the catalyst is facilitated.

Owner:BEIJING UNIV OF TECH

Water-soluble high-temperature organic acid inhibitor and preparing method and using method thereof

The invention relates to a water-soluble high-temperature organic acid corrosion inhibitor and its preparation method and use method, including: 10 to 60% of a corrosion inhibitor intermediate obtained by reacting boric acid and organic amine in a molar ratio of 1:0.5 to 3, 20~80% C1~C9 methanol, ethanol, n-propanol, isopropanol, butanol, isobutanol, 1,2-propanediol, n-pentanol, n-heptanol, n-octanol or both Monohydric or glycol solvents composed of the above components, 0.1 to 20% thiourea, benzyl chloride, sulfene, propargyl alcohol, trisodium phosphate, ammonium phosphate sulfate, diammonium phosphate, triammonium phosphate , a corrosion inhibitor film-forming component composed of one or more components of benzotriazole. Add 30 to 1000 μg / g of the corrosion inhibitor to the naphthenic acid corrosion medium, and is suitable for inhibiting 200 ~400℃ high temperature naphthenic acid corrosion in refinery vacuum tower, resistant to hydrogen sulfide and hydrogen chloride corrosion, with a corrosion inhibition efficiency of over 90%.

Owner:PETROCHINA CO LTD

A flame-retardant polyethylene cable material with anti-mold function

ActiveCN103509228BGrowth inhibitionFree from harmInsulatorsZinc hydroxideLinear low-density polyethylene

The invention provides a flame-retardant polyethylene cable material capable of preventing mould. The flame-retardant polyethylene cable material is prepared with the following components and raw materials by weight: 50-60 parts of high-density polyethylene, 30-45 parts of linear low-density polyethylene, 10-15 parts of polyester resin, 8-10 parts of organic silicon resin, 2-3 parts of simethicone, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 1-2 parts of barium sulfate, 5-6 parts of dolomite, 6-8 parts of attapulgite, 4-6 parts of celestite, 10-12 parts of zinc hydroxide, 10-15 parts of triammonium phosphate, 10-12 parts of tricresyl phosphate (TCP), 6-8 parts of poly(1,2-propylene glycol adipate), 1-2 parts of sophora flavescens alcohol extract, 0.5-0.6 parts of zanthoxylum oil, 1-2 parts of OBPA (10,10'-oxybisphenoxarsine) mould inhibitor, 1-1.5 parts of PVC (polyvinyl chloride) processing agent ACR-401 (acrylate plastic modifier), and 10-15 parts of modified filler. The cable wire has good antibacterial property, and the characteristics of weather resistance, low smoke, ageing resistance, flame retardation and so on.

Owner:蚌埠尚维知识产权运营有限公司

Special fire-fighting long-distance fire extinguishing particles and preparation method thereof

The invention belongs to a fire extinguishing material and a preparation method thereof, and particularly relates to special fire-fighting long-distance fire extinguishing particles and a preparationmethod thereof. Raw materials adopted by the special fire-fighting long-distance fire extinguishing particles are ceramsite prepared from perlite, vermiculite, shale, fired coal gangue, biological sludge, clay and fly ash, wherein the particle size of the ceramsite is generally 2-15 mm, the maximum particle size of the ceramsite is 20 mm, the internal structure of the ceramsite is characterized bybeing fine honeycomb micropores, and the ceramsite is composed of 49-51 parts by weight of optional one of the raw materials; sodium bicarbonate or potassium bicarbonate, triammonium phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate and a mixture of the sodium bicarbonate or potassium bicarbonate, triammonium phosphate, diammonium hydrogen phosphate and ammonium dihydrogen phosphate are used. According to the special fire-fighting long-distance fire extinguishing particles and the preparation method thereof, the fire extinguishing particles granulated by different materials are respectively adopted according to the stacked material properties of fire scenes, so that the physical effect of quickly striking, striking, burying and covering a fire source and the chemicaleffect of inhibiting flame combustion are achieved.

