Patents

Literature

61results about How to "Response conditions are relaxed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene hydrogel, graphene aerogel as well as preparation method and application thereof

ActiveCN106032274AAdjustable densityHigh densityOther chemical processesAlkali metal oxides/hydroxidesHigh energyFreeze-drying

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

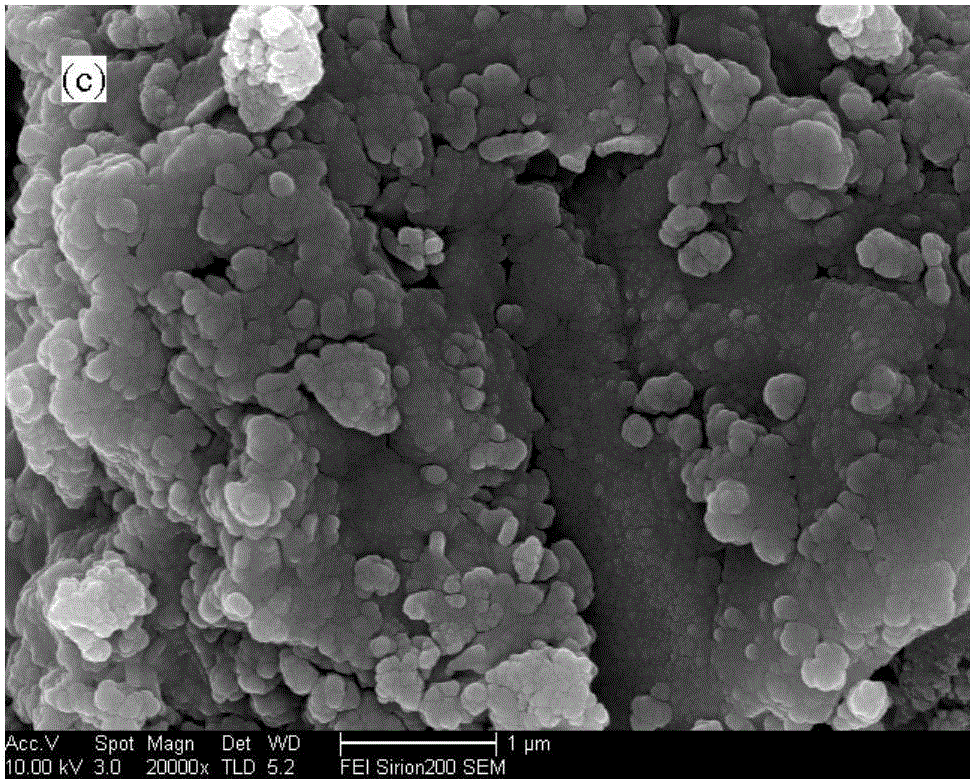

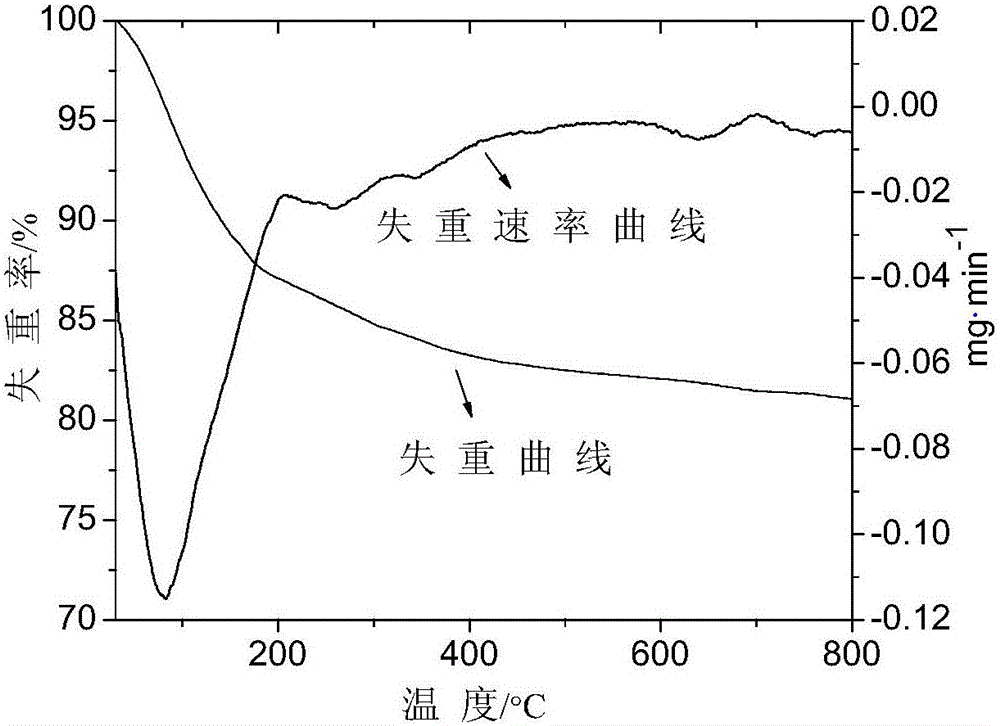

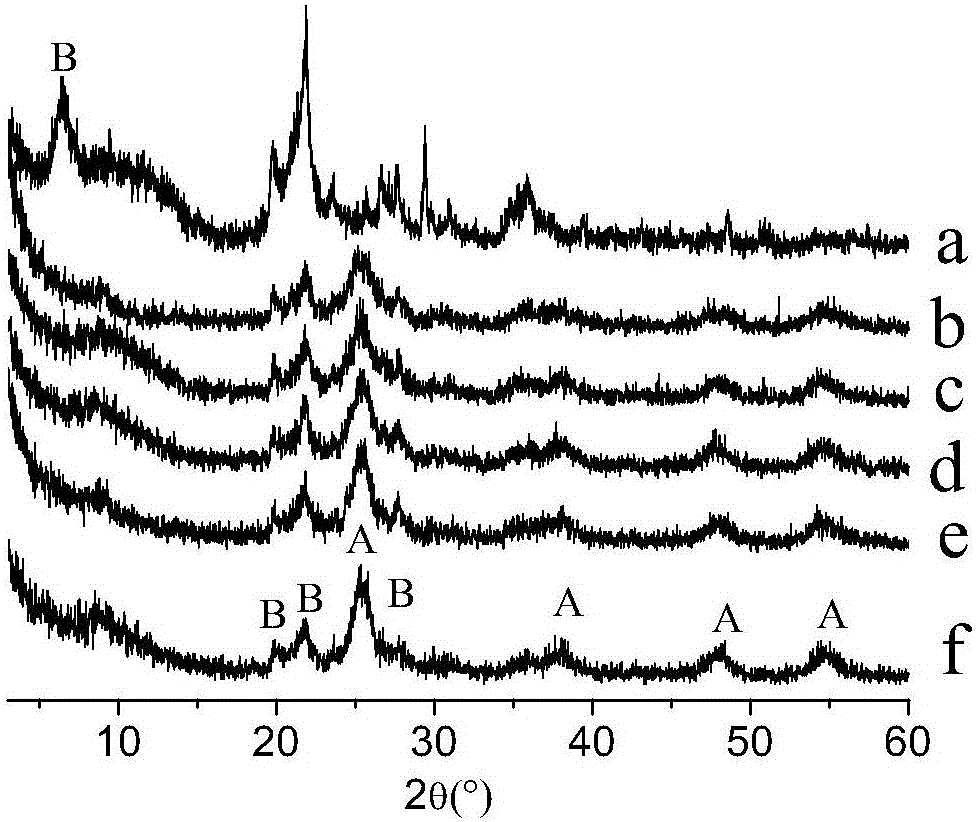

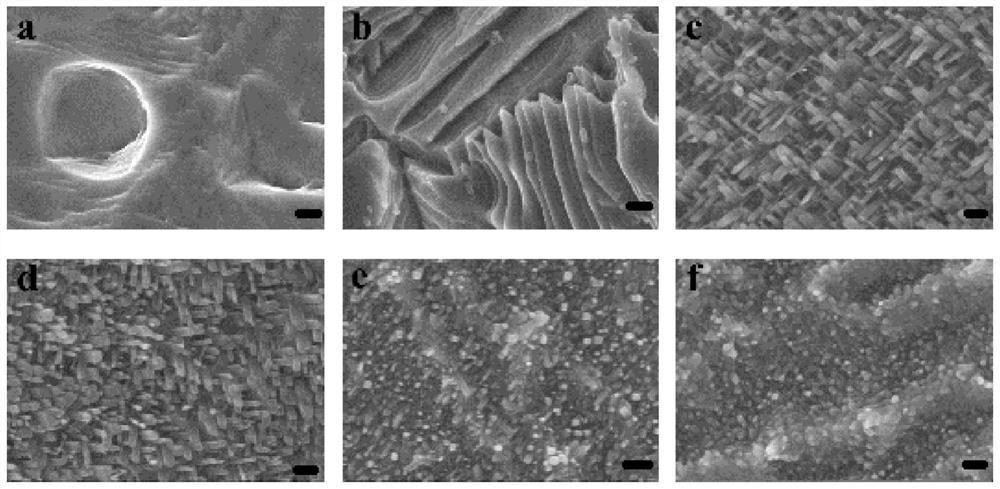

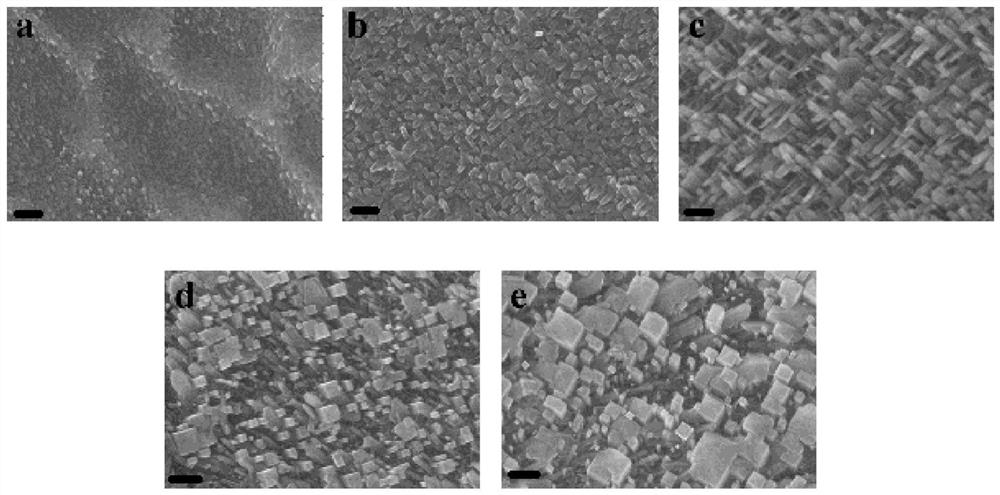

Synthetic method of titanium dioxide self-assembled particles

The invention discloses a synthetic method of titanium dioxide self-assembled particles. According to the synthetic method, water is taken as a solvent, TiCl4 or an organic alkanol titanium oxide is taken as a titanium oxide precursor, an alkylammonium hydroxide is added as a protective agent, and cauliflower-shaped and rod-shaped titanium dioxide nanoparticles are synthesized via hydrothermal method. The synthetic method is simple; synthetic conditions are not strict; operation is simple; the prepared titanium dioxide nanoparticles possess cauliflower-shaped or rod-shaped appearance, and a structure which is formed via self-assembly of titanium dioxide nanowires along an axial direction. The synthesized titanium dioxide possesses relatively high photocatalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

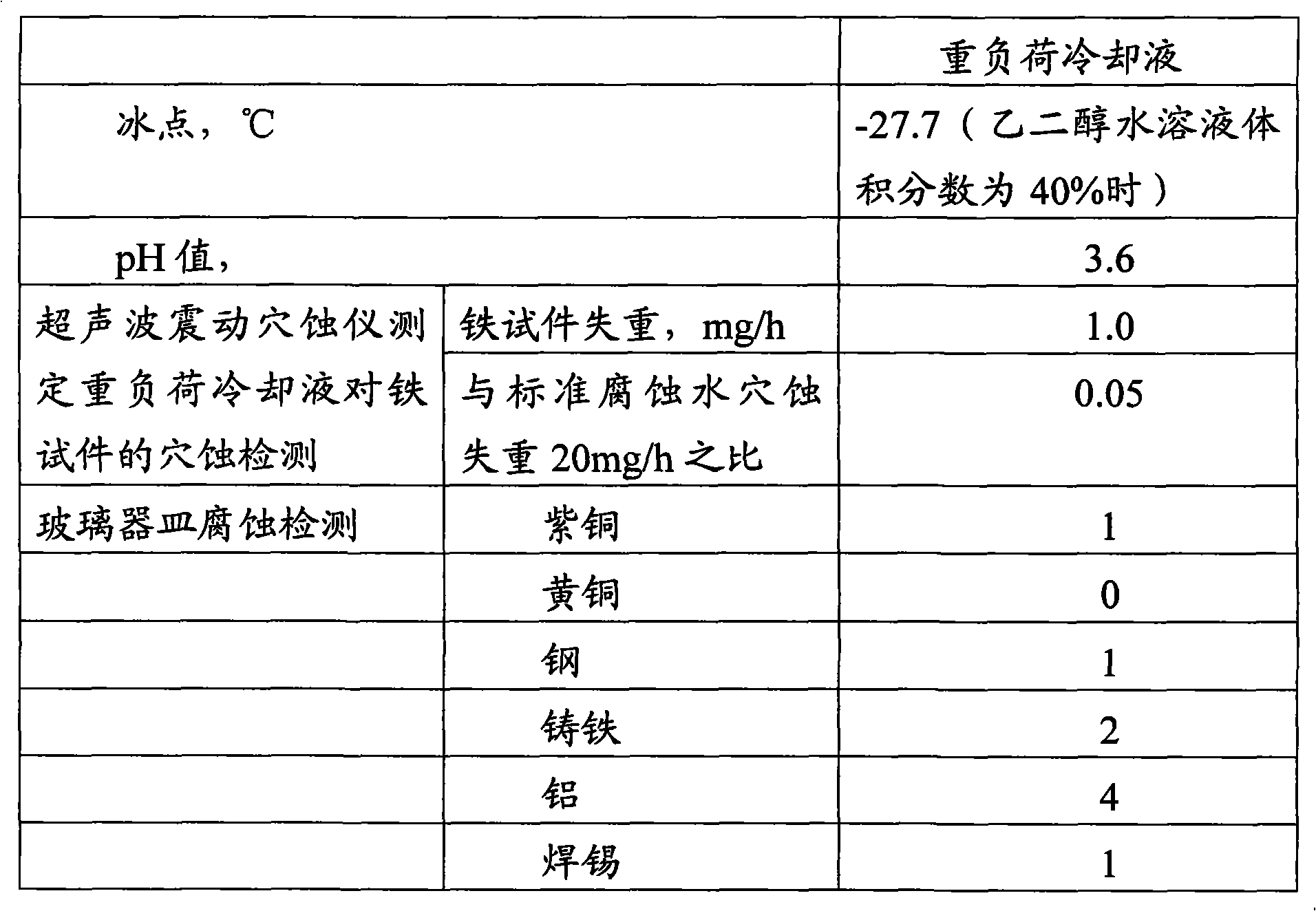

Cavitation corrosion resisting coolant used for heavy-duty engine and preparing method thereof

