Method for treating cyanide-containing waste water produced by gold industry by using diatomite/ titanium dioxide composite material

A technology of titanium dioxide and composite materials, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high raw material cost, worker irritation, high cost, etc., and achieve high metal adsorption and cyanide decomposition , eradicate the hazards of cyanide, the effect of relaxed reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

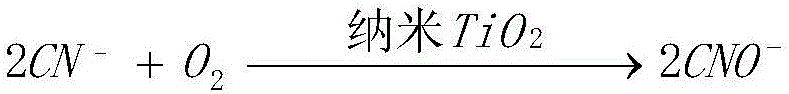

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 10L of absolute ethanol and put it into a three-necked flask, add 1.2L of butyl titanate dropwise under the condition of mechanical stirring, and slowly add 3.6L of deionized water after stirring evenly, keeping the speed at 80d / s. After the dropwise addition of water was completed, the stirring was continued for 1 h to make the solution into a light yellow transparent sol, 500 g of diatomaceous earth was added, and the stirring was continued for 4 hours. After the stirring was completed, it was poured into a beaker and left open in the air for 6 hours to age. Then transfer it to a drying oven at 70° C. for 24 hours to form a xerogel. The dried gel was baked in a muffle furnace at 500° C. for 2.5 hours to obtain a diatomite / titanium dioxide composite material.

[0031] Take 0.1g of the above material and put it into a 500mL Erlenmeyer flask, add 100mL of cyanide-containing wastewater (copper and total cyanide content are 870mg / L and 545mg / L), the pH value is 10, f...

Embodiment 2

[0033] Take 5L of absolute ethanol and put it into a three-necked flask, add 0.8L of butyl titanate dropwise under the condition of mechanical stirring, and slowly add 1.6L of deionized water after stirring evenly, keeping the rotation speed at 90d / s. After the dropwise addition of water was completed, the stirring was continued for 1 h to make the solution into a light yellow transparent sol, 260 g of diatomaceous earth was added, and the stirring was continued for 3 hours. After the stirring was completed, it was poured into a beaker, left open in the air for 7 hours, and aged. Then transfer to a 60°C drying oven to dry for 20 hours to form a xerogel. The dry gel was baked in a muffle furnace at 600° C. for 2 hours to obtain a diatomite / titanium dioxide composite material.

[0034] Take 0.1g of the above material and put it into a 500mL Erlenmeyer flask, add 100mL of cyanide-containing wastewater (copper and total cyanide content is 870mg / L and 545mg / L), the pH value is 10,...

Embodiment 3

[0036] Take 10L of absolute ethanol and put it into a three-necked flask, add 1.2L of butyl titanate dropwise under the condition of mechanical stirring, and slowly add 3.6L of deionized water after stirring evenly, keeping the speed at 80d / s. After the dropwise addition of water was completed, the stirring was continued for 1 h to make the solution into a light yellow transparent sol, 500 g of diatomaceous earth was added, and the stirring was continued for 4 hours. After the stirring was completed, it was poured into a beaker and left open in the air for 6 hours to age. Then transfer it to a drying oven at 70° C. for 24 hours to form a xerogel. The dried gel was baked in a muffle furnace at 500° C. for 2.5 hours to obtain a diatomite / titanium dioxide composite material.

[0037] Get above-mentioned material 0.5g and put into 500mL Erlenmeyer flask, add 200mL cyanide-containing wastewater (copper and total cyanide content are 870mg / L and 545mg / L), pH value is 7,8,9,10,11,12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com