Owner:刘大为

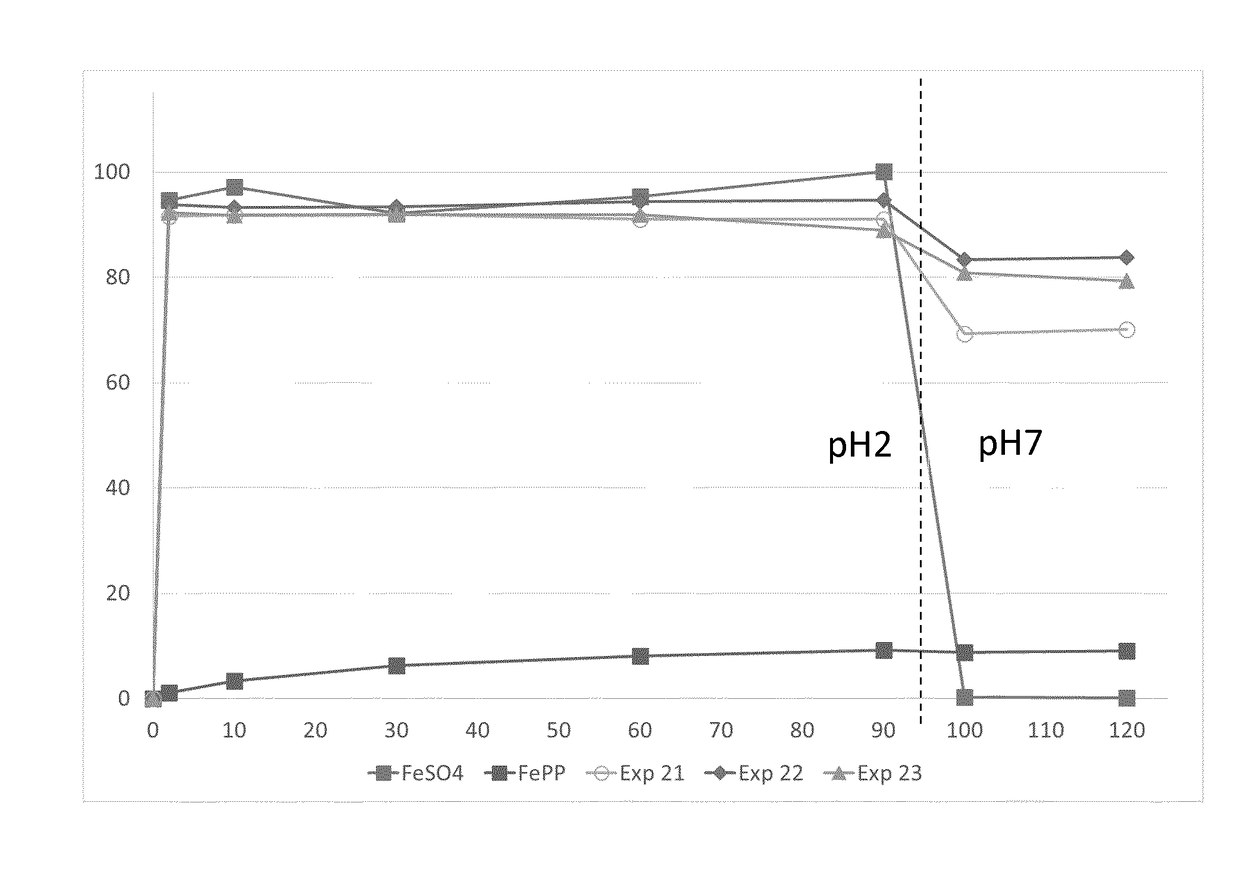

An antiperspirant composition comprising reactive salts

The present invention is in the field of antiperspirant compositions, in particular, compositions comprising antiperspirant actives. Disclosed is an aqueous antiperspirant composition having pH 2 to 5, comprising a phase wherein said phase comprises: (i) a water-soluble phosphate salt; and (ii) a water-soluble non-phosphate salt; wherein said water-soluble non-phosphate salt is the salt of a carboxylic acid, amino acid or a sulfonic acid; wherein said water-soluble non-phosphate salt is selected from calcium gluconate, calcium formate, calcium lactate, calcium propanoate, calcium acetate, calcium dobesilate, magnesium citrate, magnesium gluconate, magnesium acetate, magnesium lactate, magnesium malate, zinc citrate, zinc gluconate, copper (II) acetate, copper (II) gluconate, iron (III) citrate, calcium glycinate, zinc glycinate, copper glycinate, zirconium chloride glycinate, lanthanum acetate and silver acetate; wherein said water-soluble phosphate salt is selected from monosodium phosphate, disodium phosphate, trisodium phosphate, monopotassium phosphate, dipotassium phosphate, dipotassium phosphate, monoammonium phosphate, diammonium phosphate, triammonium phosphate, lithium dihydrogen phosphate, dilithium hydrogen phosphate and lithium phosphate; wherein said composition is not a dentifrice; wherein the solubility of said salt in water is assessed at 25° C. and atmospheric pressure.

