Patents

Literature

82 results about "Nano-anatase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing nano-anatase mine-titanium oxide water sol

InactiveCN101028937AEasy-to-implement generationEase of mass production: no production involved in the preparation processTitanium dioxideDistilled waterTitanium

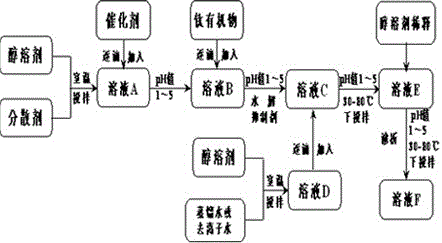

A process for preparing the hydrosol of nano-class anatase-type TiO2 features that reaction between Ti-contained organic substance, distilled water or deionized water, chelating agent and hydrodecomposing inhibitor at 30-120 deg.C for 3-12 hr while stirring and controlling pH=1-5.

Owner:YUNNAN UNIV

Preparation and application method of optical catalysed environment protection type coating

The invention provides a preparation and application method for photocatalysis environmental protection type painting, which relates to construction painting, especially provides a preparation and application method for photocatalysis function painting, which includes steps: mixing titanium-containing organic, water, chelating agent and hydrolysis inhibitor to prepare nano anatase type titanium dioxide water sol; adding metal, oxide or impure titanium dioxide photocatalyst into the titanium dioxide water sol and stirring equably. Using method is coating inorganic isolated layer firstly and coating the photocatalysis painting after drying. Advantages of the invention are: the prepared painting and using technique can be widely used for inner and outer wall surface of building and is harmless to bottom ainting, photocatalysis efficiency is high, cost is low, bonding is firm, transparency is good, preparation is simple, and usage is easy.

Owner:YUNNAN UNIV +1

Aqueous functional coatings possessing effects of self-cleaning, anti mold, sterilization and purifying air

A functional water paint with self-cleaning, antimildew, bactericiding and air-cleaning functions for building contains (5-100)-nm anatase-type titanium oxide as photocatalyst (10-46%) and water-soluble resin or polymer emulsion or silicon sol or their composition as water adhesive (26-35%). It features that the various organic substances in the air or water in contact with its surface can be decomposed into CO2 and water. Its advantages are high effect and safety and durable acting.

Owner:UNIV OF SCI & TECH OF CHINA

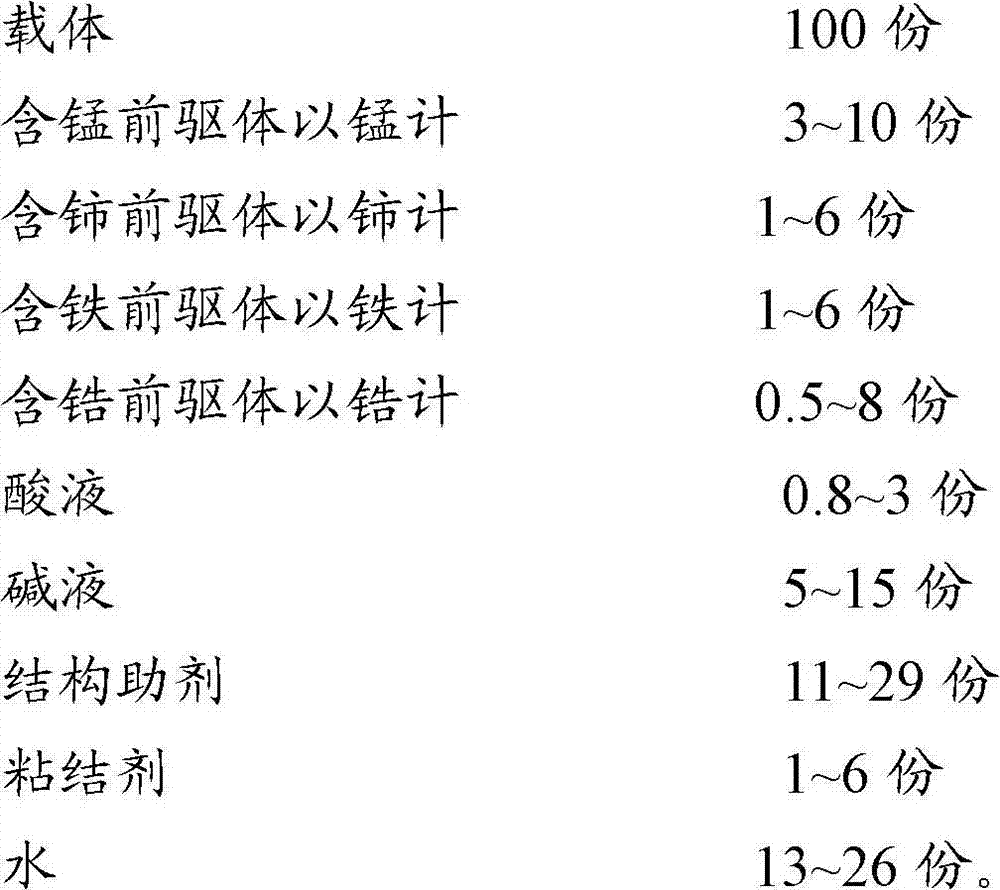

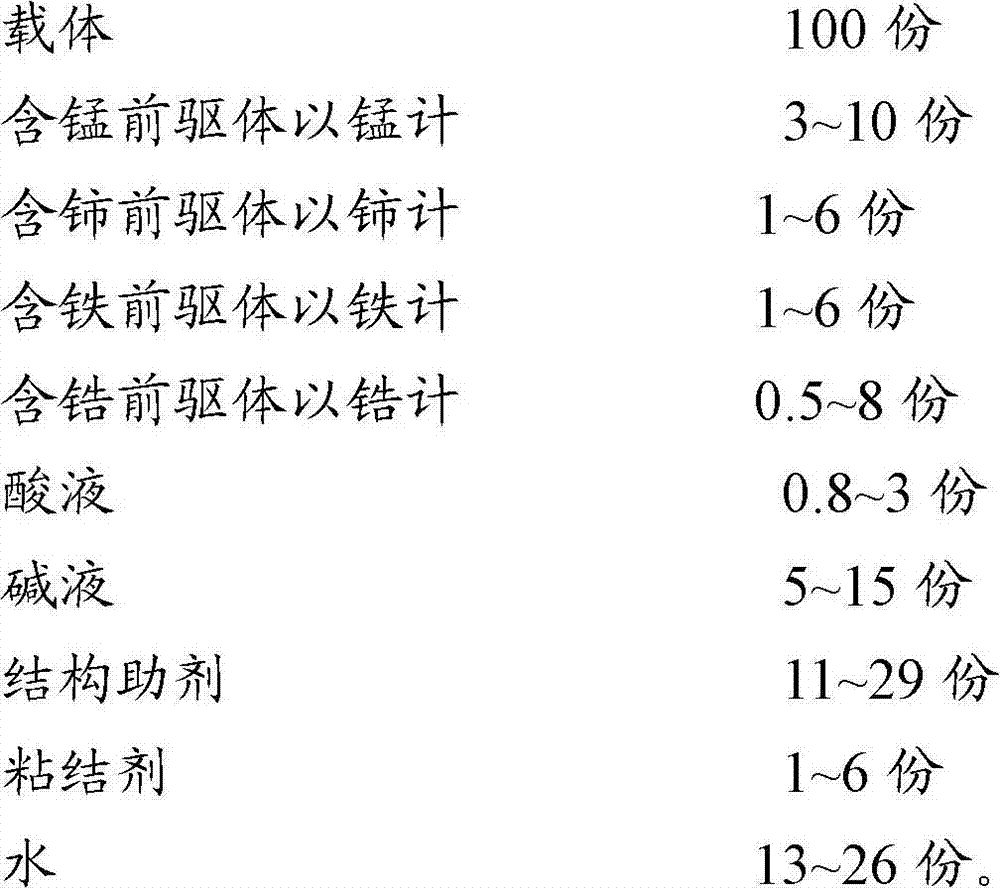

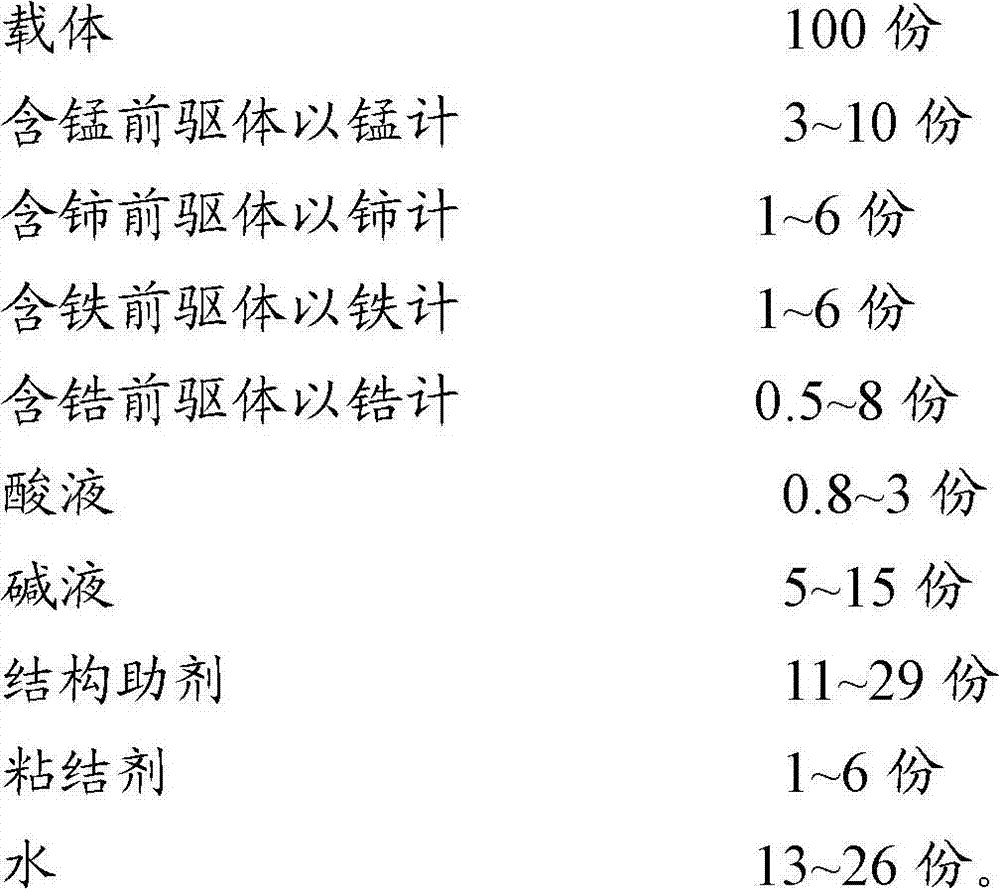

Honeycombed SCR (selective catalytic reduction) denitrification catalyst for low-temperature flue gas denitrification and preparation method thereof

ActiveCN102861595AGood flexibilityImprove plasticityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumManganese

The invention discloses a honeycombed SCR (selective catalytic reduction) denitrification catalyst for low-temperature flue gas denitrification and a preparation method of the honeycombed SCR denitrification catalyst. According to the method, mixed powder of nano-anatase titanium tungsten powder and titanium silicon powder is used as a carrier of the catalyst; active components include metal compounds containing manganese, cerium, iron and zirconium; additives include an acid solution, an alkali solution, a structural promoter and a binder; and the honeycombed SCR denitrification catalyst, based on 100 parts of carrier, is prepared by the following raw materials by mass: 100 parts of carrier, 3-10 parts of manganese-containing precursor based on manganese, 1-6 parts of cerium-containing precursor based on cerium, 1-6 parts of iron-containing precursor based on iron, 0.5-8 parts of zirconium-containing precursor based on zirconium, 0.8-3 parts of acid solution, 5-15 parts of alkali solution, 11-29 parts of structural promoter, 1-6 parts of binder, and 13-26 parts of water. According to the catalyst prepared by the preparation method provided by the invention, the low-temperature (at 80-120 DEG C) activity of the SCR denitrification catalyst is effectively improved, and the strength and the molding rate of the monolithic honeycombed SCR denitrification catalyst are greatly improved.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Composite antibacterial far infrared medical stone porous ceramic ball and preparation method thereof

The invention relates to a composite antibacterial far infrared medical stone porous ceramic ball. The surface of the porous ceramic ball is in the form of a closer porous sintered structure while the internal structure of the porous ceramic ball is three-dimensional communicated micropores which are uniformly distributed as a whole and are interlaced and connected with each other; the particle size of the porous ceramic ball is 10 microns to 5 millimeters; the volume density is 1.0-2.8 g / cm<3>; the porosity is 30-50%; the aperture size is 10-100 microns; and the compressive strength is 10-18 MPa. The porous ceramic ball is prepared from a ceramic natural mineral, a high temperature synthetic ceramic raw material and a pore-forming and binding material through the following processes of finely crushing, proportioning, pelletizing, sintering at low temperature, washing with water and drying, and the porous ceramic ball comprises the following components in parts by weight: 5-15 parts of lead-free and cadmium-free low temperature solvent, 5-15 parts of silver-loading analcite, 3-6 parts of nano-anatase TiO2 (Titanium Dioxide), 5-15 parts of high temperature synthetic far-infrared material, 5-15 parts of natural electric stone, 40-50 parts of medical stone and 10-20 parts of pore-forming and binding material. Because good whole sintering degree and a porous structure are remained and the surface of the porous ball is easy to grind, decontaminate and wash by adopting a self-created preparation process of uniformly dispersing the nano-TiO2 powder in the slurry without agglomeration, the porous ceramic ball has the advantages of strong regeneration capacity and long service life.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

Organic clay loaded with nanometer anatase type titanium dioxide and its preparation method and use

InactiveCN100998933AAvoid reunionSmall particle sizeCatalyst carriersWater/sewage treatment by irradiationNano-anataseInorganic chemistry

A organic clay carrying nano-class anatase-type TiO2 is prepared from clay through modifying it by long-chain alkyl ammonium salt and carrying the anatase-type TiO2 nanoparticles by sol-gel method. It can be used as a photocatalyst for photodecomposing the organic pollutant in sewage or photodegradating polymer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing nano titanium dioxide in anatase type from fluid of hydrothermal crystallized titanium sulfate

InactiveCN1415550AStable structureImprove performanceOxide/hydroxide preparationTitanium dioxideDispersityNano catalyst

A process for preparing nano anatase-type TiO2 from the solution of titanium sulfate by hydrothermal crystallizing includes such steps as hydrothermal precrystallizing at 80-150 deg.C, and sintering at 350-800 deg.C. Its advantages are high dispersity and stability, low cost and less environmental pollution.

Owner:SUN YAT SEN UNIV

Prepn of nanometer TiO2 antiseptic ceramic

The nano TiO2 can be uniformly dispersed in medium, then uniformly coated on the ceramic surface, and roasted at high temp. to make TiO2 nano particles uniformly distributed on the glaze, and do not affect degree of finihsed of glaze. The TiO2 can be reacted with surface water and O2 in the air under the sunlight, and can release atomic oxygen and hydrogen-oxygen free radical to kill bacteria.

Owner:WUHAN UNIV

Method for preparing finishing varnish with photocatalytic activity

The invention discloses a method for preparing a finishing varnish with photocatalytic activity, and the method belongs to the field of building coating. The method comprises the following steps of: dissolving titanium tetrachloride into a cold water to form solution, and dripping excessive hydrogen peroxide into the solution to obtain a titanium peroxide compound; dripping ammonia water into the titanium peroxide compound until the pH of the titanium peroxide compound is 10, stirring to react, filtering and washing to obtain hydration titanium peroxide; and dissolving the hydration titanium peroxide in the water, adding nano silicon dioxide sol for hydrothermal reaction, and thus obtaining a product-nano titanium dioxide compound silicon dioxide gel, i.e. the finishing varnish with photocatalytic activity. When the low-temperature decomposition hydration titanium peroxide is adopted by the method to prepare the nano titanium dioxide sol, the nano silicon dioxide sol is added, so that the photocatalytic activity of nano anatase obtained after the reaction is higher, and a film can be formed later due to hydroxyl on a silicon dioxide surface; and the nano titanium dioxide is an inorganic substance and cannot be easily decomposed through the photochemical catalytic reaction of titanium dioxide.

Owner:FIRST NEW MATERIAL TECH DEV

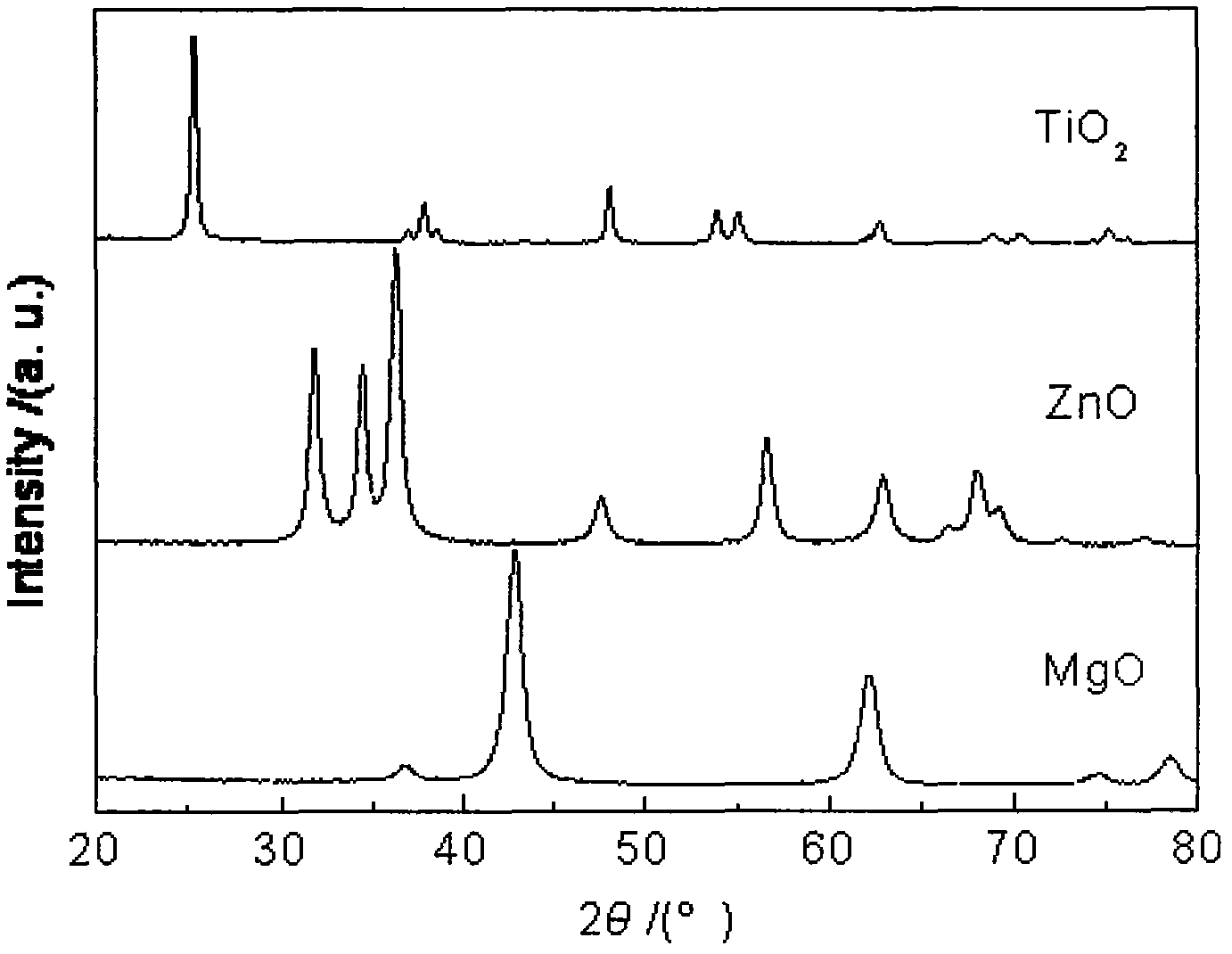

Low-temperature sintered zinc titanate high-frequency dielectric ceramic and preparation method thereof

The invention relates to a low-temperature sintered zinc titanate high-frequency dielectric ceramic and preparation method, wherein the ceramic comprises zinc oxide produced by decomposing one portion of basic zinc carbonate, one portion of anatase nano-TiO2 and 0.75-1.00 wt% of vanadium pentoxide and diboron trioxide additive, wherein the basic zinc carbonate is used for producing zinc oxide, the preparation comprises ball grinding, drying, grinding, forming, pre-calcination, sintering and silvering.

