Preparation method of sulfydryl carbon nano-tube micro-sphere conductive adhesives for liquid-crystal display circuits

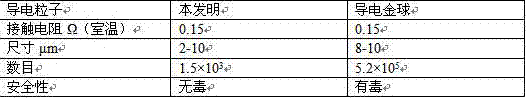

A carbon nanotube microsphere and liquid crystal display technology, applied in the field of conductive adhesive, can solve the problems of complex preparation process, high environmental pollution, and high content of conductive fillers, avoiding excessively high content, excellent conductive performance, and simple and easy-to-control process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) The ratio of parts by mass is 5 : 0.01: 0.05 : 100, taking styrene monomer, azobisisobutyronitrile initiator, chloroform and solvent ethanol, and reacting at 90°C for 5 hours to prepare a polymer micro Balls, the particle size of the polymer microspheres is 6 μm;

[0035] (2) Using single-walled carbon nanotubes with a diameter of 40 nm and a purity greater than 97% as raw materials, the original carbon nanotubes were added to H 2 SO 4 :HNO 3 =3:1 in the mixed acid, the mass ratio of the carbon nanotubes to the mixed acid was 1:180, ultrasonically dispersed for 30 min, placed on a constant temperature magnetic stirrer and stirred at 80 °C for 30 min; then the treated carbon The nanotubes are added to a large amount of deionized water to cool, centrifuged, and repeatedly sucked to neutrality, and vacuum dried to obtain carbon dioxide nanotubes. Weigh the raw materials according to the mass ratio of oxidized carbon nanotubes, 3-mercaptopropyltrimethoxysilane and di...

Embodiment 2

[0040] (1) The ratio of parts by mass is 30 : 0.2 : 0.15 : 100, taking styrene monomer, azobisisobutyronitrile initiator, mercaptoethanol and solvent ethanol, and reacting at 65°C for 18 hours to prepare a polymer Microspheres, the polymer microspheres have a particle size of 4 μm;

[0041] (2) Using multi-walled carbon nanotubes with a diameter of 10 nm and a purity greater than 97% as raw materials, the original carbon nanotubes are added to the mixed acid of H2SO4:HNO3=3:1, and the mass ratio of the carbon nanotubes to the mixed acid is It was 1:190, ultrasonically dispersed for 30 min, placed on a constant temperature magnetic stirrer, and stirred at 80 °C for 30 min; then the treated carbon nanotubes were added to a large amount of deionized water to cool, centrifuged, and repeatedly sucked to medium properties, vacuum drying, prepared carbon dioxide nanotubes. Weigh the raw materials according to the mass ratio of oxidized multi-walled carbon nanotubes, 3-mercaptopropyl...

Embodiment 3

[0046] (1) The ratio of parts by mass is 15 : 0.5 : 3 : 100, taking styrene monomer, azobisisobutyronitrile initiator, mercaptoacetic acid and solvent ethanol, and reacting at 70°C for 12 hours to prepare a polymer Microspheres, the polymer microspheres have a particle size of 5 μm;

[0047] (2) Using single-wall carbon nanotubes and multi-wall carbon nanotubes with a diameter of 30 nm and a purity greater than 97% as raw materials, the original carbon nanotubes are added to the mixed acid of H2SO4:HNO3=3:1, and the carbon nanotubes The mass ratio of the tube to the mixed acid was 1:190, ultrasonically dispersed for 30 min, and placed on a constant temperature magnetic stirrer at 80 °C for 30 min under reflux; then the treated carbon nanotubes were added to a large amount of deionized water to cool, centrifuged, And repeated suction filtration to neutrality, and vacuum drying to obtain oxidized carbon nanotubes. Weigh the raw materials according to the mass ratio of oxidized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com