InactiveCN101550332AAvoid corrosionFormulation ScienceHeat-exchange elementsEngineeringSodium nitrite

The present invention relates to a cavitation corrosion resisting coolant used for heavy-duty engine, wherein the cavitation corrosion resisting coolant comprises the following components by weight: 10-90 parts of soft water, 10-90 parts of glycol, 0.1-1.4 parts of sodium borate, 0.3-2 parts of sodium benzoate, 0.2-2.5 parts of sebacic acid, 0.08-1 part of iodine arsenide, 0.2-3 parts of benzotriazole, 0.03-0.4 part of sodium molybdate, 0.04-0.4 part of sodium nitrite, 0.05-0.5 part of sodium hydroxide, 0.05-0.5 part of corrosion resisting stabilizing agent, 0.005-0.05 part of antifoaming agent and 0.001-0.01 part of colorant. The method of the invention comprises the following steps: (1) adopting a reaction still with mixing function in normal temperature, placing the soft water into the reaction still according to the ratio; (2) adding glycol according to the amount, mixing until the time when the glycol is totally dissolved; (3) weighting the sodium borate, sodium benzoate, sebacic acid, iodine arsenide, benzotriazole, JN-4 corrosion resisting stabilizing agent, sodium molybdate, sodium nitrite, sodium hydroxide, antifoaming agent and colorant, mixing for preparing a complexing agent; (4) adding the complexing agent into the reaction still and mixing to uniform; and (5) checking the freezing point, boiling point, pH value and color of coolant routinely, and then filtering and filling. The cavitation corrosion resisting coolant of the invention has the advantages of simple preparing and remarkable effect.

Owner:TIANJIN PORT (GROUP) COMPANY

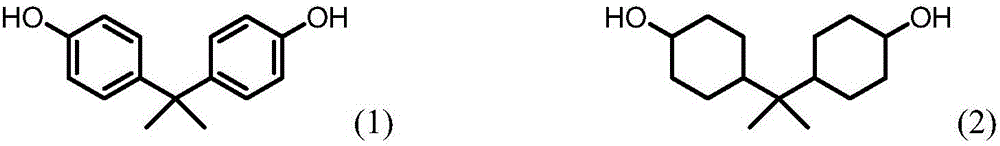

Preparation method for hydrogenated bisphenol A and catalyst for hydrogenation of bisphenol A

ActiveCN106083529ALow costResponse conditions are relaxedPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureSolvent

The invention provides a preparation method for hydrogenated bisphenol A and a catalyst for hydrogenation of bisphenol A. The preparation method comprises hydrogenating bisphenol A at a temperature of 50-100 DEG C, under a hydrogen pressure of 5-10 MPa and at presence of a solvent isopropanol and a ruthenium catalyst, so as to generate hydrogenated bisphenol A, wherein the ruthenium catalyst is a Ru-Zn-Ni / TiO2-CdO catalyst, that is, the ruthenium catalyst takes zinc and nickel as auxiliary active compositions and takes titanium dioxide and cadmium oxide as a composite carrier. The conversion rate of bisphenol A can reach 100%, meanwhile the selectivity of hydrogenated bisphenol A is larger than 97%, and the purity of hydrogenated bisphenol A is 99.5% or more.

Owner:JIANGSU QINGQUAN CHEM CO LTD

Production method of copolymerized powdered cationic polyacrylamide

InactiveCN1590421APrevent Viscosity DegradationControl molecular weightPolymer sciencePhotosensitizer

A process for preparing the powdered cationic copolyacrylamide includes optically triggered polymerizing reaction between acrylamide and cationic monomer while adding chain regulating agent, drying and pulverizing. It features that the photosensitizer is added to the reaction liquid for optical trigger.

Owner:赵吉滨

Method for preparing permanent antistatic agents

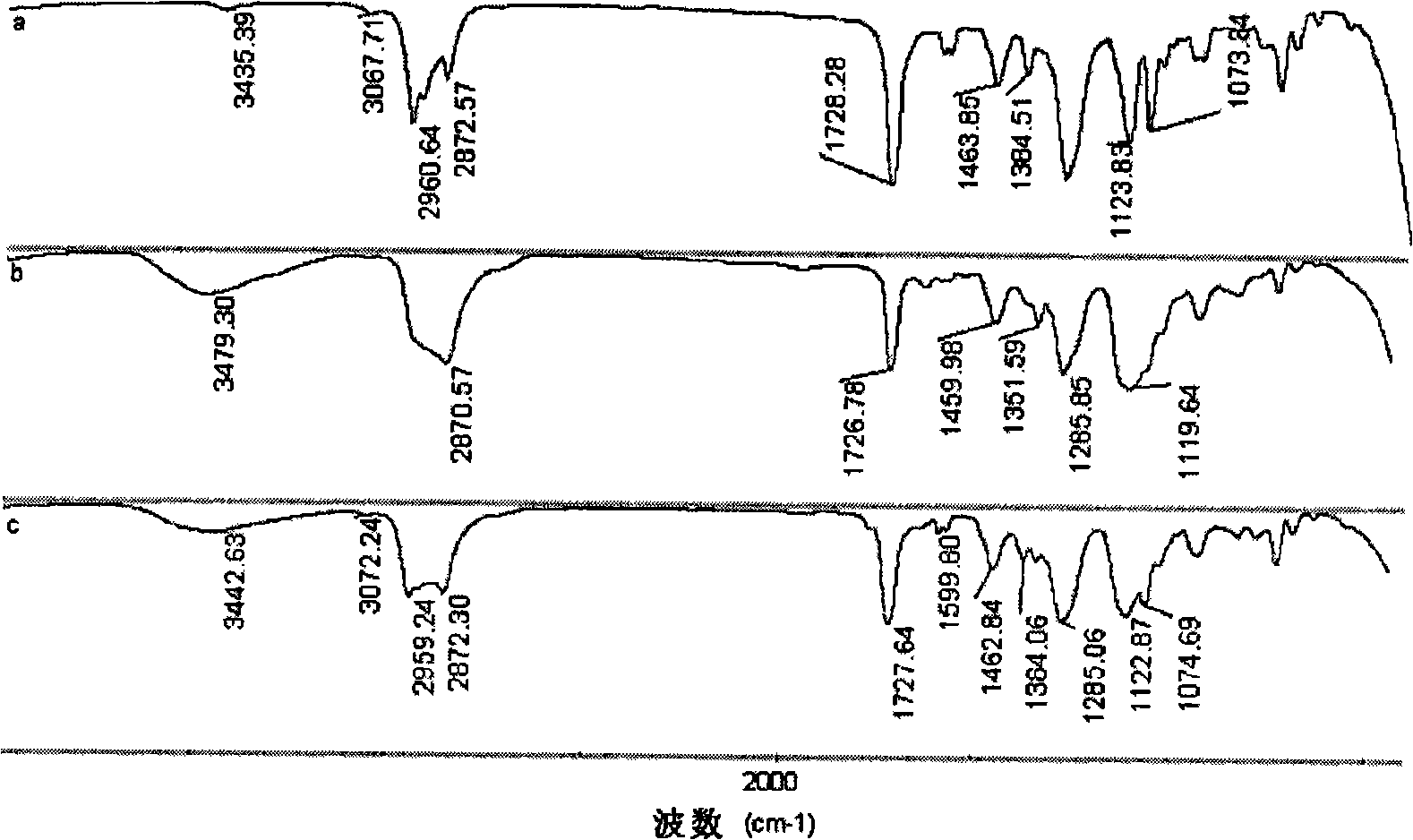

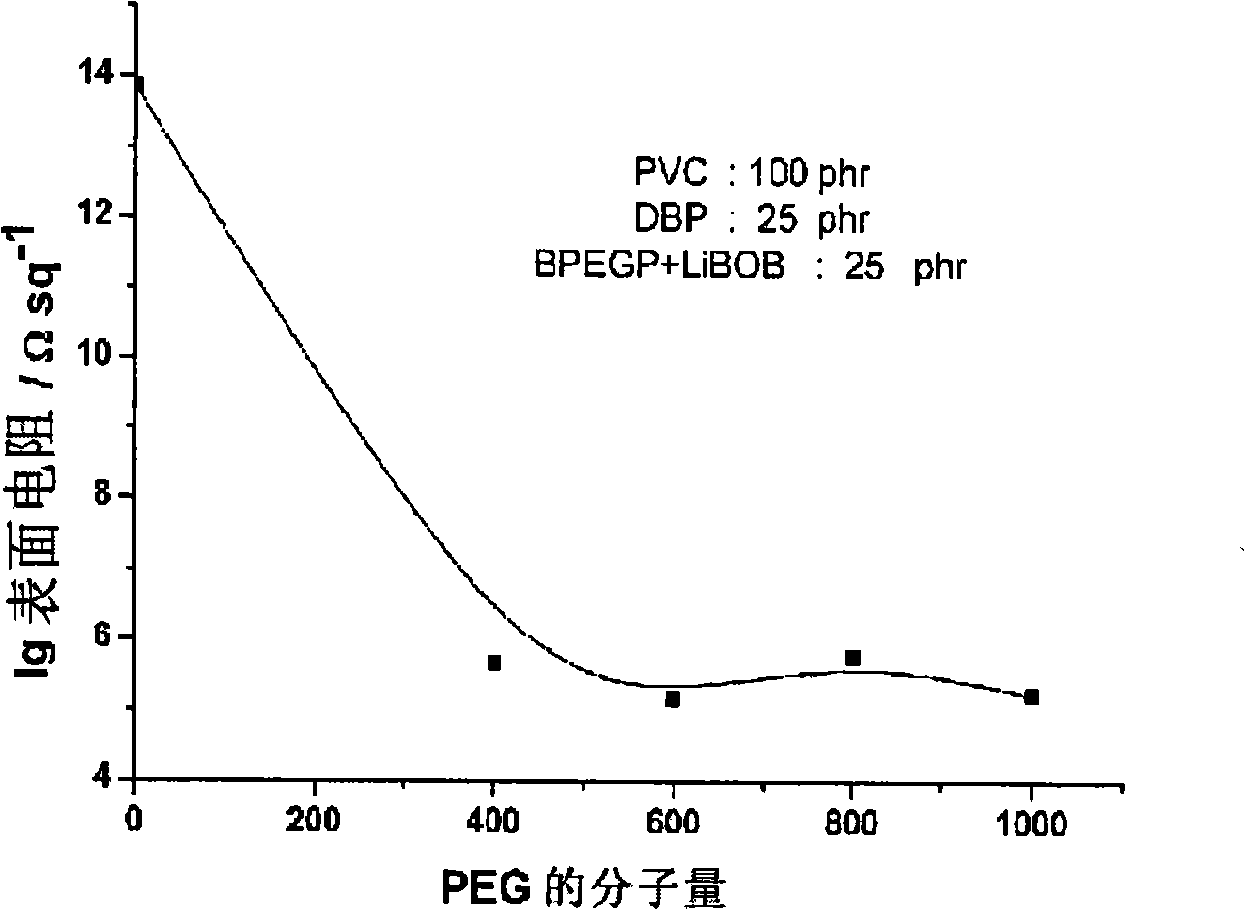

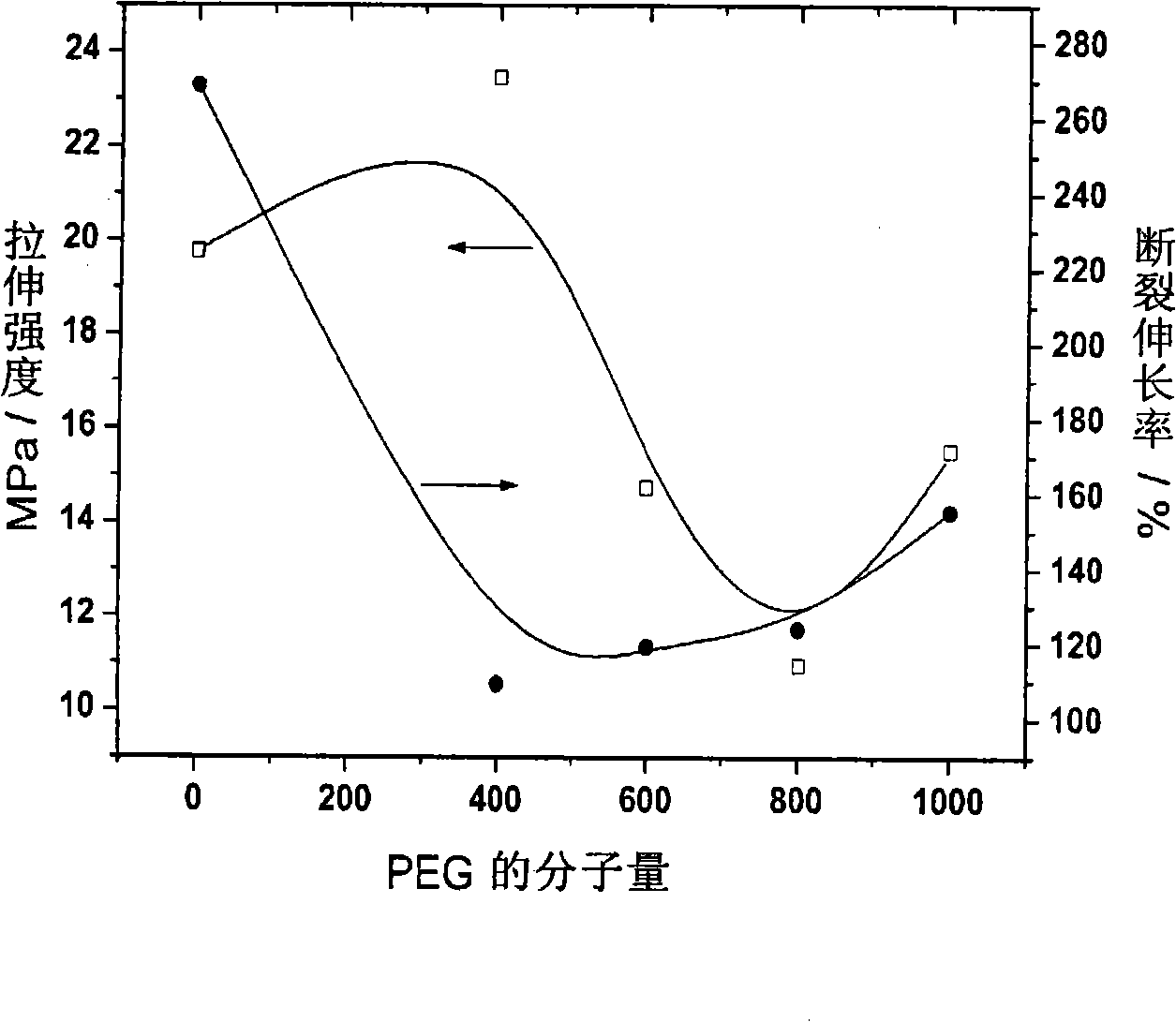

InactiveCN101358126AAdjustable molecular weightResponse conditions are relaxedOther chemical processesSolventLithium-ion battery

