Outer surface damage repair technology for shaft parts

A technology for shaft parts and damage repair, applied in the field of surface damage repair, can solve problems such as insufficient bonding force, delamination, and inability to plate iron, etc., to achieve the effects of solving insufficient bonding force, reducing costs, and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

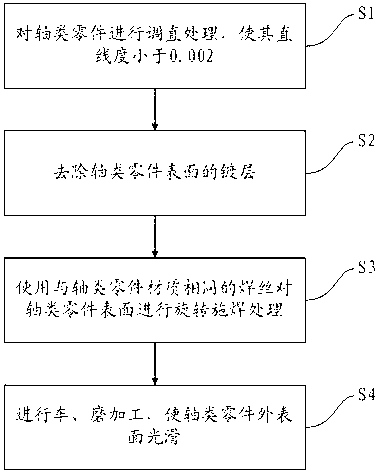

[0017] refer to figure 1 As shown, the present invention provides a process for repairing damage to the outer surface of shaft parts, which includes the following steps:

[0018] S1. Use a press or other straightening equipment to straighten the shaft parts so that the straightness is less than 0.002;

[0019] S2. Use turning and grinding to remove the coating on the surface of shaft parts;

[0020] S3. Use the welding wire with the same material as the shaft parts, and use carbon dioxide gas shielded welding to perform rotary welding on the surface of the shaft parts, so that the thickness of the welding layer is about 3 to 4 mm;

[0021] S4. Perform turning and grinding processing to make the outer surface of the shaft parts smooth.

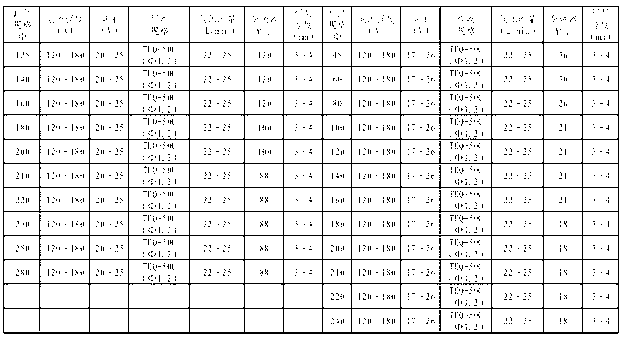

[0022] The following table 1 is a preferred fusion welding technical parameter table obtained fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com