Water-soluble high-temperature organic acid inhibitor and preparing method and using method thereof

An organic acid and corrosion inhibitor technology, applied in the field of high temperature organic acid corrosion inhibitor, can solve the problems of serious corrosion resistance of equipment and pipelines, low corrosion inhibition efficiency and poor solubility of corrosion inhibitors, and achieve excellent resistance to hydrogen sulfide and hydrogen chloride. Corrosion, wide temperature range, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

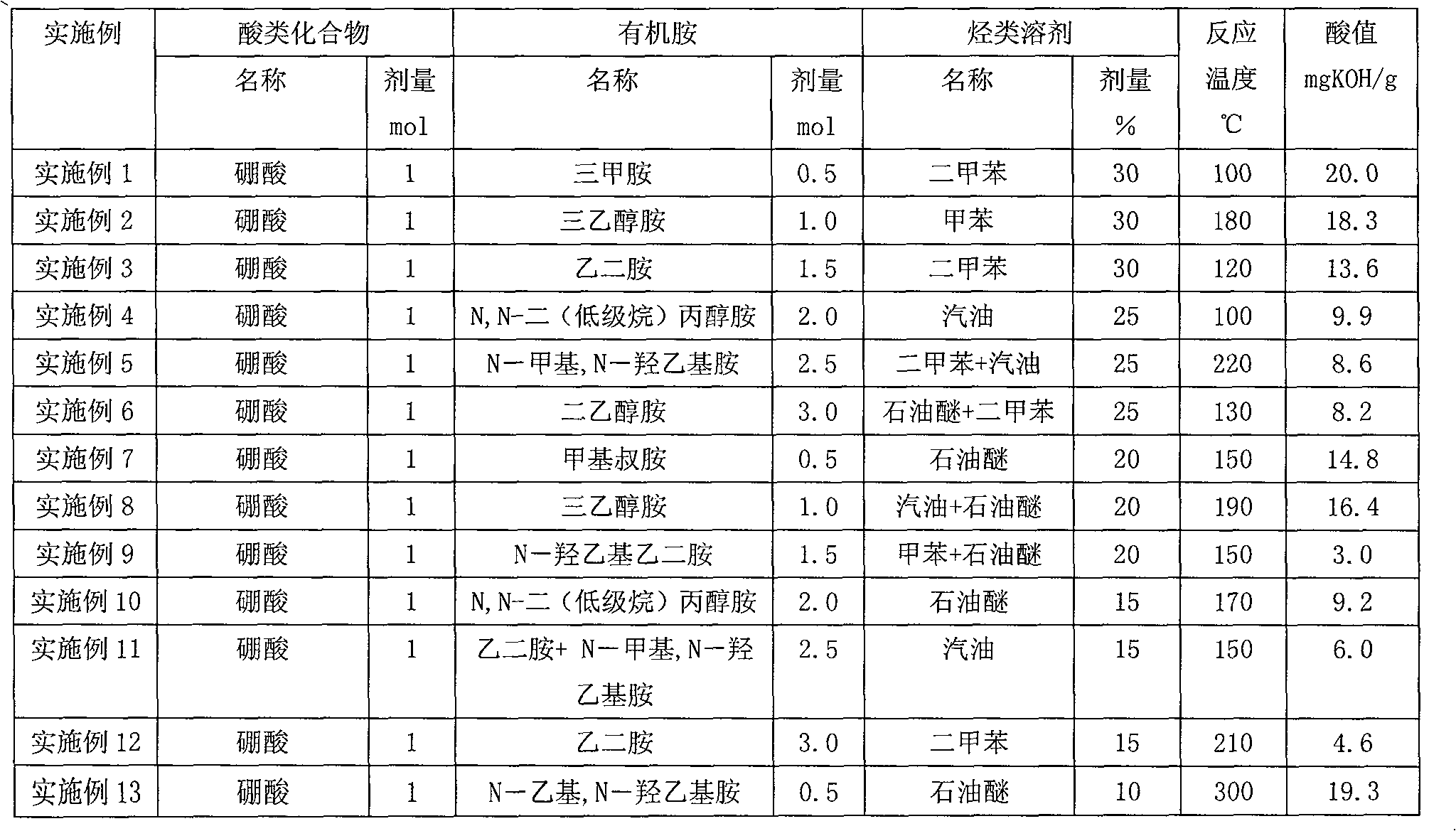

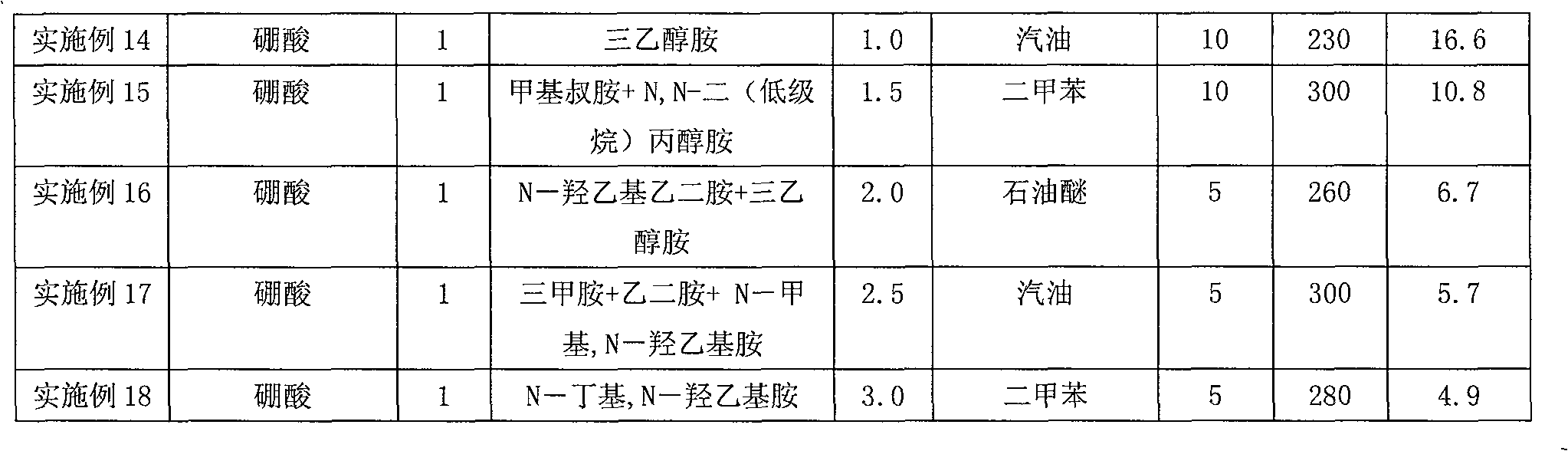

[0010] Examples 1-18: Preparation of organic acid high-temperature corrosion inhibitor intermediate

[0011] Put boric acid and organic amine in a three-necked flask at a molar ratio of 1:0.5 to 1:3, add a hydrocarbon solvent accounting for 5 to 30% of the total weight of the acid compound and organic amine, and heat up to 100 ~300°C, reflux for 2~20 hours, when the acid value of the reaction mixture reaches 3~20mgKOH / g, the reaction ends, and a high-temperature organic acid corrosion inhibitor intermediate is obtained.

[0012] The embodiment that table 1 organic acid high temperature corrosion inhibitor intermediate prepares

[0013]

[0014]

Embodiment 19~51

[0015] Examples 19-51: Preparation of a water-soluble high-temperature organic acid corrosion inhibitor