Owner:CONOPCO INC D B A UNILEVER

Triammonium phosphate compound fertilizer and preparation method thereof

InactiveCN107032845AEfficient productionSave repeated construction investmentFertilizer mixturesO-Phosphoric AcidSlurry

A triammonium phosphate compound fertilizer and its manufacturing method, which adopts an ammonification synthesis process in which the raw materials monoammonium phosphate and diammonium phosphate are excessively ammonified, and the neutralization degree reaches 1.3-1.5, and phosphoric acid meeting the process requirements is prepared. Triammonium mixed slurry, then added triammonium phosphate stabilizer, pumped to the drum granulator, mixed with potassium chloride (potassium sulfate), urea and other raw materials from the batching process, and then granulated, and then dried Drying machine, screening machine, cooling machine and other equipment and coating treatment to produce high-efficiency triammonium phosphate compound fertilizer. The composition of the triammonium phosphate compound fertilizer of the present invention: (weight ratio) urea: 30-40 parts; potassium chloride: 28-35 parts; ammonium phosphate: 28-35 parts; ammonium chloride: 3-5 parts. The invention has the advantages that: at the microscopic molecular level, raw materials such as urea, potassium chloride, triammonium phosphate, diammonium phosphate, monoammonium phosphate and potassium sulfate are used to form a balanced and stable nutrient unit. It can save the front process such as phosphoric acid neutralization and ammoniation, and save construction investment.

Owner:刘从双

Manufacture method for triammonium phosphate compound fertilizer

InactiveCN106699280AEfficient productionOmit phosphoric acidAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphatePhosphoric acid

The present invention discloses a triammonium phosphate compound fertilizer and a manufacture method thereof. An ammoniation synthetic technology of over-ammoniation of raw materials of monoammonium phosphate and diammonium phosphate and with a degree of neutralization reaching 1.3-1.5 is used to prepare triammonium phosphate mixed material slurry in line with the requirements of the technology, then a triammonium phosphate stabilizer is added, the materials are sent into a roller granulator, the materials are mixed evenly with the raw materials of potassium chloride (potassium sulfate), urea, etc. sent by accessory material processes, the mixture is granulated, then the granulated mixture is subjected to a dryer, a sieving machine, a cooler, etc. and the treated mixture is subjected to a coating treatment to obtain the triammonium phosphate high-efficient compound fertilizer. The triammonium phosphate compound fertilizer consists of the following compositions in weight ratios: 31-45 parts of urea, 25-30 parts of potassium chloride, 28-35 parts of ammonium phosphate and 3-5 parts of ammonium chloride. The advantages are as follows: the urea, potassium chloride, triammonium phosphate, diammonium phosphate, monoammonium phosphate, potassium sulfate, etc. in the microscopic molecular level are used to form the balanced and stable nutrient units. The method can save the former working procedures of phosphoric acid neutralization, ammoniation, etc. and save construction investments.

