Preparation method of nano anatase-phase titanium dioxide and application in lithium battery

A technology of titanium dioxide and nano-anatase, applied in the field of lithium-ion batteries, can solve the problems of low lithium storage capacity, performance degradation, volume expansion, etc., and achieve the effect of increasing lithium storage capacity and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

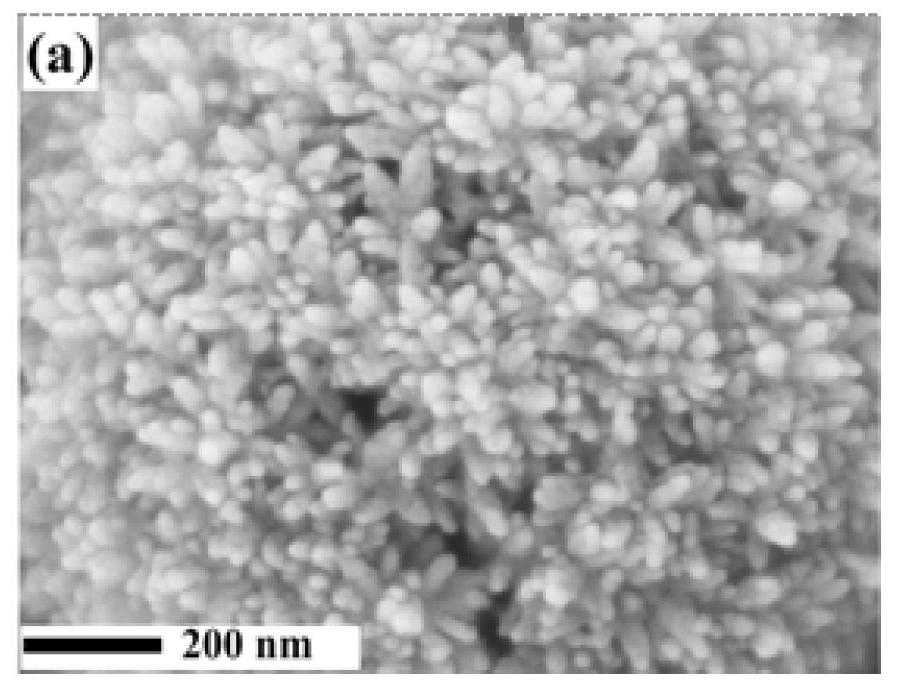

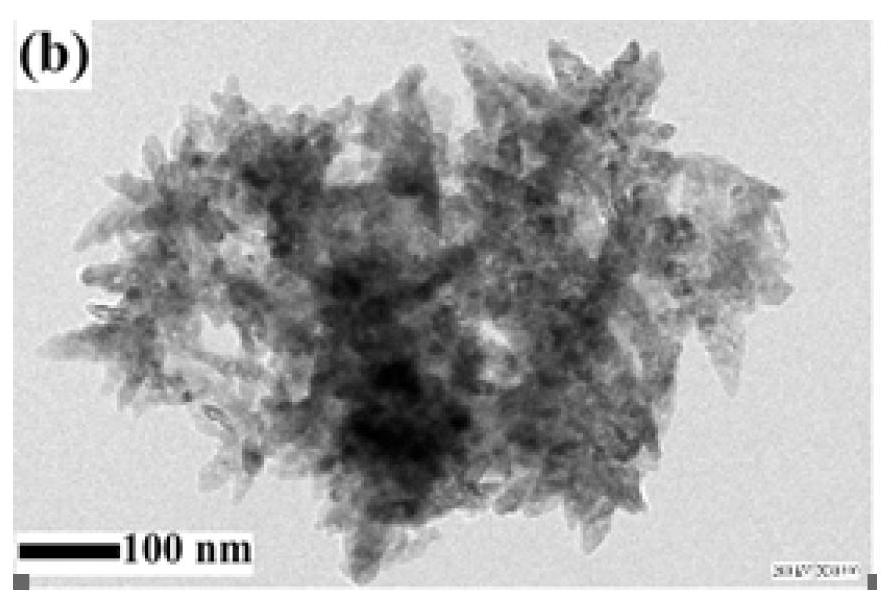

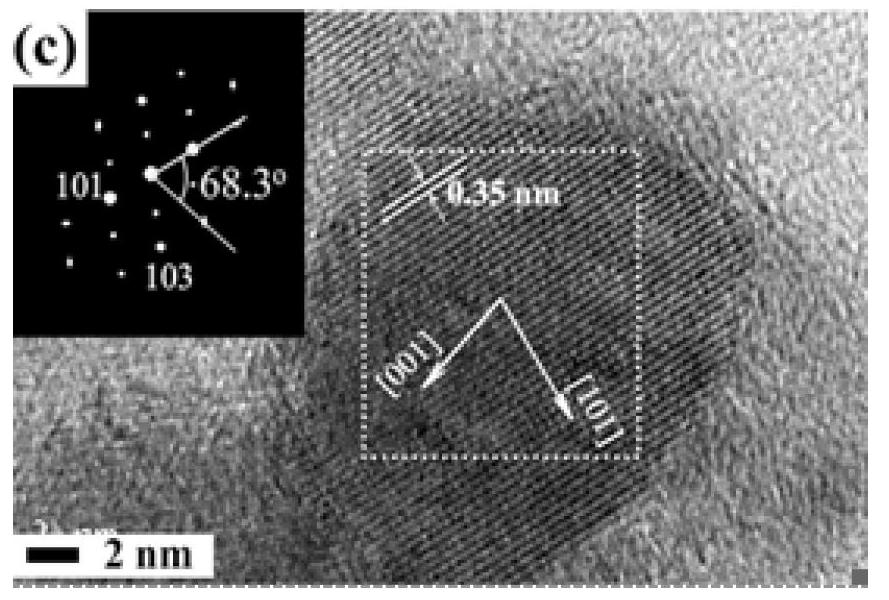

Image

Examples

Embodiment 1

[0032] 1) The preparation composition is 0.05M ammonium fluorotitanate ((NH 4 ) 2 [TiF 6 ]) and 0.15M boric acid LPD deposition solution, adjust the pH of the deposition solution to 2.9 with hydrochloric acid;

[0033]2) Keep the LPD deposition solution obtained in step 1) in a sealed polypropylene container at 50°C for 2 hours;

[0034] 3) The system obtained in step 2) is filtered, washed, and dried at room temperature to obtain a white powder;

[0035] 4) The white powder in step 3) was sintered in a muffle furnace at 450° C. and kept for 3 hours, and then cooled to room temperature with the furnace to obtain nano anatase phase titanium dioxide.

Embodiment 2

