Method for preparing nano titanium dioxide in anatase type from fluid of hydrothermal crystallized titanium sulfate

A nano-anatase and titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of expensive raw materials and achieve the effects of easy raw materials, reduced environmental pollution, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

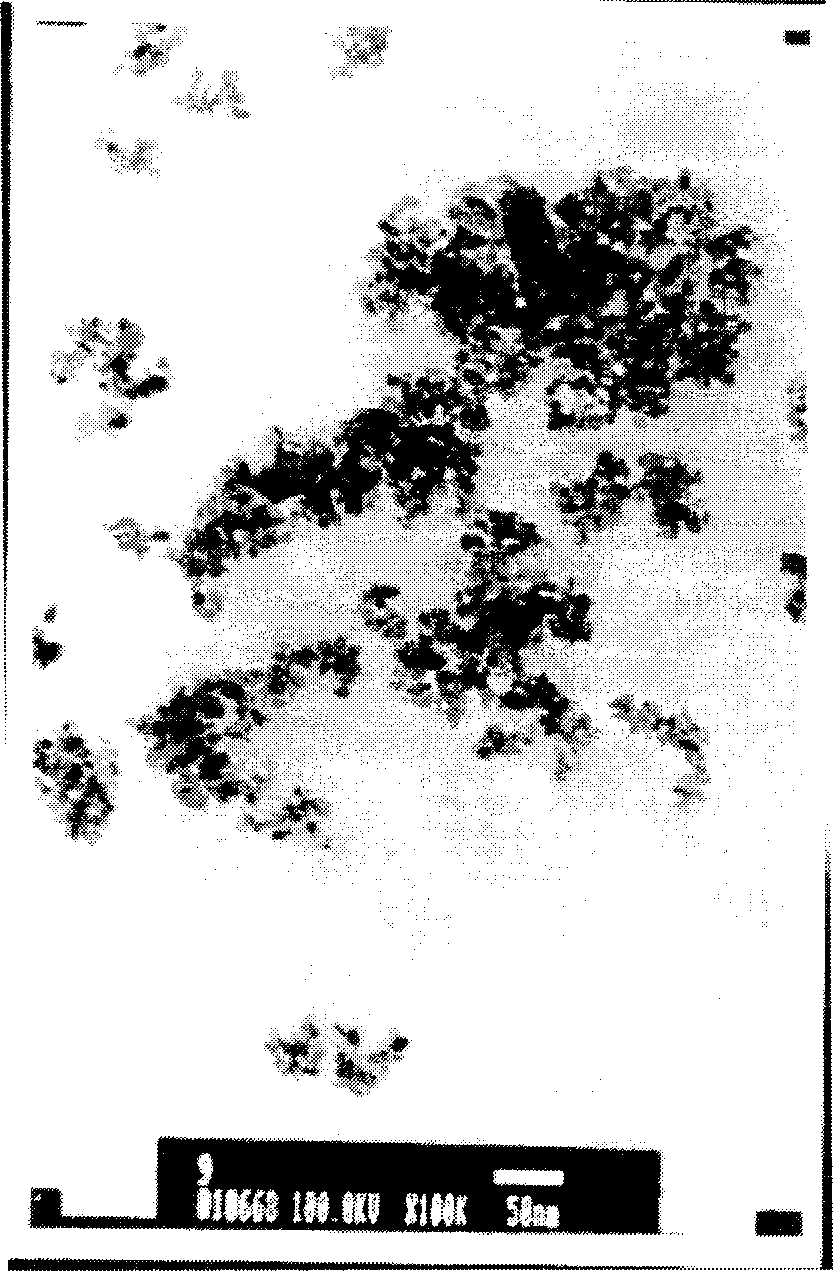

[0018] Example 1: The titanium liquid was precrystallized by hydrothermal treatment at 100°C and 120°C for 5 hours, washed with water to obtain a precipitate, and the precipitate was calcined at 350°C for 5 hours to obtain crystallized, dispersible, nano-sharp Ilmenite-type titanium dioxide products TiA1, TiB1 ( figure 2 ).

