Photochemical degradable sol composition and preparation method thereof

A technology of photochemistry and composition, which is applied in the field of photochemical degradation sol composition, can solve the problems of complex manufacturing process, high cost, and limitation, and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Photochemical degradation sol composition: (parts by weight)

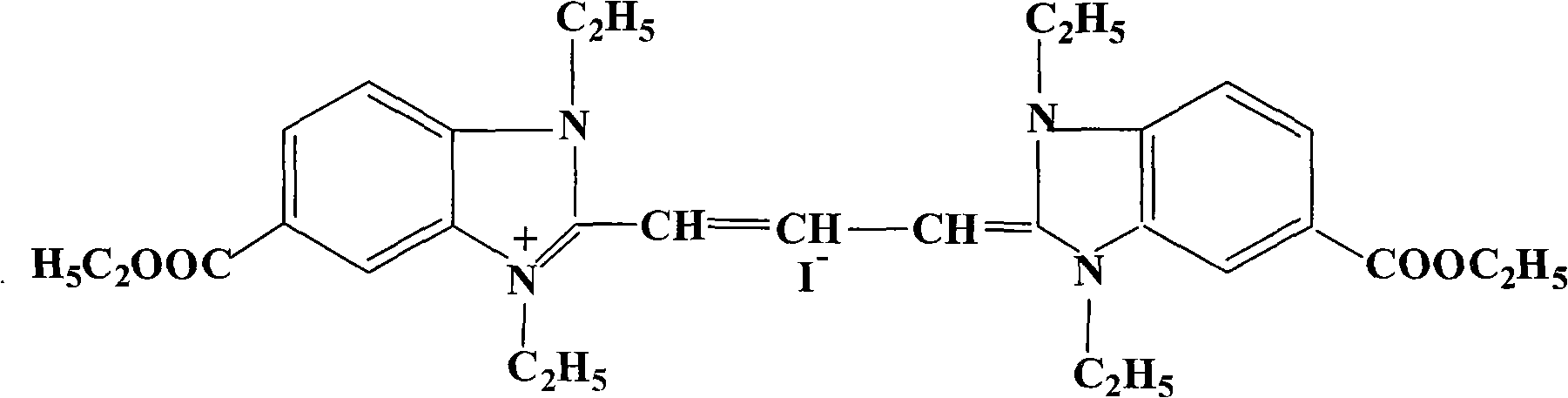

[0029] 50 parts of deionized water, 0.5 parts of photographic gelatin, 0.5 parts of Span 80, 40 parts of 20 nanometer sharp titanium dioxide, 4 parts of 40 nanometer rutile titanium dioxide, 5 parts of mixed light-absorbing cyanine dye, 0.5 part of bismuth nitrate, trichloro 0.5 part of cerium oxide, 1 part of 20 nanometer ferric oxide;

[0030] The particle size of both nano sharp titanium dioxide and nano rutile titanium dioxide is 40 nanometers;

[0031] Nano ferric oxide particle size is 50 nanometers;

[0032] The preparation method of photochemical degradation sol composition:

[0033] In the reaction kettle, add photographic gelatin to deionized water at room temperature, add Span 80 after 20 minutes, raise the temperature of the gelatin solution to 45°C, add nano-scale sharp phase titanium dioxide and nano-scale rutile type after the gelatin is fully dissolved Titanium dioxide, stir with a high-sp...

Embodiment 2

[0037] Photochemical degradation sol composition: (parts by weight)

[0038] 50 parts of deionized water, 1.5 parts of photographic gelatin, 1.5 parts of Span 80, 50 parts of 40 nanometer sharp titanium dioxide, 5 parts of 20 nanometer rutile titanium dioxide, 15 parts of mixed light-absorbing cyanine dye, 1 part of bismuth nitrate, trichloro 0.6 parts of cerium oxide, 3 parts of 30 nanometer ferric oxide;

[0039] The particle size of nano sharp titanium dioxide and nano rutile titanium dioxide is 20 nanometers;

[0040] Nano ferric oxide particle size is 20 nanometers;

[0041] The preparation method of photochemical degradation sol composition:

[0042] In the reaction kettle, add photographic gelatin to deionized water at room temperature, add Span 80 after 30 minutes, heat the gelatin solution to 55°C, add nano-scale sharp phase titanium dioxide and nano-scale rutile type after the gelatin is fully dissolved Titanium dioxide, stir with a high-speed disperser (1500 rpm)...

Embodiment 3

[0046] Photochemical degradation sol composition: (parts by weight)

[0047] 50 parts of water, 1 part of photographic gelatin, 1 part of Span 80, 45 parts of 30 nanometer sharp titanium dioxide, 6 parts of 30 nanometer rutile titanium dioxide, 10 parts of mixed light-absorbing cyanine dye, 0.6 part of bismuth nitrate, cerium trichloride 0.7 parts, 2 parts of 40 nanometer ferric oxide, nano-sharp titanium dioxide and nano-rutile titanium dioxide are both 40 nanometers in particle size;

[0048] Nano ferric oxide particle size is 30 nanometers;

[0049] The preparation method of photochemical degradation sol composition:

[0050]In the reaction kettle, add photographic gelatin to deionized water at room temperature, add Span 80 after 25 minutes, raise the temperature of the gelatin solution to 50°C, and add nano-scale sharp phase titanium dioxide and nano-scale rutile type after the gelatin is fully dissolved. Titanium dioxide, stir with a high-speed disperser (1500 rpm) for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com