[0016] After cooling the high-temperature organic acid corrosion inhibitor intermediate accounting for 10-60% by weight of the water-soluble high-temperature organic acid corrosion inhibitor to 60-70°C, add the water-soluble high-temperature organic acid corrosion inhibitor weight percentage while stirring under normal pressure. The percentage is 20~80% selected from C 1 ~C 9 One or two or more components of methanol, ethanol, n-propanol, isopropanol, butanol, isobutanol, 1,2-propanediol, n-pentanol, n-heptanol, n-octanol The combined monoalcohol or diol solvent, and 0.1-20% by weight of the water-soluble high-temperature organic acid corrosion inhibitor are selected from thiourea, benzyl chloride, thioene, propynyl alcohol, trisodium phosphate, phosphorus Corrosion-inhibiting and film-forming components composed of one of ammonium sulfate, diammonium phosphate, triammon...

3 Embodiment 52~70

[0020] 3 Examples 52-70: Examples of the practical application of corrosion inhibitors

[0021] Add 30-1000 μg / g of the corrosion inhibitor into the high-temperature organic acid corrosion medium at 200-400° C. and mix evenly. The performance evaluation of corrosion inhibition effect adopts the national standard GB10124-86 "Metal Material Laboratory Uniform Corrosion Inhibition Full Immersion Test Method" to carry out the static measurement of the corrosion rate of the corrosion inhibitor. The test container used for corrosion inhibition evaluation can be a high temperature resistant, pressure resistant, corrosion resistant sealed container, and the material of the container can be 316L, 1Cr18Ni9Ti and other stainless steel or plastic or glass.

[0022] Table 3 Practical Application Examples of Corrosion Inhibitors

[0023] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com