The present invention relates to a method for preparing a permanent antistatic agent. The method has the following characteristics: along with 0.1 to 5 mass portions of catalyst and 0 to 1000 mass portions of solvent, aromatic diester or aromatic diacid coupled with estolide compound thereof and ether alcohol compound are added into a reaction kettle provided with a thermometer, a stirrer and a reflux condenser according to a molar ratio of 1 : 1 to 2.5 to react under a temperature between 50 DEG C and 350 DEG C for one to twenty four hours, so that aromatic ester provided with a benzene ring and a polyether structure is synthesized; aromatic ether ester compound is obtained after the solvent and the unreacted monomers are removed; according to a mass ratio of 1 : 1 to 30, alkali metal salt and the compound are mixed so that the aromatic ether-ester permanent antistatic agent is produced. Even under a low humidity level, the aromatic ether-ester permanent antistatic agent can keep a good antistatic effect and can plasticize various polymer materials. The aromatic ether-ester permanent antistatic agent is used for the antistatic modification of general-purpose plastics and anti-corrosion, acid-and-alkali-resisting, anti-static and flame-retarding wind tubes, conveyer belts and gas-pumping-and-exhausting tubes used by coal mines, dust-free computer rooms, antistatic floorings, packages or lithium ion batteries.

Owner:SICHUAN UNIV

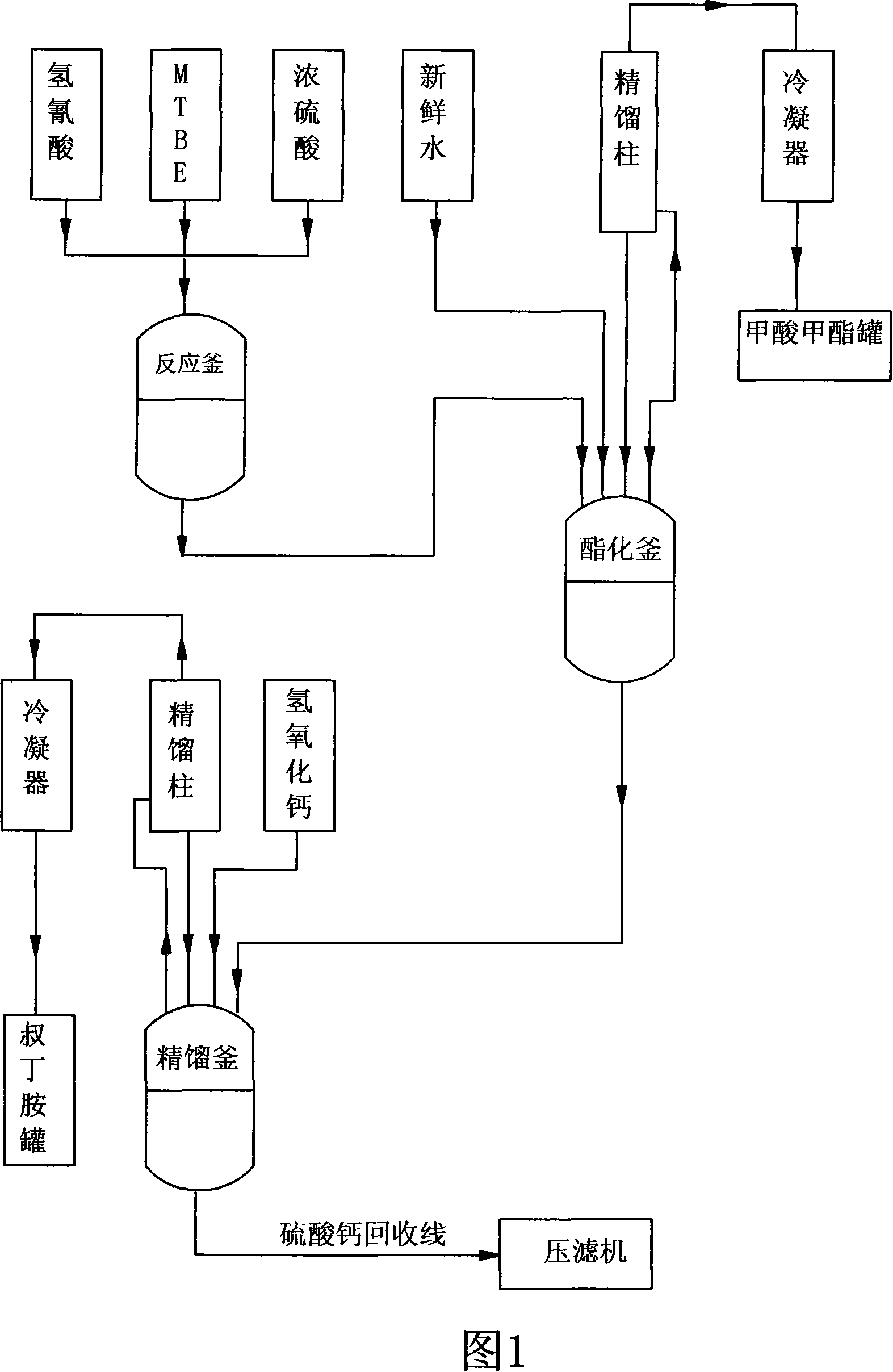

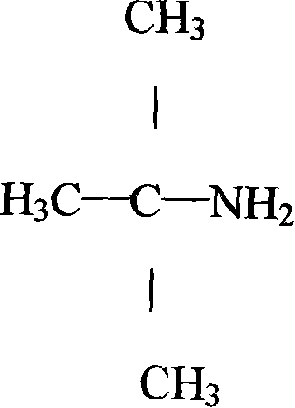

Technique for synthesizing tert-butylamine

ActiveCN101108806APromote hydrolysisPromote esterification reactionOrganic compound preparationAmino compound preparationTert-ButylamineCALCIUM HYDROXIDE SOLUTION

The invention belongs to the fine chemical field, which is mainly used for the synthesis of rubber accelerator NS and the intermediate raw material of the rifampicin-tert-butylamine. The invention is characterized in that: the methyl tert-butyl ether-hydrocyanic acid method is adopted to produce tert-butylamine; under normal pressure, the methyl tert-butyl ether is added with hydrocyanic acid and is added with concentrated sulphuric acid to carry out fully catalytic reaction; the methanol produced in the catalytic reaction is fully adopted and is added with water to perform hydrolysis, deep hydrolysis and esterification, and methyl formate and methanol without react completely are distilled; sulphates in calcium hydroxide solution and the butylamine to replace the butylamine to gain the butylamine through rectification and produce the byproduct calcium sulfate. The invention adopts the water instead of the methanol to carry out the hydrolysis and esterification and neutralizes the raw materials and adopts the calcium hydroxide to produce butylamine, which has the advantages of simple process, short production period, high yield, stable product quality, low production cost and small environment pollution.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Contrast medium for fluorescent-magnetic resonance dual-mode targeting biological imaging and preparation method thereof

ActiveCN106075473AReduce contentGood for bioimagingNMR/MRI constrast preparationsLongitudinal Relaxation RateCitric acid

The invention discloses a contrast medium for fluorescent-magnetic resonance dual-mode targeting biological imaging and a preparation method thereof. The method comprises the following steps that 1, a chelating agent and a compound containing Gd3+ react in water to obtain a Gd3+ chelate solution; 2, citric acid and polyethyleneimine are dissolved into water, and then the Gd3+ chelate solution is added to be mixed; 3, the mixture obtained in the step 2 is dissolved and evaporated to dryness repeatedly, centrifuging is performed on the dissolved and dried products, a supernate is taken for dialysis in water to obtain a dialysis solution, and a dialysis solution is subjected to freeze-drying, and Gd doped carbon dots are obtained. Meanwhile, the invention further discloses a contrast medium for fluorescent-magnetic resonance dual-mode targeting biological imaging. The contrast medium is synthetized in an environment-friendly mode, is low in gadolinium content, promotes surface functionalization, and has the quite high longitudinal relaxation rate and the fluorescence quantum yield, and the good biological compatibility and blood compatibility.

Owner:SUN YAT SEN UNIV

Method for preparing gypsum whisker by calcium citrate

InactiveCN101230483AReduce manufacturing costResponse conditions are relaxedPolycrystalline material growthFrom normal temperature solutionsManufacturing technologyFine chemical