Owner:李志强

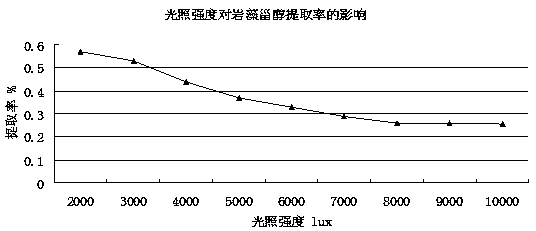

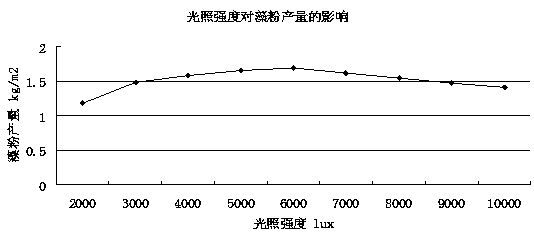

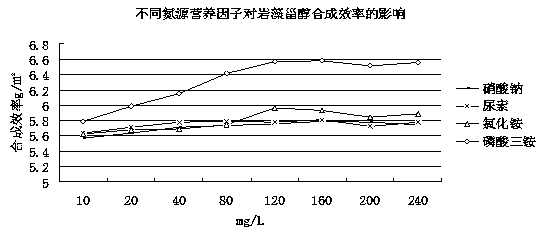

Technology for increasing efficiency of synthesizing fucosterol from sargassum thunbergii

PendingCN111235207AImprove resource utilizationReduce energy consumptionMicroorganism based processesSteroidsBiotechnologySodium metasilicate

The invention belongs to the technical field of biological culture of algae, and discloses a technology for increasing the efficiency of synthesizing fucosterol from sargassum thunbergii. The technology comprises steps as follows: the sargassum thunbergii is inoculated to a sargassum thunbergii culture solution for culture, and algae are collected; and the sargassum thunbergii culture solution isprepared by extra addition of sodium metasilicate nonahydrate and triammonium phosphate on the basis of f / 2 culture medium. Nutrient substances and illumination conditions of a cultivating environmentare regulated and controlled purposefully in the cultivating process of sargassum thunbergii seedlings, and by means of appropriate nutritive salt concentration and proportion, higher fucosterol synthesis rate can be realized.

Owner:HANGZHOU BROTHER BIO TECH CO LTD

Magnesium alloy material, and method for treatment of surface of magnesium alloy material

InactiveUS20100196726A1Reduce solubilityAccurate temperatureAnodisationPretreated surfacesHydrogen phosphateDiammonium phosphate

A magnesium alloy material contains a complex made from a phosphate-containing magnesium, such as dittmarite and the like, and magnesium hydroxide, the complex being formed by a steam curing of the magnesium alloy material conducted using (i) at least one compound chosen among diammonium hydrogen phosphate, ammonium dihydrogen phosphate, and triammonium phosphate, and (ii) water. In this way, it is possible to provide a magnesium alloy material having excellent corrosion resistance, shock resistance and the like, and to provide a method for treatment of surface of magnesium alloy material allowing the manufacture of a magnesium alloy material having excellent corrosion resistance, shock resistance and the like.

