Method for preparing lithium iron phosphate material suitable for power battery

A lithium iron phosphate, power battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of poor conductivity, low specific capacity, low purity of lithium iron phosphate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a lithium iron phosphate material suitable for power batteries, comprising the steps of:

[0027] (1). Preparation of nanoscale lithium iron phosphate primary particles

[0028] According to the proportion of the three salts being P:Fe:Li=1:1:1, the three medicines were weighed and dissolved in water respectively, stirred with a magnetic stirrer, and the pH range of the solution was measured to be about 7. The fully stirred solution was poured into a round-bottomed flask for heating in an oil bath at a temperature of 100-130°C. After 1-2 hours of heating, a precipitate formed at the bottom. After repeated filtration and separation, primary particles of lithium iron phosphate were obtained.

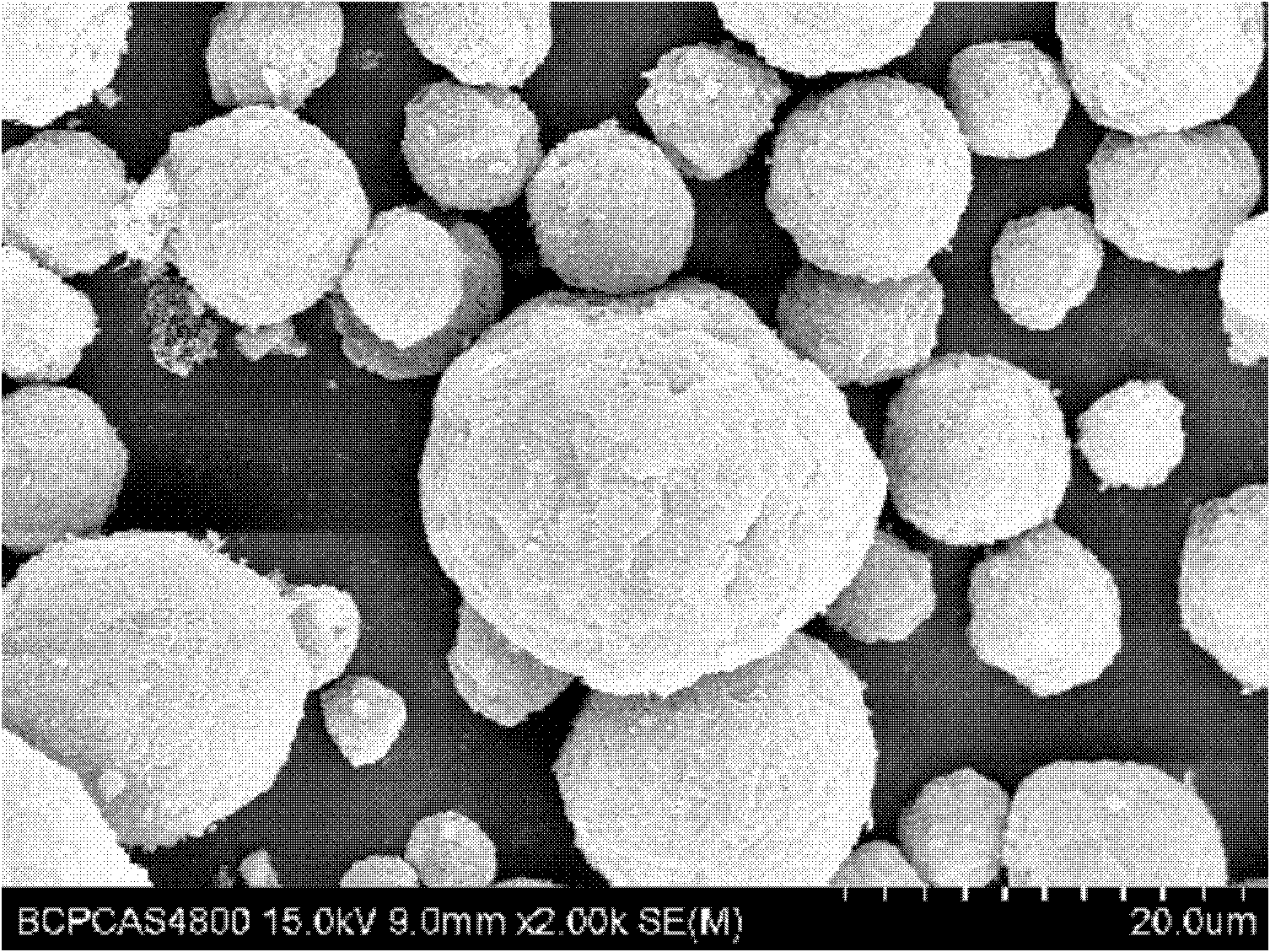

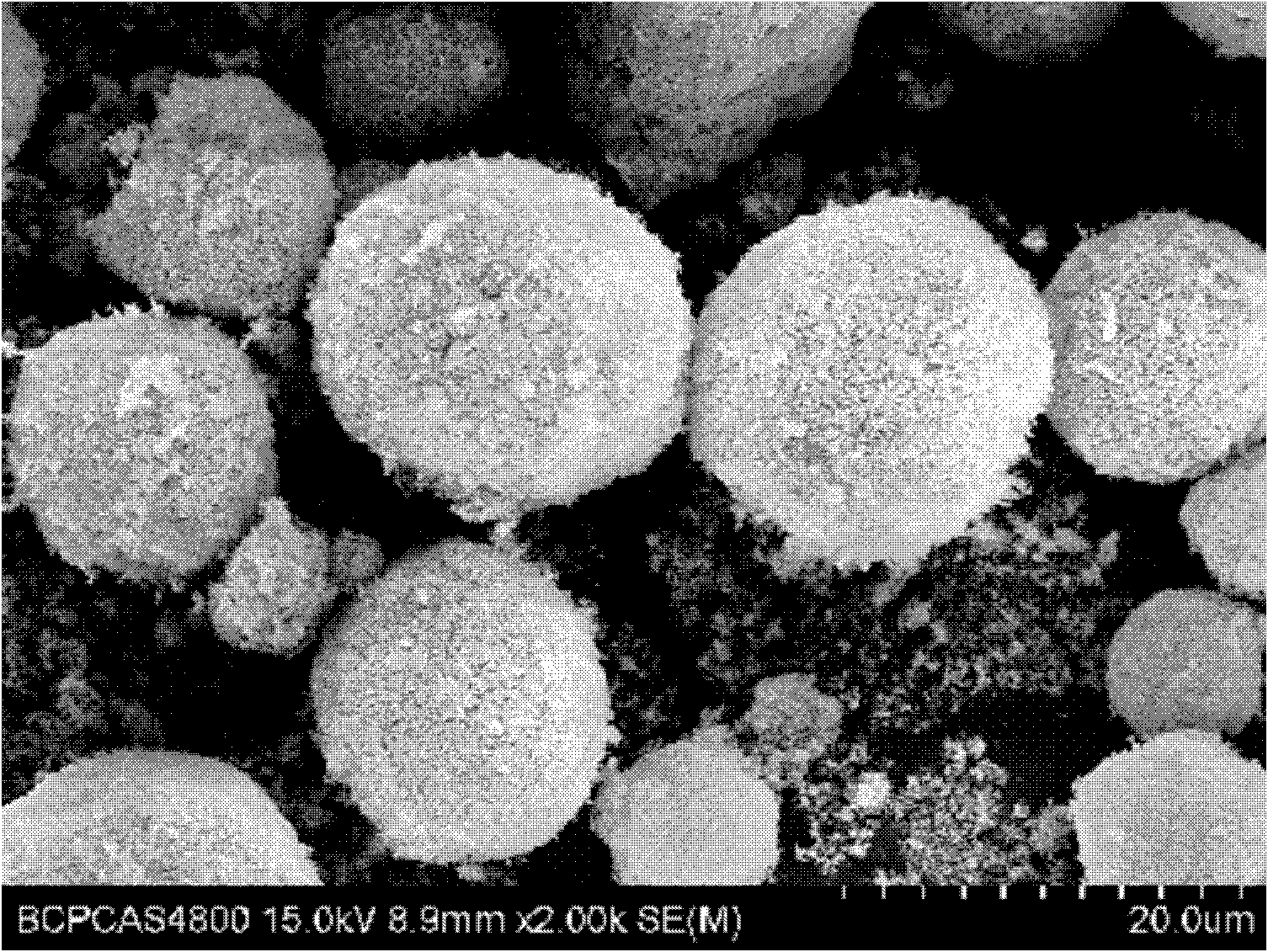

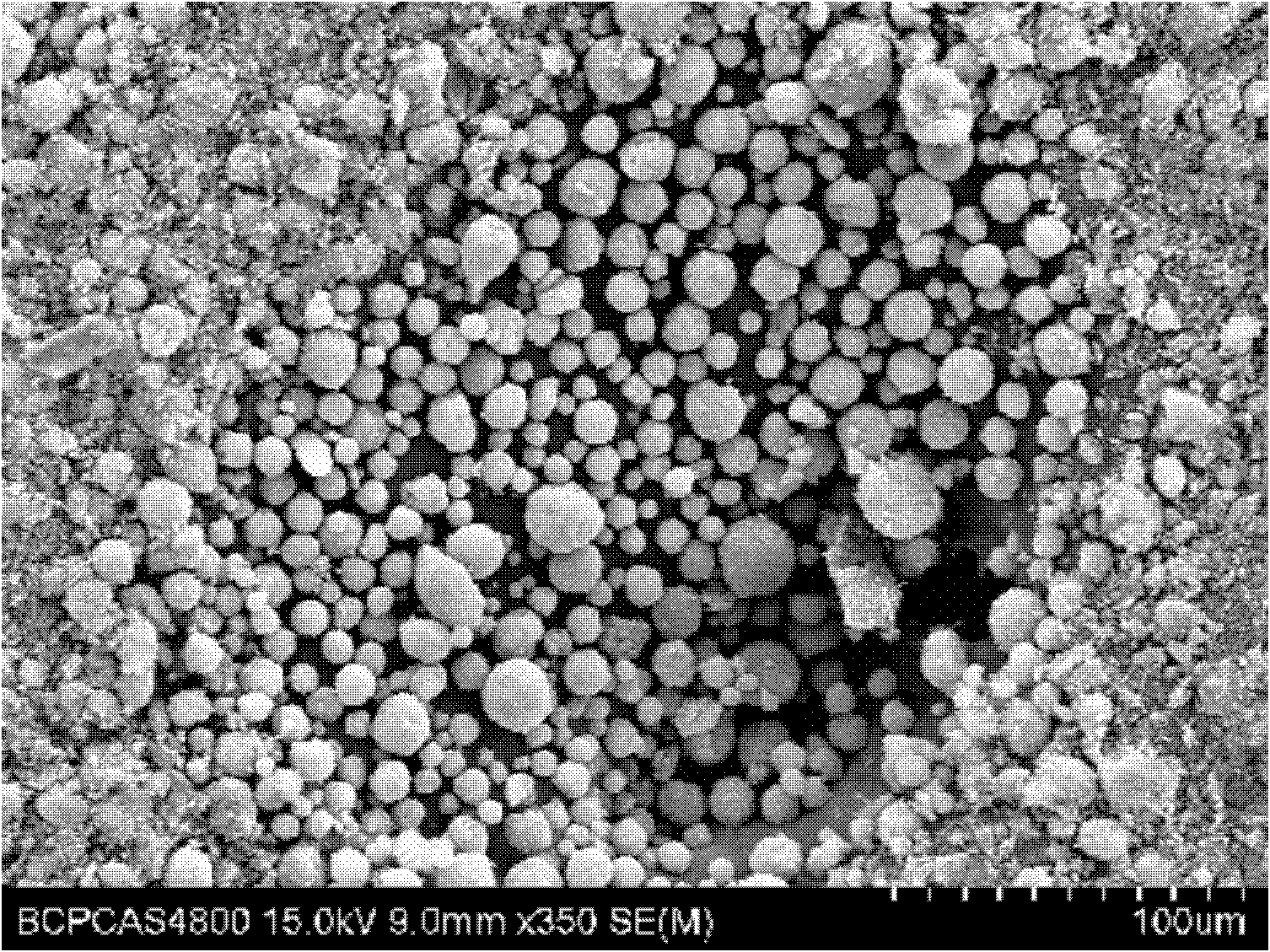

