A kind of polyester amide elastomer and preparation method thereof

A polyester amide and elastomer technology, applied in the field of polyester amide elastomer preparation, can solve the problems of incomplete polymerization, poor physical and mechanical properties, and low polymer molecular weight in the polycondensation reaction stage, and achieve excellent low temperature and fatigue resistance , fewer side reactions, and improved process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

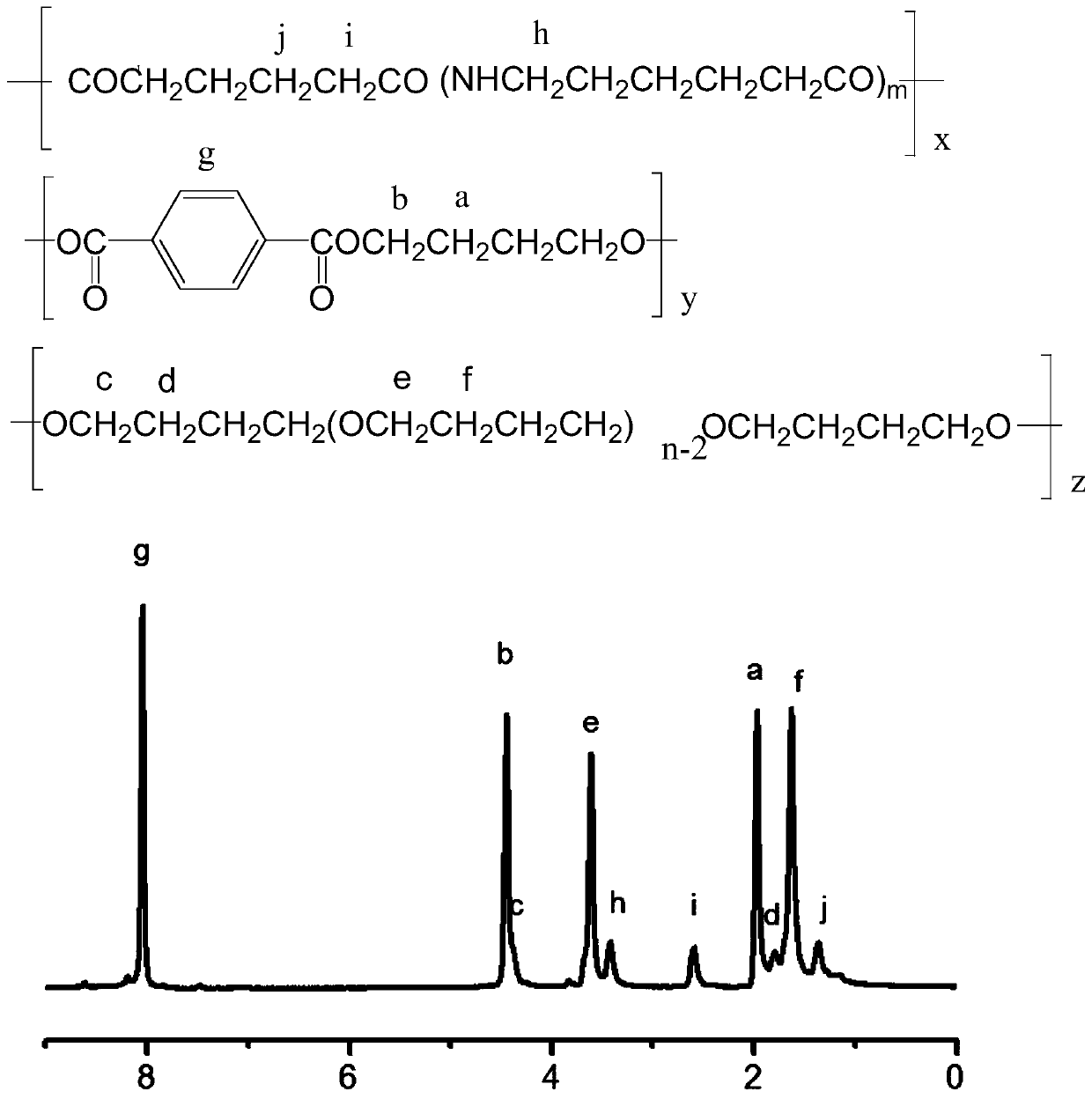

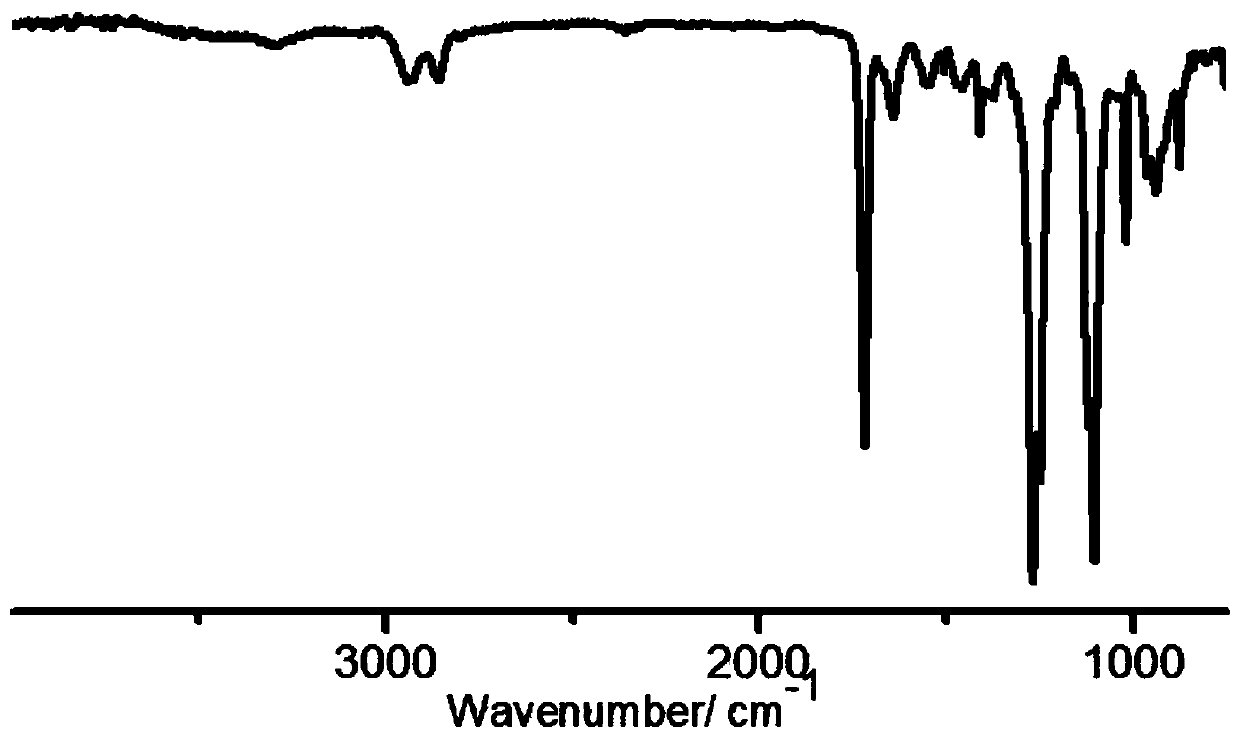

Image

Examples

Embodiment

[0046] A kind of preparation method of polyester amide elastomer of the present invention, comprises the following steps:

[0047] (1) Add the first monomer, catalyst a, and end-capping agent into a stainless steel high-pressure reactor according to the ratio shown in Table 1 below, replace the air in the reactor with nitrogen, raise the temperature to 250°C and keep it for 3 hours, and the reaction pressure 0.1MPa~1.5MPa, vacuumize 2h after depressurization, the pressure is -0.7MPA, obtain intermediate product A after reacting and discharging, dry for later use; In specific embodiment 1-6, the first monomer selects caprolactam respectively , one or more in laurolactam, aminoundecanoic acid (see the following table 1 for specific formula); in specific embodiment 1-6, catalyst a all selects water for use; in specific embodiment 1-6 Among them, adipic acid is selected as the end-capping agent;

[0048] (2) Add the intermediate product A and monohydric alcohol obtained in the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com