Owner:西安广芯电子科技有限公司

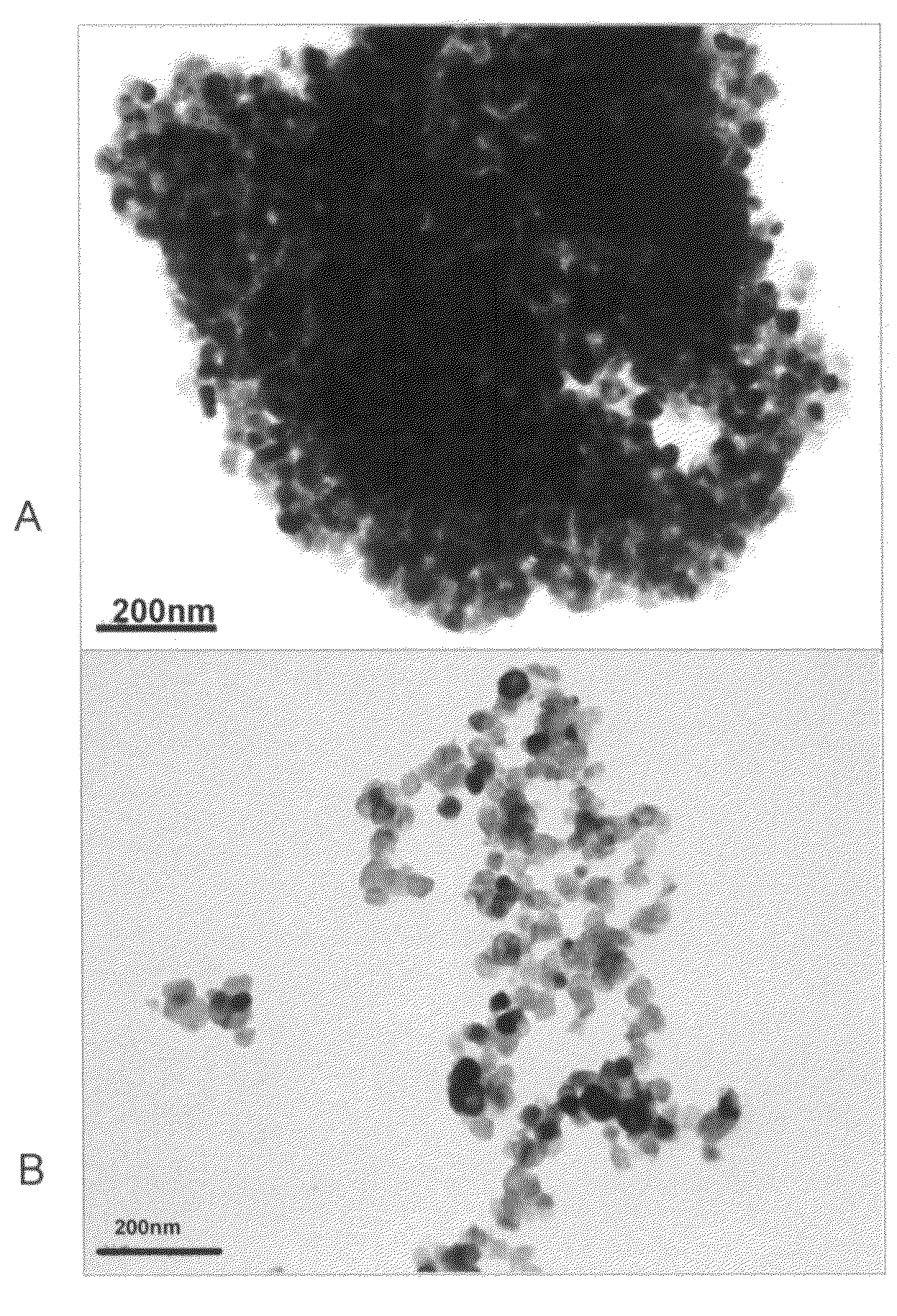

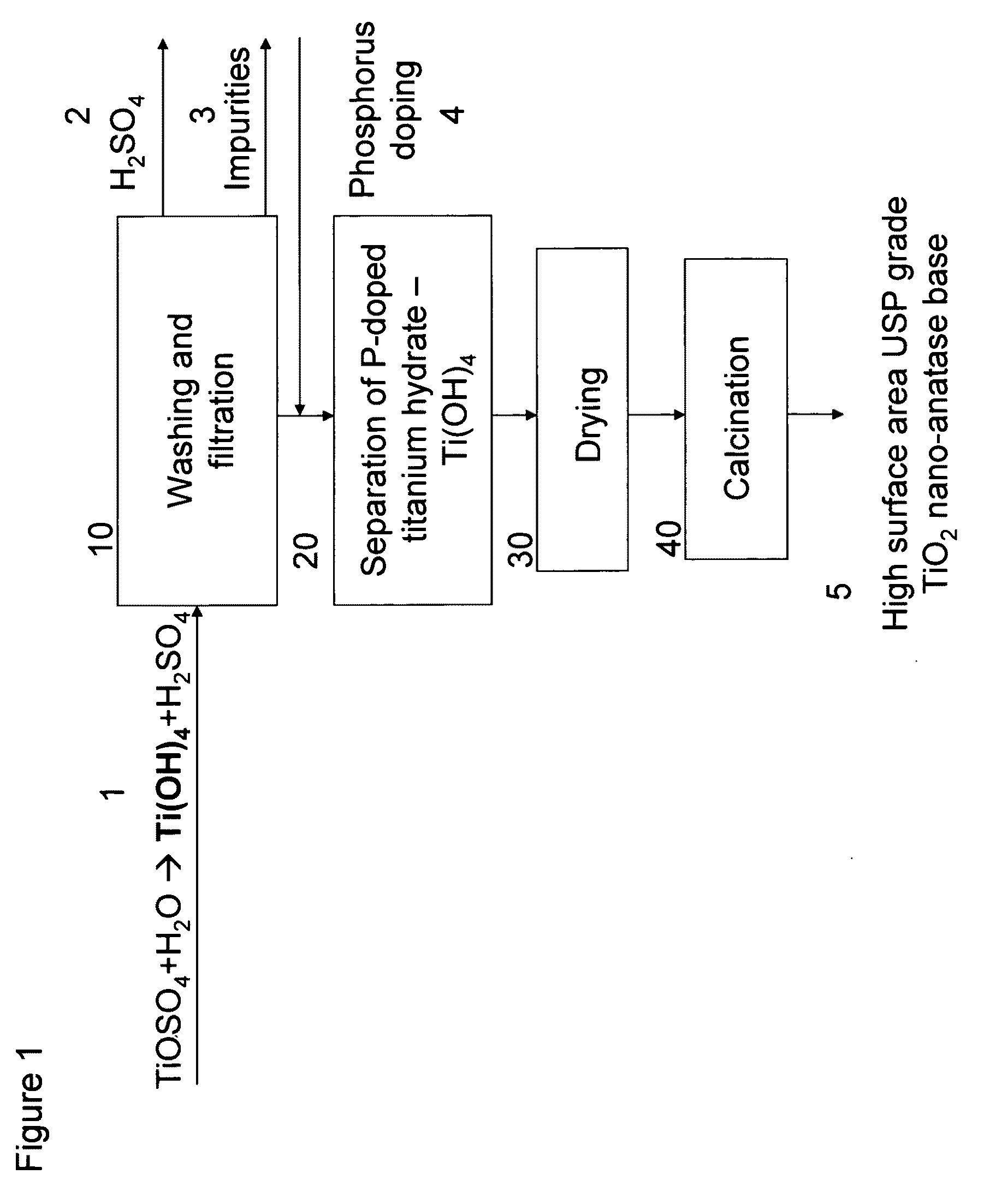

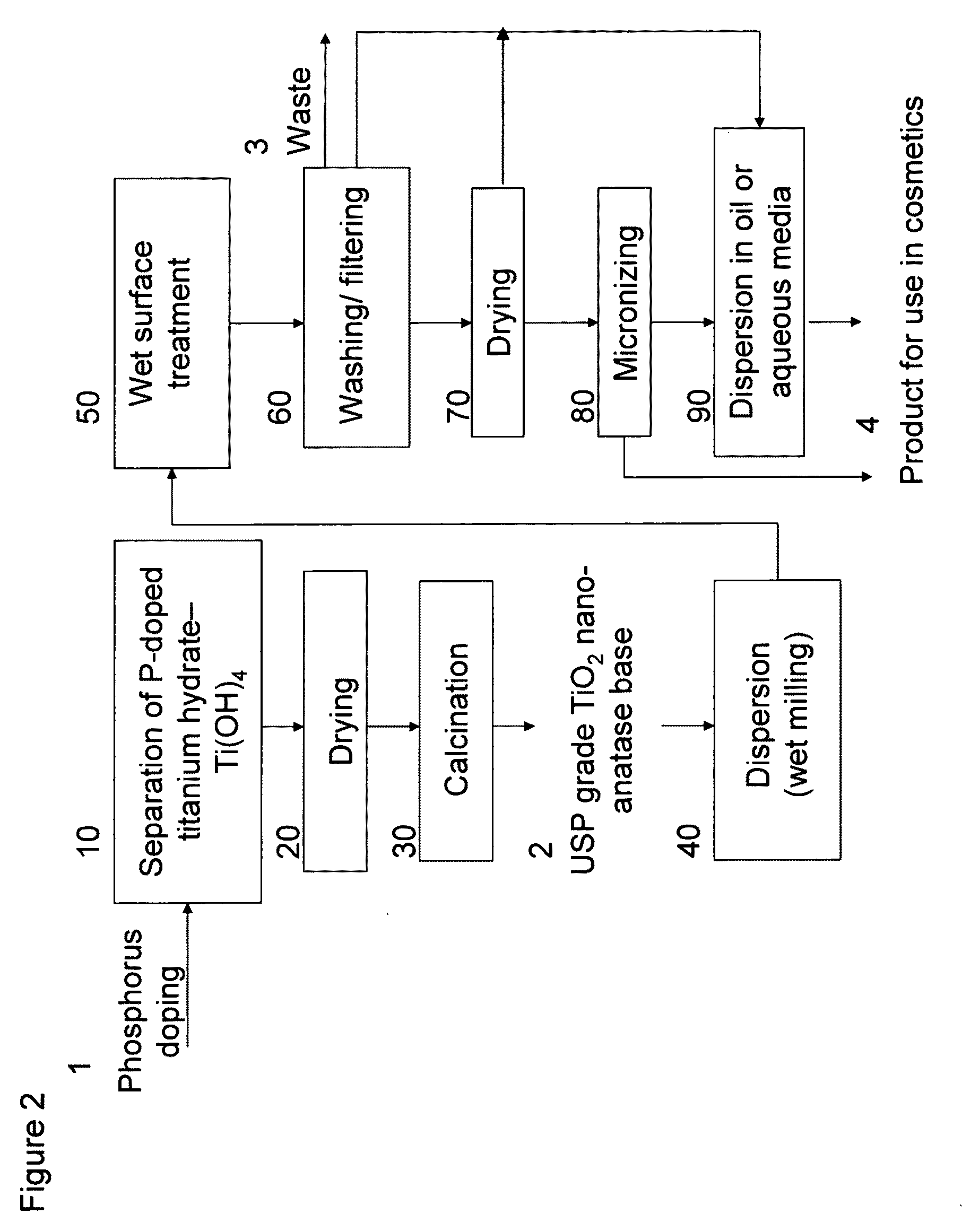

Process for manufacturing of high surface area USP grade nano-anatase base

The present invention provides a novel manufacturing process for producing a high surface area USP grade titanium dioxide in the nano-anatase form. In a manufacturing method aspect of the present invention, a process of producing a high surface area USP grade TiO2 nano-anatase base is provided. The method involves steps of: a) phosphorus doping of the titanium hydrate obtained in hydrolysis of a titanium compound; b) drying and calcination of the doped paste, thereby producing a high surface area USP grade titanium dioxide in the anatase crystal form with nano-particles suitable for UV screens and cosmetics.

Owner:PROCHAZKA JAN R

Method for preparing stable nano anatase titanium dioxide alcohol phase sol at low temperature

ActiveCN105664808AEasy to makeEasy to manufactureTitanium dioxideSol preparationPtru catalystOrganosolv

The invention relates to a method for preparing a stable nano anatase titanium dioxide alcohol phase sol, which belongs to a preparation method of a semiconductor photoelectric material. The invention provides a simple method for preparing a nano anatase titanium dioxide nano nanocrystalline alcohol phase sol at low temperature by using a one-step method, and the raw materials comprise a titanium-containing organic matter, an organic solvent, distilled water or deionized water, a dispersant, a hydrolysis inhibitor and a catalyst with a corresponding mol ratio of 1:(20-100):(0.5-3):(1-5):(0.1-3):(0.01-1.5). According to the invention, the titanium organic matter is added in an alcoholic solution mixed with the dispersant and the catalyst, the hydrolysis inhibitor and the water are added, the materials are stirred for 3-48 hours under normal pressure and at the temperature of 25-100 DEG C, a pH value of a reactant is controlled to 1-5, and the transparent stable nano anatase titanium dioxide alcohol phase sol can be obtained. A hydrolysis intermediate product can be removed by using a dialysis technology finally. The sol has the advantages of good sol crystallinity, stability and transmittance performance, and concentration of the sol can be diluted by alcohol according to requirement. The prepared sol enables direct film forming on various high temperature-resistant or high-temperature-intolerant material substrates, and also can be used for directly preparing photocatalytic aqueous environmentally-friendly coatings or visible light-excited photocatalytic environmentally-friendly coatings.

Owner:YUNNAN UNIV

Process for preparing nano anatase titanium oxide

InactiveCN1566217ASimple processGood process compatibilityInorganic pigment treatmentFractionationAqueous solution

The invention discloses a process for preparing nano anatase titanium oxide from metatitanic acid as raw material through the steps of, processing ammonium bicarbonate aqueous solution, dipping, agitating, filtering, high temperature heat treatment for disintegrating fractionation.

