Method of preparing transparent and decorated fireproof coating with two components

A fire-resistant coating, a two-component technology, applied in the direction of fire-resistant coatings, coatings, phosphorus organic compounds, etc., can solve the problems of cracking of the coating film, poor flexibility of the coating film, etc., and achieve relaxed reaction conditions, low cost, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

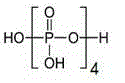

Image

Examples

Embodiment 1

[0024] (1) Dissolve 50g of polyphosphoric acid in 200ml of dioxane, heat and stir until the polyphosphoric acid is evenly dissolved. 25 g of pentaerythritol was added to the system, and the temperature was raised to 80° C. for reaction. After 6 hours of reaction, the solvent was evaporated using a rotary evaporator. The product was grafted with 25g PEG200 under the reaction condition of 100°C for 8 hours to obtain polyethylene glycol grafted polyphosphate;

[0025] (2) Make a 50% aqueous solution of the prepared grafted polyphosphate, weigh 400g, and blend and stir for 30 minutes. After the stirring is completed, the bubbles in the paint will naturally dissipate, and it will be a two-component transparent finish. type fire retardant coating.

Embodiment 2

[0027] (1) Dissolve 40g of polyphosphoric acid in 300ml of tetrahydrofuran, heat and stir until the polyphosphoric acid is evenly dissolved. 40 g of pentaerythritol was added to the system, and the temperature was raised to 90° C. for reaction. After 10 h of reaction, the solvent was evaporated using a rotary evaporator. The product was grafted with 20g PEG300 under the reaction condition of 120°C for 12 hours to obtain polyethylene glycol grafted polyphosphate;

[0028] (2) Make the prepared grafted polyphosphate into 50% aqueous solution, weigh 400g of water-based hexamethylol melamine formaldehyde resin, blend and stir for 30min, and wait for the bubbles in the paint to dissipate naturally after stirring. It is a two-component transparent finish type fire retardant coating.

Embodiment 3

[0030] (1) Dissolve 45g of polyphosphoric acid in 250ml of dimethylformamide, heat and stir until the polyphosphoric acid is evenly dissolved. 32.5 g of pentaerythritol was added to the system, and the temperature was raised to 85° C. for reaction. After 8 hours of reaction, the solvent was evaporated using a rotary evaporator. The product was grafted with 22.5g PEG400 under the reaction condition of 110°C for 10 hours to obtain polyethylene glycol grafted polyphosphate;

[0031] (2) Make the prepared grafted polyphosphate into 50% aqueous solution, weigh 400g of water-based hexamethylol melamine formaldehyde resin, blend and stir for 30min, and wait for the bubbles in the paint to dissipate naturally after stirring. It is a two-component transparent finish type fire retardant coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com