Translucent natural marble composite board and method for producing the same

A technology of marble slabs and composite slabs, applied in chemical instruments and methods, natural mineral layered products, building structures, etc., can solve the problems of no special requirements, lack of natural texture, voids in the interface layer, etc., and achieve utilization rate Improve, make easy, overcome the effect of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

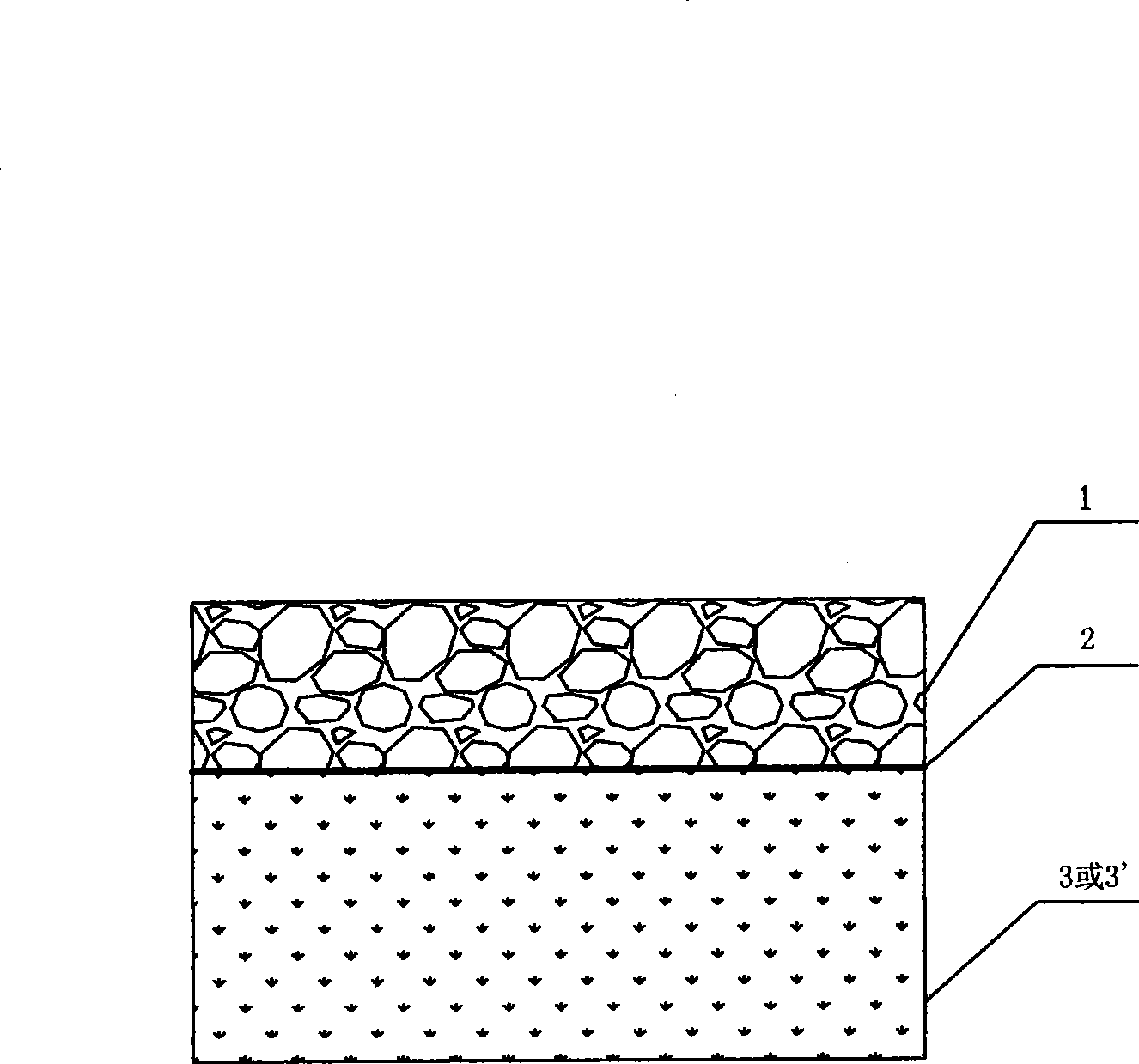

[0015] Prepare a natural marble slab 1 with a pattern and light transmission with a thickness of 1.5mm to 10mm, preferably 1.8mm, and an inorganic glass plate 3 or organic glass plate 3' of the same size and shape. The thickness of the glass plate is 8mm to 10mm. 25mm, preferably 15mm; after cleaning, apply a thin layer of epoxy adhesive 2 on each side, preferably the epoxy adhesive specially used for dry-hanging stone curtain walls, such as JC887-2001 type. Since epoxy adhesives are divided into components A and B, they must be used in time and processed in time. When bonded into a composite panel (see figure 1 As shown), send it to the vacuum environment immediately, gradually evacuate to an absolute vacuum of 80Kpa ~ 95Kpa (kiloPascal), then keep it, and maintain it at a temperature of 10°C ~ 30°C for 10 hours to 30 hours, until the composite board After being completely bonded firmly, the vacuum is released, and the workpiece is taken out to obtain the light-transmitting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com