[0029] (2). Spray to form secondary particles

[0030] Use a sprayer for spraying, set the spray parameters as: inlet temperature 100-150°C, outlet temperature 50-100°C, after repeated experiments, the spray parameters are in this range, and the shape of the ...

Embodiment 1

[0035] Accurately weigh 149g (NH 4 ) 3 PO 4 , 91.5g FeCl 2 , 25g LiF, and then dissolve them in 500ml of water respectively, fully dissolve and mix them with a magnetic stirrer, stir for about 20 minutes, the reagents are completely dissolved, the solution becomes a uniform solution, and the solution has no visible crystal particles by naked eyes, use the acid-base indicator The instrument measures the pH value, and the pH value should be 7. At this time, under the action of the mechanical stirring paddle (rotating speed=400 rpm), pour the three prepared solutions into the large round bottom flask successively while stirring, and use an oil bath to (Silicon oil is used in this laboratory) Heating at 120°C for 2 hours, stirring with a mechanical stirrer (speed = 400 rpm) while heating, repeatedly cleaning and filtering the solid at the bottom of the flask, and finally obtaining lithium iron phosphate once particles.

[0036] The primary particles of lithium iron phosphate are...

Embodiment 2

[0040] Accurately weigh 14.9g (NH 4 ) 3 PO 4 , 9.15g FeCl 2 , 2.5g LiF, and then dissolve them in 50ml of water, fully dissolve and mix with a magnetic stirrer, stir for about 20 minutes, the reagents are completely dissolved, and the solution becomes a uniform solution, and the solution has no visible crystal particles. Utilize the acid-base indicator to measure the pH value, and the pH value should be 7. At this time, under the action of the mechanical stirring paddle (rotating speed=400 rpm), pour the three prepared solutions into the large round bottom flask in turn while stirring. , use an oil bath (silicon oil is used in this laboratory) to heat at 120°C for 2h, while heating, use a mechanical stirrer (speed = 400 rpm) to stir, repeatedly wash and filter the solid at the bottom of the flask, and finally get Lithium iron phosphate primary particles.

[0041] The primary particles of lithium iron phosphate are sprayed to obtain secondary particles of lithium iron phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com