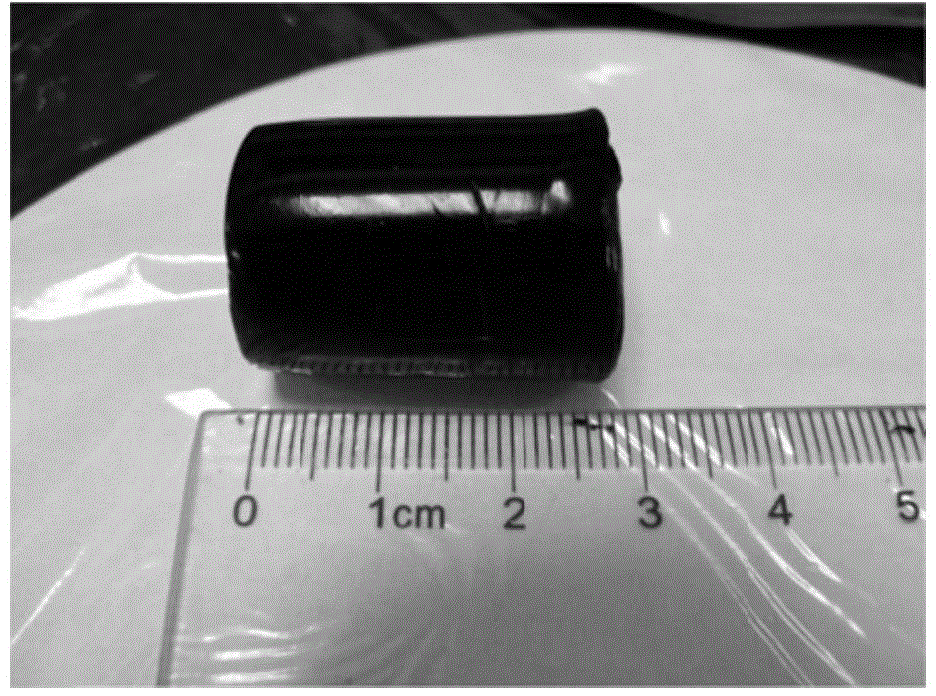

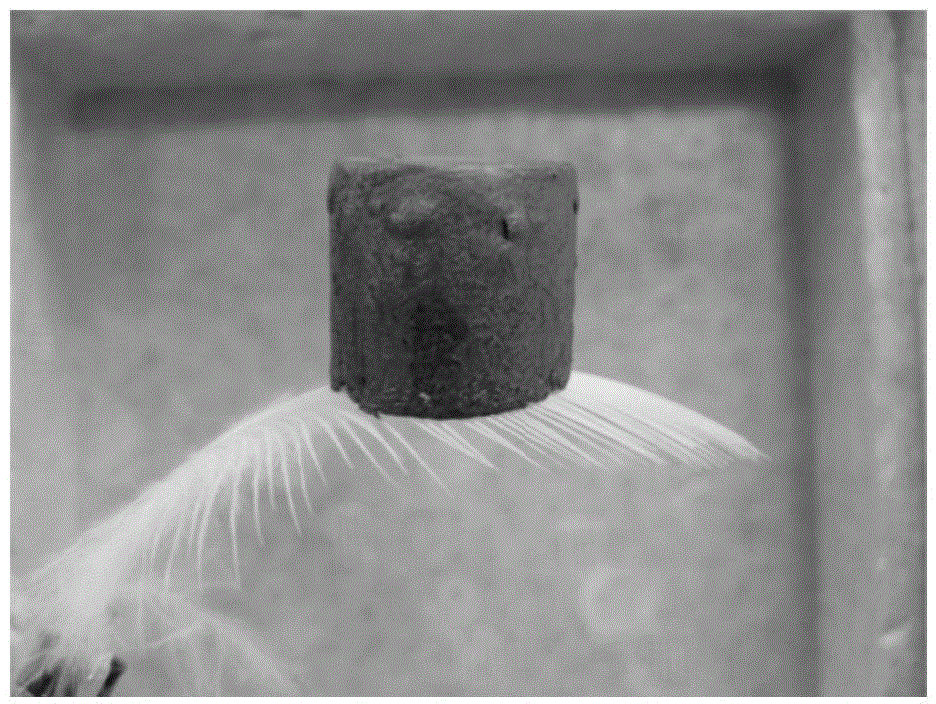

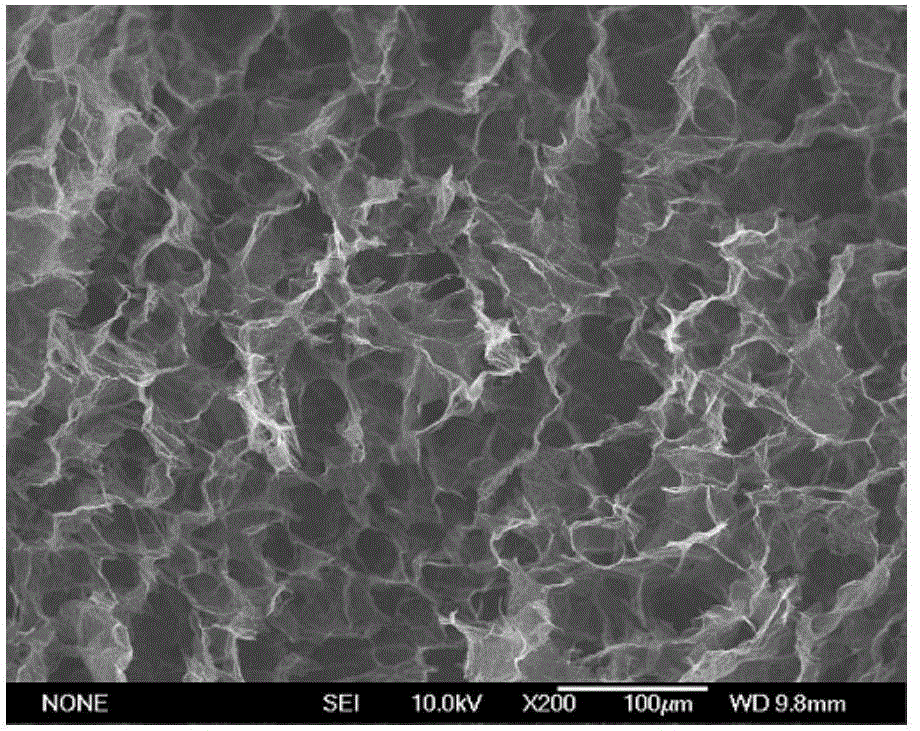

The invention provides a method of manufacturing plaster crystal whiskers by utilizing calcium citrate and belongs to the field of fine chemical manufacturing technology. Combined with the citric acid manufacturing technique, the invention manufactures plaster crystal whiskers while the calcium citrate is acidolysised to generate citric acid. The invention includes the following steps: firstly, after the sulphuric acid is added in, the calcium citrate serum is well stirred, placed in an autoclave for reaction at a temperature of 120 to 130 EDG C for 10 to 50 minutes and then cooled to be filtered; and secondly, the filtrate is used for crystallizing and separating out the citric acid product. The filtering medium is washed in water for 1 to 3 times, drained and then dried at a temperature of 80 to 100 DEG C and finally plaster crystal whiskers with a length of 50 to 400 micrometers, a diameter of 1 to 4 micrometers and a diameter ratio of 40 to 160 are obtained. The invention generates plaster crystal whiskers from the medium rich in citric acid by using the hydrothermal method, the reacting conditions are loose, the quality of the crystal whisker is obviously enhanced and the manufacturing cost for the crystal whisker is greatly reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

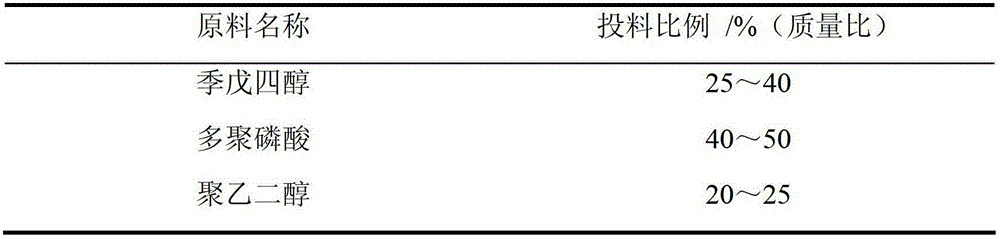

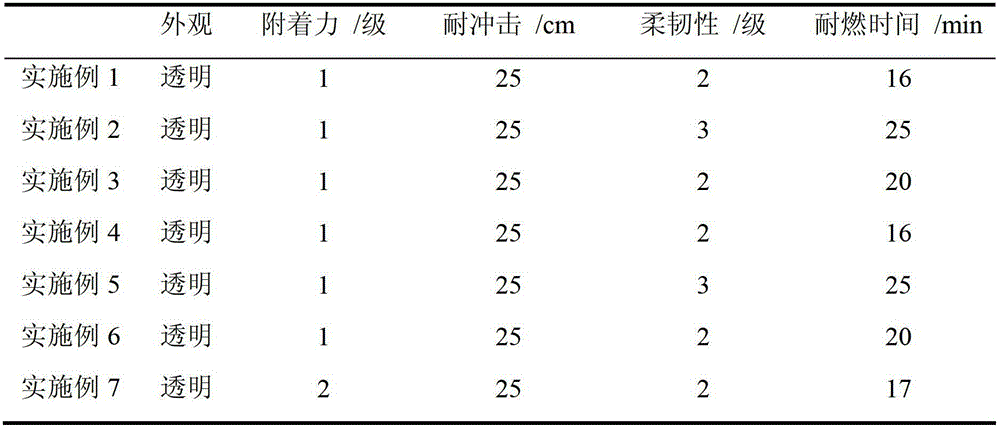

Method of preparing transparent and decorated fireproof coating with two components

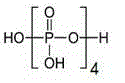

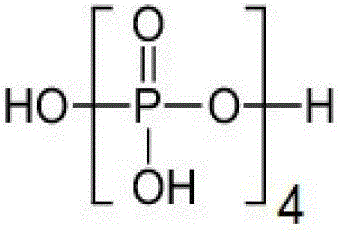

InactiveCN102746764AWide variety of sourcesLow costFireproof paintsPhosphorus organic compoundsPentaerythritolPolyethylene glycol

The invention relates to a method of preparing a transparent and decorated fireproof coating with two components. The method comprises steps of: preparing a polyethylene-glycol-grafted polyphosphate by using polyphosphoric acid, pentaerythritol and polyethylene glycol through a solution synthesis method; preparing an aqueous solution or an ethanol solution with a certain concentration of the grafted polyphosphate, and blending the solution with an aqueous amino resin by stirring to get the transparent and decorated fireproof coating with two components. According to the present invention, the preparation method is simple and feasible, the cost is low, and the prepared transparent and decorated fireproof coating with two components can greatly improve flexibility of a coating film on the basis of ensuring excellent fireproof property of the coating.

