Process for preparing nano anatase titanium oxide

A nano-anatase and titanium oxide technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of incomplete desorption, increase in cost, and inability to remove, and save washing water and surface activity. The effect of reducing the cost of agents, raw materials and production, and shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

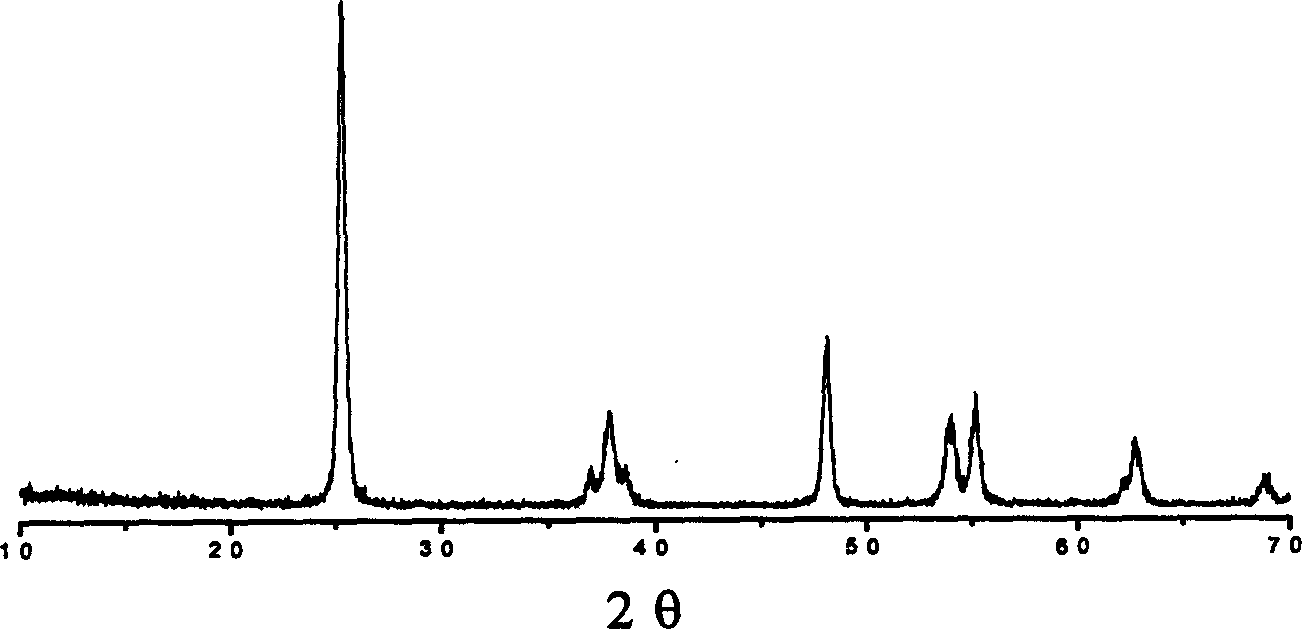

[0014] Example 1: Weigh 23g of metatitanic acid, add 600ml of water and 3.13g of ammonium bicarbonate to form a mixed aqueous solution, stir for 1 hour, let it stand, filter, and after drying the obtained filter cake, take it out after heat treatment at 650°C for 1 hour , grinding. It is analyzed as anatase titanium oxide by X-ray diffraction (XRD), and its finished product particle size measured by transmission electron microscope is 20-50nm ( Figure 1A , Figure 1B ).

