Metal material with modified surface and preparation method and application thereof

A metal material and surface modification technology, applied in metal material coating technology, nanotechnology for materials and surface science, pharmaceutical formulations, etc., can solve the problem that the bonding strength between the coating and the base material cannot be guaranteed, and the scope of application is limited, etc. problem, to achieve the effect of inhibiting bacterial adhesion, promoting proliferation, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

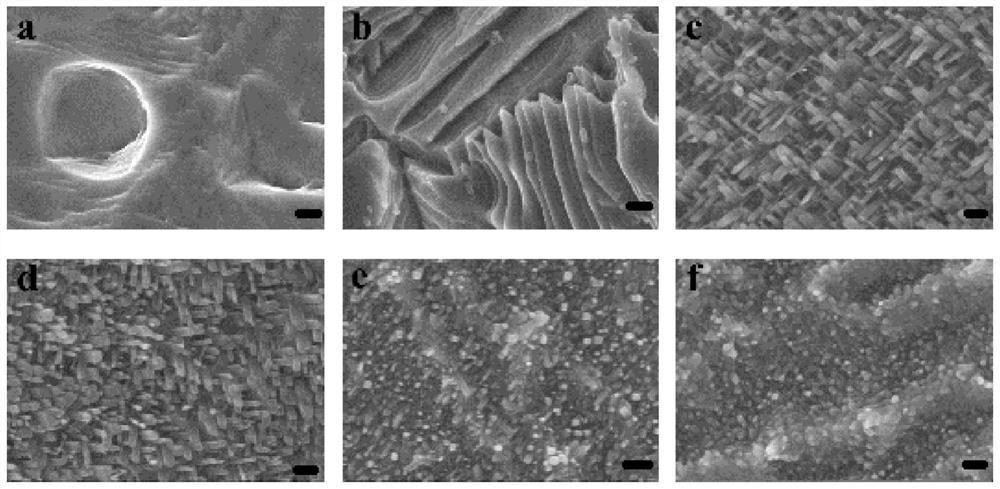

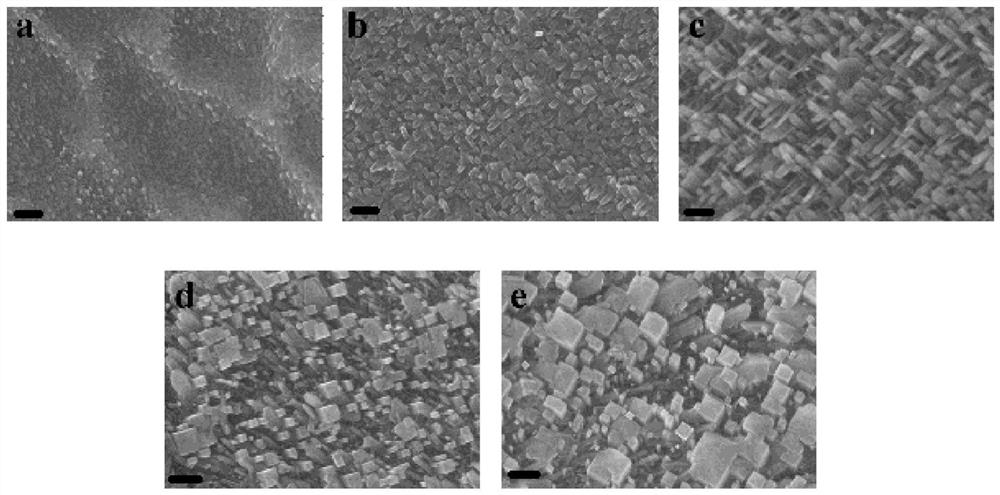

[0055] This embodiment provides a surface-modified titanium alloy. The surface-modified titanium alloy includes a titanium alloy substrate and a titanium oxide film with a nano-topological structure formed in situ on the surface of the substrate. Its preparation method is:

