Method for manufacturing copper-plated aluminum nitride ceramic substrate

A technology of aluminum nitride ceramics and a manufacturing method, which is applied in the field of metallization of ceramic substrates, can solve the problems of high porosity, low peel strength, insufficient bonding force between copper foil and aluminum nitride ceramic substrates, etc., and achieve reduction of air porosity, Effect of improving peel strength, good affinity and cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

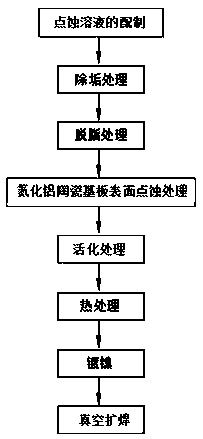

Image

Examples

Embodiment 1

[0043] The manufacturing method of the copper-clad aluminum nitride ceramic substrate of the present embodiment comprises the following steps:

[0044] (1) Preparation of pitting solution: The pitting solution is made by mixing sodium sulfate, sulfuric acid, slow-release agent and additives, wherein the slow-release agent is made of ethylene glycol, glycerin or a mixture of both, and the additives are oxalic acid, Either one of EDTA or both are mixed, the selected reagents are dissolved in deionized water in proportion, and stirred at 50°C, the stirring speed is 500rpm, and the pitting solution is obtained by filtering after stirring for 40min;

[0045] (2) Descaling treatment: immerse the aluminum nitride ceramic substrate in the degreasing solution, clean it with an ultrasonic cleaning process, remove the dirt on the surface of the aluminum nitride ceramic substrate, and rinse the surface with deionized water under the action of sodium sulfate;

[0046] (3) Degreasing treatm...

Embodiment 2

[0065] The manufacturing method of the copper-clad aluminum nitride ceramic substrate of the present embodiment comprises the following steps:

[0066] (1) Preparation of pitting solution: The pitting solution is made by mixing sodium sulfate, sulfuric acid, slow-release agent and additives, wherein the slow-release agent is made of ethylene glycol, glycerin or a mixture of both, and the additives are oxalic acid, Either one of EDTA or both are mixed, the selected reagent is dissolved in deionized water in proportion, and stirred at 50°C, the stirring speed is 600rpm, and the pitting solution is obtained by filtering after stirring for 60min;

[0067] (2) Descaling treatment: immerse the aluminum nitride ceramic substrate in the degreasing solution, clean it with an ultrasonic cleaning process, remove the dirt on the surface of the aluminum nitride ceramic substrate, and rinse the surface with deionized water under the action of sodium sulfate;

[0068] (3) Degreasing treatmen...

Embodiment 3

[0087] The manufacturing method of the copper-clad aluminum nitride ceramic substrate of the present embodiment comprises the following steps:

[0088] (1) Preparation of pitting solution: The pitting solution is made by mixing sodium sulfate, sulfuric acid, slow-release agent and additives, wherein the slow-release agent is made of ethylene glycol, glycerin or a mixture of both, and the additives are oxalic acid, Either one of EDTA or both are mixed, the selected reagents are dissolved in deionized water in proportion, and stirred at 50°C, the stirring speed is 550rpm, and the pitting solution is obtained by filtering after stirring for 50min;

[0089] (2) Descaling treatment: immerse the aluminum nitride ceramic substrate in the degreasing solution, clean it with an ultrasonic cleaning process, remove the dirt on the surface of the aluminum nitride ceramic substrate, and rinse the surface with deionized water under the action of sodium sulfate;

[0090] (3) Degreasing treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com