[0037] 1) The preparation composition is 0.05M ammonium fluorotitanate ((NH 4 ) 2 [TiF 6 ]) and 0.15M boric acid LPD deposition solution, adjust the pH of the deposition solution to 2.9 with hydrochloric acid;

[0038] 2) Keep the LPD deposition solution obtained in step 1) in a sealed polypropylene container at 50°C for 4 hours;

[0039] 3) The system obtained in step 2) is filtered, washed, and dried at room temperature to obtain a white powder;

[0040] 4) The white powder in step 3) was sintered in a muffle furnace at 450° C. and kept for 3 hours, and then cooled to room temperature with the furnace to obtain nano anatase phase titanium dioxide.

Embodiment 3

[0042] 1) The preparation composition is 0.05M ammonium fluorotitanate ((NH 4 ) 2 [TiF 6 ]) and 0.15M boric acid LPD deposition solution, adjust the pH of the deposition solution to 2.9 with hydrochloric acid;

[0043] 2) Keep the LPD deposition solution obtained in step 1) in a sealed polypropylene container at 50°C for 6 hours;

[0044] 3) The system obtained in step 2) is filtered, washed, and dried at room temperature to obtain a white powder;

[0045] 4) The white powder in step 3) was sintered in a muffle furnace at 450° C. and kept for 3 hours, and then cooled to room temperature with the furnace to obtain nano anatase phase titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com