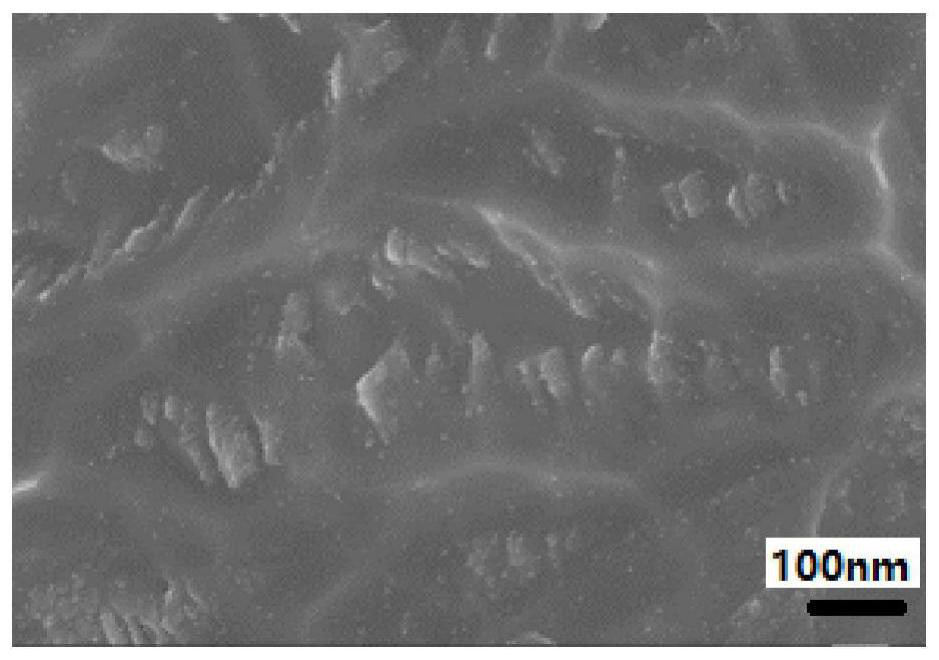

[0056] (1) Clean the surface of titanium alloy (TC4, Baoji Junhang Metal Material Co., Ltd.) with acid solution for 30s, then wash it with deionized water for 3 times, and dry it for later use; the preparation method of the acid solution is: Ionized water, 6mL of 48% hydrofluoric acid and 4mL of 48% nitric acid were mixed and diluted 15 times. The surface morphology of the pickled titanium alloy was observed with a scanning electron microscope, as shown in figure 1 shown.

[0057] (2) the above-mentioned titanium alloy (surface area 2826mm 2 ) mixed with 0.18mol / L hydrochloric acid aqueous solution (30mL) and then hydrothermally reacted at 180°C for 4h to in-situ form a titanium oxide film with a nano-...

Embodiment 2

[0059] This embodiment provides a surface-modified titanium alloy. The surface-modified titanium alloy includes a titanium alloy substrate and a titanium oxide film with a nano-topological structure formed in situ on the surface of the substrate. Its preparation method is:

[0060] (1) Clean the surface of the titanium alloy with acid solution for 20 seconds, then wash it twice with deionized water, and dry it for later use; 15 times.

[0061] (2) the above-mentioned titanium alloy (surface area 5652mm 2 ) mixed with 0.01mol / L hydrochloric acid aqueous solution (50mL) and then hydrothermally reacted at 300°C for 30h to form a titanium oxide film with a nano-topological structure on the surface of the titanium alloy in situ, take it out and cool it to 20°C, and wash it with deionized water Washing 5 times and drying to obtain the surface-modified metal material.

Embodiment 3

[0063] This embodiment provides a surface-modified titanium alloy. The surface-modified titanium alloy includes a titanium alloy substrate and a titanium oxide film with a nano-topological structure formed in situ on the surface of the substrate. Its preparation method is:

[0064] (1) Clean the titanium alloy surface with acid solution for 40s, then wash it with deionized water for 5 times, and dry it for later use; the preparation method of the acid solution is: mix 20mL deionized water and 10mL48% nitric acid and dilute it 15 times .

[0065] (2) the above-mentioned titanium alloy (surface area 5652mm 2 ) mixed with 0.5mol / L hydrochloric acid aqueous solution (50mL) and then hydrothermally reacted at 100°C for 2h to form a titanium oxide film with a nano-topological structure on the surface of the titanium alloy in situ, take it out and cool it to 30°C, and wash it with deionized water Washing 5 times and drying to obtain the surface-modified metal material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com