Synthetic method of nano titanium dioxide powder

A nano-titanium dioxide, synthesis method technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology and other directions, can solve the problems of equipment and experimental personnel hazards, operation hazards, high reaction temperature, and achieve good water and ethanol dispersibility, Ease of operation, low synthesis temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

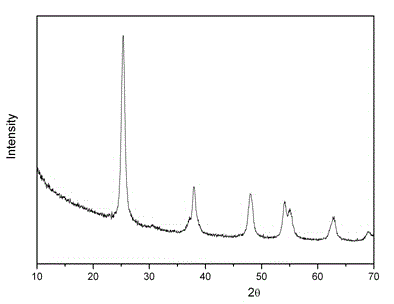

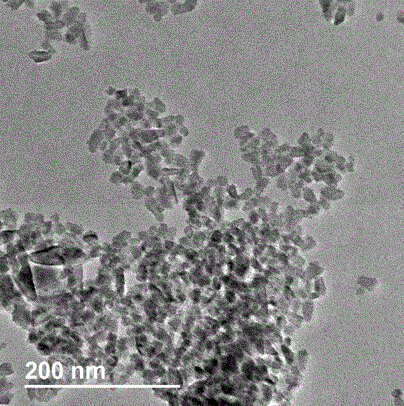

[0039] Under the condition of room temperature and magnetic stirring, 20 mL of tetraisopropyl titanate was dropped into 100 mL of distilled water at 10 mL / min, and a white precipitate gradually appeared. The white precipitate was separated by suction filtration, and the filter cake was put back into distilled water, stirred for 20 minutes, and then separated by suction filtration. This process was repeated 3 times. After mixing the white product with 200 mL of water, 8 mL of a 25 wt % tetrapropylammonium hydroxide aqueous solution was added and stirred for 2 hours. Transfer the above solution to a 500mL static reaction kettle, seal it, put it in a drying oven at 80°C for 24 hours of constant temperature reaction, add 4.5mL of glacial acetic acid, raise the temperature of the oven to 120°C, and react at constant temperature for 24 hours. Take out the reaction kettle, and after cooling down to room temperature naturally, the white powder will be separated by centrifugation. Rin...

Embodiment 2

[0041] According to the process of Example 1, with TiCl 4 For titanium precursor, TiCl 4 The addition amount was 5 mL, the sample treatment conditions were the same as in Example 1, and the product B was obtained, which was used for transmission electron microscope observation and XRD analysis. The transmission electron microscope structure showed that the particle size of titanium dioxide was about 20 nm; XRD diffraction results showed that titanium dioxide was an anatase structure.

Embodiment 3

[0043] 25 mL of tetrabutyl titanate was dropped into 120 mL of deionized water to form a white precipitate. The following process was the same as in Example 1, except that the hydrothermal treatment temperature was 140° C. and the reaction time was 12 hours. The obtained product C was used for transmission electron microscope observation and XRD diffraction experiment. Transmission electron microscope results showed that the size of titanium dioxide was about 15 nm; XRD results showed that titanium dioxide had an anatase structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com