Synthetic method of self-assembly nano titanium dioxide

A technology of titanium dioxide and self-assembly, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of environmental pollution and high cost, and achieve the effects of reducing environmental pollution, large product output and loose reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

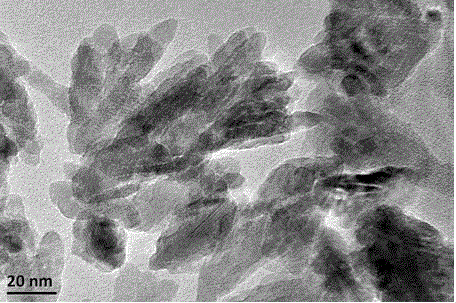

[0042] Mix 100 mL of ethanol aqueous solution at a volume ratio of 1:1, and drop 10 mL of tetraisopropyl titanate into the ethanol aqueous solution at room temperature and magnetic stirring at a rate of 10 mL / min, and a white colloidal solution gradually appears. After stirring for 20 minutes, 5 mL of 25 wt % tetraethylammonium hydroxide aqueous solution was added, and stirring was continued for 30 minutes. Transfer the above solution to a 500mL static reaction kettle, seal it, put it into a 100°C drying oven for 24 hours of constant temperature reaction, add 10 grams of ammonium bicarbonate, raise the temperature to 120°C, and react at a constant temperature for 24 hours. Take out the reaction kettle, and after cooling down to room temperature naturally, the white powder will be separated by centrifugation. Wash with distilled water three times, and separate the white powder by centrifugation each time. The centrifugation speed is 8000rpm, and finally dry at 70°C for 24 hours...

Embodiment 2

[0044] According to the experimental process of Example 1, the ratio of the aqueous ethanol solution is 1:2, and tetraisobutyl titanate is used as the titanium source. The sample processing conditions were the same as in Example 1 to obtain product B. It is used for transmission electron microscope observation. The transmission electron microscope results show that the particle size of titanium dioxide is about 65 nanometers, and has a self-assembled structure. The diameter of the assembled spindle fiber is 9 nanometers and the length is 55 nanometers.

Embodiment 3

[0046] According to the experimental process of Example 1, 10 mL of 30 wt % tetraethylammonium hydroxide aqueous solution was added, and the sample treatment conditions were the same as in Example 1 to obtain product C. For transmission electron microscope observation, the transmission electron microscope results show that the particle size of titanium dioxide is about 85 nanometers, and has a self-assembled structure. The diameter of the assembled spindle fiber is 12 nanometers and the length is 78 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com