Embodiment 2

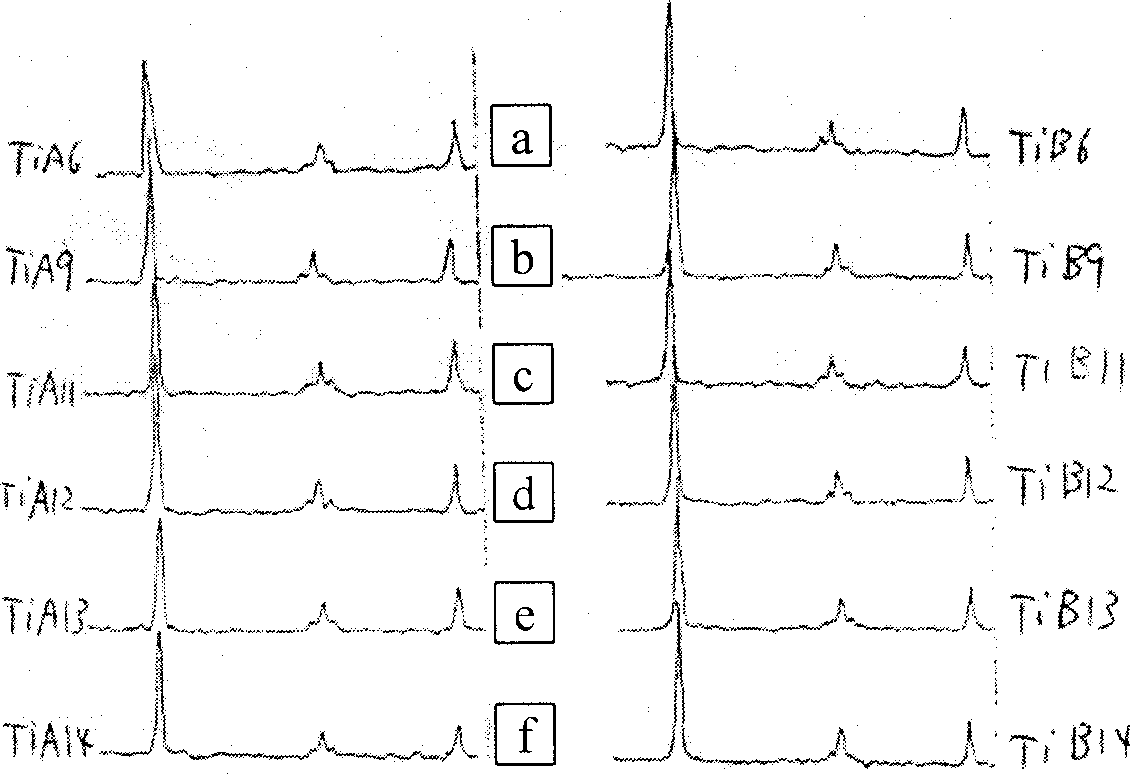

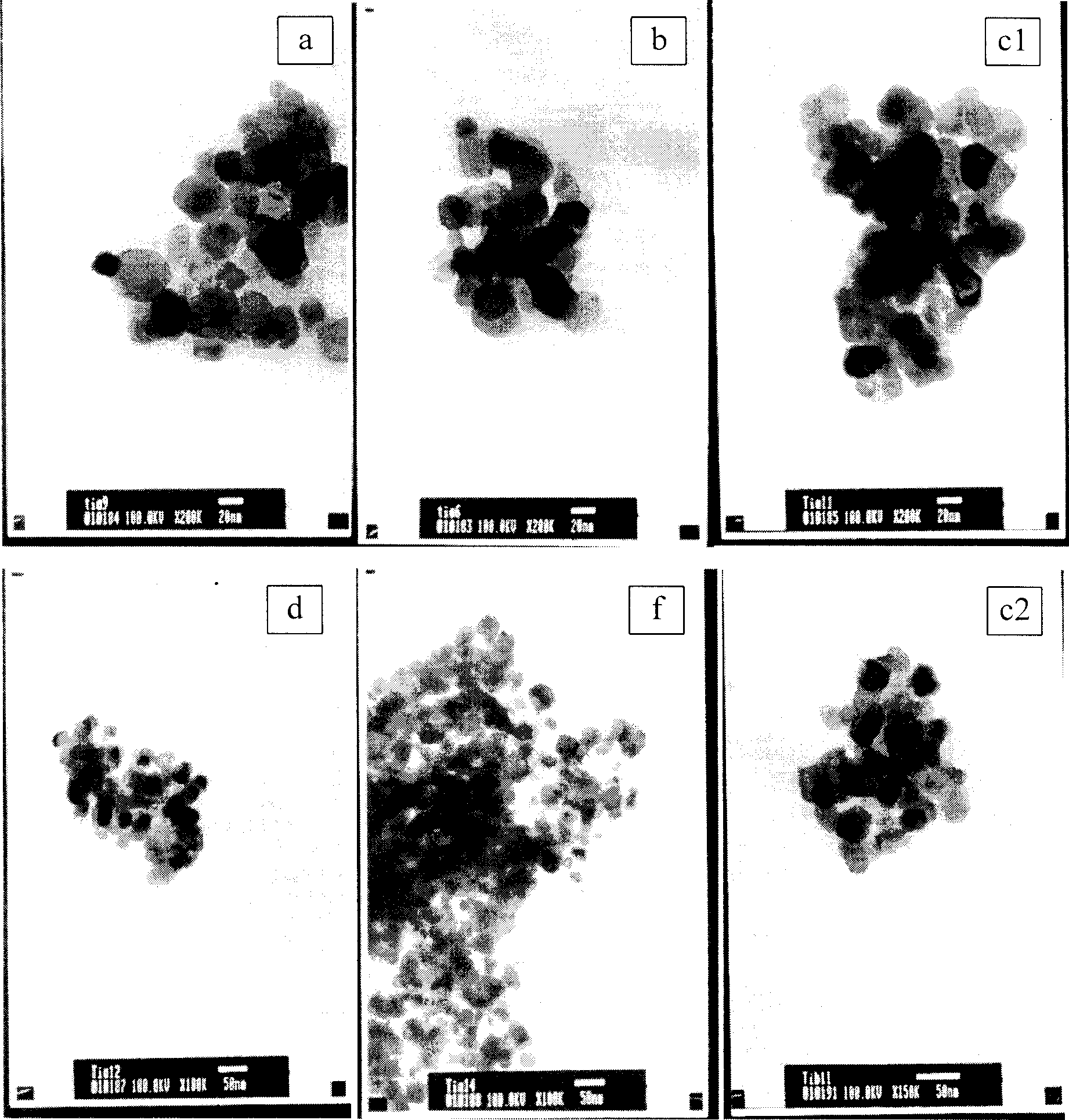

[0019] Example 2: The titanium solution was precrystallized by hydrothermal treatment at 100°C and 120°C for 5 hours respectively, and washed with water to obtain precipitate A, which was treated with 1.0ml of 0.2M dilute acetic acid per gram of precipitate for 2 hours and then washed with water , to obtain precipitate B, and then each gram of precipitate was treated with 1.0ml 0.2M ammonia water for 2 hours, washed with water to obtain precipitate C, and then per gram of precipitate was treated with 1.0ml 0.1% polyvinylamide for 2 hours to obtain precipitate D. After precipitation D was washed with water and separated, it was calcined at 800°C for 5 hours to obtain crystallized and dispersible nano anatase titanium dioxide TiA6 and TiB6 ( figure 1 a. image 3 a).

Embodiment 3

[0020] Example 3: The titanium solution was precrystallized by hydrothermal treatment at 100°C and 120°C for 5 hours respectively, and washed with water to obtain precipitate A, which was treated with 1.0ml of 0.2M dilute hydrochloric acid per gram of precipitate for 2 hours and then washed with water , to obtain precipitate B; then washed with water, to obtain precipitate C. After the precipitate C was washed with water and separated, it was calcined at 800°C for 5 hours to obtain crystallized, dispersible, nano anatase titanium dioxide TiA9, TiB9 ( figure 1 b. image 3 b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com