Embodiment 2

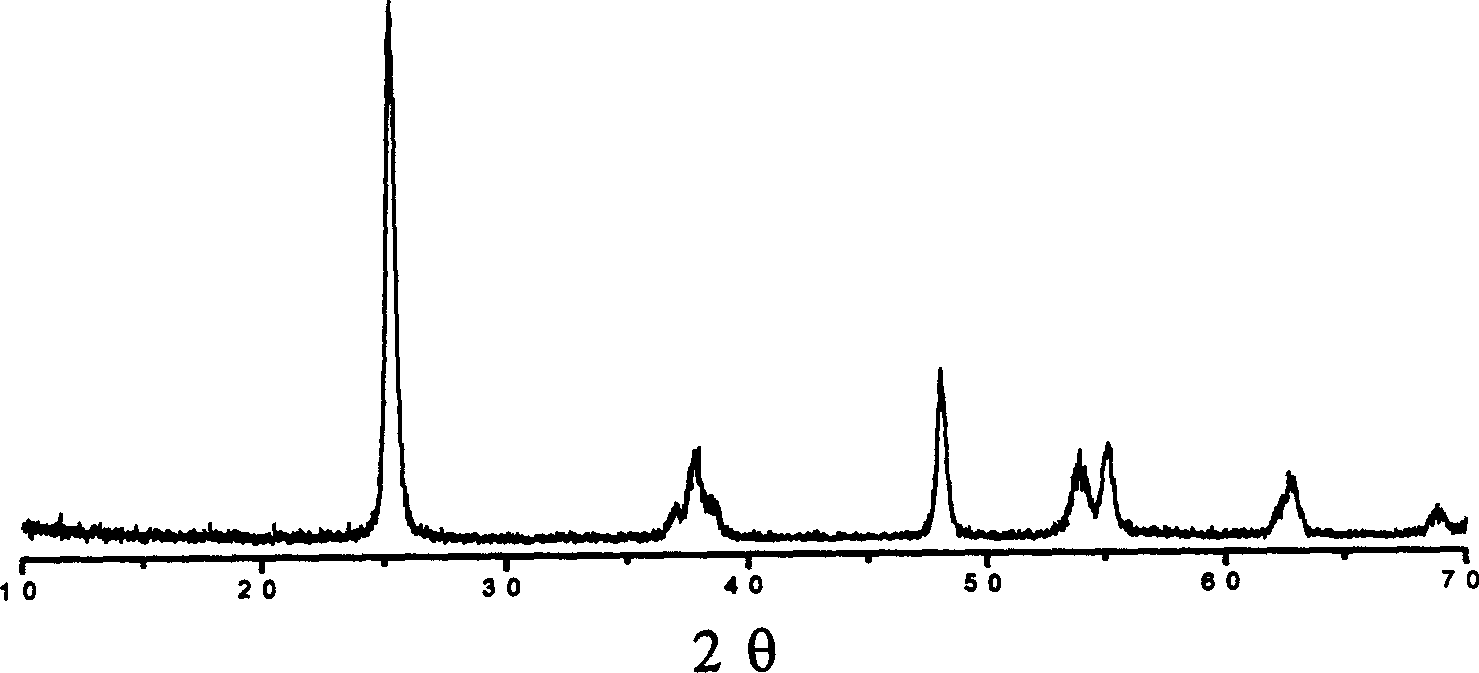

[0015] Example 2: Weigh 23g of metatitanic acid, add 600ml of water and 3.89g of ammonium bicarbonate to form a mixed solution, stir for 1 hour, let it stand, filter, and after the obtained filter cake is dried, take it out after heat treatment at 600°C for 1 hour , grinding. It is analyzed as anatase titanium oxide by X-ray diffraction (XDR), and the particle size of finished product measured by transmission electron microscope is 20-50nm ( Figure 2A , Figure 2B ).

[0016] Example 3: Weigh 23g of metatitanic acid, add 600ml of water and 4.51g of ammonium bicarbonate mixed solution, stir for 1 hour, let stand, filter, after the obtained filter cake is dried, take it out after heat treatment at a temperature of 550°C for 1 hour, grind. It is analyzed as anatase titanium oxide by X-ray diffraction (XRD), and the particle size of finished product measured by transmission electron microscope is 15-50nm ( Figure 3A , Figure 3B ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com