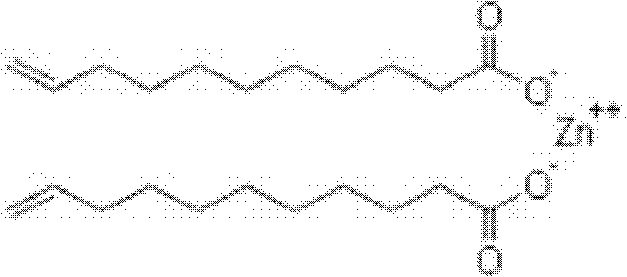

Production method for zinc undecylenate

A technology of zinc alkenoate and alkenoic acid, applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of incomplete reaction, non-conformity, uneven thickness of finished products, etc., and achieves obvious reaction end point, loose reaction conditions, and post-treatment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

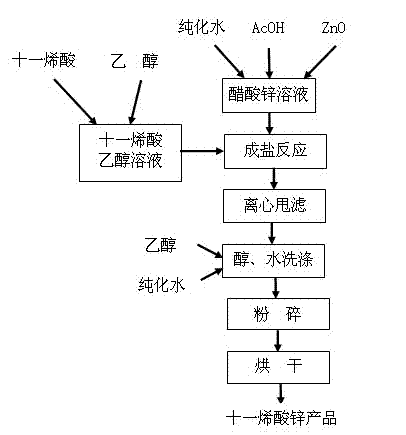

Method used

Image

Examples

Embodiment 1

[0042] Ingredients ratio:

[0043] Zinc oxide: glacial acetic acid: water = 1:1.5:8 (W / W)

[0044] Undecylenic acid: ethanol = 1:1 (W / W)

[0045] 70.4kg of purified water, 13.2kg of glacial acetic acid, and 8.8kg of zinc oxide are dropped into the reaction tank respectively by zinc oxide: glacial acetic acid: water=1: 1.5: 8 batching ratio, and are heated to 80~100 ℃ under stirring, react After 1 hour, after the zinc oxide was completely dissolved, the aqueous solution of zinc acetate was filtered to obtain a colorless and transparent zinc acetate solution for subsequent use. Accurately weigh 40kg of 96.0% undecylenic acid fine product and put it into the reaction tank, then add 40kg of 95% ethanol in the weight ratio of undecylenic acid: ethanol=1:1, fully stir, and heat up to 70°C , to obtain a clear and transparent undecylenic acid ethanol solution for subsequent use. Slowly add the undecylenic acid ethanol solution into the above-prepared zinc acetate solution under sti...

Embodiment 2

[0047] Ingredients ratio:

[0048] Zinc oxide: glacial acetic acid: water = 1:1.6:8 (W / W)

[0049] Undecylenic acid: ethanol = 1:2 (W / W)

[0050] Accurately take by weighing zinc oxide 9.2kg by batching ratio, then by zinc oxide: glacial acetic acid: water=1: 1.5: 8 batching ratio 70.4kg of purified water, 14.72kg of glacial acetic acid, zinc oxide 9.2kg are dropped in the reaction tank respectively, and Heating to 80-100° C. under stirring, and reacting for 1.5 hours to completely dissolve the zinc oxide, then filter the zinc acetate aqueous solution to obtain a colorless and transparent zinc acetate solution for future use. Accurately weigh 96.0% undecylenic acid fine product 40.0kg and put it into the reaction tank, then add 80% ethanol 80kg in the weight ratio of undecylenic acid: ethanol=1:2, fully stir, and heat up to 70 °C, a clear and transparent ethanol solution of undecylenic acid was obtained and set aside. Slowly drop the undecylenic acid ethanol solution into t...

Embodiment 3

[0052] Ingredients ratio:

[0053] Zinc oxide: glacial acetic acid: water = 1:1.7:8 (W / W)

[0054] Undecylenic acid: ethanol = 1:4 (W / W)

[0055] Accurately weigh 9.6 kg of zinc oxide according to the proportion of ingredients for subsequent use. Then press zinc oxide: glacial acetic acid: water=1: 1.7: 8 batching ratio with purified water 70.4kg, glacial acetic acid 16.32kg, zinc oxide 9.6kg drop into reaction tank respectively, and under stirring, be heated to 80~100 ℃, After reacting for 2 hours, after the zinc oxide was completely dissolved, the zinc acetate aqueous solution was filtered to obtain a colorless and transparent zinc acetate solution for subsequent use. Accurately take content and be that 40.0kg of 96.0% undecylenic acid fine products are put into reaction tank, then add content and be 80% ethanol 160kg by the weight ratio of undecylenic acid: ethanol=1:2, fully stir, and heat up to 70 °C, a clear and transparent ethanol solution of undecylenic acid was obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com