Owner:UNIV OF SCI & TECH OF CHINA

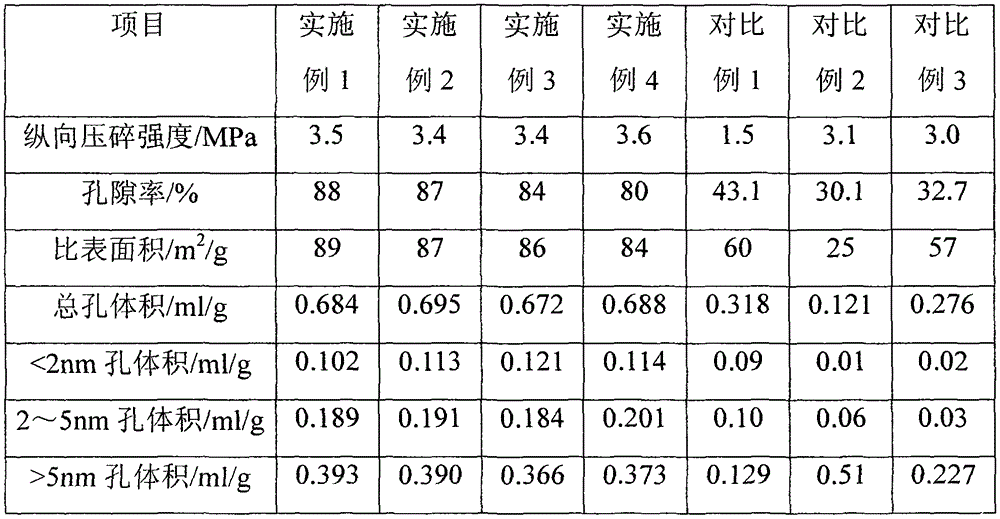

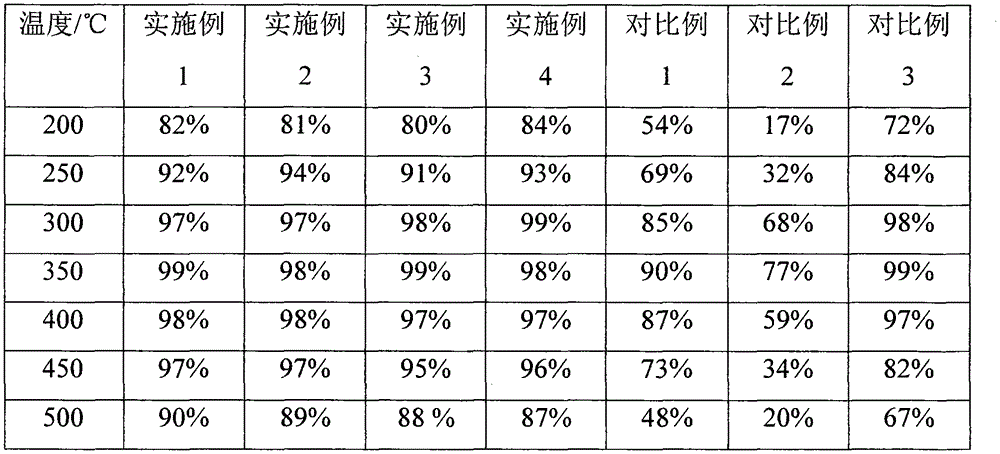

Nontoxic rare-earth denitration catalyst and preparation method and application thereof

ActiveCN104923213AGuaranteed mechanical strengthGood NOx conversion activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseRare earth

Owner:REZEL CATALYSTS CORP

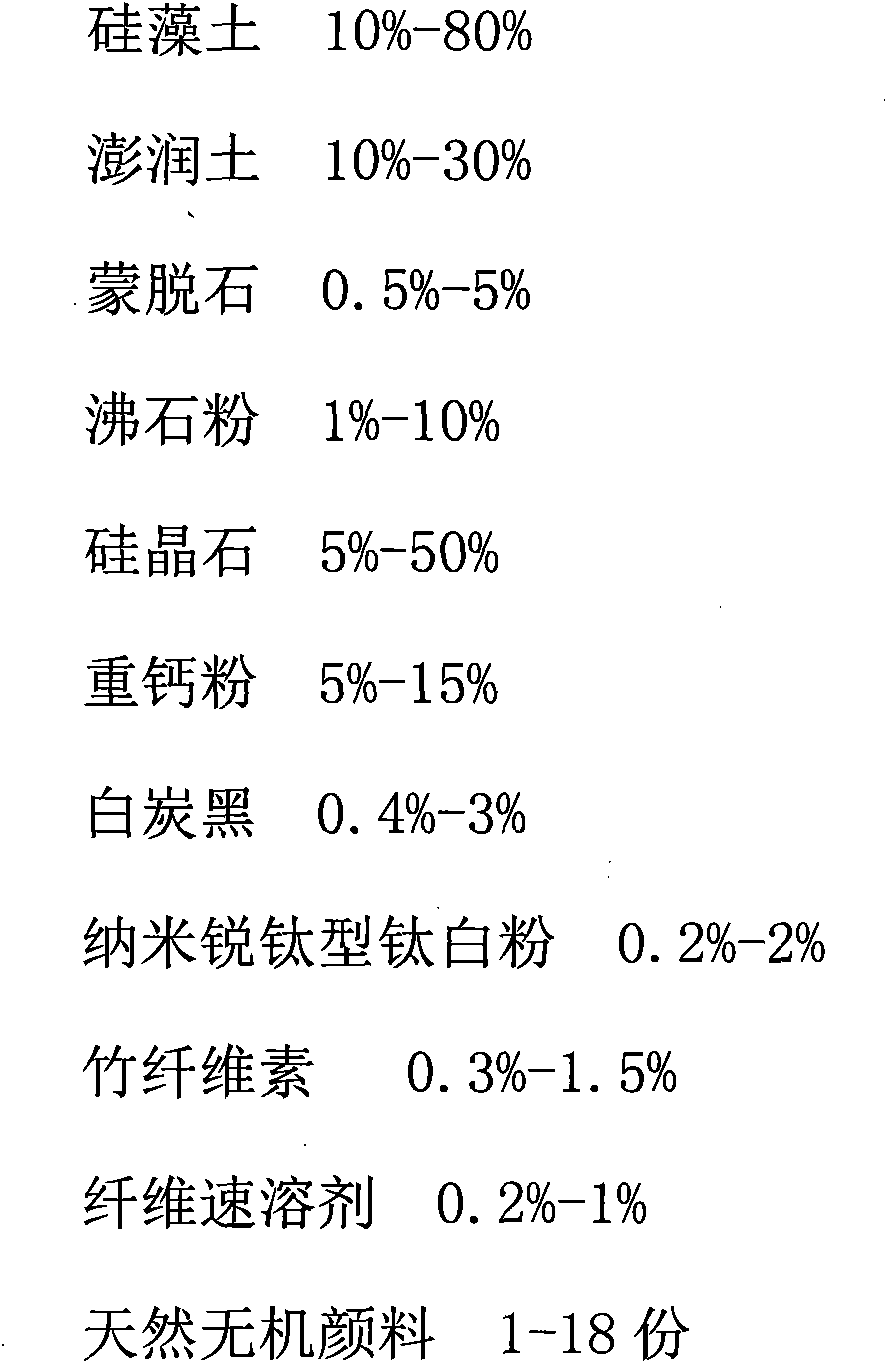

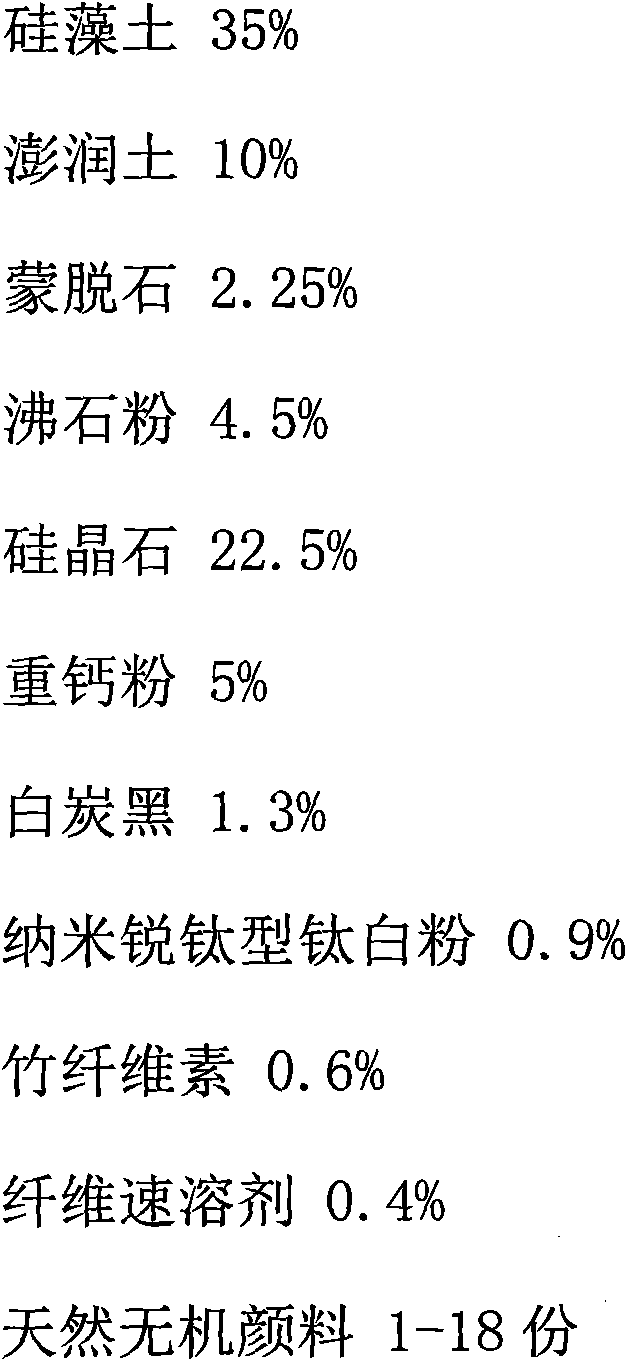

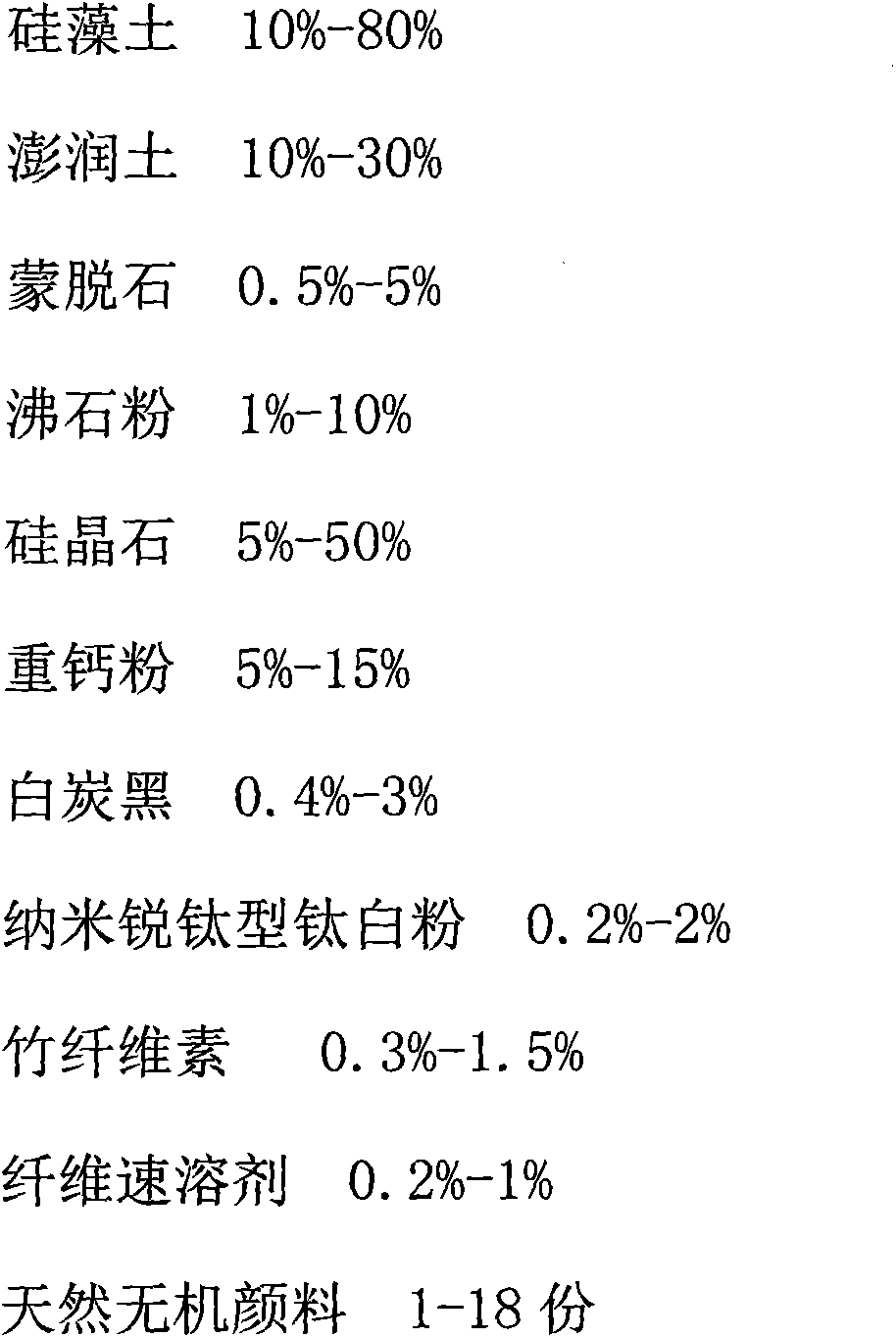

Preparation method of novel diatom ooze coating

The invention relates to a preparation method of a novel diatom ooze coating. The novel diatom ooze coating comprises the following raw materials: 10%-80% of 200-600-mesh kieselguhr, 10%-30% of 200-600-mesh bentonite, 0.5%-5% of 325-600-mesh montmorillonite, 1%-10% of 325-400-mesh zeolite powder, 5%-50% of 325-400-mesh silicon crystal, 5%-15% of 325-600-mesh ground calcium carbonate powder, 0.4%-3% of 325-400-mesh white carbon black, 0.2%-2% of 352-400-mesh nano anatase titanium dioxide, 0.3%-1.5% of 80-400-mesh bamboo cellulose, 0.2%-1% of 325-400-mesh fiber instant agent, and 1-18 parts of a natural inorganic pigment. The materials are mixed with water according to the ratio, and then are put into horizontal high-speed stirring equipment to fully stir evenly. The novel diatom ooze coating is applied to wall decoration and plate surface coating, has multiple advantages and is worthy of popularization.

Owner:蒋闯隆

Synthetic method of nano titanium dioxide powder

ActiveCN105523583AHigh yieldSimple methodMaterial nanotechnologyTitanium dioxideNanoparticleAmmonium hydroxide

The invention discloses a synthetic method of nano anatase titanium dioxide powder. The method comprises the following steps: 1) dropping a titanium oxide precursor in water, performing a hydrolysis reaction to obtain white precipitate, after reaction is completed, obtaining a solid-liquid mixture; 2) adding an alkyl ammonium hydroxide solution in the mixture obtained in the step 2), uniformly mixing the materials and aging the materials; and 3) adding a glacial acetic acid solution in the aged product obtained in the step 2), performing a constant temperature reaction, after the reaction is completed, separating the product, cleaning the product and drying the product to obtain the nanometer titanium dioxide powder. The method has the advantages of simple process, low synthesis temperature, mild condition, easy operation and high output, the size of the prepared titanium oxide nanoparticle is small, and the method is suitable for preparing a catalyst for selective catalytic denitration or a photocatalysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

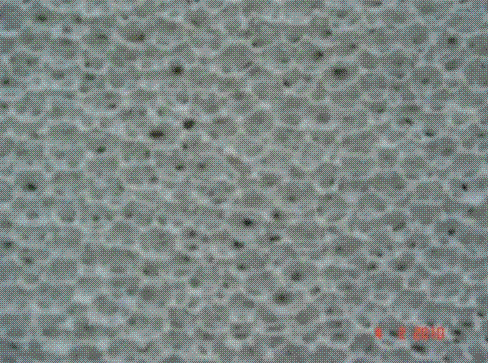

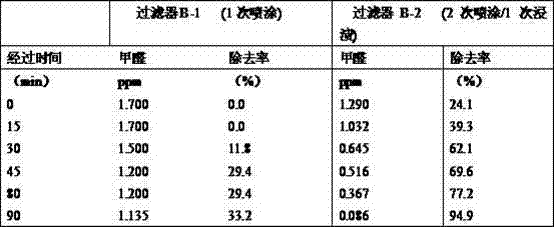

Preparation method for photocatalyst TiO2 supporter and manufacturing method for photocatalyst air cleaner

InactiveCN102784633AEfficient decompositionEffective decomposition and removalOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationAluminum silicateHigh activity

The invention provides a photocatalytic photocatalyst supporter, and a manufacturing method for a photocatalytic photocatalyst air cleaner adopting the supporter as a filter, wherein the photocatalytic photocatalyst supporter has characteristics of fine pores, high film strength, and high activity photoreactivity semiconductor adhesion. According to the photocatalytic photocatalyst supporter, alkyl metal.TiO2 or a nanometer TiO2 sol is subjected to coating, drying, and solidification to form a film on a ceramic porous material of alumina, aluminum silicate, silicon carbide and other fire resistance materials, then firing at a high temperature of 250-700 DEG C is performed to form a finely-porous photocatalyst ceramic film, wherein performing of a lot of laminating is adopted as a characteristic. The anatase crystal TiO2 nanoparticles of the photocatalytic film formed on the surface of the supporter provide antibacterial, odor removing and other purification effects for air or water under an action of light.

Owner:李文发

Preparation method of nano anatase-phase titanium dioxide and application in lithium battery

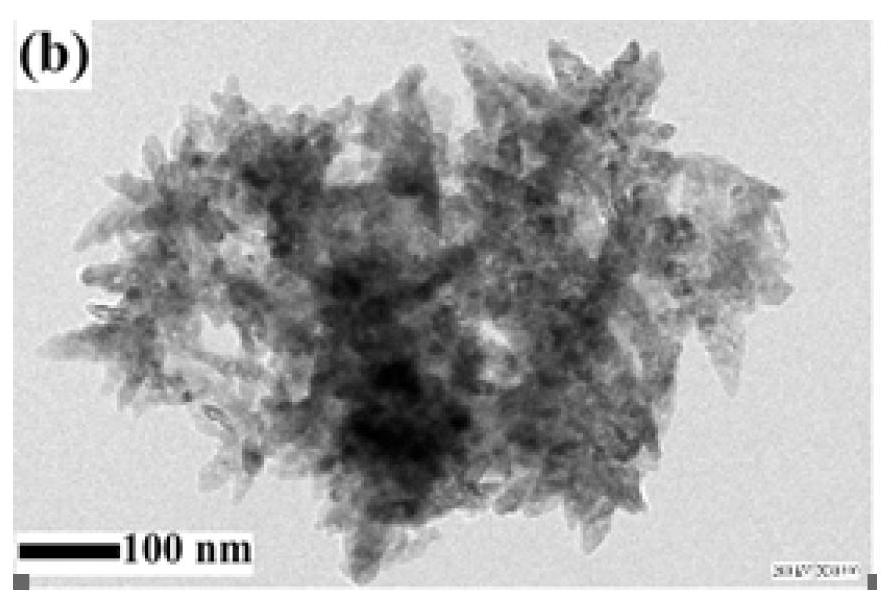

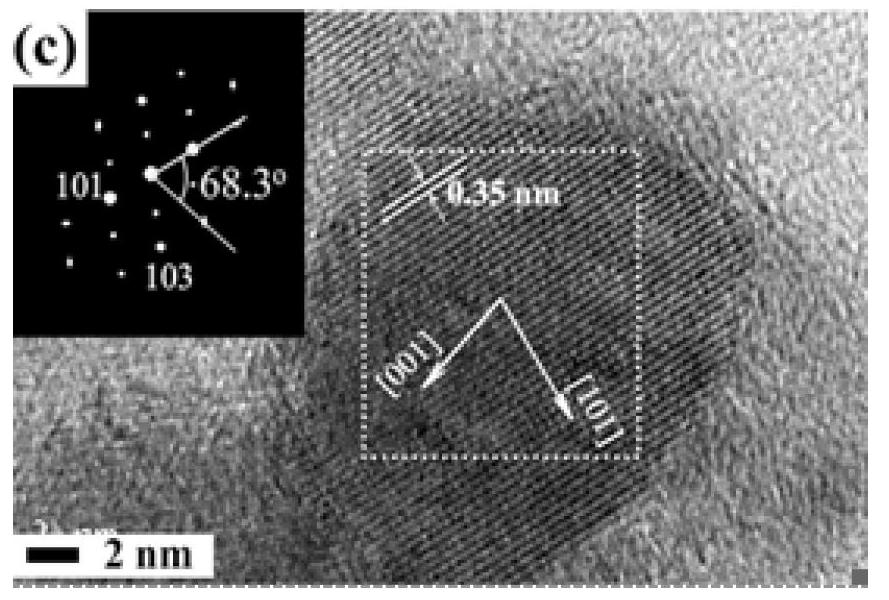

InactiveCN102646822AHigh lithium storage capacityExcellent rate performanceCell electrodesSecondary cellsThermal insulationNano-anatase

The invention discloses a preparation method of a nano anatase-phase titanium dioxide, which adopts a liquid-phase depositing method and comprises the following steps of: 1) preparing an LPD (liquid phase depositing) depositing solution composed of 0.05 M of titanium salt and 0.1-0.15 M of boric acid; adjusting pH of the depositing solution to 2.8-3.0 by hydrochloric acid; 2) sealing the LED depositing solution obtained by the step 1) and performing thermal insulation for 2-8 hours and controlling the temperature in a range of 45-55 DEG C; 3) filtering and washing the system obtained by the step 2) and drying at a room temperature; and 4) sintering the product dried by the step 3), wherein the sintering temperature is 450 DEG C; and performing thermal insulation for 2-3 hours and cooling to the room temperature. Compared with the titanium dioxide without a nano cone characteristic, the lithium storage capacity of the titanium dioxide is improved by a nano cone structure containing a {100} crystal face, and the multiplying power performance is improved, and thus the preparation method provided by the invention lays a good foundation for constructing a lithium battery cathode composite material with high performance and the practicability of the lithium battery cathode composite material.

