A low-formaldehyde-content environmentally friendly density fiberboard and a manufacturing method thereof

A density board, environmental protection technology, applied in pulp beating/refining method, fiberboard, textiles and papermaking, etc., can solve the problems of ecological environment damage and inefficient utilization, so as to reduce the application amount, improve product quality grade, The effect of reducing formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

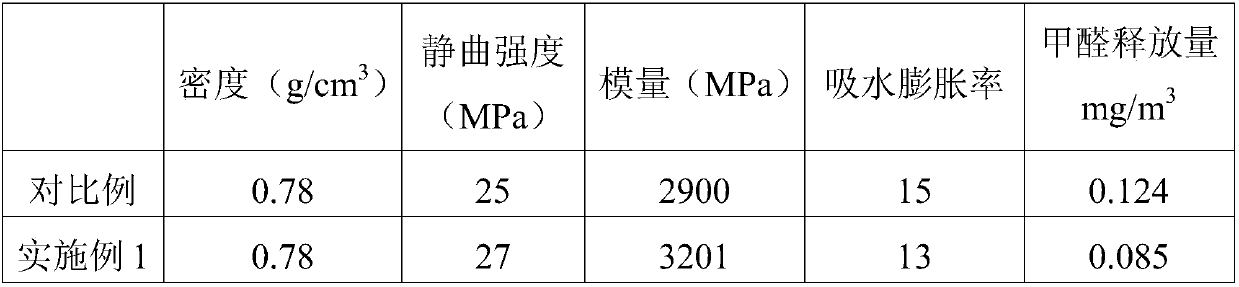

Embodiment 1

[0027] Raw materials and dosage: 55 parts of pine wood, 30 parts of papermaking waste, and 15 parts of urea-formaldehyde glue.

[0028] The pine wood is cut into wood chips that meet the production specifications, providing better conditions for its fiber separation, and the papermaking waste is crushed into papermaking waste particles of a certain particle size;

[0029] The obtained wood chips are preheated and cooked, and mechanically separated to obtain fibers;

[0030] The obtained paper-making waste particles are put into a thermal mill, and mixed evenly with the cooked wood chips in proportion, the gap between the grinding discs is controlled at 0.6 mm, the steam pressure is controlled at 0.65 MPa, and the mixture of fibers and paper-making waste is obtained through mechanical separation;

[0031] Use steam spray glue for the obtained fiber papermaking waste mixture, so that the glue is more evenly sprayed on the fiber surface;

[0032] Drying: The mixture of fibrous a...

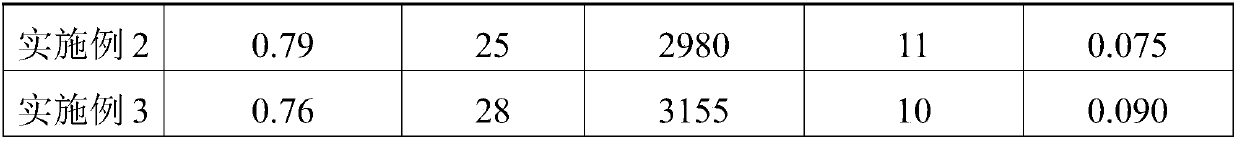

Embodiment 2

[0037] Raw materials and dosage: 55 parts of pine wood, 35 parts of papermaking waste, and 10 parts of urea-formaldehyde glue.

[0038] The wood is cut into wood chips that meet the production specifications to provide better conditions for its fiber separation, and the papermaking waste is crushed into papermaking waste particles of a certain particle size;

[0039] The obtained wood chips are preheated and cooked, and mechanically separated to obtain fibers;

[0040] The obtained paper-making waste particles are put into a thermal mill, and mixed evenly with the cooked wood chips in proportion, the gap between the grinding discs is controlled at 0.6mm, the steam pressure is controlled at 0.75MPa, and the fiber and paper-making waste mixture is obtained through mechanical separation;

[0041] Use steam spray glue for the obtained fiber papermaking waste mixture, so that the glue is more evenly sprayed on the fiber surface;

Embodiment 3

[0047] Raw materials and dosage: 50 parts of pine wood, 30 parts of papermaking waste, 20 parts of urea-formaldehyde glue.

[0048] The pine wood is cut into wood chips that meet the production specifications, providing better conditions for its fiber separation, and the papermaking waste is crushed into papermaking waste particles of a certain particle size;

[0049] The obtained wood chips are preheated and cooked, and mechanically separated to obtain fibers;

[0050] The obtained paper-making waste particles are put into a thermal mill, and mixed evenly with the cooked wood chips in proportion, the gap between the grinding discs is controlled at 0.6mm, the steam pressure is controlled at 0.75MPa, and the fiber and paper-making waste mixture is obtained through mechanical separation;

[0051] Use steam spray glue for the obtained fiber papermaking waste mixture, so that the glue is more evenly sprayed on the fiber surface;

[0052] Drying: heat-grinding fiber papermaking wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com