Owner:TONGJI UNIV

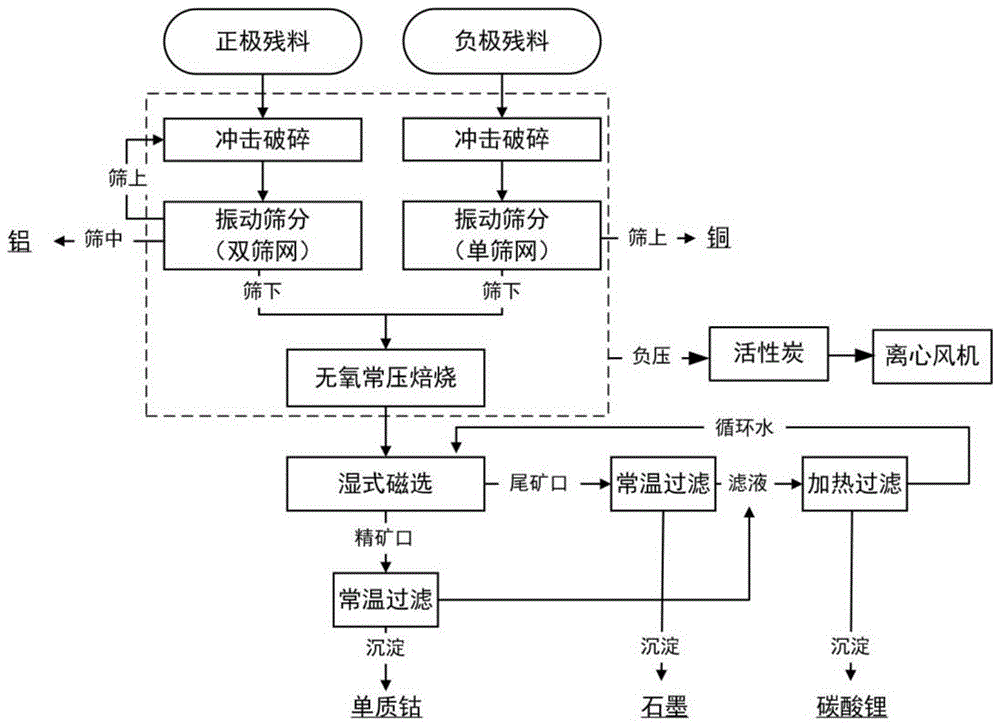

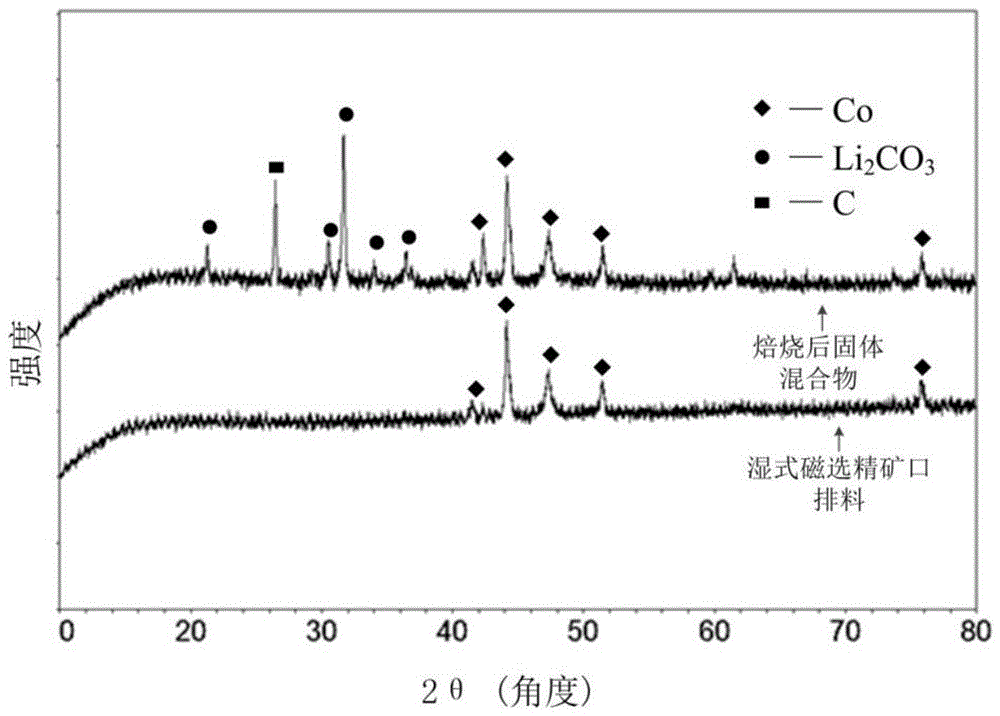

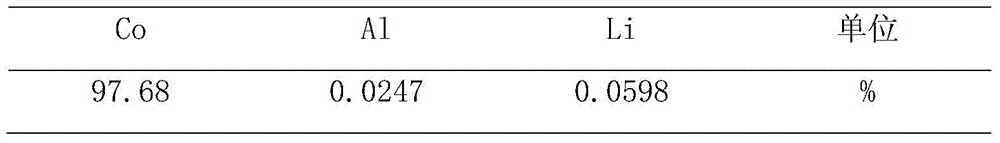

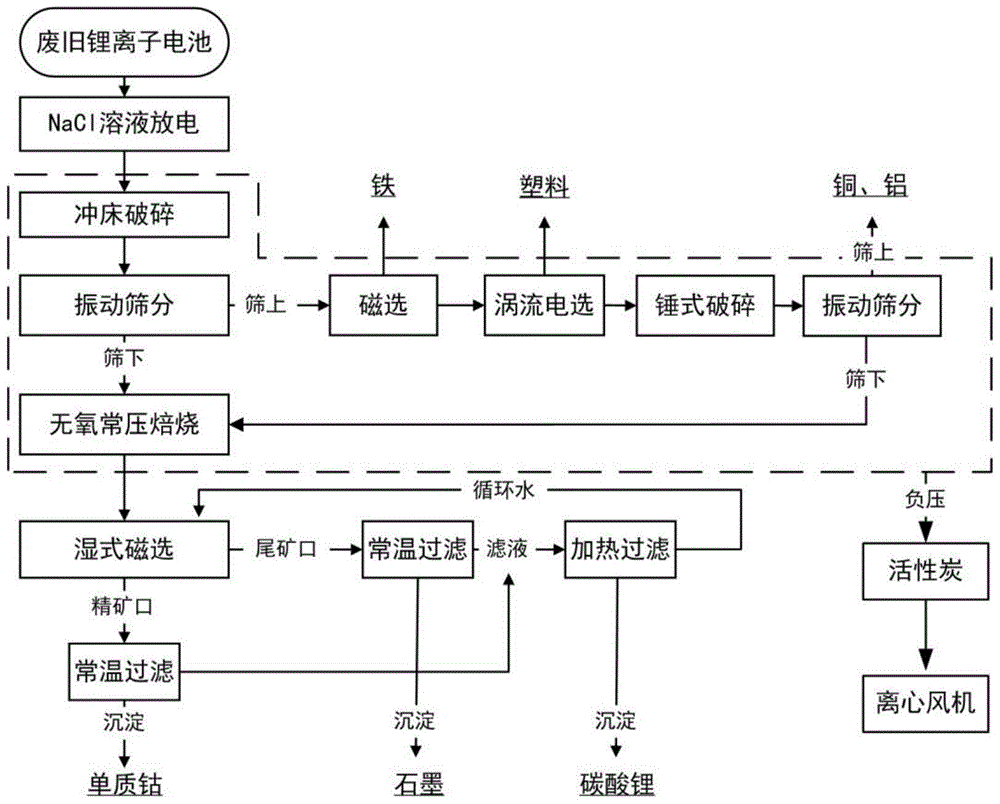

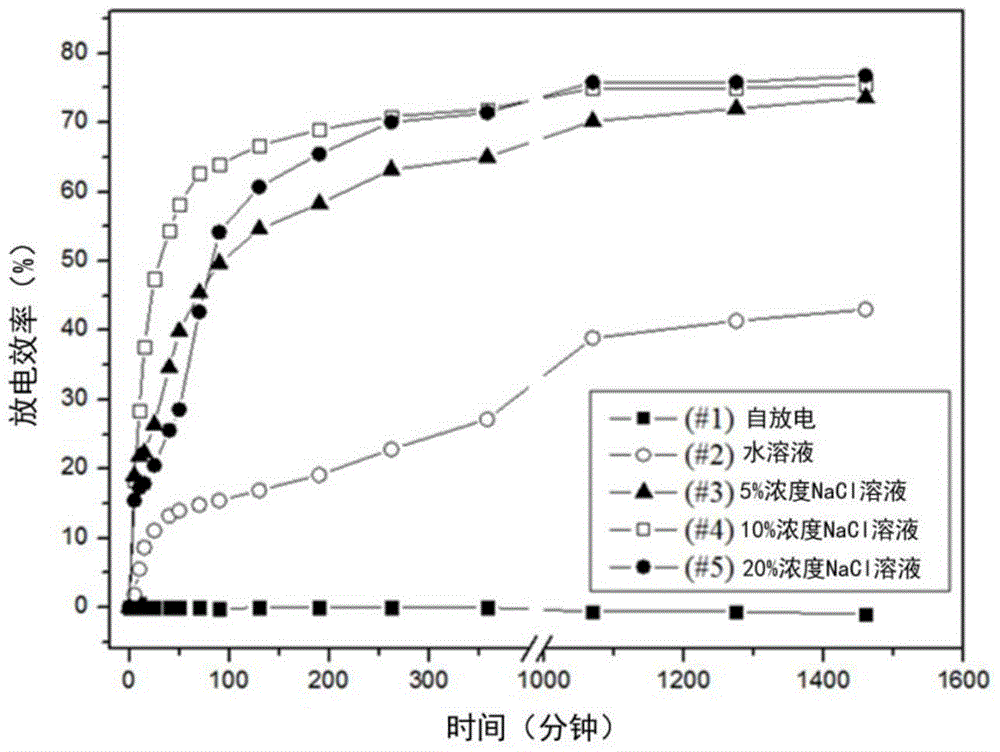

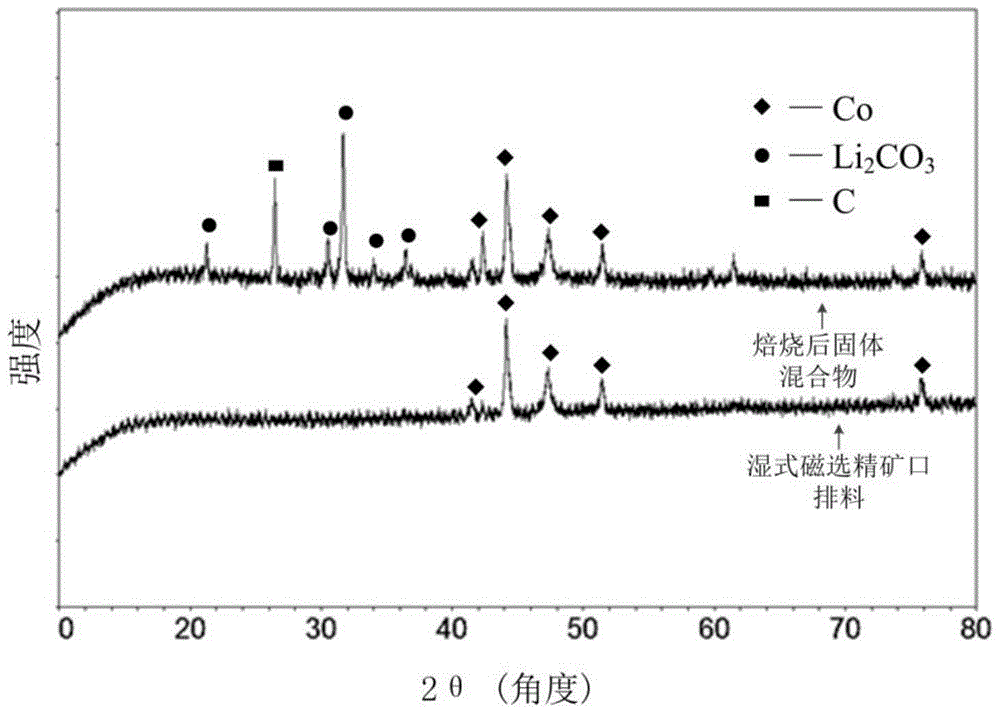

Recycling method of positive and negative electrode residues of waste lithium cobaltate lithium ion battery

ActiveCN104593606BNo secondary pollutionLow costWaste accumulators reclaimingProcess efficiency improvementFiltrationSecondary mineral

The invention discloses a method for recycling positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries. By combing technologies such as high-speed impact crushing, vibration screening, anaerobic atmospheric roasting, wet-type magnetic separation and temperature-variable filtration, products such as elemental cobalt, lithium carbonate and graphite powder are prepared from the positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries; the materials are separated and enriched in such manners as high-speed impact crushing, vibration screening and wet-type magnetic separation, the original physical properties of the materials are retained, the negative electrode graphite material is fully utilized, the in-situ preparation of resources is achieved and the cost is saved; the anaerobic atmospheric roasting is adopted, the reaction conditions are relatively loose, the graphite material loss is decreased, the flow is simplified, any chemical agent is not needed in the entire process, no secondary pollution is caused and the industrial application practice is facilitated. By the method, the problem of pollution-free treatment of leftover material generated in the manufacturing of the lithium-ion batteries for battery manufacturers is solved and meanwhile, a method for mining secondary mineral, namely, a cobalt resource is provided.

Owner:SHANGHAI JIAO TONG UNIV

Bicomponent transparent finishing fire retardant coating and preparation method thereof

The invention relates to a bicomponent transparent finishing fire retardant coating and a preparation method thereof. The preparation method includes steps of using polyphosphoric acid, pentaerythritol and polyethylene glycol to obtain polyethylene glycol grafted polyphosphate by means of a fusion synthesis method and mixing and blending a component A and a component B to obtain the bicomponent transparent finishing fire retardant coating, wherein the component A is an aqueous solution or an absolute ethyl alcohol solution of the grafted polyphosphate, and the component B is an aqueous amino resin. According to the obtained bicomponent transparent finishing fire retardant coating, the flexibility of a coating film is greatly improved on the basis of a good fire retardant performance of the coating, and the preparation method of the bicomponent transparent finishing fire retardant coating is easy and simple to operate.

Owner:DONGGUAN DAXING CHEM

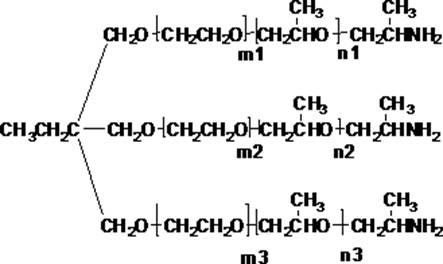

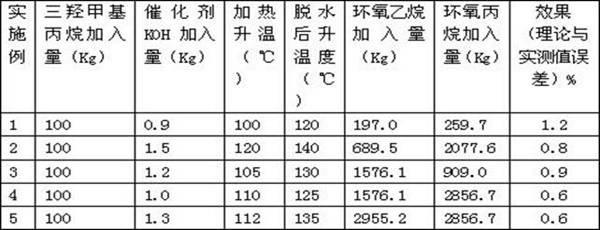

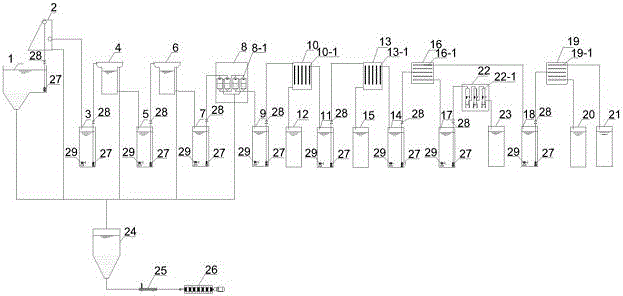

Polyether amine for textile printing and dyeing auxiliary and preparation method for polyether amine

InactiveCN102634006AOvercome drifting oilOvercome stabilityOrganic compound preparationFibre treatmentEmulsionWoven fabric

The invention discloses polyether amine for a textile printing and dyeing auxiliary and a preparation method. The preparation method includes: adding trimethylolpropane serving as initiator and catalyst KOH (potassium hydroxide) into a reaction kettle, and sequentially feeding epoxyethane and epoxypropane into the reaction kettle so that a polyether crude product is prepared by means of reaction; neutralizing and adsorbing the reactant prior to filtering dehydration, and then refining through reduced pressure distillation and dehydration so that polyether is prepared; and adding the prepared polyether, supported catalyst, liquid ammonia and hydrogen so that the polyether amine for the textile printing and dyeing auxiliary is prepared. The polyether amine serves as a textile printing and dyeing softener, demulsification temperature of emulsion is high, polyether consumption is less, and total production cost can be reduced. The polyether amine prepared by the preparation method is high in amino terminating ratio, equimolar consumption of a main system is reduced, system viscosity is increased, and produced textiles are integrally softer in hand feeling. Besides, the preparation method is less in reaction by-products, loose in reaction condition, low in equipment requirements and small in equipment investment.

Owner:ZHEJIANG HUANGMA TECH

Biogas slurry concentration and nutrient enrichment system for large biogas project and application method thereof

InactiveCN106365369ACommercializeReduction industry chainBio-organic fraction processingClimate change adaptationNutrientNanofiltration

The invention relates to a biogas slurry concentration and nutrient enrichment system for a large biogas project and an application method thereof. The system is mainly composed of a biogas slurry pretreatment device, a sand filtration device, an ultrafiltration device, a nanofiltration device, a reverse osmosis device, a low-temperature multiple-effect evaporation device, a sludge thickening tank, a screw pump, a horizontal centrifugation machine, concentration tanks and a slurry storage tank through connection. The application method of the system comprises the steps that biogas residues and biogas slurry produced from the large biogas project firstly pass through the pretreatment device to remove suspended matter in the biogas slurry, coarse filtration is performed through the sand filtration device, the biogas slurry passes through the two-stage ultrafiltration device respectively to obtain penetrated liquid and concentrated liquid, the penetrated liquid obtained after ultrafiltration passes through the nanofiltration device to obtain ionic liquid and concentrated liquid, then the biogas slurry concentrated liquid passes through the low-temperature multiple-effect evaporation device to obtain high-concentration biogas slurry concentration liquid. The costs for capital construction and equipment investment is effectively reduced, the area occupied by equipment is decreased, the equipment utilization rate is improved, the temperature requirement in the biogas slurry concentration process is low, energy is saved, the biogas slurry concentration and nutrient enrichment system is environmentally friendly, turns waste into wealth and is remarkable in application effect.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

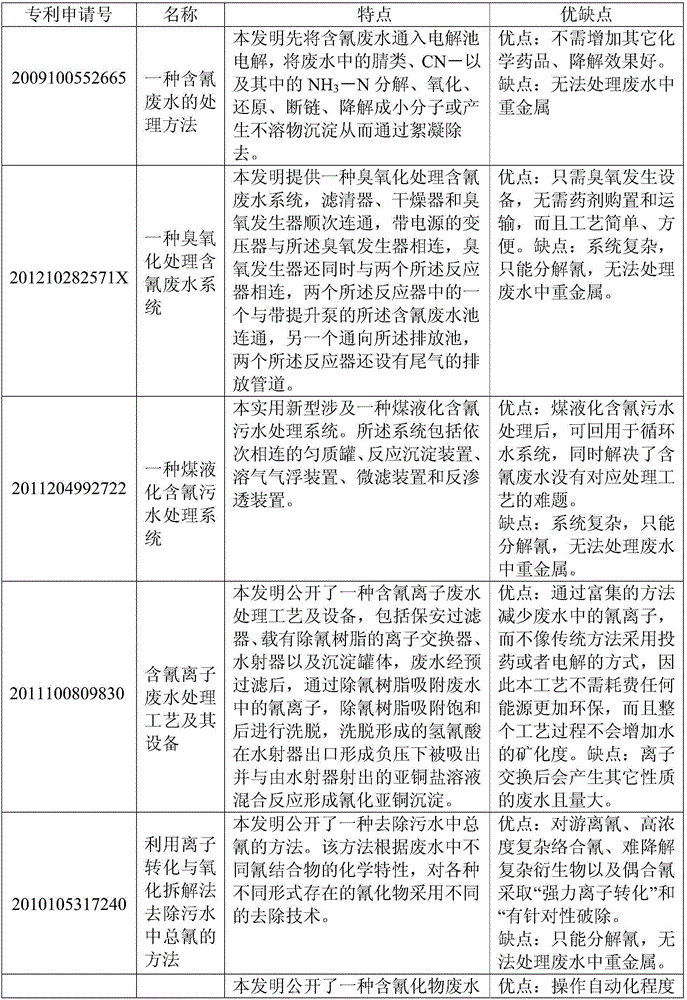

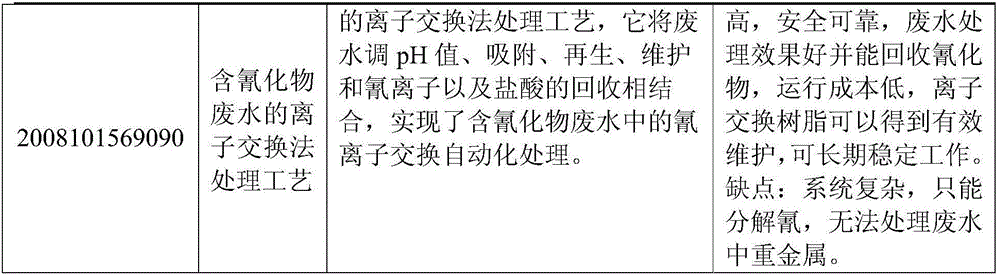

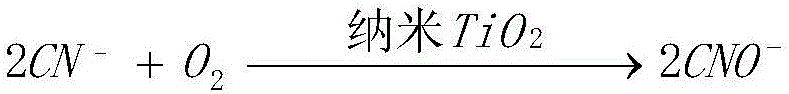

Method for treating cyanide-containing waste water produced by gold industry by using diatomite/ titanium dioxide composite material

InactiveCN105854790AAvoid pollutionEasy to operatePhysical/chemical process catalystsWater/sewage treatment by irradiationDecompositionHigh pressure

The invention relates to a method for treating cyanide-containing waste water produced by gold industry by using a diatomite / titanium dioxide composite material, belonging to the technical field of waste water treatment. The method comprises the following steps: mixing butyl titanate and absolute ethyl alcohol, evenly stirring, then adding deionized water into the mixture, and continuously stirring until light yellow transparent sol is formed; adding diatomite into the light yellow transparent sol, stirring, standing still and drying to obtain dried gel; roasting the dried gel to obtain the diatomite / titanium dioxide composite material; adding the cyanide-containing waste water into the diatomite / titanium dioxide composite material, oscillating and then irradiating by a high-pressure mercury lamp; filtering to obtain a filter cake and filtrate, analyzing the concentrations of cyanogen and copper in the filtrate, and washing the filter cake. The method is simple in operation, is capable of decomposing heavy metal ions and cyanogen while treating the cyanide-containing waste water, and is high in metal adsorbing capacity and cyanogen decomposition amount.