Owner:HYB BATTERY

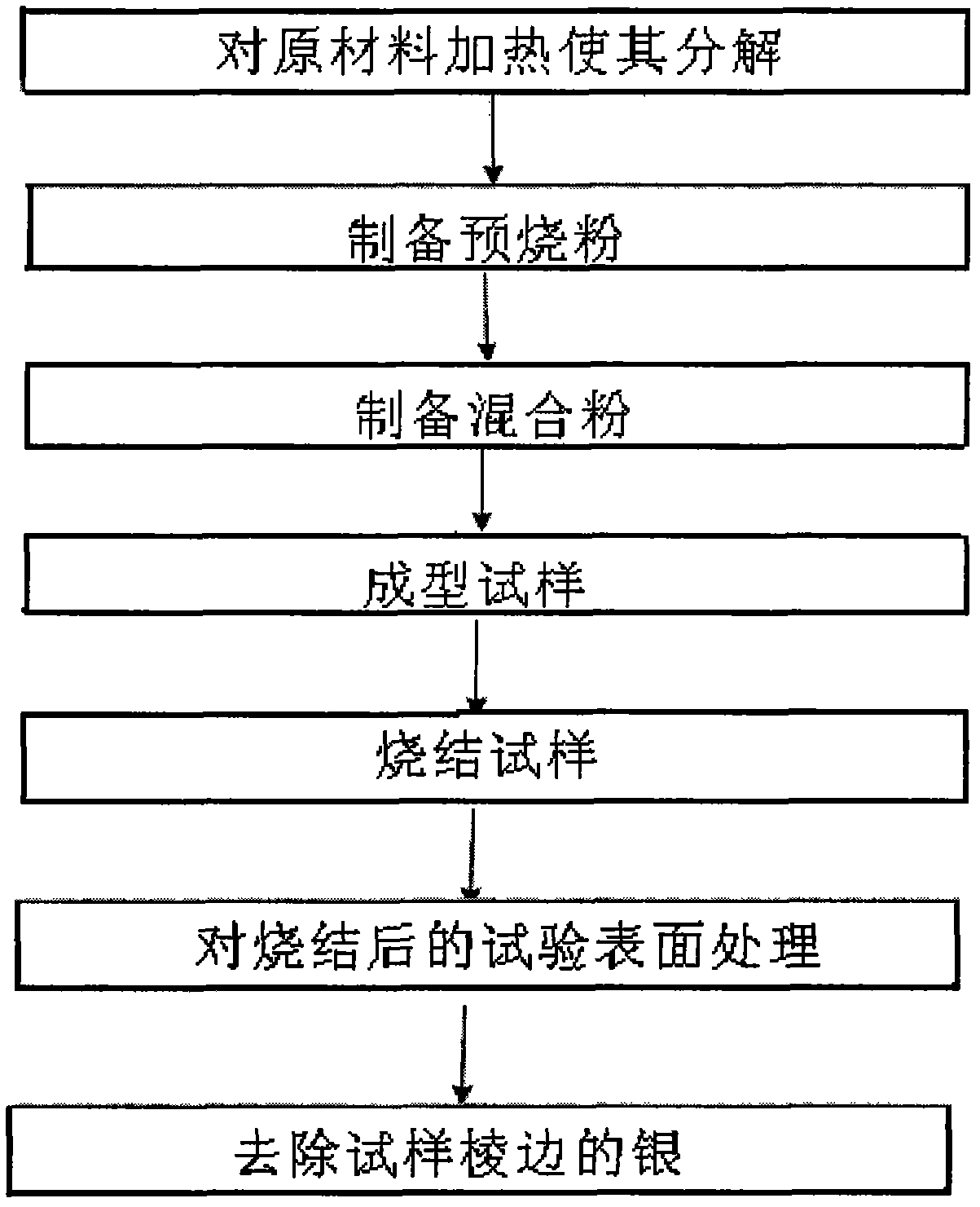

Dielectric ceramic for high-frequency section and preparation method thereof

The invention discloses dielectric ceramic for a high-frequency section and a preparation method thereof. The dielectric ceramic comprises basic zinc carbonate, nanoanatase titanium dioxide, basic magnesium carbonate, tin dioxide and additives, and specifically comprises the following raw materials in parts / percentage by weight: 1-x parts of generated zinc oxide, x parts of generated magnesium oxide, 1-y parts of nanoanatase titanium dioxide, y parts of tin dioxide and 1.0-2.0 percent of additives, wherein x is more than or equal to 0 and less than or equal to 0.8; y is more than or equal to 0.08 and less than or equal to 0.2; and the molar ratio of the additives is 3:1. The preparation method comprises the following steps of: heating the raw materials for decomposing; pre-burning; preparing mixed powder; molding; and sintering to obtain the dielectric ceramic for the high-frequency section. The dielectric ceramic for the high-frequency section is derived on the basis of doping and modification of a system, has high chemical stability, and is suitable for making a flaky element taking a sputtered metal such as silver, copper or silver / copper alloy and the like as an inner electrode. By adopting the dielectric ceramic, the manufacturing cost of the flaky element is effectively lowered.

Owner:XIAN UNIV OF SCI & TECH

Method for synthesizing non-aqueous system zirconium doping nano anatase titanium dioxide

InactiveCN101164898ASimple processSimple and fast operationTitanium dioxideOrganic acidZirconium doping

This invention discloses a method for synthesizing nanometer anatase titanium dioxide doped by non-aquo zirconium. In this method, C1-C9 organic acid (1), tetrabutyl titanate (2) and zirconium isopropoxide (3) are used as raw materials with molar ratio of: (1):(2)=(2-20):1, After mixing the mixture is put in a reactor, heating to 80-240deg.C for reaction for 8-24hrs, and then is washed by ethanol for 3-5times, being dried under 80-160 deg.C to obtain this inventive product. This invention has advantages of: simple process, convenient operation, mild reaction condition, high yield, high crystallinaty of final product, high specific surface area and small graininess.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Vanadium pentexide modified nano composite material capable of decomposing oil fume

InactiveCN101537364ALower energy gapImprove photocatalytic activityPhysical/chemical process catalystsDispersed particle separationWater vaporTungsten trioxide

The invention discloses a vanadium pentexide modified nano composite material capable of decomposing oil fume. The material comprises the following components by weight: 80 to 120 g of nanometer anatase titanium dioxide, 10 to 15 g of tungsten trioxide, 20 to 65 g of vanadium pentexide, 500 to 1,000 g of water, and 5 to 20 g of sodium hexametaphosphate. The material can be spread on a range hood to decompose the oil fume into carbon dioxide gas and vapor to volatilize the oil fume without cleaning in any mode and kill other viruses and bacteria in a kitchen to protect the environment.

