Nano-anatase titanium oxide preparation

A technology of nano-anatase and titanium oxide, which is applied in the direction of chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of mixed crystal or poor crystallinity, reduced photocatalytic activity, complex process, etc. Large surface, high surface activity, and the effect of improving the specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

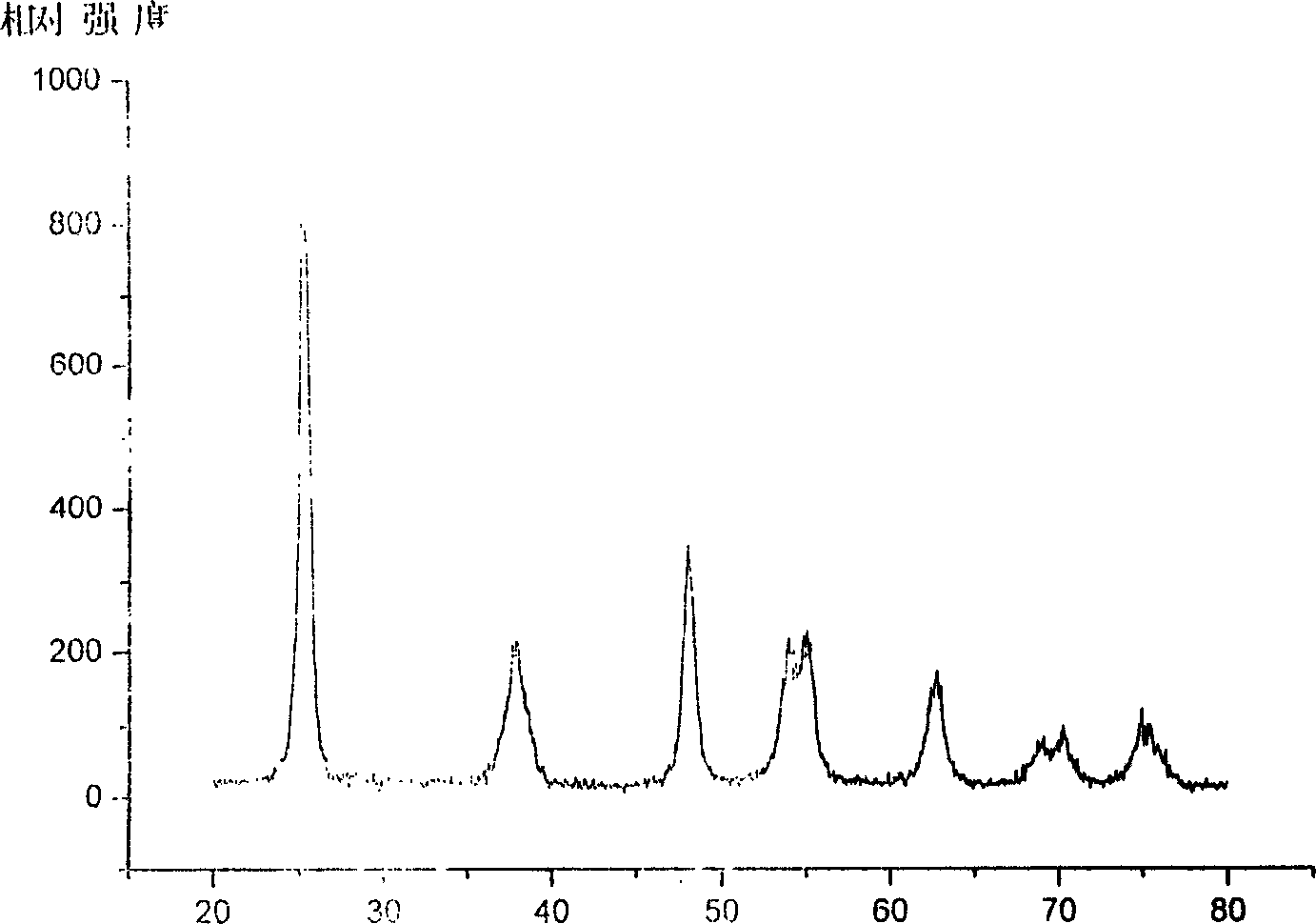

[0012] Embodiment 1: at first 400 grams of nano-structured carrier material silicon-based oxides are added to 1500 ml of deionized water, dispersed with ultrasonic waves, then at room temperature, adding concentration is 120 ml of 15% titanium tetrachloride solution while stirring, and aging after adding After 1 hour, the pH was adjusted to 6.5 with sodium hydroxide solution, and the obtained reactant was centrifugally washed to be free of chloride ions, washed twice with ethanol, then dried at 450°C for 2 hours, dispersed by a jet mill, and finally obtained The crystal form of nano-anatase titanium oxide is shown in the attached figure.

Embodiment 2

[0013] Embodiment 2: at first 300g nano-structure carrier material nano-alumina is added to 3000ml deionized water, disperse with ultrasonic wave, then add concentration while stirring at room temperature and be 150ml of titanium tetrachloride solution of 30%, aging 1 after adding hour, and then adjust the pH to 9 with 10% potassium hydroxide solution, and the obtained reactant is centrifugally washed until there is no chloride ion, and washed twice with ethanol, then dried at 450°C for 2 hours, dispersed by a jet mill, and finally nano-anatase is obtained Mineral type titanium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com