Owner:NAT INST OF ADVANCED IND SCI & TECH

An antiperspirant composition comprising reactive salts

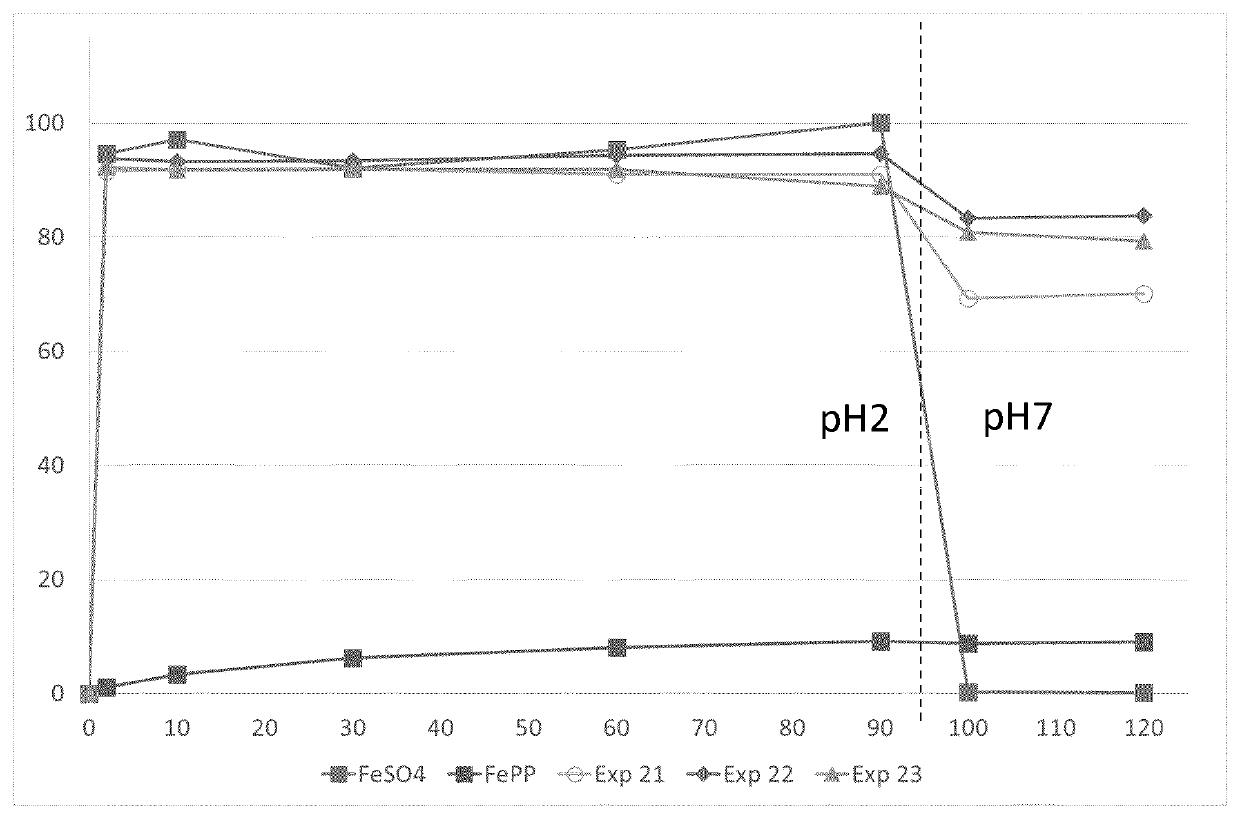

PendingUS20220168195A1Reduce sweatingAvoid problemsCosmetic preparationsToilet preparationsIron sulfatePropanoic acid

The present invention is in the field of antiperspirant compositions, in particular, compositions comprising antiperspirant actives. Disclosed is an aqueous antiperspirant composition having pH 2 to 5, comprising: (i) a water-soluble phosphate salt; (ii) a water-soluble non-phosphate salt; and, (iii) a retarding agent; wherein said water-soluble phosphate salt is selected from monosodium phosphate, disodium phosphate, trisodium phosphate, monopotassium phosphate, dipotassium phosphate, tripotassium phosphate, monoammonium phosphate, diammonium phosphate, triammonium phosphate, lithium dihydrogen phosphate, dilithium hydrogen phosphate and lithium phosphate; wherein said water-soluble non-phosphate salt is selected from calcium chloride, calcium gluconate, calcium nitrate, calcium bromide, calcium formate, calcium lactate, calcium propanoate, calcium acetate, calcium dobesilate, magnesium chloride, magnesium nitrate, magnesium sulphate, magnesium citrate, magnesium gluconate, magnesium acetate, magnesium lactate, magnesium malate, ferric chloride, ferric nitrate, ferric sulphate, zinc chloride, zinc nitrate, zinc citrate, zinc sulphate, zinc gluconate, copper chloride, copper sulphate, copper nitrate, copper(II) acetate, copper(II) gluconate, iron(III) citrate, zirconium nitrate, zirconium tetrachloride, zirconium oxychloride, strontium chloride, strontium nitrate, barium chloride, barium nitrate, lanthanum chloride, lanthanum acetate, Tin(II) chloride, Tin (IV) chloride, and silver nitrate; wherein said retarding agent is a compound which comprises at least one functional group selected from —COOH, —COO−, —SO3H or —SO3−; wherein said composition is not a dentifrice; wherein said water-soluble phosphate salt, water-soluble non-phosphate salt and retarding agent are present in one phase; wherein the solubility of said salt in water is assessed at 25° C. and atmospheric pressure.

Owner:CONOPCO INC D B A UNILEVER

Triammonium phosphate composite fertilizer and its making process

ActiveCN1312081CEfficient productionSave repeated construction investmentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidTriammonium phosphate

The invention provides a triammonium phosphate composite fertilizer and its making process, wherein the composite fertilizer comprises (by weight portion) urea 30-40 parts, potassium chloride 28-35 parts, phosphoric ammonium 28-35 parts, ammonium chloride 3-5 parts.

Owner:STANLEY AGRI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com