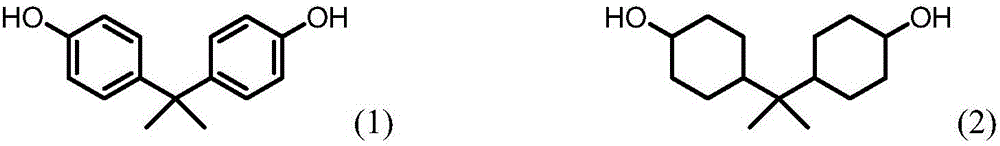

Preparation method for hydrogenated bisphenol A and catalyst for hydrogenation of bisphenol A

A technology for hydrogenating bisphenol and catalyst, which is applied in hydrogenation preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. The high cost of hydrogenation catalysts, the inability to take into account the selectivity and purity of conversion products, etc., achieve the effects of good catalytic effect, low cost, low toxicity and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Catalyst preparation

[0024] Preparation of the carrier: the TiO 2 Add a certain proportion of 0.3mol / L cadmium salt solution to the nano powder, adjust the pH value of the solution to 10 with 0.3mol / L sodium hydroxide solution, and dry naturally to obtain TiO 2 -CdO composite carrier. Among them, CdO and TiO 2 The molar ratios are 1:1, 1:2 and 1:3, respectively.

Embodiment A1

[0025] Embodiment A1: a certain amount of carrier (CdO and TiO 2 The molar ratio is 1:2) impregnated in the mixed solution of 0.5mol / L ruthenium nitrate, zinc nitrate, nickel nitrate (the molar ratio of ruthenium nitrate, zinc nitrate, nickel nitrate is 1:0.05:0.001), ultrasonic 0.5h, dipping 24h, dried under infrared lamp, and then calcined in a muffle furnace at 500°C for 2h to obtain Catalyst 1.

Embodiment A2

[0026] Embodiment A2: a certain amount of carrier (CdO and TiO 2 The molar ratio is 1:2) impregnated in a mixed solution of 0.5mol / L ruthenium nitrate, zinc nitrate, and nickel nitrate (the molar ratio of ruthenium nitrate, zinc nitrate, and nickel nitrate is 1:0.1:0.001), ultrasonic 0.5h, dipping 24h, dried under infrared lamp, and then calcined in a muffle furnace at 500°C for 2h to obtain Catalyst 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com