Owner:HUNAN YIPIN NANO TECH INVESTMENT

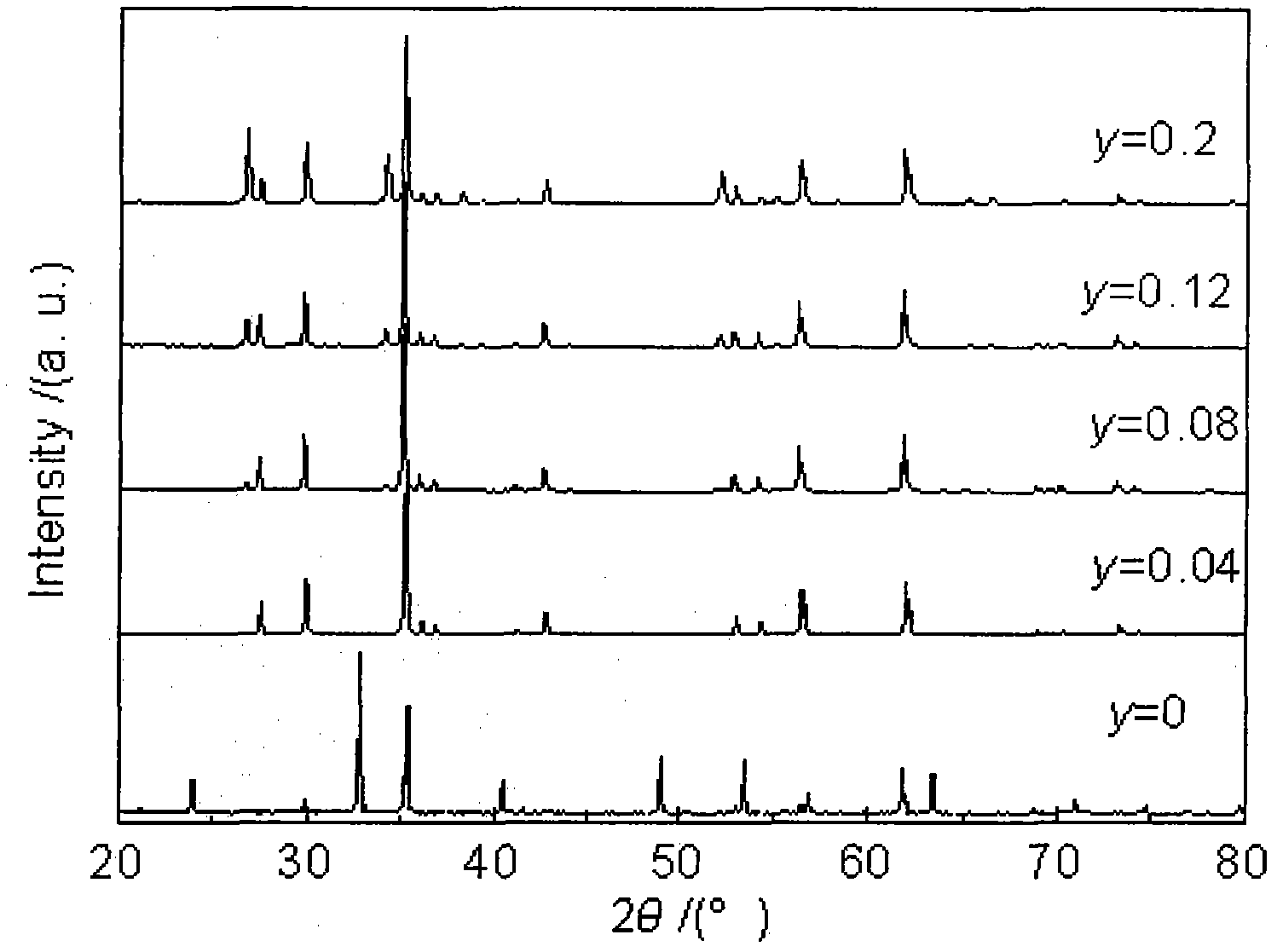

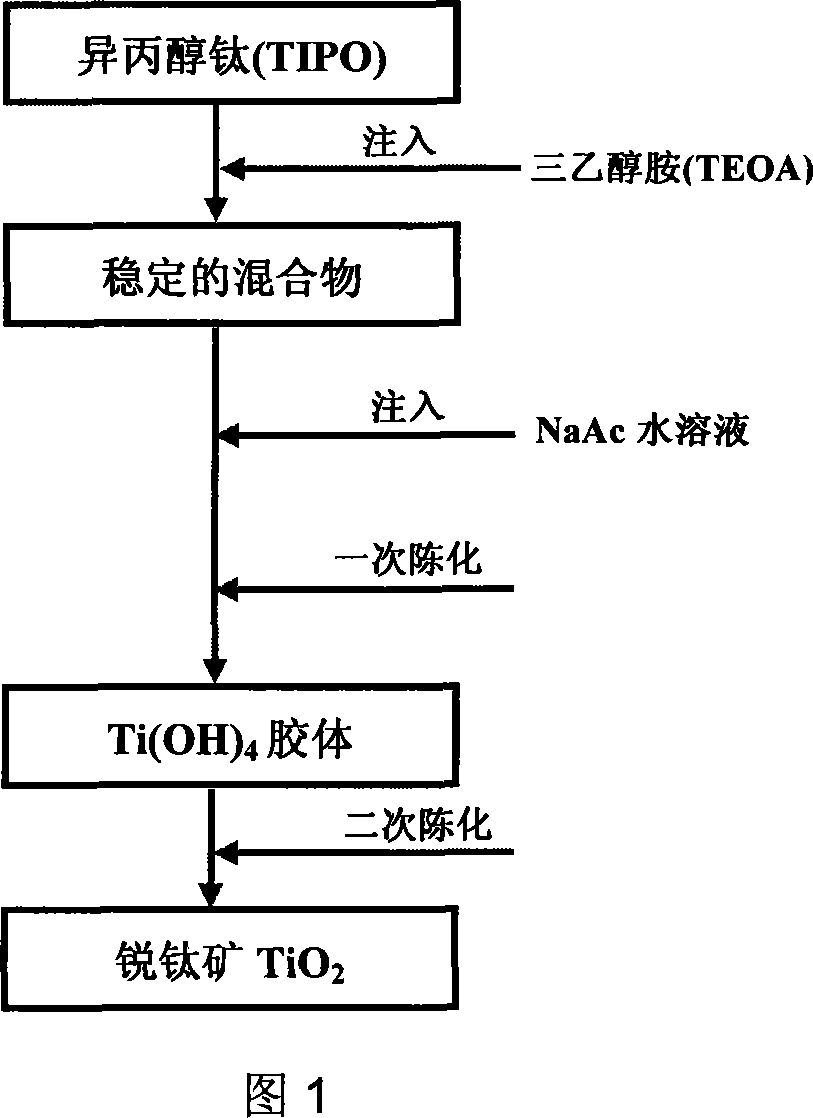

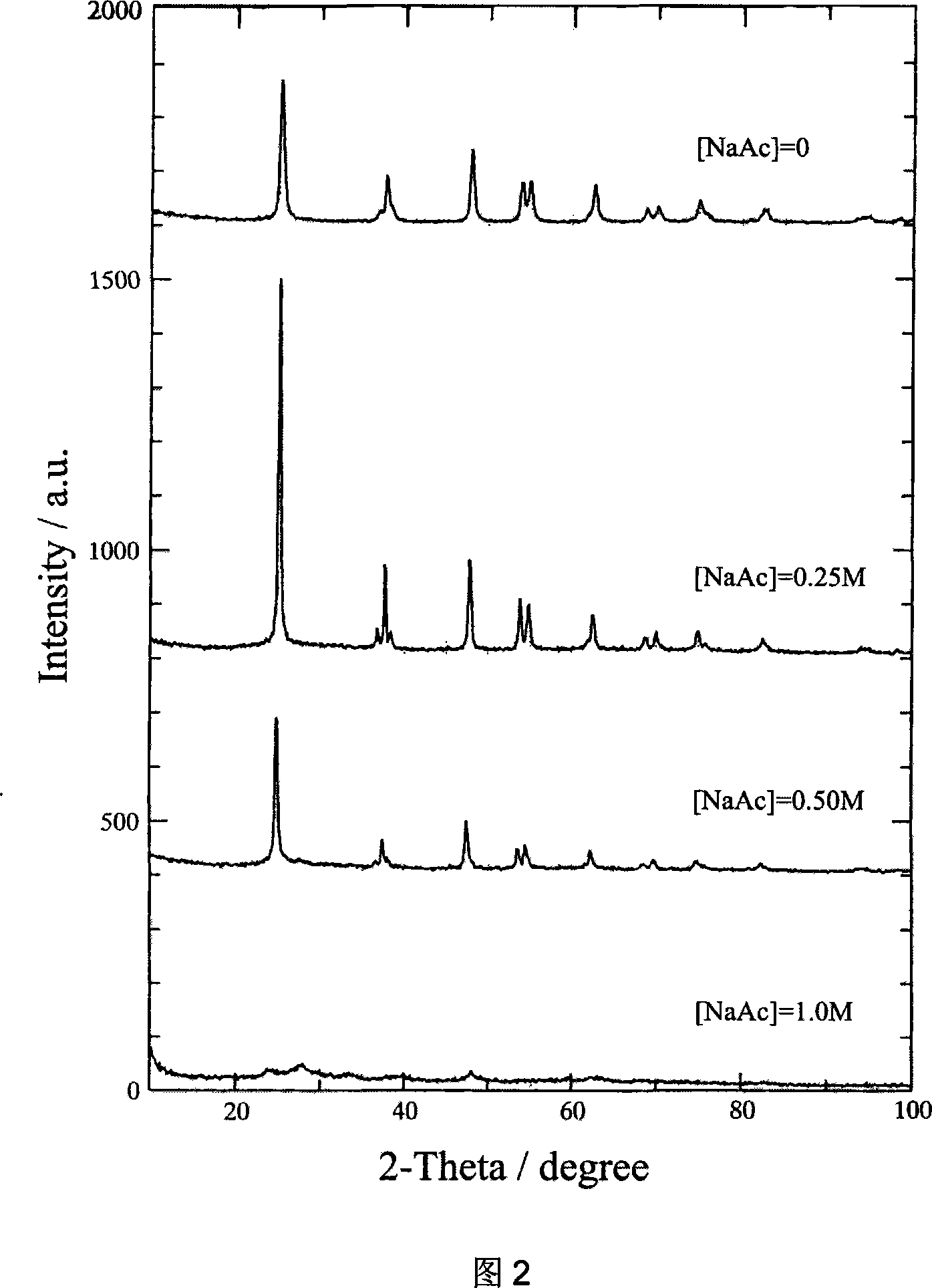

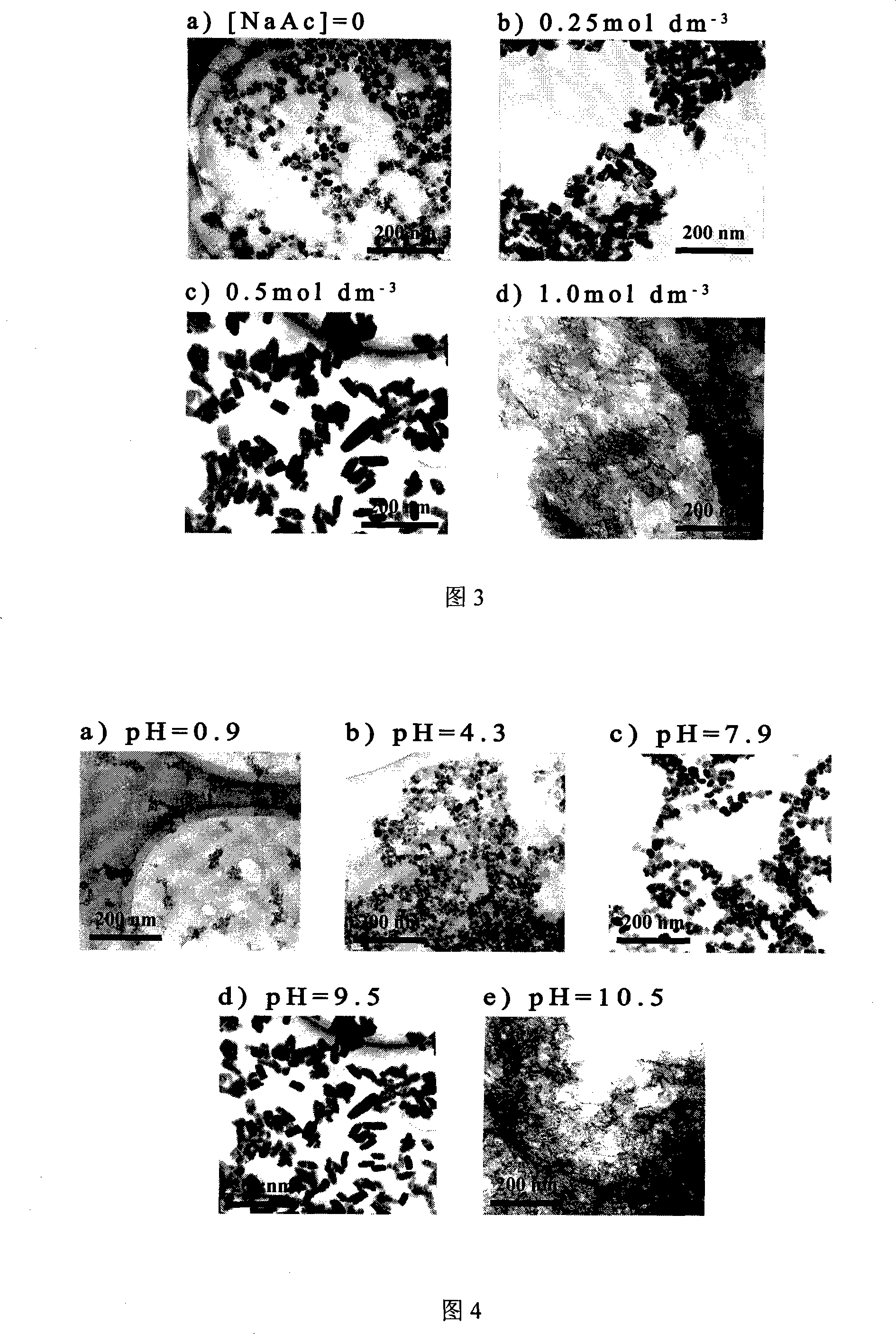

Method for controlling nano-anatase TiO* feature with NaAc as additive agent

InactiveCN101172650AUniform particle sizeGood dispersionNanostructure manufactureTitanium dioxideGranularityTitanium

The invention relates to a method for controlling the appearance of the anatase Tio2 by taking NaAc as additive. The method comprises the steps as follow: (1) isopropyl titanate is used as the raw material and trolamine is used as stabilizing agent, and then water is added into to form the Ti4+ solution, and the mol rate of trolamine and isopropyl titanate is 0: 1.0; (2) water is added into the Ti4+ solution in the same volume of the Ti4+ solution and then is mixed evenly; (3) the additive NaAc which is used for controlling the appearance is added into, and the solution PH value is adjusted to implement a first aging so as to obtain viscolloid; and (4) the nanometer anatase Tio2 grain is obtained after being aged by gelling. The anatase TiO2 prepared with the invention has the advantages of even granularity, good dispersivity, simple preparation technology and easy generalization, thereby being capable of controlling the appearance into a cube shape and a stick shape.

Owner:DONGHUA UNIV

Synthesis method of photochromic titanium dioxide sol

The invention discloses a method for synthesizing photochromism titanic anhydride. The method comprises the following steps: at normal temperature, at the condition of magnetic stirring, putting titanic chloride alcoholic solution with triethanolamine, getting pasty complex compound; The ratio of titanic chloride and triethanolamine being 1:2, using alcohol as dissolvant, and the volume of alcohol being 3 times than triethanolamine; keeping the complex compound at 20-60Deg.C for spell of time, adding deionized water to get saturated solution, at the condition of magnetic stirring, dipping the saturated solution into the AMP95 solution whose mass concentration is 0.5-2%, and getting nanometer octahedrite titanii oxydum gel; putting the gel on the window sill, then the titanii oxydum gel near the window becoming atropurpureus.