Owner:SHANDONG UNIV OF TECH

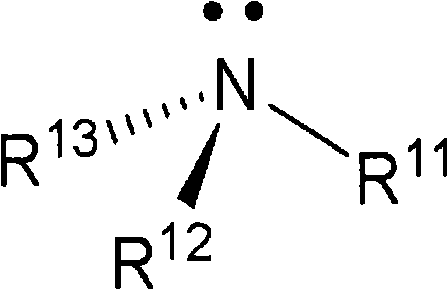

Synthesis method of alcohol with optical activity

ActiveCN103408399ALow costHigh yieldOrganic compound preparationHydroxy compound preparationPtru catalystAlcohol

The invention relates to the field of chemistry, particularly relates to the field of compound preparation, most particularly relates to a synthesis method of alcohol with optical activity, and aims to find a synthesis method of alcohol with optical activity, which is simple in operation, low in raw material cost, simple in purification process and high in yield, wherein the alcohol is shown as the formula I. According to the invention, a compound II is reduced through (S)-CBS-Me or (+)-DIP-Cl to prepare a compound I, only a reducing agent and corresponding solvent systems are needed, but other catalysts do not need to be added, so that the raw material input cost is reduced; and the requirement for the reaction condition is lower, and harsh conditions such as high temperature, high pressure and the like do not need, so that the synthesis method is suitable for industrial production.

Owner:NANJING OCEAN PHARMA TECH

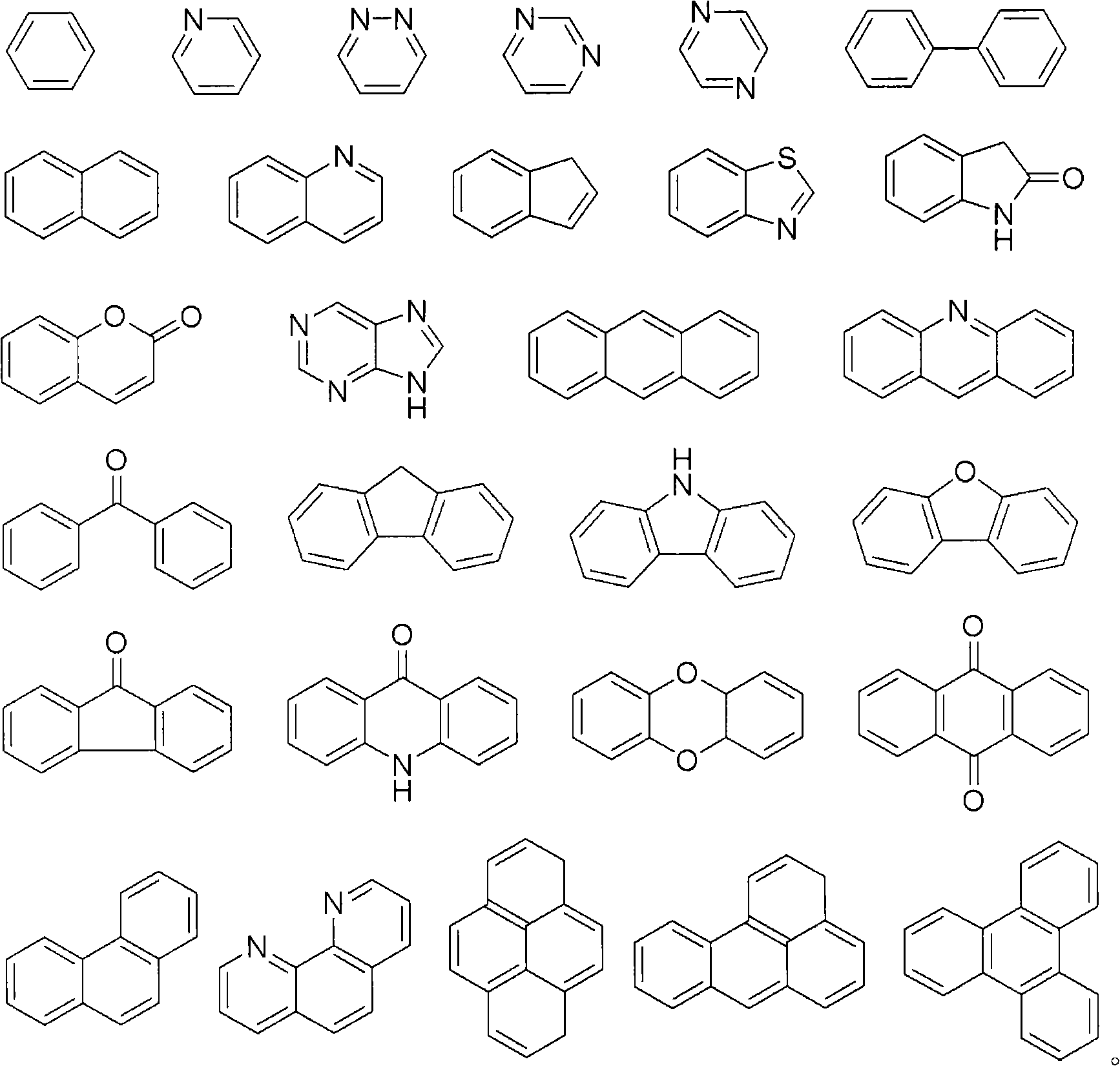

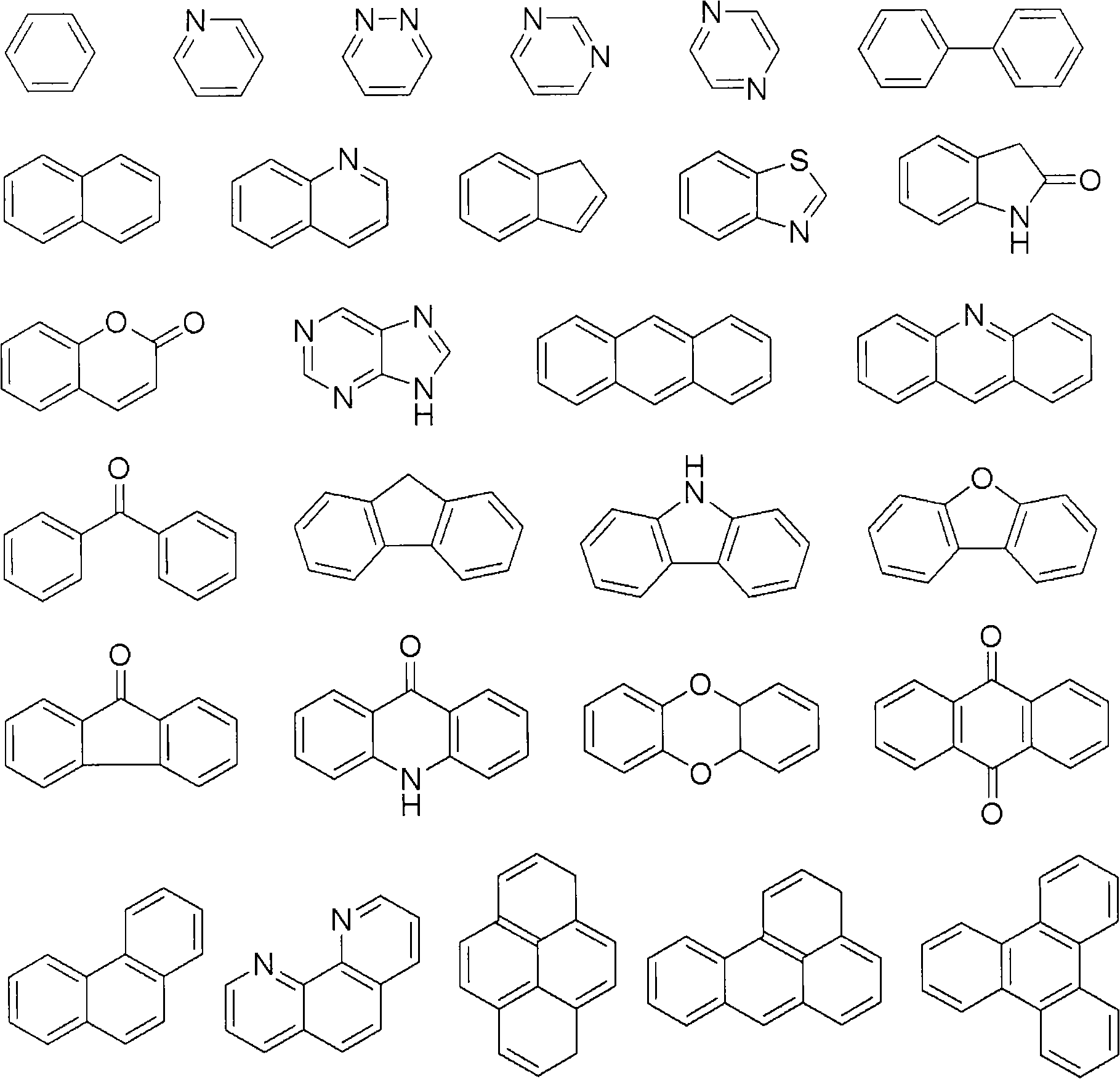

Advanced preparation method of organic-transition metal hydride used as hydrogen storage materials

InactiveCN101525345AHigh yieldResponse conditions are relaxedReversible hydrogen uptakeOther chemical processesALUMINUM HYDRIDETransition metal hydride

The present invention relates to an advanced preparation method of organic-transition metal hydride used as hydrogen storage materials, the method including: preparing organic-transition metal-aluminum hydride complexes by reacting the organic-transition metal halide with metal aluminum hydride compounds; and preparing the organic-transition metal hydride by reacting the organic-transition metal aluminum hydride complexes with Lewis bases. Since the preparation method of the organic-transition metal hydride according to the present invention does not use catalysts, it has advantages that it does not cause problems due to poisoning and can prepare the organic-transition metal hydride at high yield under less stringent conditions. The hydrogen storage materials containing the organic-transition metal hydride prepared from the preparation method can safely and reversibly store a large amount of hydrogen.

Owner:HANWHA CHEMICAL CORPORATION

Preparation method of aluminium sol and application thereof

InactiveCN1962062AStrong adhesionIncrease coverageGroup 4/14 element organic compoundsCatalyst carriersAluminum IonAlcohol

The invention relates to a method for preparing aluminum gel, which comprises: (1), using diaspore powder as material, via mol ratio of aluminum and water is 1:20-50, adding into deionized water, mixing, dispersing; (2), via mol ratio between hydrogen ion and aluminum ion is 1:1-20, adding inorganic acid, mixing, dissolving in normal temperature to form semi-transparent gel; (3), mixing for 2-5hours, to form stable product. When in application, adds needed catalyst into said aluminum gel to form slurry, to coat it on the metal beehive or ceramic beehive surface, baking at 500-800Deg. C for 3-5h, and fixing the catalyst on the carrier via aluminum gel; washing it with alcohol solution for 10min via ultrasonic wave at 100Hz, its carrier fall ratio is lower than 5%.

Owner:天津市环科机动车尾气催化净化技术有限公司

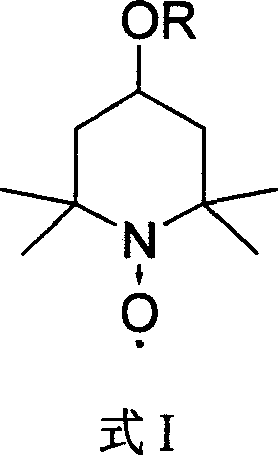

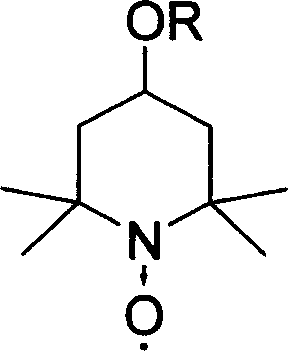

Catalyst for selective oxidation of protection monosaccharide primary hydroxy group

ActiveCN101134741ASave raw materialsEliminate the chance of introducing impuritiesOrganic-compounds/hydrides/coordination-complexes catalystsSaccharide with acyclic radicalsCarboxyl radicalHydroxy group

The present invention relates to selective oxidation catalyst and process capable of protecting primary hydroxyl group in monosaccharide. It is found that using 4-alkoxyl group or acryloxy substituted 2, 2, 6, 6-tetramethyl piperidino-N-oxide as catalyst in the reaction of the protected monosaccharide and hypohaloid solution can oxidize the protected primary hydroxyl group in monosaccharide selectively into carboxyl group without need of auxiliary oxidant and with yield as high as 95 %.

