Polyether amine for textile printing and dyeing auxiliary and preparation method for polyether amine

A textile printing and dyeing and polyether amine technology, applied in the field of polymer organic amine compounds, can solve the problems of easy oil drift, weak electrolyte resistance, poor thermal stability of the system, etc., and achieve less reaction by-products, low equipment requirements, and system The effect of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

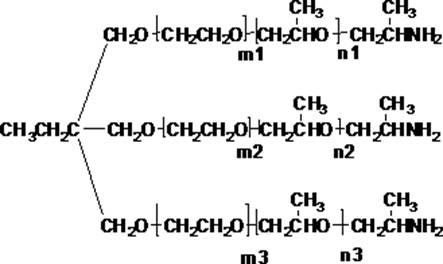

Image

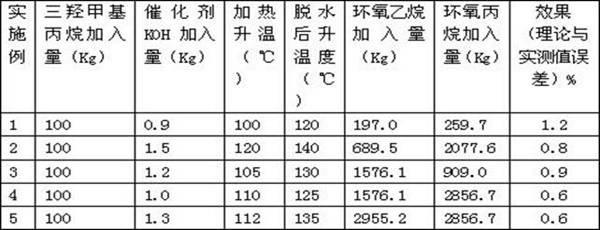

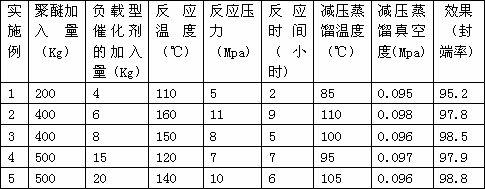

Examples

Embodiment Construction

[0021] 1. Preparation of supported catalyst

[0022] The supported catalyst can use any one or a mixture of two or more of nickel nitrate, copper nitrate, cobalt nitrate, chromium nitrate, and lanthanum nitrate, and add any one or two or more of cerium oxide, ammonium molybdate, and ammonium rhenate The mixture was dissolved in distilled water, stirred while heating until completely dissolved, and then transferred to a petri dish. In the mixture of two or more kinds of nickel nitrate, copper nitrate, cobalt nitrate, chromium nitrate and lanthanum nitrate, the ratio of each component can be adjusted at will. In the mixture of more than two kinds of cerium oxide, ammonium molybdate and ammonium rhenate, the ratio of each component can also be adjusted at will.

[0023] 45 g of the pre-dried silicon dioxide and aluminum oxide mixed carrier were uniformly placed in the above-mentioned petri dish, ultrasonically oscillated for 15 minutes with an ultrasonic cleaner, and then tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com