Owner:ZHEJIANG SCI-TECH UNIV

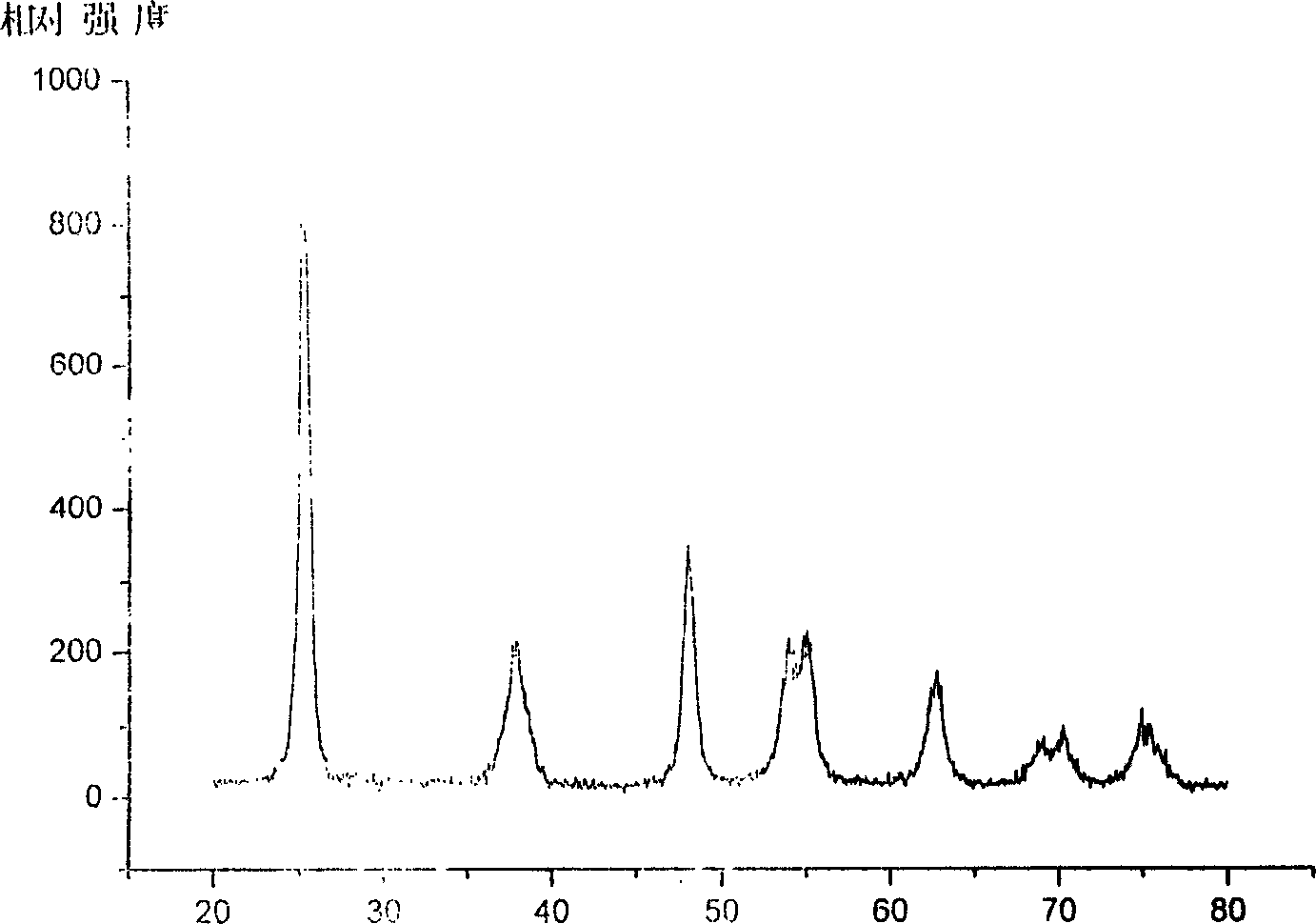

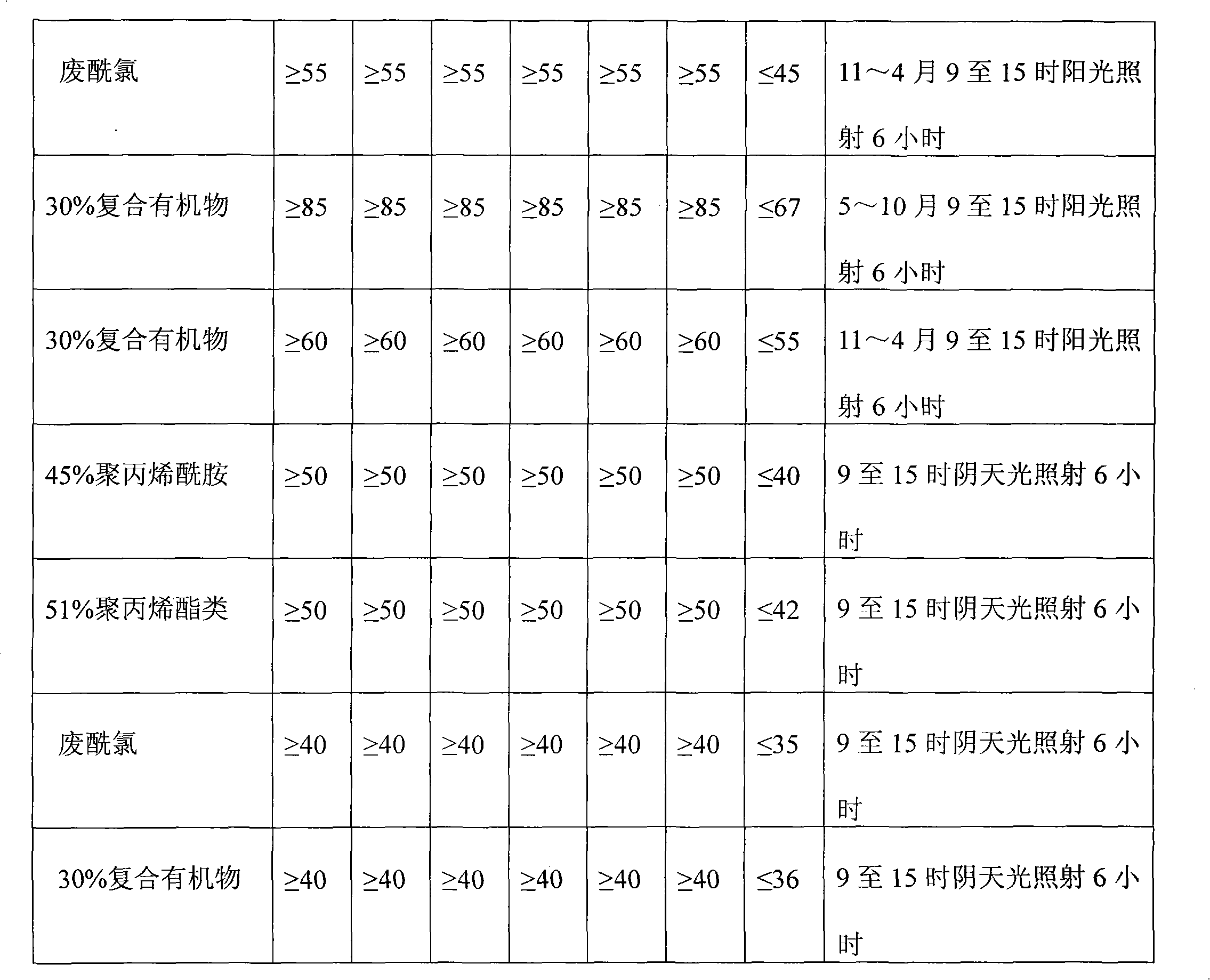

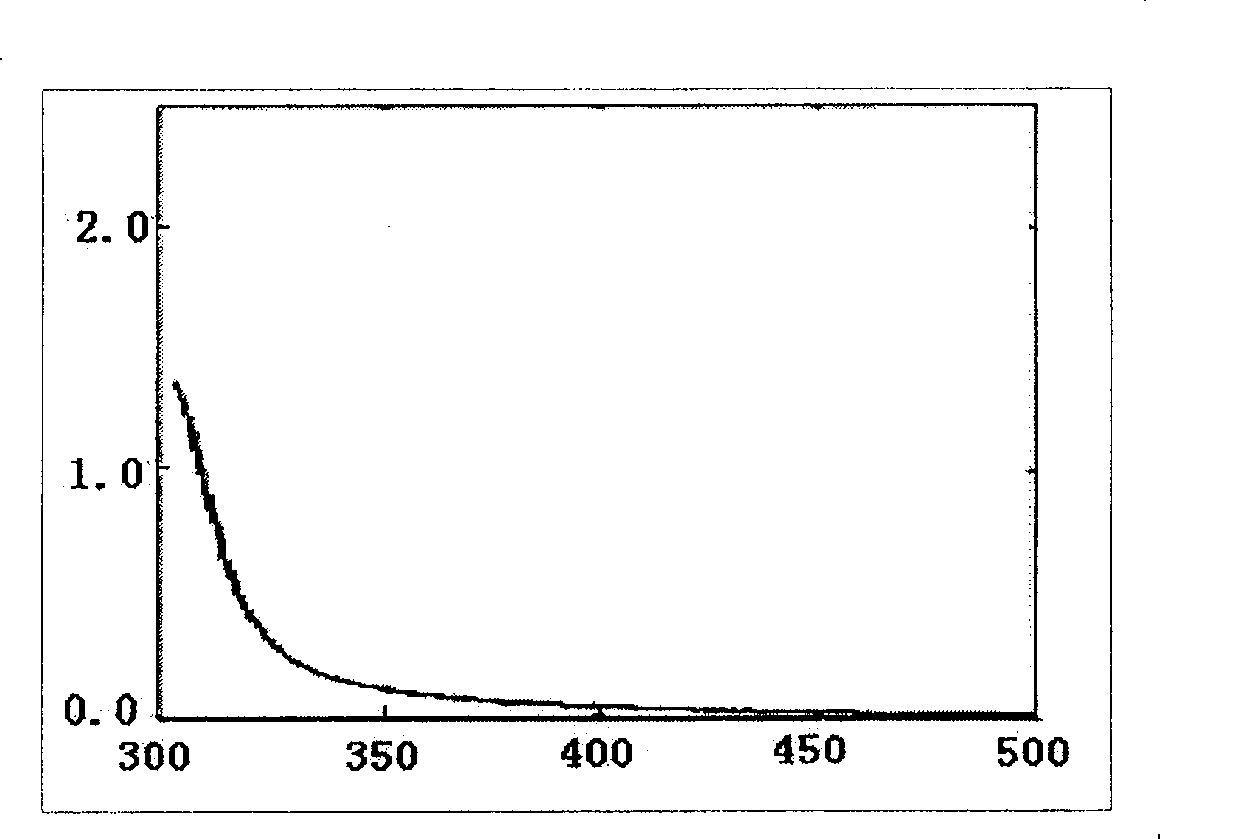

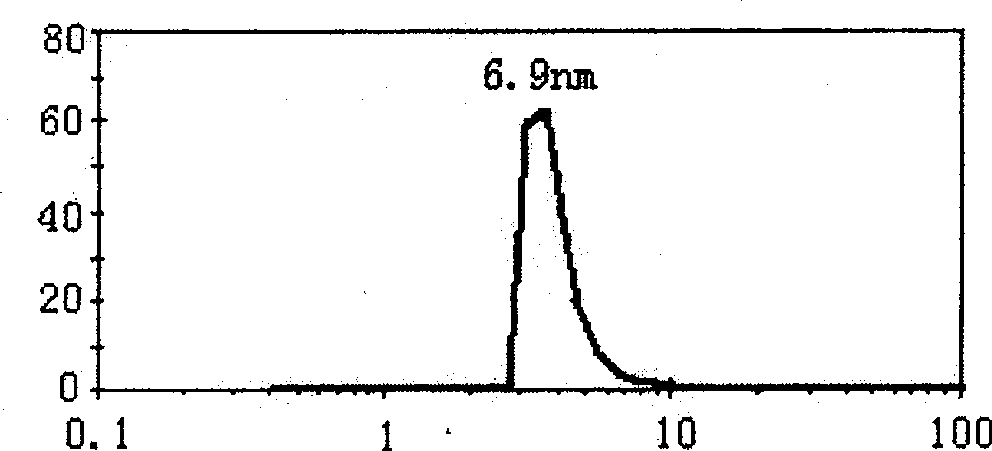

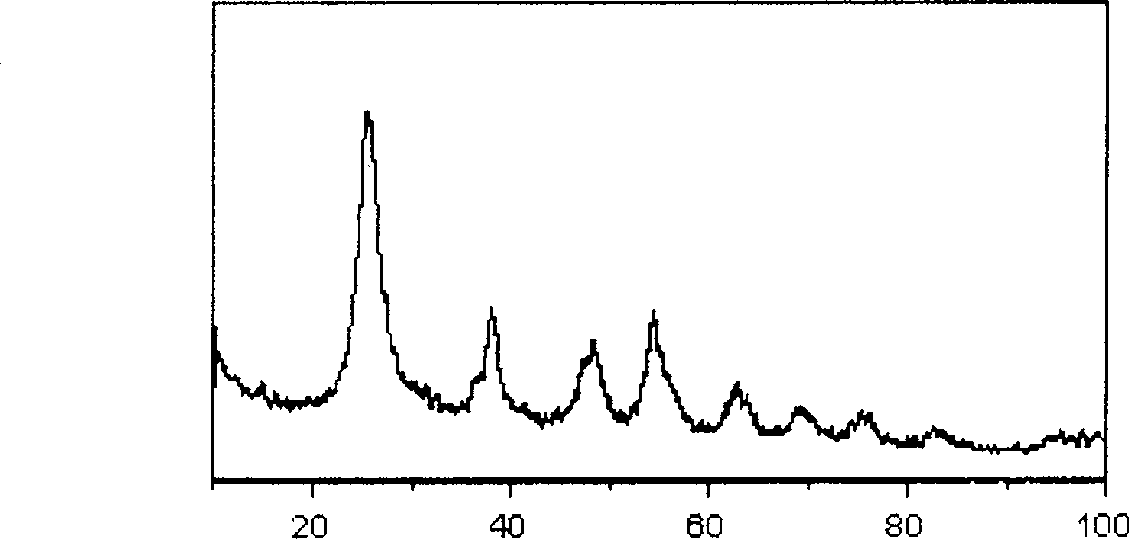

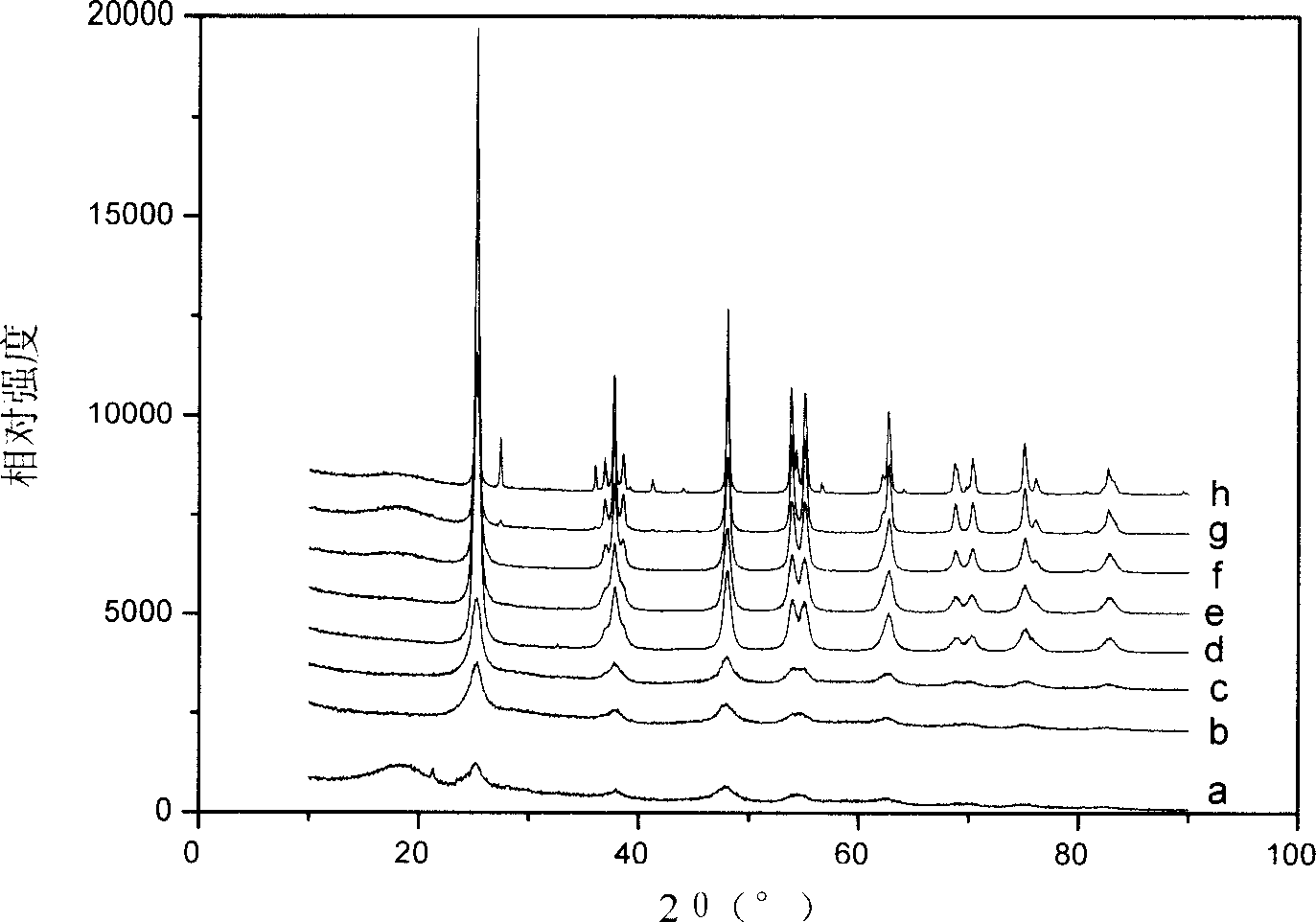

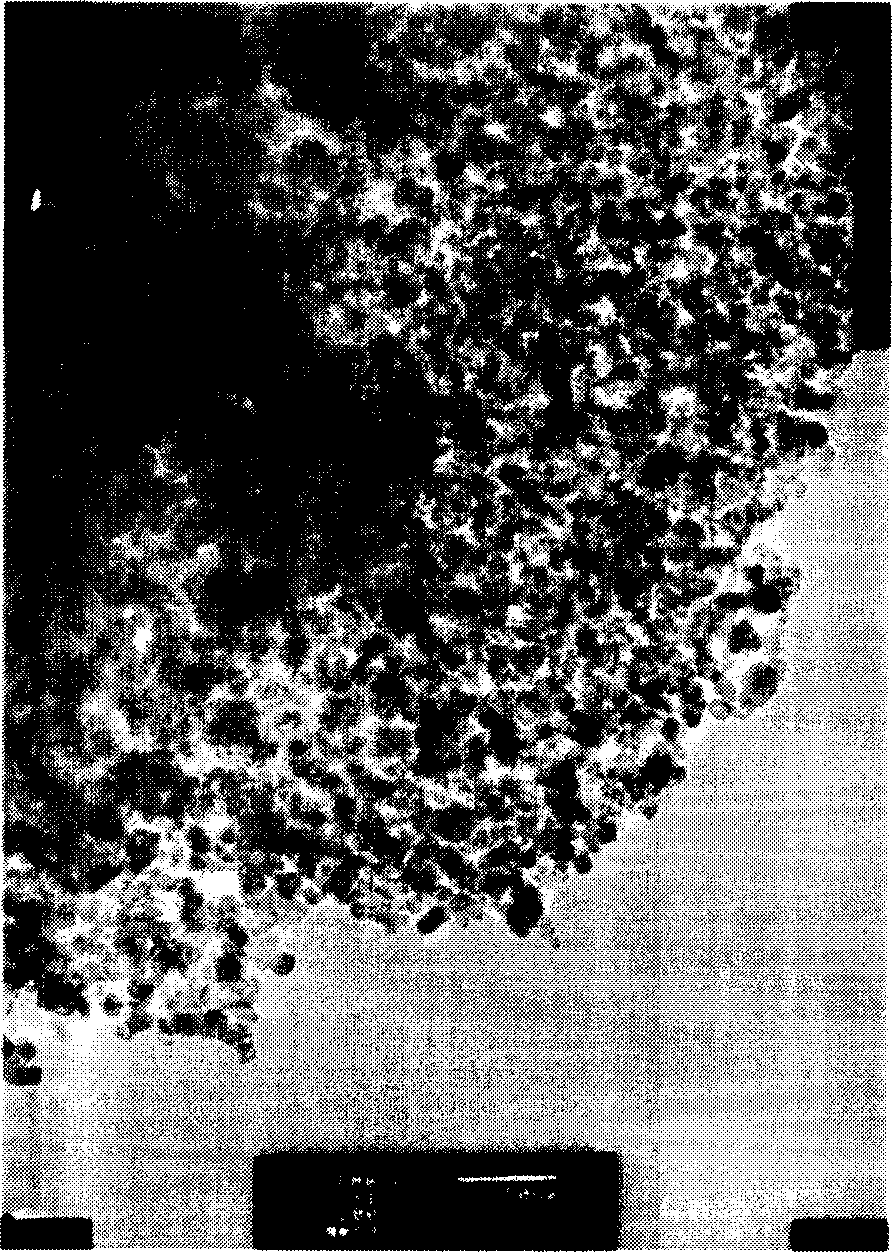

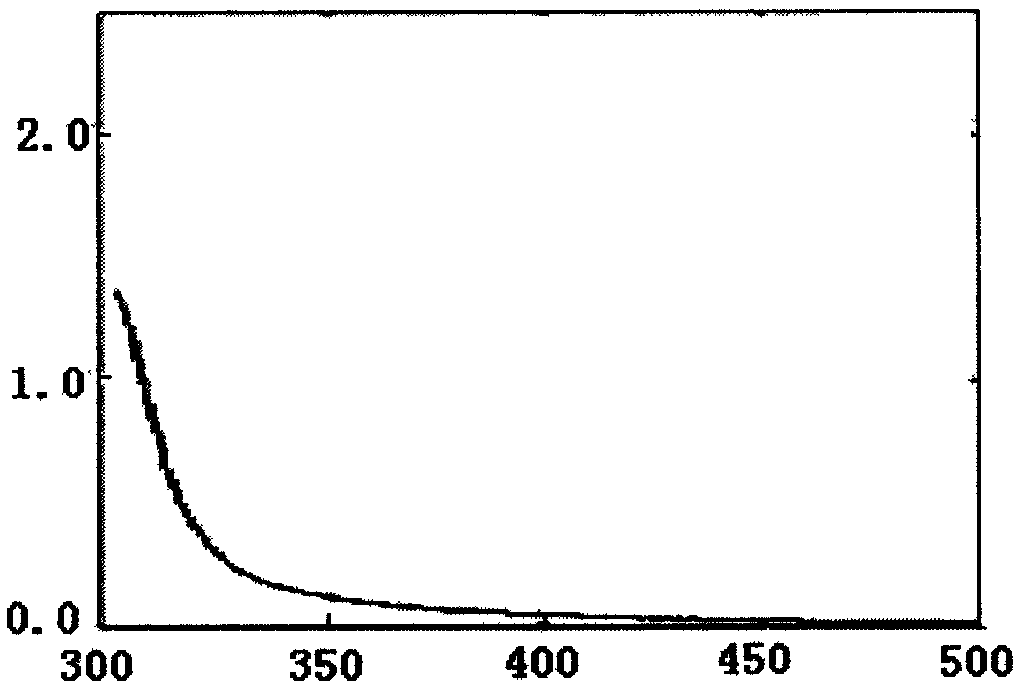

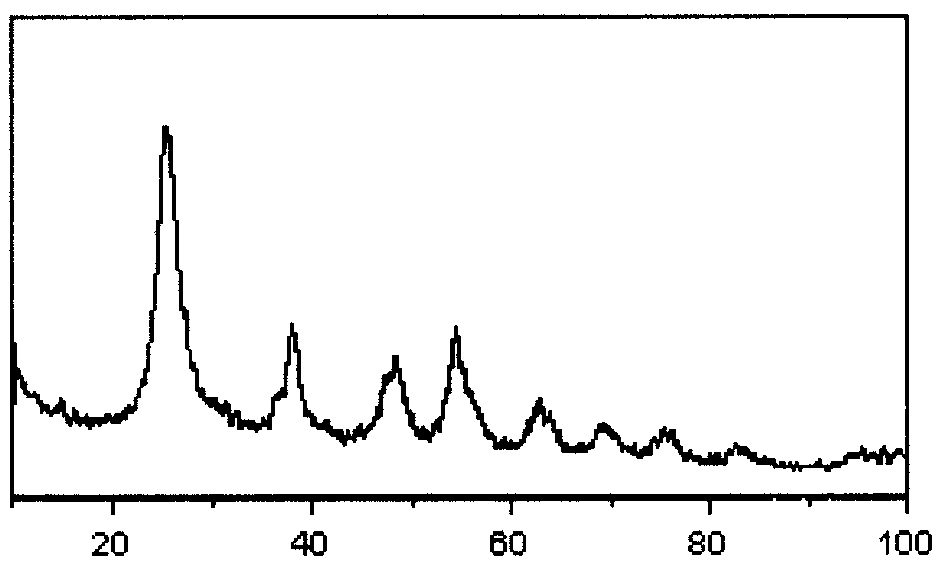

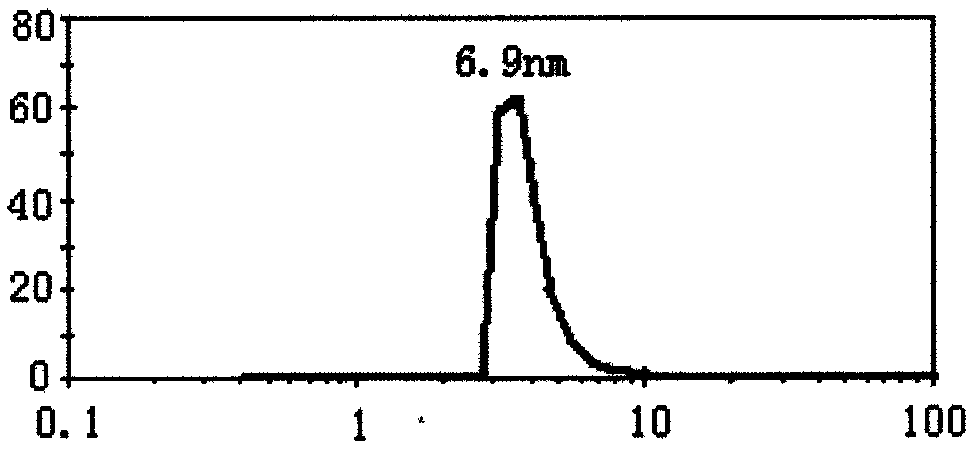

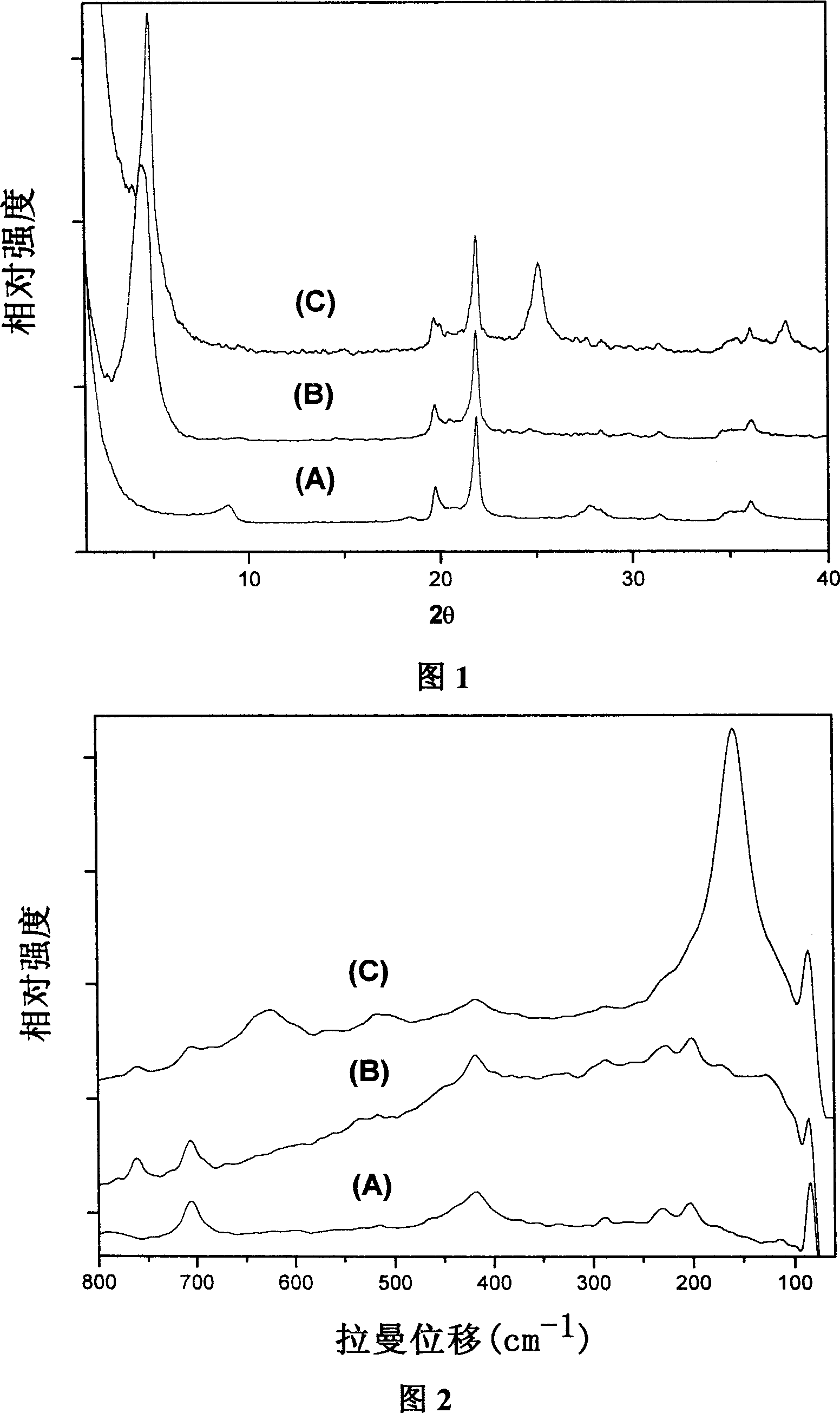

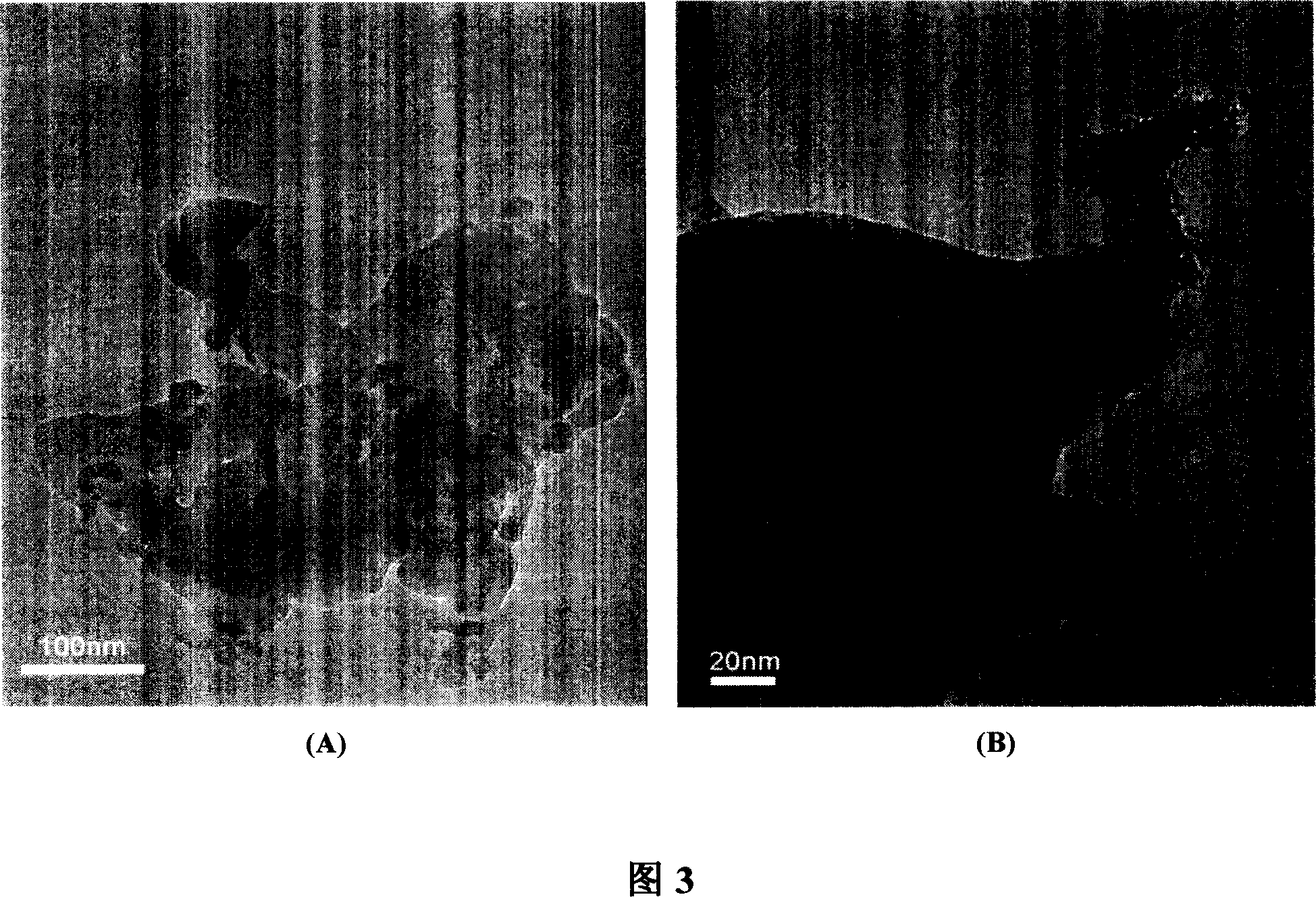

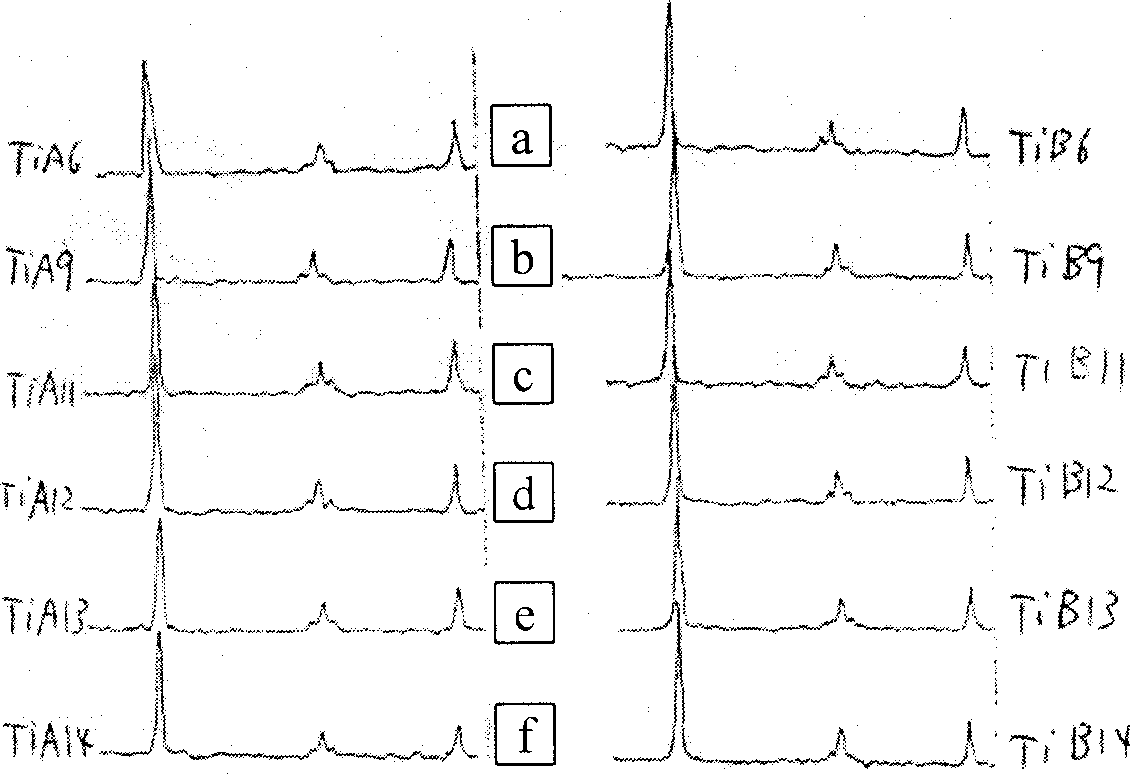

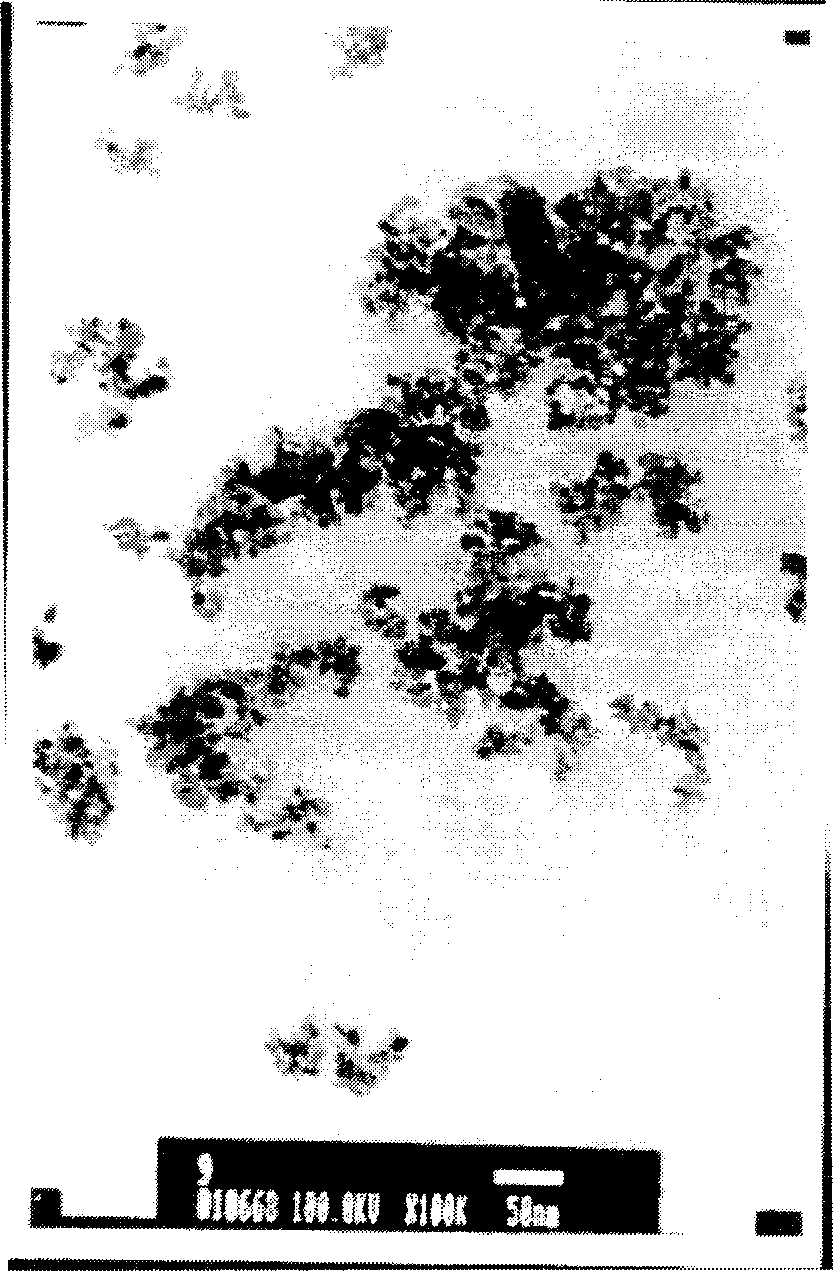

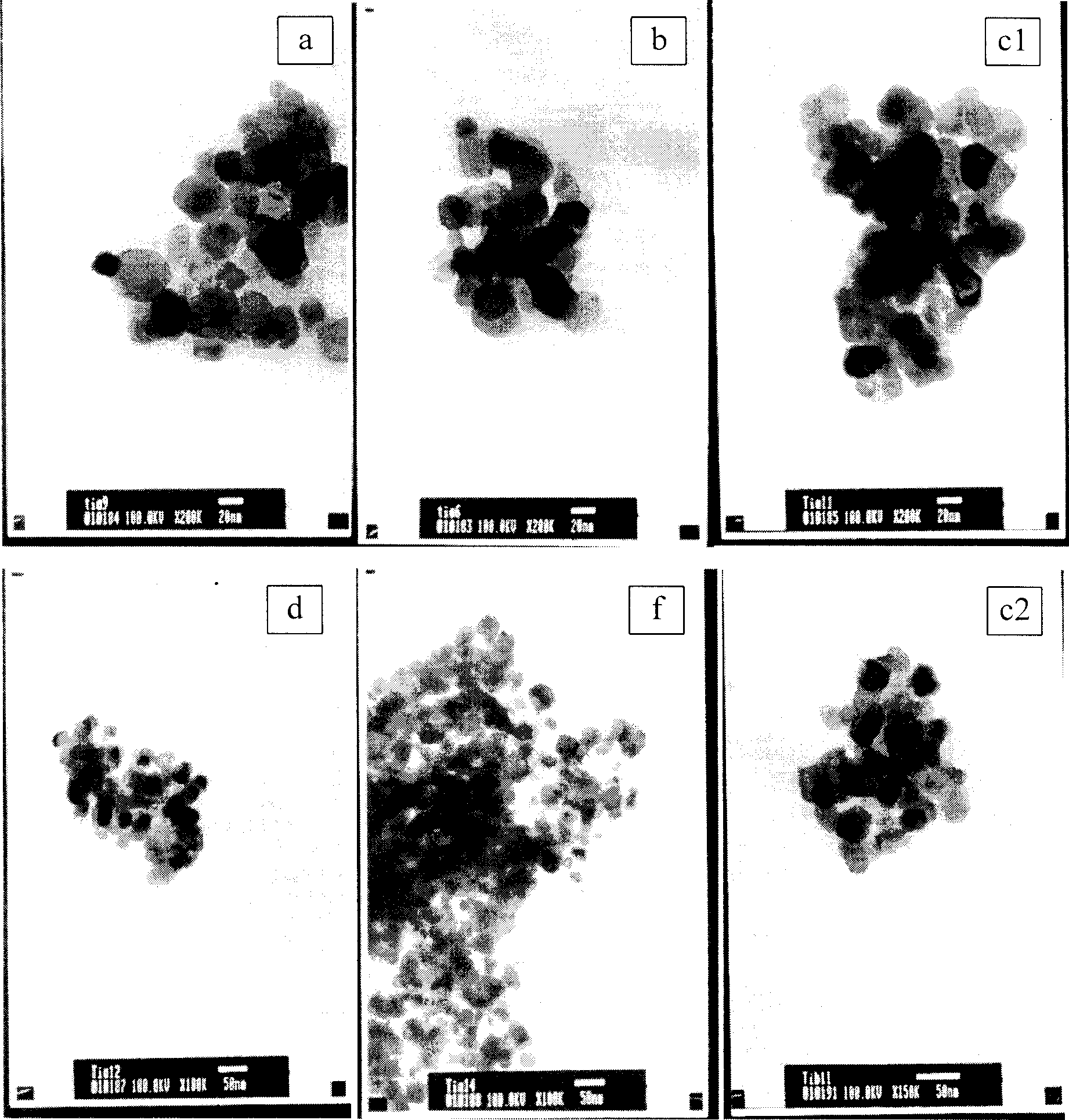

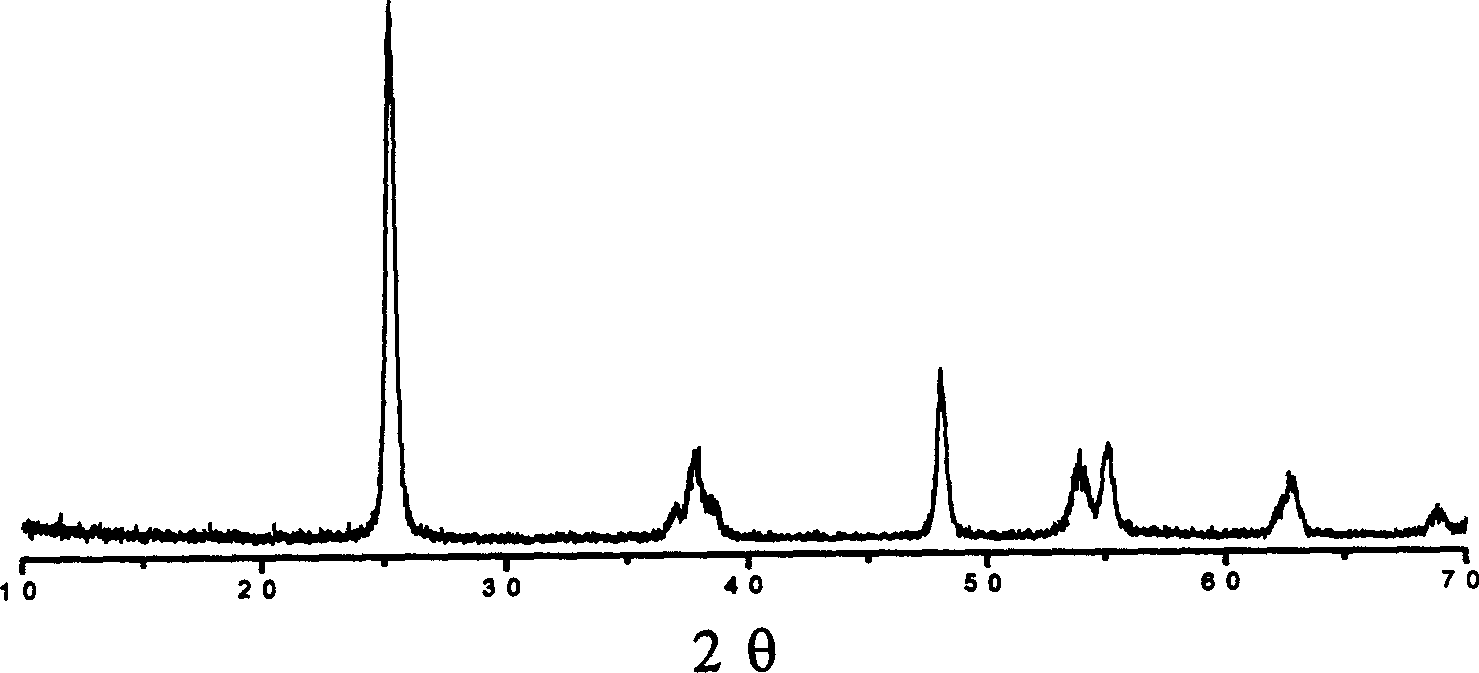

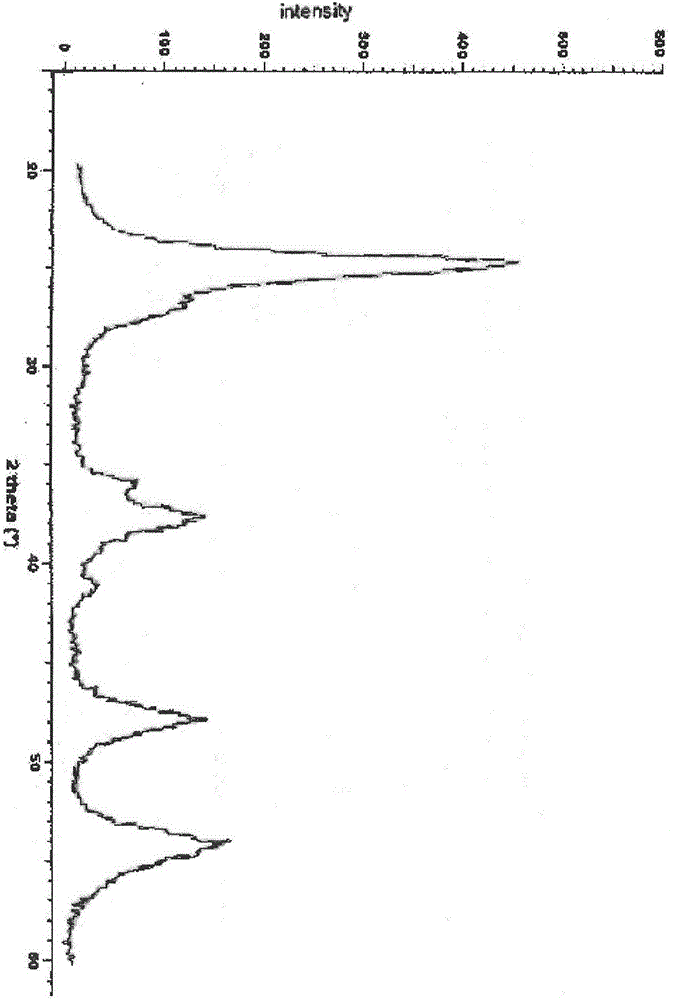

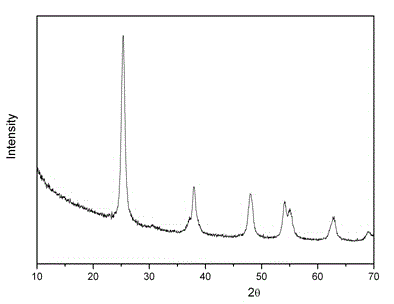

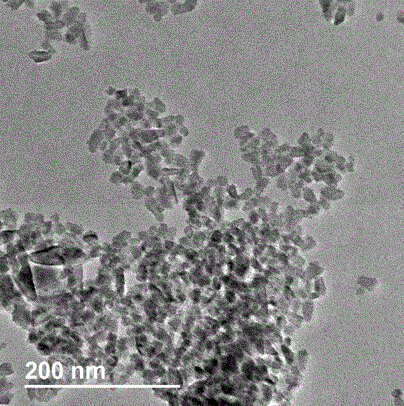

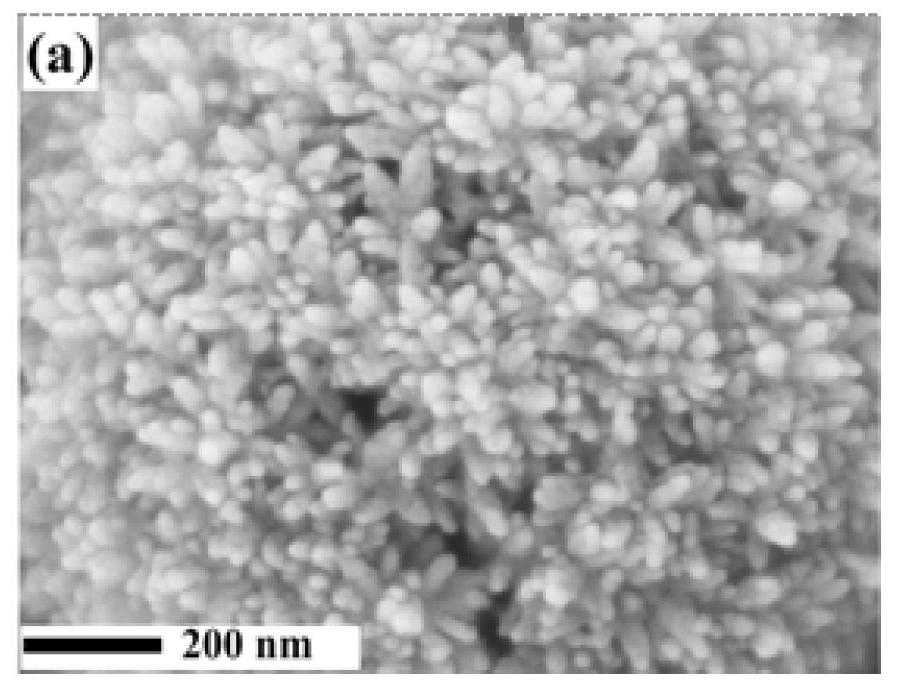

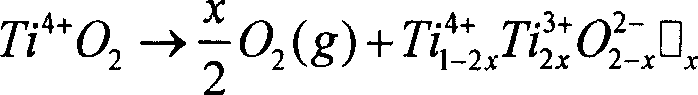

Method for improving photoluminescence of nano anatase TiO#-[2]

InactiveCN1594495AEnhanced photoluminescence intensityLuminescent compositionsPhotoluminescenceFluorescence

The invention disclose a method for improving photoluminescence of nano anatase TiO#-[2] by employing an electron beam co-radiation method in the environment of atmospheric temperature and normal atmosphere, wherein methyl methacrylate is grafted on the nanocrystalline surface of the anatase titanium dioxide (Anatase. A-TiO2). The processed anatase TiO2 nano powder can be combined firmly with methyl methacrylate (MMA) through chemical bonds.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Nano-anatase titanium oxide preparation

InactiveCN1407028AHigher than the surfaceImprove photocatalytic activityInorganic pigment treatmentNitrogen oxideHigh surface

A process for preparing nano-class anatase-type titanium oxide includes such steps as preparing the suspension of naon carrier with water, proportionally adding solution of TiCl4, adding alkali solution to regulate pH value to 6-9, generating solid phase, washing and calcining. Its advantages are high specific surface area, and high surface activity.

Owner:舟山明日纳米材料有限公司

Low-temperature flue gas denitration catalyst powder and preparation method of low-temperature flue gas denitration catalyst powder

InactiveCN105749943AIncreased loading areaIncrease contact areaPhysical/chemical process catalystsAmmonium paratungstateCopper nitrate