Owner:陕西汉江药业集团股份有限公司

Bentonite composite material for treating high-zinc and copper cyaniding wastewater and application of bentonite composite material

InactiveCN105749857AEfficient decompositionAchieve adsorptionWater/sewage treatment by irradiationOther chemical processesSodium BentoniteMaterials science

The invention relates to a bentonite composite material for treating high-zinc and copper cyaniding wastewater and application of the bentonite composite material, and belongs to the technical field of wastewater treatment.The preparation method of the bentonite composite material comprises the following steps: mixing butyl titanate, absolute ethyl alcohol and concentrated nitric acid to obtain a mixture A; dissolving lanthanum nitrate hexahydrate in deionized water, adding the concentrated nitric acid, and then adding the absolute ethyl alcohol to obtain a mixture B; dropwise adding the mixture B in the mixture A to obtain a mixture C, and after dropwise adding is finished, continuing stirring to obtain milky liquid; adding bentonite and the deionized water in the milky liquid to obtain a mixture D; and settling, evaporating to dryness, grinding, sieving, roasting, and cooling to room temperature to obtain the bentonite composite material.The titanium dioxide is generated in a reaction process, the generated titanium dioxide is loaded on the bentonite, high-zinc and copper cyaniding wastewater in the gold industry is treated through modification, cyanogens in the cyanide-containing wastewater can be degraded and heavy metal ions are effectively adsorbed.

Owner:SHANDONG UNIV OF TECH

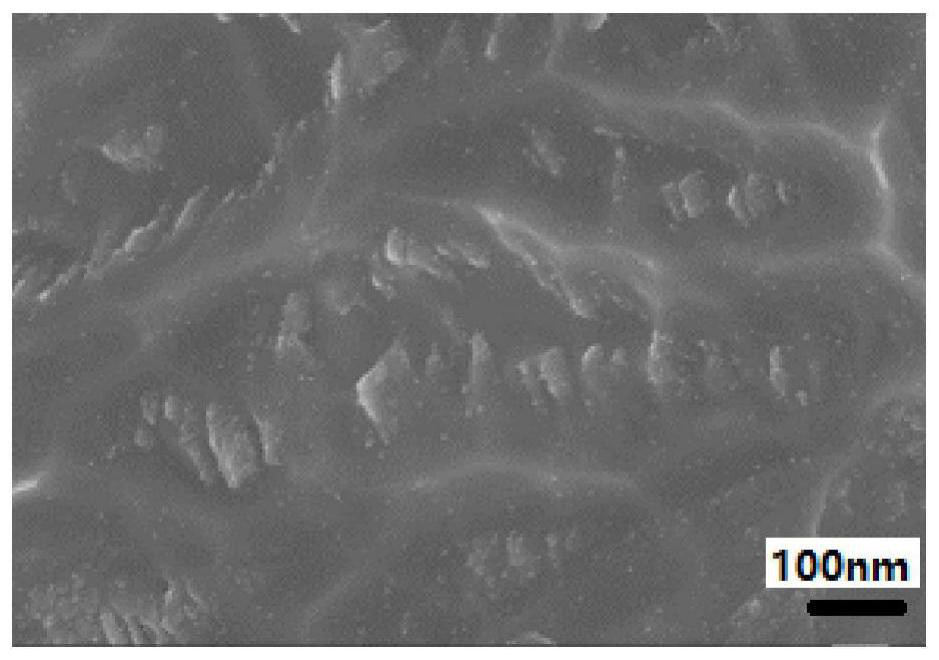

Metal material with modified surface and preparation method and application thereof

ActiveCN112111733AGood biocompatibilitySpecial light absorption propertiesMaterial nanotechnologyPharmaceutical delivery mechanismMetallic materialsBiocompatibility

The invention relates to a metal material with the modified surface and a preparation method and application thereof. The metal material with the modified surface comprises a metal material matrix andan oxidation film which is formed on the surface of the matrix in an in-situ manner and provided with a nanometer topological structure. According to the preparation method of the metal material, themetal material and an acid solution are mixed and then subjected to a hydrothermal reaction, and thus the metal oxidation film provided with the nanometer topological structure is formed on the surface of the metal material in an in-situ manner. By means of formation of the oxidation film, biocompatibility of the material can be improved remarkably, and the material has a good tissue growth induction ability and good antibacterial performance. The oxidation film is formed on the metal matrix in an in-situ manner, an obvious interface between the oxidation film and the matrix material is avoided, the risk that the oxidation film falls off from the matrix is reduced greatly, bonding strength between a decorating layer and a substrate material is ensured, and the application range of the metal material is enlarged.

Owner:SHENZHEN INST OF ADVANCED TECH

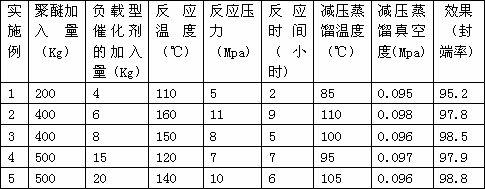

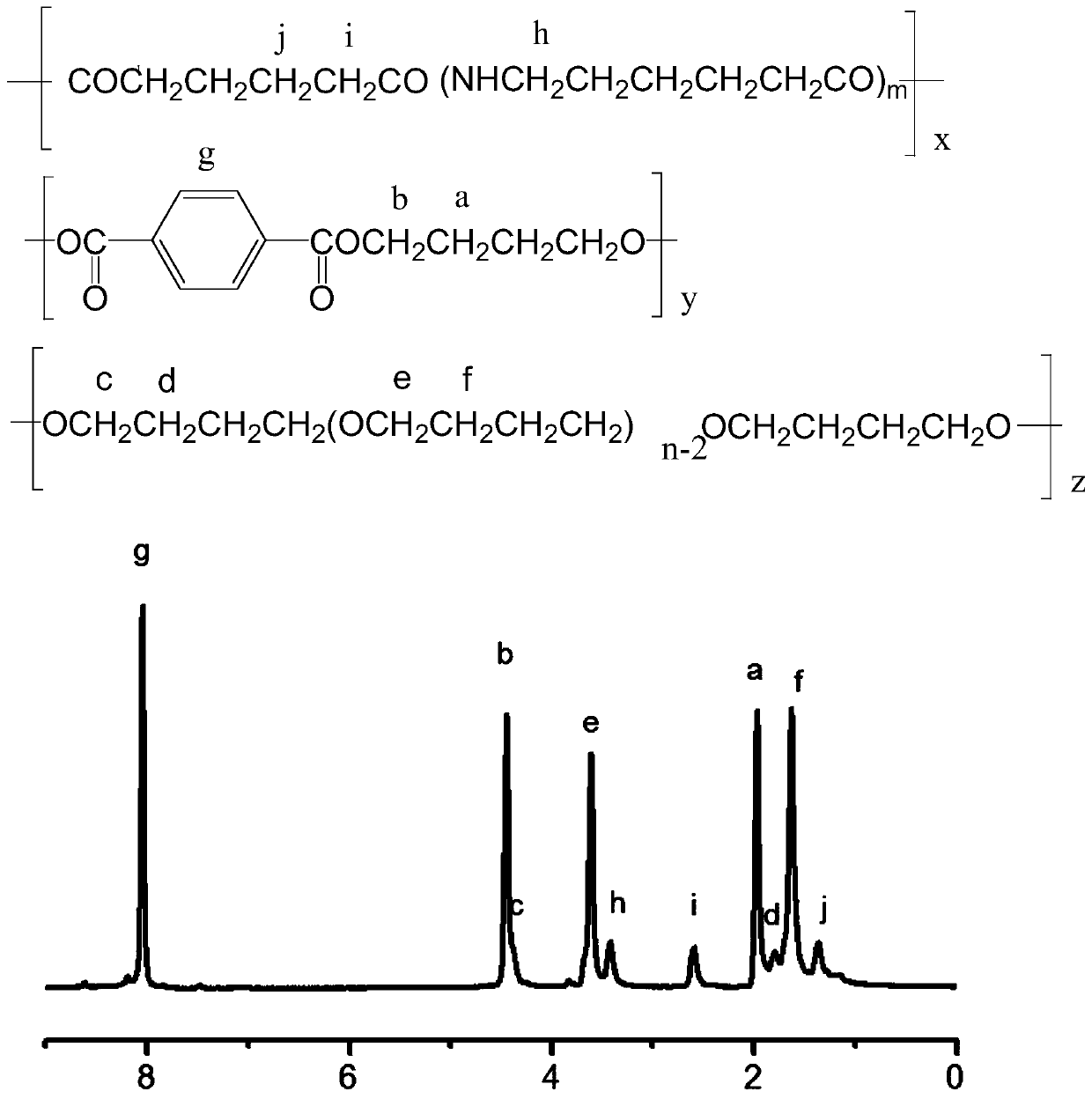

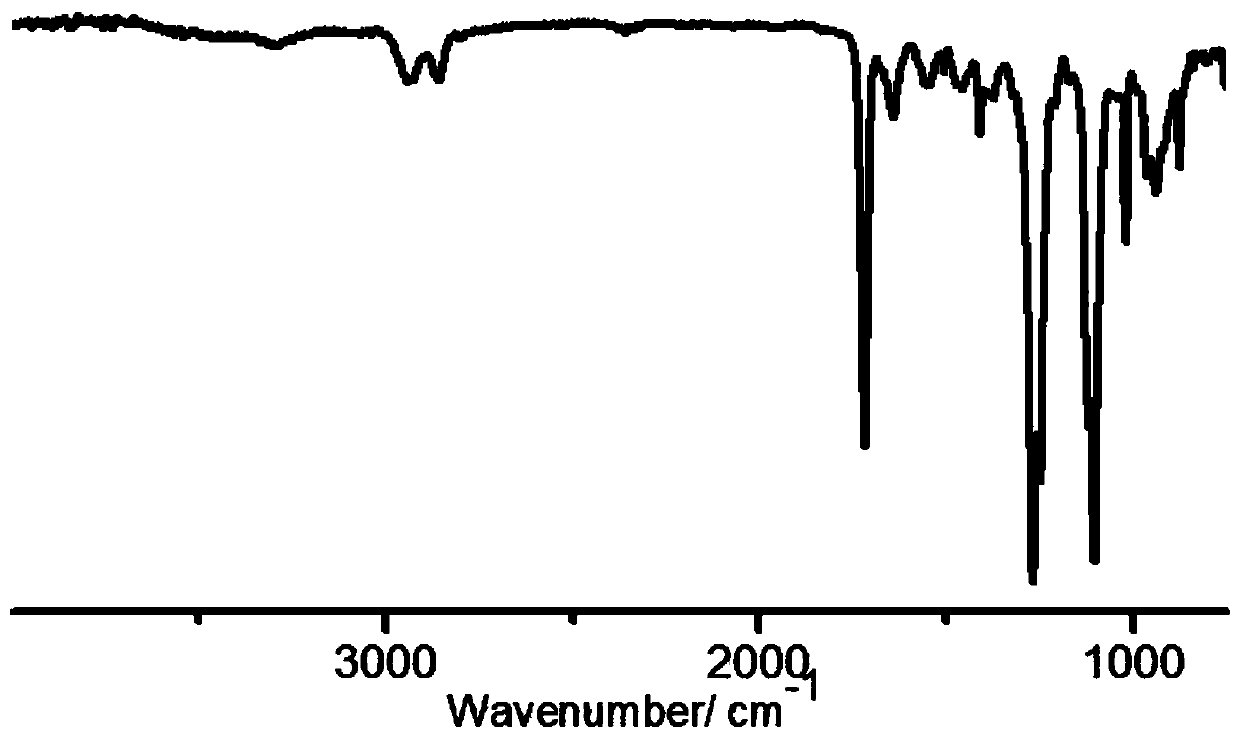

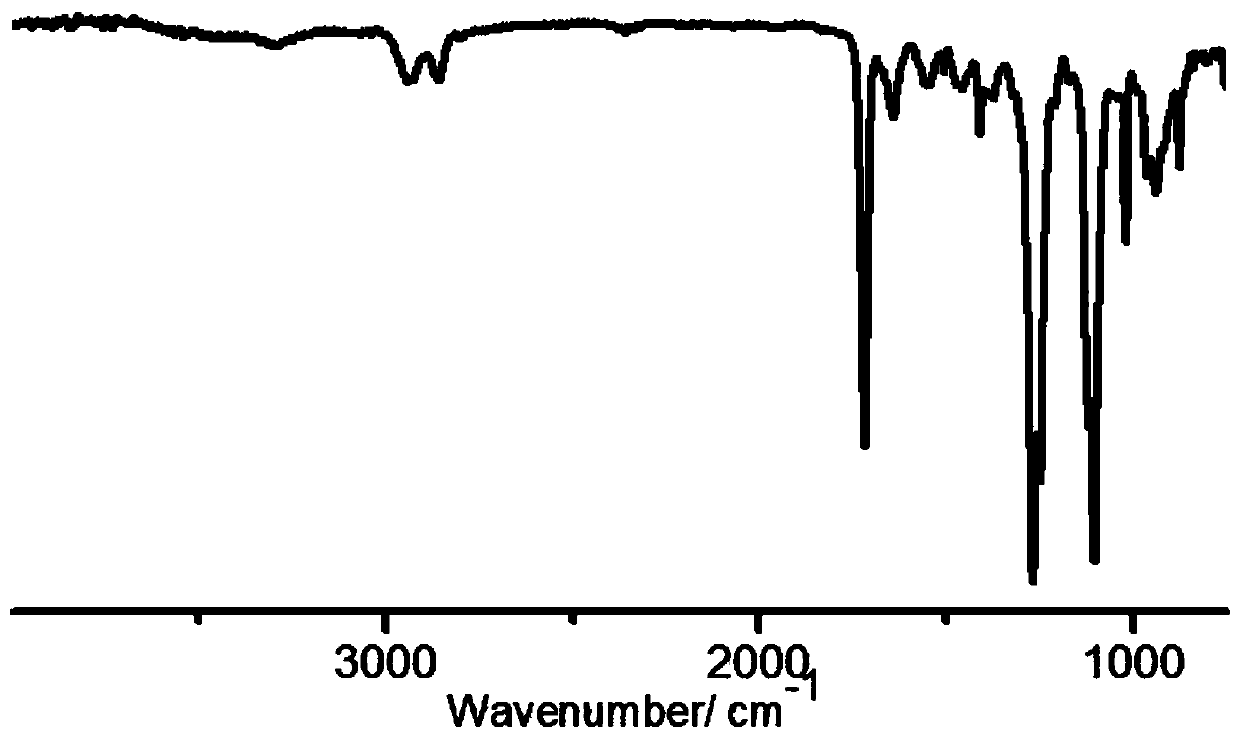

A kind of polyester amide elastomer and preparation method thereof

The invention discloses a preparation method of a polyesteramide elastomer. The preparation method comprises the following steps: (1) carrying out decompression and pumping vacuum after enablinga first monomer, a catalyst a and a capping agentto react, so asto obtain an intermediate product A; (2) enablingthe intermediate product A to be esterified with monohydric alcohol, and carrying out decompression, so as to obtain an intermediate product B of which the end group is an ester group; (3) carrying out transesterification on the intermediate product B, a second monomer, dihydric alcohol and a catalyst b to obtain an intermediate product C of which the end group is a hydroxy group; (4) carrying out polycondensation on the obtained intermediate product C and polyether diolto obtain the polyesteramide elastomer, wherein the polyether diol is blocked by hydroxylends, and dihydric alcohol is aliphatic diols of C2-C10. The polyesteramide elastomer disclosed by the invention is simple and controllable in process route, loose in reaction conditions and fewerin side reactions, and combines the advantages of the polyesteramide elastomer and a polyester elastomer, thereby being better in performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Two-component transparent fireproof coating material preparation method