The invention discloses low-temperature flue gas denitration catalyst powder and a preparation method of the low-temperature flue gas denitration catalyst powder. The low-temperature flue gas denitration catalyst powder takes vanadium oxide, molybdenum oxide and tungstic oxide as main active components, takes phosphorus oxide, boron oxide and copper oxide as auxiliary active components and takes titanium dioxide as a carrier. The preparation method comprises the following steps: dissolving ammonium metavanadate, ammonium heptamolybdate and ammonium paratungstate into de-ionized water, and adding copper nitrate, boric acid and triammonium phosphate; heating and adjusting the pH value of the solution to be 2.0 to 3.0; slowly adding nano anatase titanium dioxide into an active component solution and dispersing the mixed active component solution by utilizing ultrasonic waves; drying and calcining to obtain the catalyst. According to the low-temperature flue gas denitration catalyst powder, the activity and the catalytic capability of the low-temperature denitration catalyst are remarkably improved; the low-temperature flue gas denitration catalyst powder has higher mechanical strength and anti-corrosion property, has stronger industrial application value and can be widely applied to NH3 selective catalytic reduction of nitrogen oxide in flue gas.

Owner:东营信拓汽车消声器有限公司

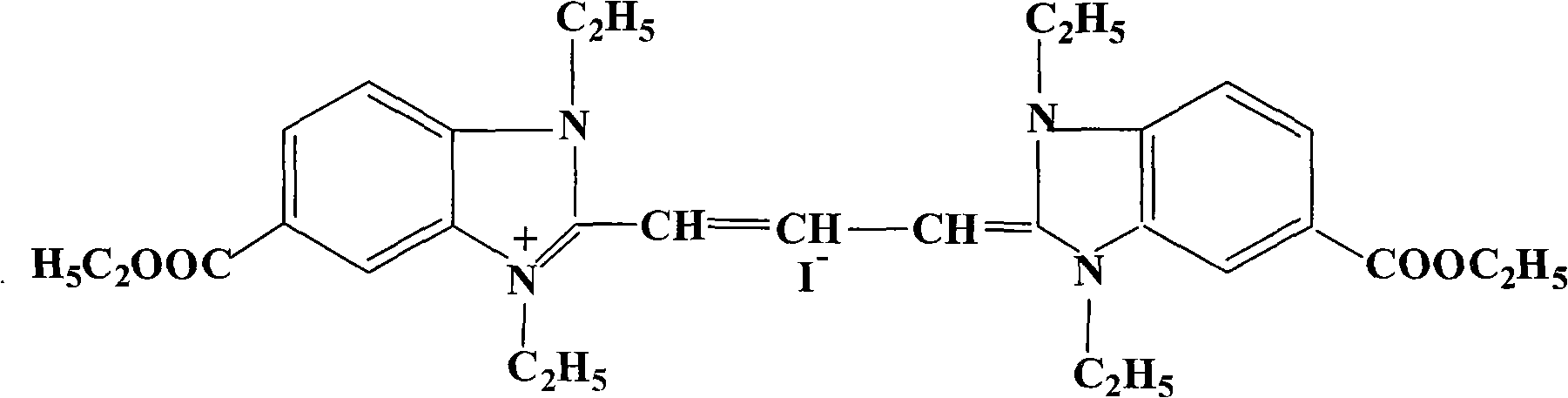

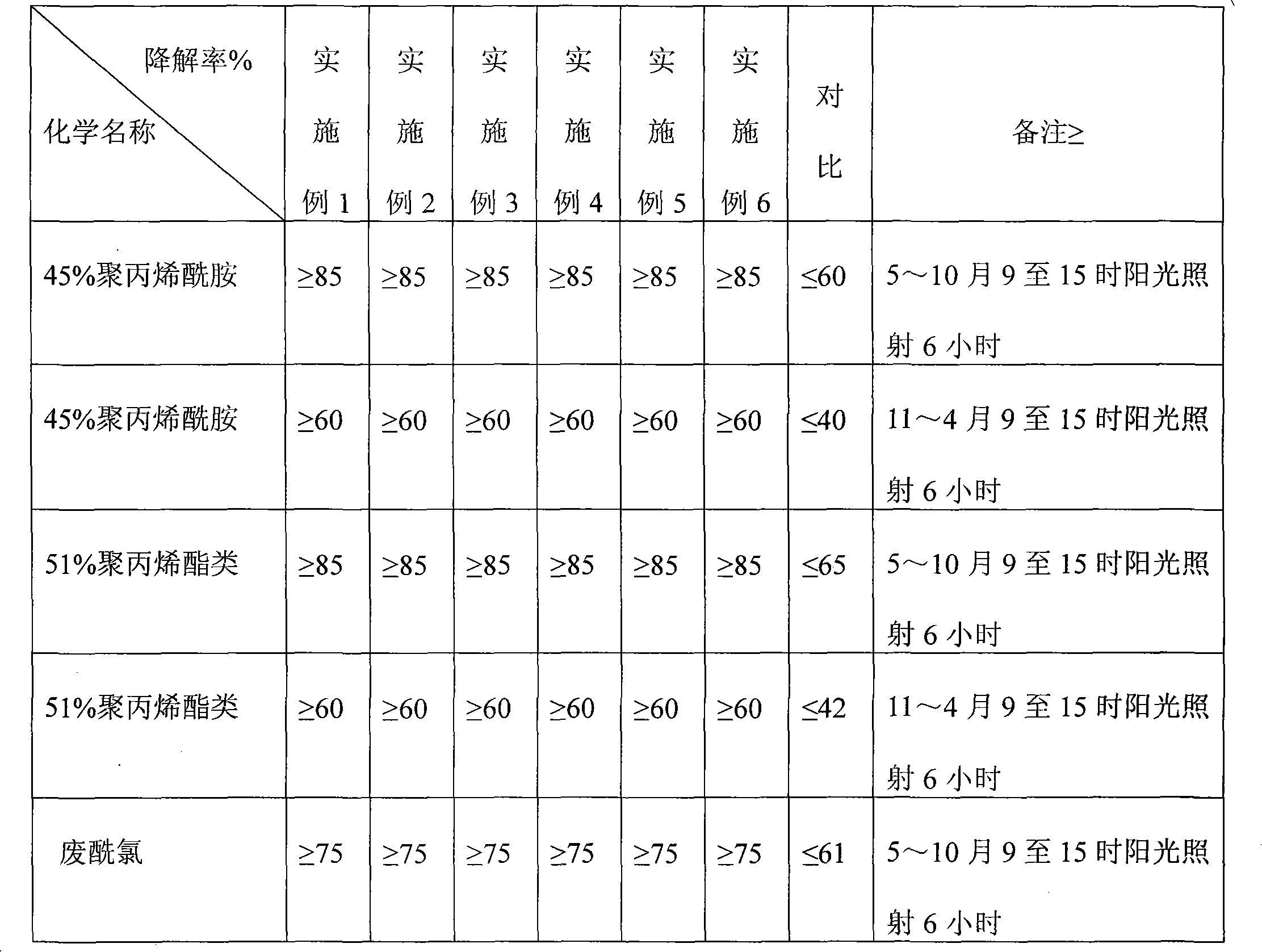

Photochemical degradable sol composition and preparation method thereof

ActiveCN102039194AImprove efficiencyLow costOrganic-compounds/hydrides/coordination-complexes catalystsSesquioxidePhotochemical degradation

The invention provides a photochemical degradable sol composition and a preparation method thereof. The composition comprises the following components in part by weight: 50 parts of water, 0.5 to 1.5 parts of photographic gelatin, 0.5 to 1.5 parts of span 80, 40 to 50 parts of nano anatase titanium white powder, 4 to 8 parts of nano rutile titanium white powder, 5 to 15 parts of mixed light absorbing cyanine dye, 0.5 to 1 part of bismuth nitrate, 0.5 to 1 part of cerous chloride and 1 to 3 parts of nano iron sesquioxide. The degradable sol composition integrates photochemistry, catalysis technology and nano chemistry; sunlight serving as inexhaustible natural resource can be fully utilized and combined with non selectively of modern advanced photochemistry, catalysis technology and nano chemistry on organic waste degradation and oxidation effects; and the method has low cost, is simple and convenient to operate, and is suitable for developing medium and small enterprises.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Method for producing nano-anatase mine titanium oxide water sol

InactiveCN100494072CNot involved in the productionHigh degree of crystallizationTitanium dioxideDistilled waterTitanium

Owner:YUNNAN UNIV

Method for preparing anatase type nano titanium dioxide photocatalyst

InactiveCN1762581AUniform growthShorten the hydrolysis timeCatalyst activation/preparationTitaniumHydrolysis

The invention provides a preparation method for nano anatase-type titania photocatalyst, which comprises: heating titanium sulfate solution till boil to hydrolyze and generate hydrated titania crystal nucleus, adjusting upward the pH value with ammonia to boost hydrolysis and make hydrated titania grow evenly; depositing fully, separating, cleaning, drying, and calcining at 300-600Deg. This process needs low cost and short time, and has high yield without pollution. The product has 5-25nm primary grain size, can degrade organic pollutant in water high efficiently, and can recycle for usage.

Owner:UNIV OF SCI & TECH LIAONING

Polyurethane antistatic floor paint

InactiveCN106047122ASolve anti-staticPrevent static electricityConjugated diene hydrocarbon coatingsAnti-corrosive paintsDisiloxaneLacquer

The invention discloses polyurethane antistatic floor paint. The floor paint comprises the following components in parts by weight: waterborne polyurethane resin 65-70 parts, hexamethyl disiloxane 6-8 parts, nano anatase titania 5-8 parts, styrene-butadiene emulsion 13-15 parts, a polyurethane curing agent 5-12 parts, benzoguanamine formaldehyde resin 13-15 parts, p-methyl benzenesulfonic acid 3-5 parts, acetic acid 8-11 parts, ethylenediaminetetraacetic acid disodium salt 10-12 parts, a polyurethane type dispersant 10-15 parts, vinyltriethoxysilane 6-12 parts, and mica powder 10-15 parts. The polyurethane antistatic floor paint can effectively prevent static electricity, is environmentally friendly, and high in weatherability, and a paint film is smooth in surface, hard, wear-resistant, pressure-resistant and impact-resistant, corrosion resistance is good, effect protection can be implemented, the service life is long, and construction is facilitated.

Owner:张海棠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for improving photoluminescence of nano anatase TiO#-[2] Method for improving photoluminescence of nano anatase TiO#-[2]](https://images-eureka.patsnap.com/patent_img/4bd70a9b-15a9-46e9-b19e-e66892f2584d/A0313579200071.PNG)

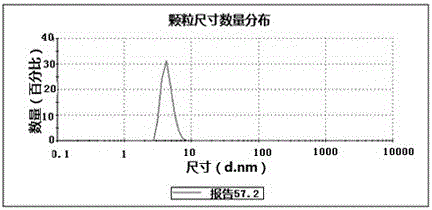

![Method for improving photoluminescence of nano anatase TiO#-[2] Method for improving photoluminescence of nano anatase TiO#-[2]](https://images-eureka.patsnap.com/patent_img/4bd70a9b-15a9-46e9-b19e-e66892f2584d/A0313579200072.PNG)

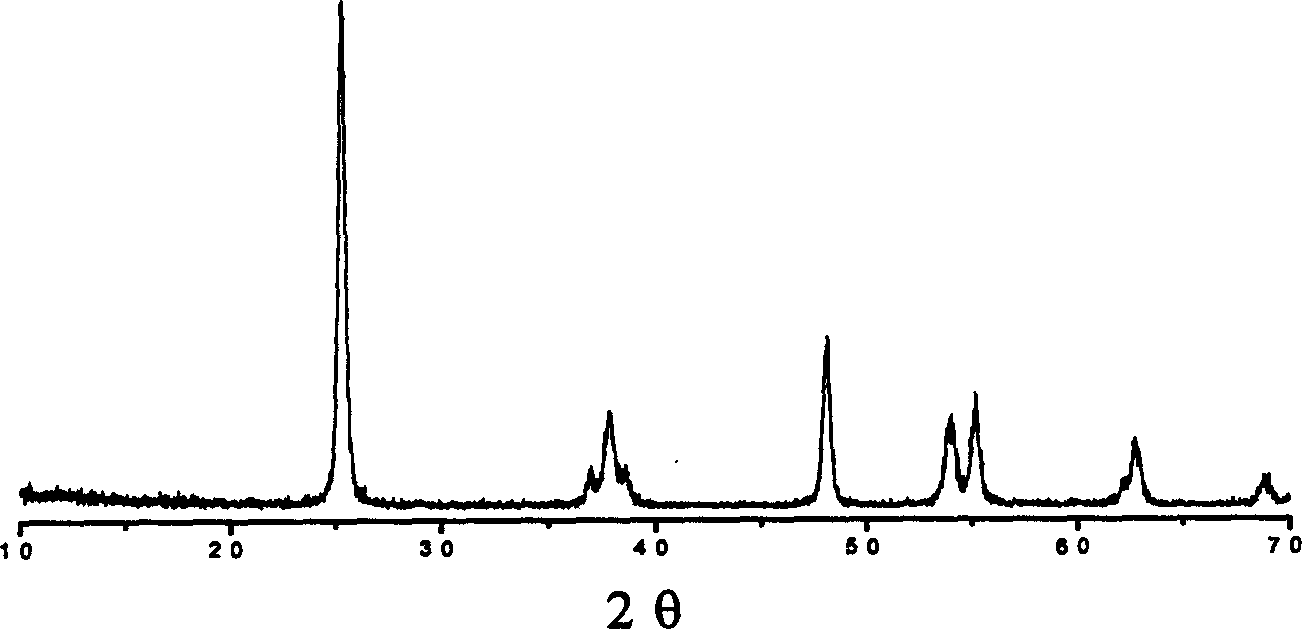

![Method for improving photoluminescence of nano anatase TiO#-[2] Method for improving photoluminescence of nano anatase TiO#-[2]](https://images-eureka.patsnap.com/patent_img/4bd70a9b-15a9-46e9-b19e-e66892f2584d/A0313579200073.PNG)