InactiveCN106147504AWide variety of sourcesLow costFireproof paintsPhosphoric Acid EstersPolymer science

The present invention relates to a two-component transparent fireproof coating material preparation method, which specifically comprises that a polyglycol-grafted polyphosphate is prepared from polyphosphoric acid, pentaerythritol and polyethylene glycol through a solution synthesis method, an aqueous solution or absolute alcohol solution having a certain concentration is prepared from the polyglycol-grafted polyphosphate, and the obtained aqueous solution or absolute alcohol solution and an aqueous amino resin are subjected to blending stirring to obtain the two-component transparent facing fireproof coating material. According to the present invention, the preparation method is simple and feasible, and has the low in cost, and with the prepared two-component transparent facing fireproof coating material, the flexibility of the coating film is substantially improved on the basis of assurance of the excellent fire resistance of the coating material.

Owner:泉州市合创涂料科技有限公司

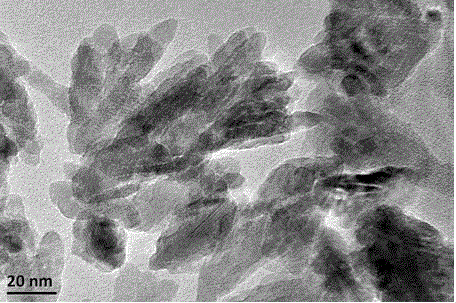

Synthetic method of self-assembly nano titanium dioxide

ActiveCN106186053AReduce application volumeReduce pollutionMaterial nanotechnologyTitanium dioxideReaction temperatureAlkali salt

The invention discloses a synthetic method of self-assembly nano titanium dioxide. According to the method, a titanium oxide precursor is hydrolyzed in an ethanol aqueous solution, low-concentration alkyl ammonium hydroxide is added as a protective agent, low-temperature hydro-thermal pretreatment is employed; weak alkali salt is added, a hydro-thermal reaction is re-carried out under high temperature to form the dendritic titanium dioxide self-assembly particles. The method has the characteristics of low reaction temperature, high output, little usage amount of alkyl ammonium hydroxide, and little pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of treatment method of recycling waste lithium cobaltate lithium ion battery

ActiveCN104577249BFully resourcedReduce lossesWaste accumulators reclaimingBattery recyclingPunch pressCobalt

The invention relates to a method for recycling waste lithium cobalt oxide lithium ion battery. The method is characterized in that valuable components in the waste lithium ion battery are completely recycled by integrating the processes of crushing by a punch press, magnetic separation, eddy current selection, anaerobic atmospheric roasting, temperature-variable filtering and the like, and products with the relatively high additional values, such as elemental crude cobalt, lithium carbonate, graphite, copper, aluminum, iron, and plastics are obtained. Manners of crushing by a punch press, magnetic separation, eddy current selection and the like are adopted for performing material separation, so that the original physical properties of materials are kept. Meanwhile, positive powder and negative powder of an electrode material are cooperatively treated, the negative graphite material is effectively utilized, the in-situ preparation of a resource can be realized, and the waste lithium ion battery can be relatively completely recycled. The anaerobic atmospheric roasting is adopted, so that the reaction condition is relatively loose, the loss of a graphite material is reduced, the cost is saved, the technological flow is simplified, and the industrial application practice can be facilitated.

Owner:SHANGHAI JIAO TONG UNIV

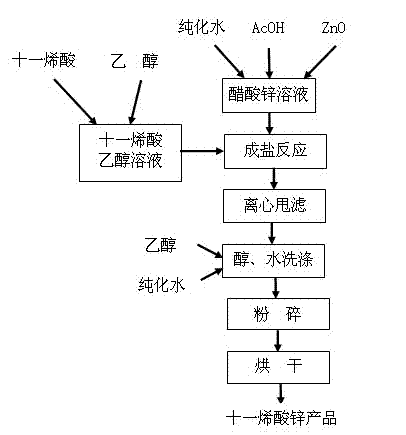

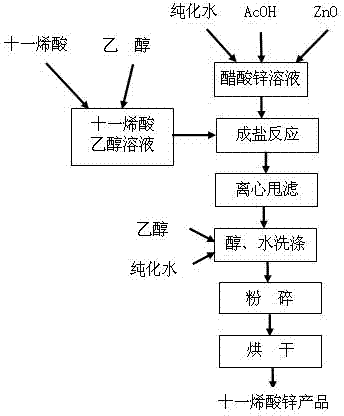

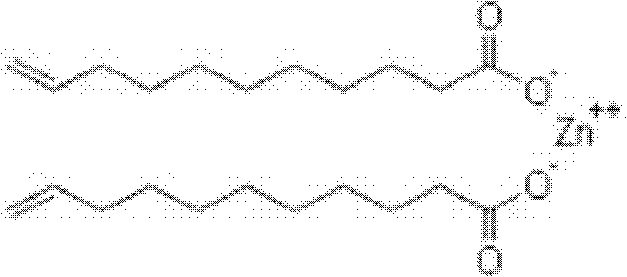

Production method for zinc undecylenate

ActiveCN102417446AResponse conditions are relaxedEasy to controlCarboxylic acid salt preparationZinc Acetate DihydrateAqueous solution

The invention discloses a production method for zinc undecylenate. The production method comprises the following steps: adding glacial acetic acid and zinc oxide into purified water, thereby preparing a zinc acetate aqueous solution; dropwise adding an undecylenate ethanol solution into the zinc acetate aqueous solution; heating, keeping the temperature at 40-80 DEG C, and reacting for 1-2 hours; and filtering, washing, crushing and drying, thereby obtaining a white or light yellow powder zinc undecylenate product.

Owner:广西两面针亿康药业股份有限公司

Method for preparing gypsum whiskers from calcium hydrogen citrate

InactiveCN105568388AReduce manufacturing costResponse conditions are relaxedPolycrystalline material growthFrom normal temperature solutionsHydrogenCITRATE ESTER

The invention relates to the field of citric acid production, and particularly provides a method for preparing gypsum whiskers from calcium hydrogen citrate; the method comprises that calcium hydrogen citrate in a citric acid production process is used as a raw material and undergoes a reaction with concentrated sulfuric acid, and the gypsum whiskers are prepared while citric acid is obtained; the method mainly comprises the steps: carrying out a reaction of a calcium hydrogen citrate slurry with sulfuric acid in a citric acid solution with the pressure of 1-2 kg for 80-600 minutes, to obtain the gypsum whiskers; and filtering with a belt type filter, refining and purifying the filtrate to obtain the citric acid product, and after the filter cake is dried, drying at the temperature of 80-100 DEG C, to obtain the gypsum whiskers with the whisker length of 50-400 microns, the diameter of 1-4 microns and the diameter ratio of 20-100. The gypsum whiskers are generated through the hydrothermal method in a medium having a large amount of citric acid, the reaction conditions are loose, the whisker quality is obviously improved, and moreover, the production cost of the gypsum whiskers is greatly reduced.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Method for preparing gypsum whisker by calcium citrate

InactiveCN101230483BReduce manufacturing costResponse conditions are relaxedPolycrystalline material growthFrom normal temperature solutionsManufacturing technologyFine chemical

The invention provides a method of manufacturing plaster crystal whiskers by utilizing calcium citrate and belongs to the field of fine chemical manufacturing technology. Combined with the citric acidmanufacturing technique, the invention manufactures plaster crystal whiskers while the calcium citrate is acidolysised to generate citric acid. The invention includes the following steps: firstly, after the sulphuric acid is added in, the calcium citrate serum is well stirred, placed in an autoclave for reaction at a temperature of 120 to 130 EDG C for 10 to 50 minutes and then cooled to be filtered; and secondly, the filtrate is used for crystallizing and separating out the citric acid product. The filtering medium is washed in water for 1 to 3 times, drained and then dried at a temperatureof 80 to 100 DEG C and finally plaster crystal whiskers with a length of 50 to 400 micrometers, a diameter of 1 to 4 micrometers and a diameter ratio of 40 to 160 are obtained. The invention generatesplaster crystal whiskers from the medium rich in citric acid by using the hydrothermal method, the reacting conditions are loose, the quality of the crystal whisker is obviously enhanced and the manufacturing cost for the crystal whisker is greatly reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

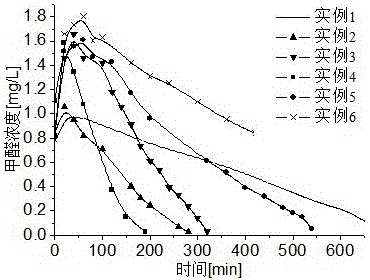

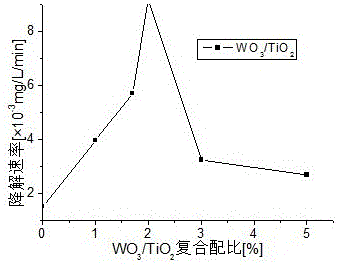

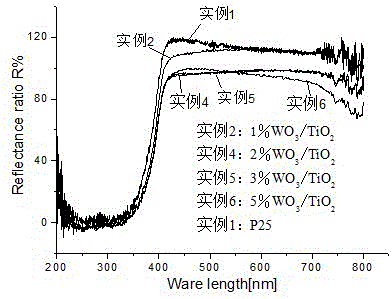

A Tungsten Trioxide Composite Titanium Dioxide Photocatalyst for Degrading Formaldehyde

ActiveCN103537294BReduce energy consumptionLow costMetal/metal-oxides/metal-hydroxide catalystsTungstatePhotocatalytic degradation

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

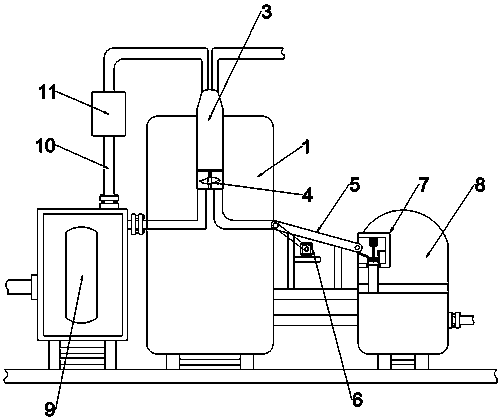

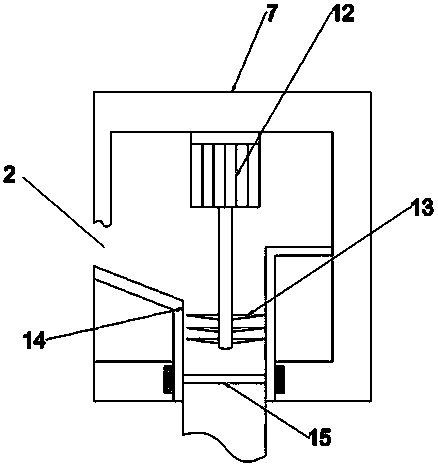

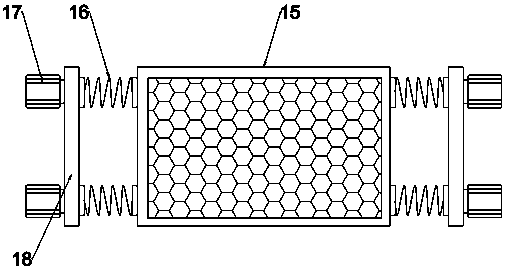

Device and method for utilizing plasmas for separating out carbon disulphate by-product hydrogen sulfide

InactiveCN108584884AReduce wasteReduce investmentCarbon disulfideSulfur preparation/purificationMelting tankPlasma generator

The invention discloses a device and method for utilizing plasmas for separating out carbon disulphate by-product hydrogen sulfide. The device comprises a reaction tank, a plasma generator, a boosterfan, a conveyor belt, a first motor, a smashing assembly, a sulfur melting tank, a pressure swing adsorption cavity, a connecting pipe and an exhaust assembly. The plasma generator is installed insidethe reaction tank, the booster fan is installed at the bottom end of the plasma generator, the conveyor belt is arranged at one side of the reaction tank, the sulfur melting tank is arranged at one end of the conveyor belt, and the smashing assembly is arranged at the joint of the conveyor belt and the top end of the sulfur melting tank. The device and method for utilizing plasmas for separatingout the carbon disulphate by-product hydrogen sulfide have the advantages of being recyclable and high in separating efficiency, and the high using effectiveness and high usability are improved.

Owner:山西铁峰化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com